Igloo, as a globally leading cooler brand, has a manufacturing layout that combines efficiency and scale. The company’s main production base is located in Katy, Texas, USA, with an area of approximately 1.8 million square feet and employing about 1,200 workers. It’s one of the largest hard cooler production facilities in North America. It is claimed that they produce over 55,000 hard-sided coolers every day, which means that they produce over 16 million of them annually.

In addition to domestic production in the United States, some product lines of Igloo (such as soft-sided coolers, accessories, and specific models) are also produced globally through supply chains in China, Southeast Asia, and Mexico to optimize costs and product portfolio.

- How Are Hard Coolers Made?

- Who Owns Igloo Coolers?

- Why the Manufacturing Location Matters for Cooler Boxes’ Production?

- How Does Igloo Plan Its Product Line?

- Background of the Cooler Market and Growth Factors

- What Manufacturing Strategies Do Those Famous Cooler Brands Adopt?

- Cooler Purchase Guide for Different Types of Buyers

- Key Recommendations for Private Label and OEM/ODM Buyers

- KingStar: Your Reliable OEM/ODM Hard Cooler Supplier

- Conclusion

- Get In Touch

How Are Hard Coolers Made?

As an experienced Igloo cooler manufacturer, we know that the performance of a cooler is largely determined by its manufacturing technique. Currently, the mainstream ice chest manufacturing processes include these two:

