The Yangtze River Delta region has become the most intensive area for plastic processing industry, and Jiangsu Province accounts for more than 40% of the output

Thanks to multiple factors such as the improvement of the industrial chain and market demand, the Yangtze River Delta region has become the largest and most intensive area for plastic processing industry in the country.

On March 29, at the press conference of the “CHINAPLAS 2023 International Rubber and Plastic Exhibition” held in Shanghai, the Jiangsu Plastics Industry Association released the “2020-2022 Jiangsu Plastic Industry Operation and Development Report” (hereinafter referred to as the “Report”). The “Report” shows that the annual output of plastic products in the Yangtze River Delta region currently exceeds 10 million tons, accounting for about 1/8 of the national proportion; among them, Suzhou City’s plastic product output in 2021 reached 5.78 million tons, accounting for 16% of the entire Yangtze River Delta region and 38% of the province’s output. The output that year can rank second in the provincial output ranking.

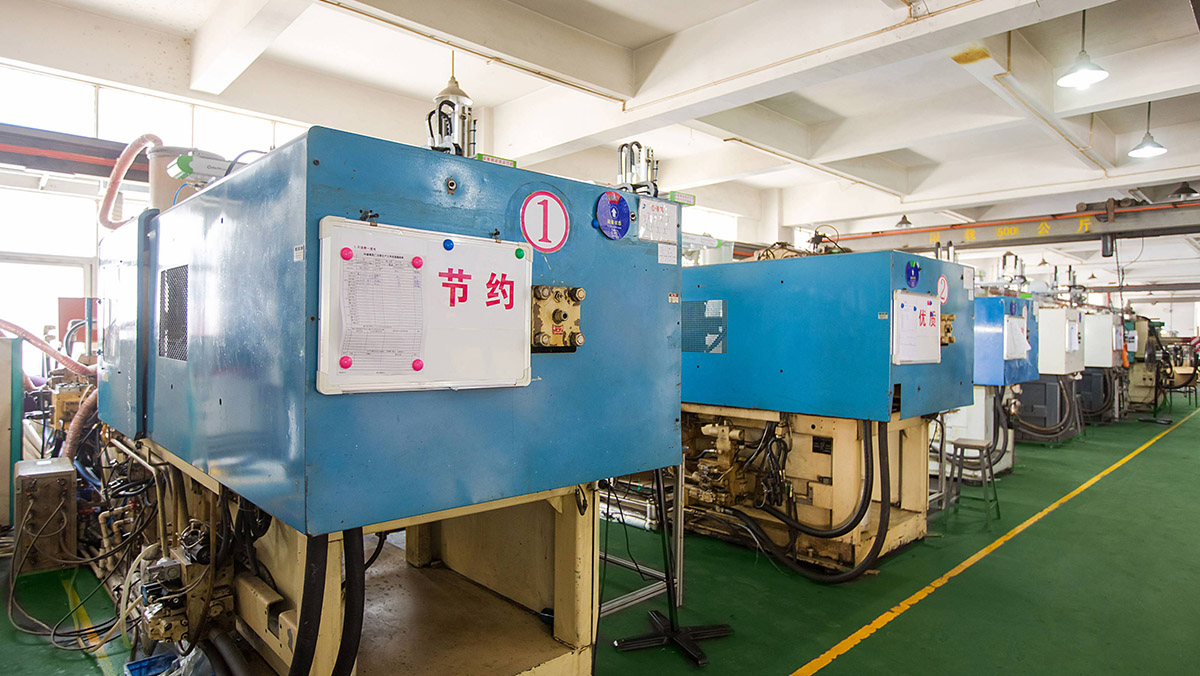

The “Report” stated that Jiangsu Province is a major province for plastic machinery manufacturing. In the three years of the epidemic, the output of plastic machinery has changed greatly, with an average annual output growth of 1% in three years, but the industry’s operating income and profits have increased significantly. The province’s plastic machinery manufacturing industry has a complete range of plastic injection molding, extrusion, film blowing, auxiliary machinery and other machine manufacturing enterprises, which are competitive in the national industry.

From the perspective of regional division of labor in the Yangtze River Delta region, Suzhou is mainly engaged in civilian plastic products, while other places are mainly industrial products. Suzhou itself has a good foundation in the plastic industry, and after years of development, a plastic industry cluster has also been formed here. From the perspective of product categories, Suzhou’s plastic products are mostly civilian products, such as pipes, foams, films, etc., while Shanghai is more of an industrial supporting product, focusing on the production of high-end materials, and the Yangtze River Delta region can do a good job of cooperation.

In the three years from 2020 to 2022, the industry income, total output value, and output of the plastic products processing industry in Jiangsu Province have experienced twists and turns and slowly increased, but profits have remained steadily rising over the past three years.

The traditional plastic products processing industry and product structure in the Yangtze River Delta region are accelerating the transformation and upgrading towards high efficiency and high quality.

Regarding how the industry will maintain high-quality development, a survey of more than 30 large enterprises on the application needs of key basic materials (including polymer materials) showed that 32% of key basic materials are in production gaps and 52% rely on imports. The plastic products processing industry in the Yangtze River Delta region needs to accelerate the research and development of polymer materials, solve the current high dependence on imports of basic materials for some plastic products, or even a blank state, and correspondingly improve the process technology and equipment manufacturing level of the research and development, processing and production process. This is also the current goal of high-quality development of the plastic industry in Jiangsu Province (and the Yangtze River Delta region).

The entire Yangtze River Delta region has a complete industrial chain, and the downstream fields of the plastic industry, such as home appliances and automobiles, have a large demand for high-end plastic products, which can also help the industry achieve high-quality development.

In 2022, Jiangsu’s automobile production increased by 22%, the highest increase in recent years. Jiangsu’s high-performance plastic application industry consumption demand is conducive to supporting the high-quality development of the plastic industry.

From a national perspective, in 2022, the national plastic products industry completed a production of 77.716 million tons, a year-on-year decrease of 4.3%; China’s plastic machinery industry revenue and profit fell by 7% and 11% year-on-year respectively; the profit margin remained at 10%, higher than the 6% profit margin of the machinery industry in the same period. Entering 2023, China’s economy is facing a good momentum of stabilization and recovery. As an important basic industry in the manufacturing industry, plastics are about to usher in a new round of development opportunities.