Custom Manufacturing that Fits Your Product Life Cycle

KingStar’s Custom Manufacturing Services

Enjoy various manufacturing processes, flexible order volumes, and experienced engineers. From prototyping to custom part mass production, we deliver quality with good price. Scale your production with KingStar now!

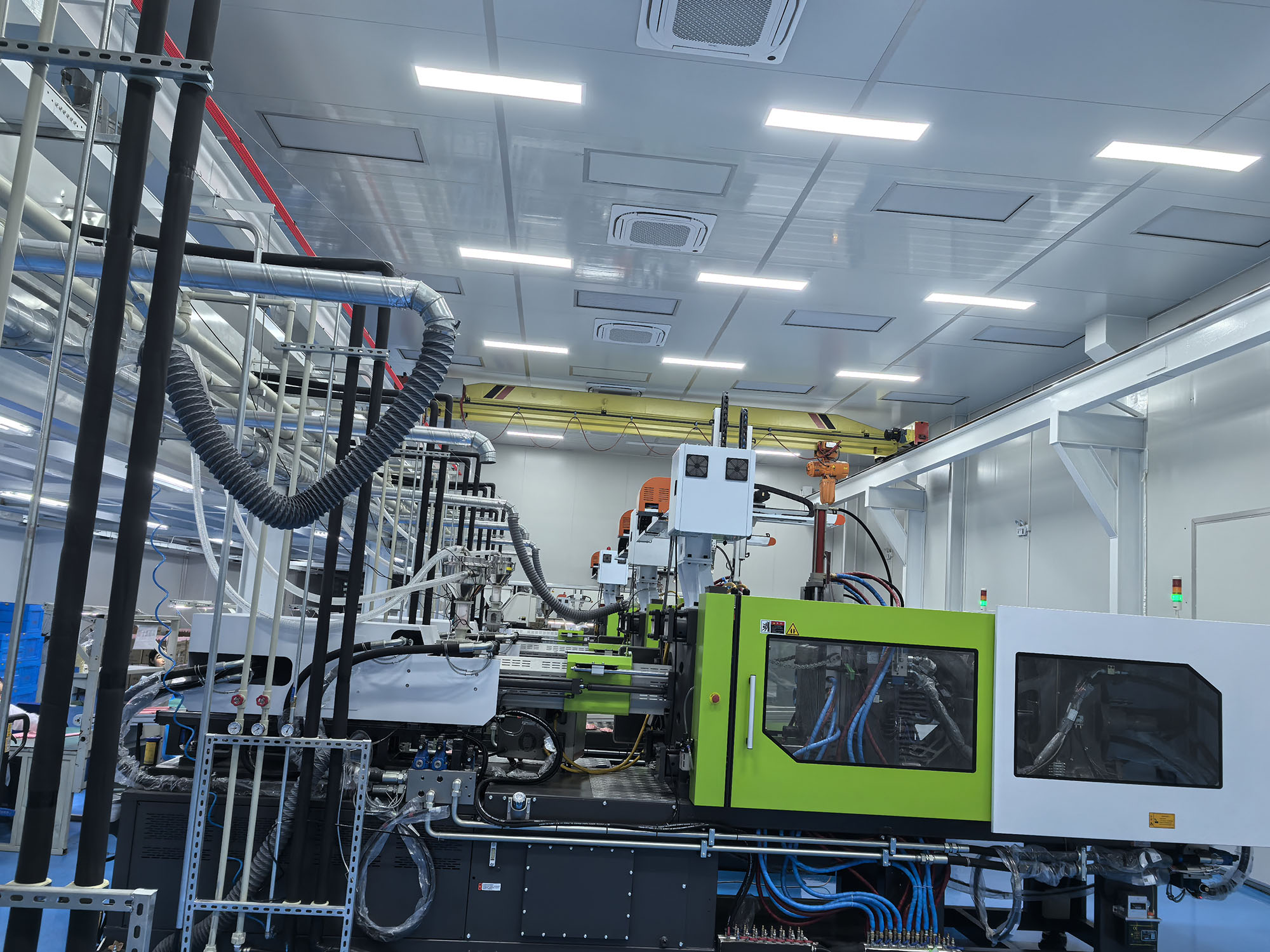

Injection Molding

KingStar offers comprehensive services of injection molding, producing a wide range of parts through two-shot molding, overmolding and custom molding techniques.