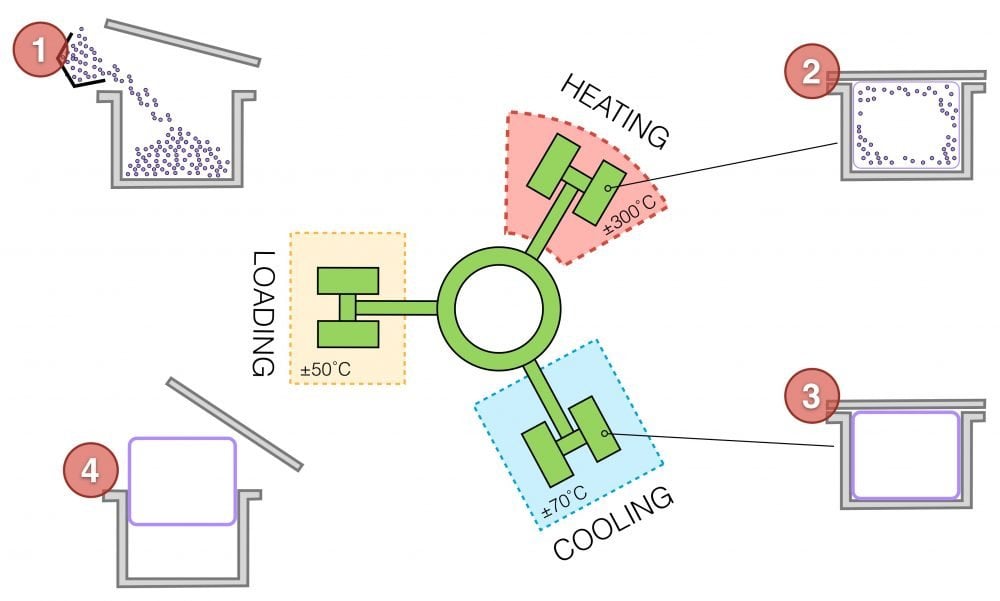

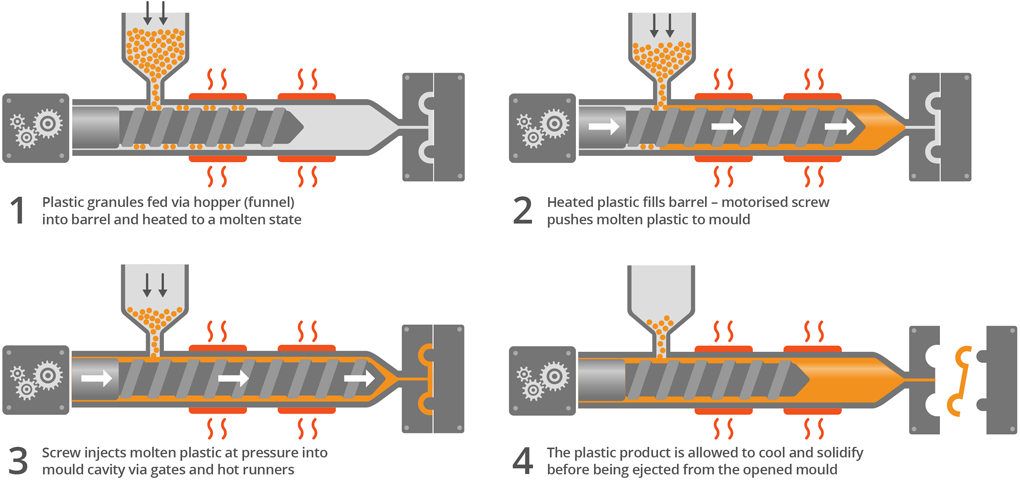

This technology generally works in this way: placing the plastic powder into the mold, heating it up and rotating it along the two axes. By utilizing centrifugal force, the melted plastic is evenly adhered and shaped to form a single-piece, seamless hollow shell in one go.

Since this technology utilizes centrifugal force to distribute the molten plastic evenly, rather than relying on the specific shape of the mold to maintain the shape of the high-pressure injected plastic (thus avoiding many problems that often occur in injection molding), the finished products feature uniform thickness (usually quite thick), strong structure, excellent impact resistance, and outstanding heat insulation properties. Therefore, most high-end outdoor cooler brands typically utilize rotational molding.

Firstly, the outer shell and inner liner are separately molded, then assembled, and polyurethane foam is injected into the middle cavity as a thermal insulation layer. The products formed through injection molding inevitably have seams, and due to technical limitations, the wall thickness is usually thinner than that of rotational molding, but it also has its advantages: such as a short production cycle(suitable for large-scale batch production), the ability to achieve more complex designs, lighter product weight, etc. Therefore, injection molding technology is still widely used in many mid-to-low-end household and commercial hard-sided cooler boxes (also used in some models of certain high-end cooler brands), especially for those models that require bulk and consistent supply and cost control.

Rotational Molding vs Injection Molding: Process Comparison Overview Table

| Feature | Rotational Molding | Injection Molding + Foam Filling |

| Typical Products | High-end, durable one-piece coolers | Lightweight, stackable coolers with bulk supply requirements |

| Strength/Durability | Excellent (thick walls, impact-resistant) | Good (dependent on wall-thickness and assembly level at the seam) |

| Insulation Performance | Typically thicker foam layer, high thermal mass | Dependent on wall-thickness and assembly level |

| Mold Cost | Relatively low (suited for large hollow parts) | Higher (requires precision steel molds) |

| Production Cycle & Cost | Slow cycle, higher unit cost | Fast cycle, low unit cost for high-volume production |

| Best Use Case | High-end market demanding extreme durability | Mass production&consistent supply, mainstream market focusing on cost and efficiency |

For more detailed explanation about hard cooler manufacturing process, please refer to our previous written blog: How Are Cooler Boxes Made?

Who Owns Igloo Coolers?

Founded in 1947 as an independent company, Igloo Products Corp. began as a small metalworking shop in Texas, producing metal water coolers for workers in the oil fields. After launching its first all-plastic ice chest in the early 1960s and receiving widespread praise for the iconic Playmate cooler in 1971, which went on to become a design classic and is now included in museum collections, the brand rapidly gained popularity.

Igloo experienced several ownership changes in the decades that followed. In the early decades it operated independently and later under the name Texas Tennessee Industries (TTI) before officially taking on the Igloo name.

The business went through multiple private equity hands in the 2000s:

Igloo was purchased by Westar Capital from its former owners in 2001.

Another private equity firm, J.H. Whitney & Company, acquired the majority stake in 2008.

Igloo was acquired by the Washington, D.C.-based private equity firm ACON Investments from J.H. Whitney in 2014.

The goal of these private equity alliances was to keep Igloo’s core identity as a top cooler brand while growing its product line, retail reach, and operational scale.

The most recent major change occurred in 2021, when Dometic Group, a Sweden-based outdoor and mobile living products company, acquired Igloo for approximately $677 million. Igloo’s market leadership in passive cooling solutions and Dometic’s worldwide distribution and outdoor lifestyle portfolio were combined in this acquisition, which made Igloo a fully-owned subsidiary of Dometic.

Igloo is still headquartered in Katy, Texas, where it maintains significant U.S. manufacturing operations, even though it is now a part of Dometic’s family of outdoor brands.

Why the Manufacturing Location Matters for Cooler Boxes’ Production?

- Quality assurance and batch consistency

Large-scale production facilities that are centralized, such as Igloo’s base in Katy, are better suited to enforcing consistent and stringent quality standards and can quickly implement mold debugging and process improvements than production bases that are spread across several locations or that buy some components for assembly rather than manufacturing all components internally.

- Delivery time and logistics

Domestic production can significantly shorten the delivery cycle because all transportation routes are within the nation, thus avoiding the risks and delays associated with international transportation. However, this usually comes with higher manufacturing costs (materials, labor, equipment, facilities, operation and maintenance, etc.). In contrast, overseas production gives a higher cost advantage, but requires more investment in transportation.

- Cost structure

According to industry analysis, producing in Southeast Asia and other regions, the unit cost can be 20%-35% lower than that in the United States’ domestic production, mainly due to differences in labor and operating costs.

- Sustainability and materials

Large production bases have the ability to integrate environmental protection measures. For example, Igloo has launched the ECOCOOL series using recycled plastic (PCR), which requires a stable and large-scale supply chain of recycled materials and dedicated production processes.

How Does Igloo Plan Its Product Line?

Igloo’s success can be attributed to both its manufacturing layout and its well-defined product line planning, which strives to satisfy the demands of various price points and consumption scenarios. Four main series can be used to roughly categorize its products:

Classic series (such as Playmate or Kooltunes):

- Target market: High-value, mass market, for everyday household use.

- The manufacturing process primarily uses filled foam technology in conjunction with injection molding to achieve cost-effective large-scale production.

- Features: Available in a variety of colors and styles, lightweight, and simple to stack. The primary product line that sustains its market share and brand awareness is this one. To cut costs, many models are made abroad.

10L/20L Portable Handle Picnic Cooler Playmate

Unit Price: $6.48-13.25

15L/20L/28L Multi-functional Music Radio Coolers with Speakers 15.8QT/21.1QT/29.6QT

Unit Price: $22.32-41.61

High-performance series (like the Trailmate or Marine series):

- Target market: Campers, fishing enthusiasts, and the mid-to-high-end outdoor market who want improved durability and cold retention.

- Manufacturing process: In order to provide thicker box walls and better insulation qualities, some high-end models have started to use injection molding.

- Features include stronger hinges and locks, a better drainage system, detachable partitions, and a longer cold preservation time (usually claimed to be up to 3-5 days). These goods are essential to its ability to compete with professional brands in the mainstream market. Some are produced in a factory in Texas to emphasize quality.

52.8QT High Quality Hard Cooler Box Big Food Ice Chest with Wheels for Picnic 50L

Unit Price: $29.4-34.4

167QT Cooler Box With Wheels Insulated PE Outdoor Custom Blow Mold Ice Chest 158L

Unit Price: $48.4-50.3

Soft-sided cooler and accessories:

- By providing extra scenarios like quick trips, in-car use, and sporting events, the objective is to highlight portability and flexibility.

- Manufacturing: Nearly all are made using the established textile and cushion manufacturing capabilities in China and Southeast Asia, which are part of the global supply chain.

- Features: The product line is incredibly varied, including foldable, hand-held, and backpack-style models. It forms an ecosystem with hard box accessories like cutting boards and wheels, increasing average order value and user loyalty.