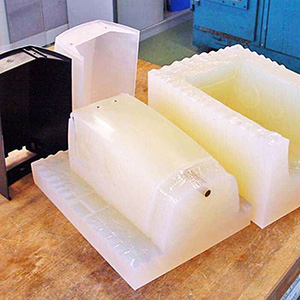

Mold Making

At KingstarMold, we develop and produce precision injection molds, die casting molds, stack molds, liquid silicone rubber(LSR) mold and two-color molds using state-of-the-art equipment.

Sheet Metal Fabrication

We provide precise sheet metal fabrication solutions, offering custom-made parts with exceptional durability, tailored to meet the specific requirements of your project.

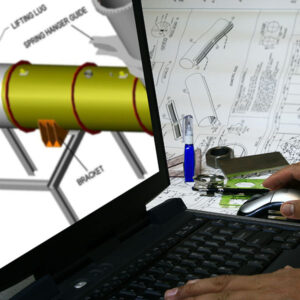

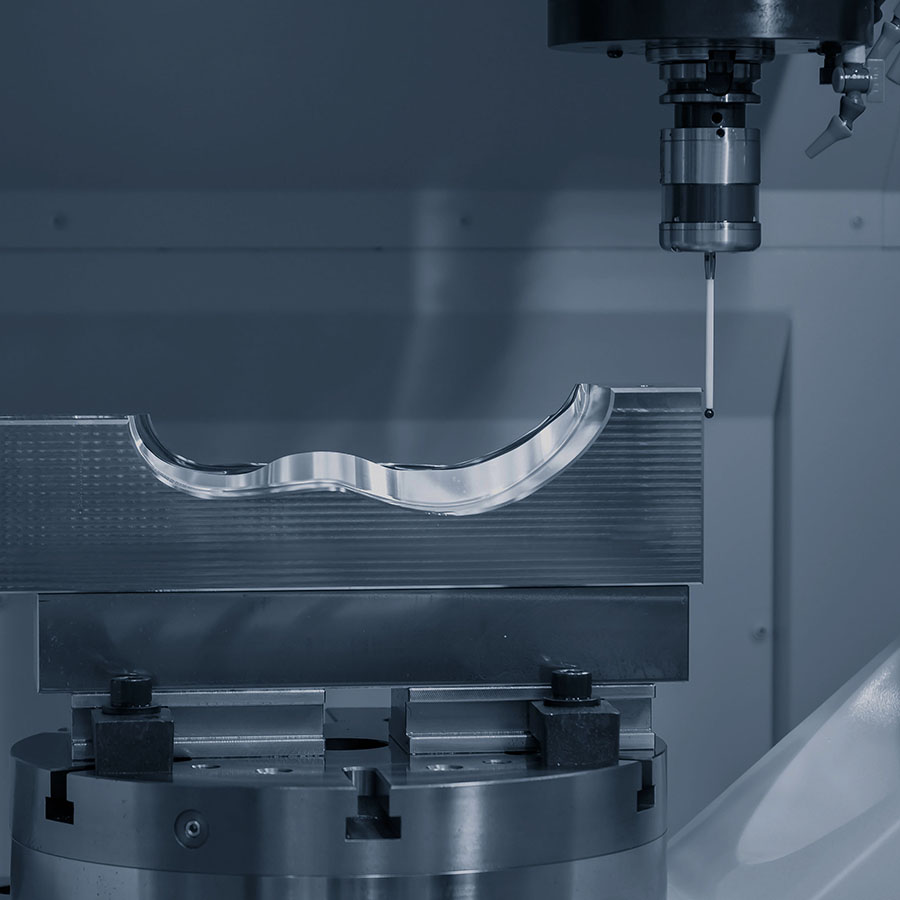

CNC Machining

CNC milling, turning and EDM. Our CNC machining includes both 4-axis and 5-axis capabilities, with a focus on optimizing equipment arrangement to enhance efficiency. Faster, easier and cheaper.

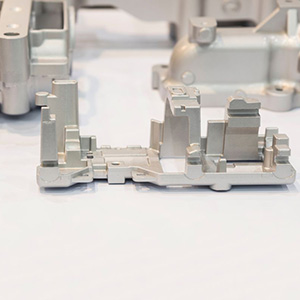

Die Casting

Our die casting service ensures high-precision, high-volume production of metal parts with excellent surface finishes and tight tolerances.