Innovation and Sustainability Series (such as the Tag Along Too or new series ECOCOOL):

Igloo has also launched some innovative hard coolers, such as the portable small cooler Tag Along Too, which is shaped like a handbag. These are designed to fill the market gap and gain a competitive edge in advance. At the same time, in an effort to improve brand perception and conform to the ESG (Environment, Society, and Governance) trend, these series are aimed at customers who have a high level of environmental consciousness. It communicates the idea of environmental protection, makes use of recycled materials, and streamlines packaging. Using its large-scale production system, post-consumer recycled plastic (PCR) is incorporated into the production process.

10.57QT Igloo Hard Cooler Custom Fall Resistant Portable PU Foaming Insulated Box 10L

Unit Price: $8.15-12.90

71.9QT Hard Cooler Box Large Capacity Industrial Multifunction Ice Chest With Tap 68L

Unit Price: $28.3-33.2

These are deep integrations of manufacturing strategies and brand marketing.

Igloo has achieved market coverage through the strategy of “matching product positioning with manufacturing process and origin”. The high-end line uses rotational molding and local production to support the “durability” story, the basic line uses injection molding and global production to ensure cost-effectiveness and profit.

Background of the Cooler Market and Growth Factors

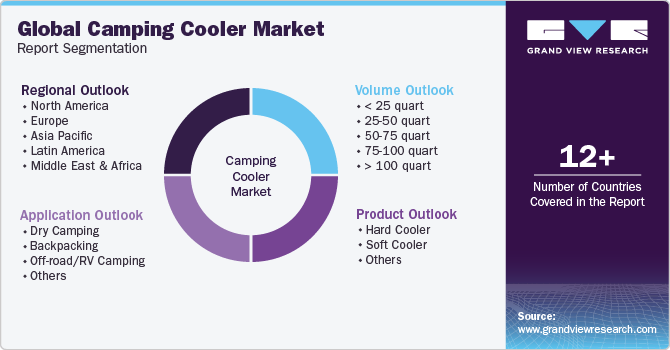

The global retail cooler market was estimated to be worth 3.38 billion US dollars in 2024, and Grand View Research projects that it will continue to grow at a mid-single-digit to low double-digit annual compound growth rate in the years to come.

The market is driven by a number of factors, including an increase in outdoor recreational activities, a growing demand for home entertainment, “last mile” cold chain solutions, and an improvement in consumer demand for durable and high-performance coolers.

Therefore, knowing the size of the market enables OEM/ODM buyers to evaluate the market potential and plan their mold investment, minimum order quantity (MOQ), and inventory strategies logically.

What Manufacturing Strategies Do Those Famous Cooler Brands Adopt?

| Brand | Key Manufacturing Strategy | Primary Production Locations |

| Igloo | Most of the core hard-sided cooler boxes produced domestically, with global supply chain as supplement | USA (Katy, Texas), China, Southeast Asia, etc. |

| YETI | Hybrid manufacturing; some high-end hard-shell products made in USA/PH, with accessories produced overseas | USA, Philippines, China, etc. |

| Coleman | Highly-globalized production strategy | USA, China, Vietnam, among others |

| RTIC | Mostly produced overseas driven by cost consideration | China, Cambodia, Thailand |

Brand positioning determines the choice of production location. High-end brands tend to retain some domestic production to support their quality promotion and achieve rapid response, while direct-to-consumer (DTC) or cost-performance-focused brands will fully utilize overseas supply chains and partially or entirely outsource production to overseas factories to reduce costs.

Cooler Purchase Guide for Different Types of Buyers

For different buyers who plan to purchase coolers or develop your own cooler brand, you need to clearly define specific core considerations and strategies:

1. New/DTC (Direct to Consumer) brand:

You might hope to verify the market feasibility with as little initial investment as possible, to iterate the product at a fast pace, and to establish the brand image as soon as possible.

- Process selection: Injection molding should be given priority as it has relatively lower production costs, a shorter production cycle, and is convenient for small-batch and multi-run trial production.

- Supply chain selection: The Asian supply chain is the inevitable choice to obtain the lowest minimum order quantity and competitive costs.

- Key points of cooperation: Seek factories that can provide comprehensive ODM support. The key points to evaluate about factories to choose are the design capacity, the speed of prototype production, and whether they are willing to accept a lower initial minimum order quantity. Clearly define the ownership of the molds to prepare for future expansion.