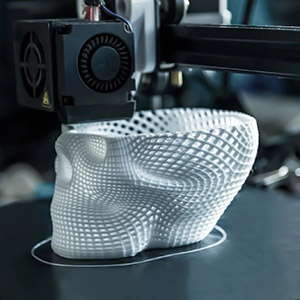

Vacuum Casting

With vacuum casting, we produce high-quality, detailed prototypes and low-volume parts with exceptional accuracy.

Our Factory In China

KingStar Mold is a leading manufacturer based in China, specializing in custom injection molds and the production of plastic and silicone components. With over ten years of experience, we offer comprehensive solutions from mold design to production, ensuring the highest standards of quality and precision.

Our factory is equipped with advanced machinery and staffed by skilled professionals, dedicated to delivering tailored, high-performance parts for a variety of industries. Whether it’s plastic, silicone, or a combination of materials, KingStar Mold provides reliable, cost-effective solutions for every project.

Leveraging On-demand Manufacturing

Flexible Production Scheduling

Cost-Efficiency and Customization

Quality and Precision

Expertise and Experience

With years of industry experience, we have the knowledge to handle complex injection molding projects with precision and efficiency.

State-of-the-Art Technology

Our advanced machinery and equipment enable us to deliver high-quality, precise parts, regardless of your production scale.

Fast Turnaround Times

We prioritize quick lead times, ensuring your orders are completed on schedule to meet tight project deadlines.

Why Choose Us For Your Project

Wide Range of Materials

We offer a diverse selection of materials, from standard plastics to specialty compounds, to meet your specific product requirements.

Customization and Flexibility

Our team works closely with you to create customized solutions that align with your unique needs and specifications.

Commitment to Quality

We follow rigorous quality assurance procedures to make sure that every component we manufacture delivers exceptional durability and top-tier performance.

30 +

Monthly Molds Fabrication

2,000,000 +

Monthly Parts Production

90-1000 T

Injection Molding Tolerance

0.005 mm

Mold Tolerance

Injection Molding Machines

Additional Equipment

| Production Capability | Details | Production Capability | Details |

|---|---|---|---|

| Injection Molding Machines | 30+ advanced machines for high-volume production | Production Speed | High-volume runs, up to 2,000,000 + parts per month |

| Part Weight | Up to 2,000 grams per part | Tolerance | ±0.005 mm precision |

| Max Mold Size | 600mm x 600mm (L x W) | Quality Control | Rigorous inspections for every batch |

| Material Options | Thermoplastics, elastomers, specialty plastics | Lead Time | As fast as 7–14 days depending on complexity |

Working with KingStar Mold has been a game-changer for us. Their team consistently delivers top-notch quality and precision, with quick turnaround times that help us meet even the tightest deadlines. Their expertise in injection molding and mold building has significantly enhanced our production efficiency, and their customer-focused approach makes every project feel like a true partnership.

——Sarah Lee, Product Development Manager

TechAdvance Solutions

Other Online Solutions We Offer

eBooks

Our e-books provide in-depth insights into manufacturing processes, offering practical knowledge and best practices for industry professionals.

Yes, we specialize in both small batch production and large-volume manufacturing, providing scalability and efficiency for all project sizes.

Absolutely! Whether it’s a custom mold, specific material, or unique design, we work closely with you to create solutions that are perfect for your project.

We prioritize quick turnaround times without compromising quality, offering flexible production scheduling to meet even the tightest deadlines.

We combine advanced technology, expertise, and a customer-first approach to deliver tailored solutions that meet your exact needs with unmatched precision and efficiency.

Getting a quote is easy—simply reach out to us with your project details, and our team will provide a customized quote based on your specific needs.

By leveraging on-demand manufacturing and advanced technologies, we minimize waste and optimize production processes to keep costs down while maintaining high-quality results.

We implement rigorous quality control checks throughout the manufacturing process to ensure every product meets the highest standards of precision and reliability.

We serve a wide range of industries, including automotive, electronics, medical, consumer goods, and more, providing tailored solutions to meet the demands of each sector.