- Risk Control: The first batch should focus on 1-2 core capacities and popular colors to avoid inventory buildup. Strict sample performance tests must be conducted either by oneself or through a third party.

2. Large retailers / chain supermarkets:

While ensuring reliable quality, you might aim to achieve the highest possible cost-effectiveness and be able to provide stable seasonal supply.

- Process selection: It depends on the positioning. For the economy-oriented product line, injection molding is used; if you want to launch a “high-end benchmarking” product line, rotational molding can be considered.

- Production location selection: A mixed strategy can be adopted. For the basic model, procurement from Asia can be used to control costs; if the “Made in the USA” marketing strategy is the main focus, cooperation with local factories similar to Igloo can be considered.

- How to arrange the supply chain: The reliability and compliance of the supply chain are of utmost importance. Factories must possess excellent social responsibility certifications (such as BSCI) and quality management certifications (such as ISO), and be able to maintain a stable production capacity throughout the year. Packaging and logistics solutions need to be highly standardized and efficient.

- Risk control: Conduct multi-factory backup assessments, sign strict supply agreements, which should include relevant quality penalty clauses.

3. Corporate gifting/brand promotions:

Through the purchased products, you might want to achieve brand exposure or gift them as employee benefits, emphasizing the customization uniqueness.

- Process selection: Usually, mature ODM standard models are chosen for customization to reduce costs and delivery time. Pay attention to whether the factory has rich experience in silk screen printing, heat transfer printing, embossing, etc. for customization.

- Place of production: Prioritize production costs and minimum order quantities. Asia is a good choice.

- Key points of cooperation: The response speed of the factory’s customized service team and the smoothness of the sample confirmation process. It is necessary to confirm the minimum order quantity for customization and the price tiers corresponding to different customization processes.

- Risk Control: Allocate sufficient time for sample production and verification, and clearly define and conduct random checks on the color difference and positioning of the logo on the final product.

Key Recommendations for Private Label and OEM/ODM Buyers

If you plan to purchase or develop unbranded hard coolers, when choosing a partner, you should focus on the following points:

- Matching processing expertise: Clearly define whether you need to choose between rotational molding (high durability with high cost) and injection molding (less durable but supports more complex designs with lower costs), and select a igloo cooler factory with rich experience and successful cases in that specific process.

- Mold capabilities and intellectual property: Review mold photos and mold flow analysis reports. Molds for rotational molding cost lower (approximately $15,000 to $50,000), while precision injection molds cost higher (over $100,000 or more), and the mold ownership must be clarified.

- Performance data verification: Require the supplier to provide ice retention test reports based on ASTM standards or strict internal standards (such as 24-hour, 48-hour, and 72-hour insulation data) as well as durability tests (such as drop tests) results.

- Sustainability compliance: If environmentally friendly materials are used(such as recycled resins, recycled polyester fabrics), material certification (such as GRS) and traceability documents must be requested.

- Capacity and supply chain resilience: Verify the daily production capacity of the factory, existing order scheduling, and raw material inventory. Ensure that its capacity can match your growth in demand and has the flexibility to cope with peak seasons.

KingStar: Your Reliable OEM/ODM Hard Cooler Supplier

We provide one-stop manufacturing services for brands, enterprises, distributors, and retailers:

- Full process support: We cover both production technique – rotational molding and injection molding for you to choose, and provide professional structural design and DFM analysis.

- Customized development: From rapid prototyping to custom mold development, we support customers in deep customization of color, capacity, logo, accessories, and packaging.

- Performance and quality assurance: We can provide insulation performance test reports and each batch of factory QC documents from the testing center you specified or any other authoritative ones.

- Sustainable manufacturing options: Upon your request, we are available to use 30%-50% Post-Consumer Recycled (PCR) plastic to produce the shell and provide environmental packaging solutions.

- Flexible cooperation solutions: We support from small batch trial production to bulk, large-scale continuous supply and optimized MOQ.

- Integrated logistics services: We offer a complete logistics planning and execution service from the factory to the destination port or warehouse, ensuring the safe and efficient delivery of goods. Or you can also choose to appoint a third-party logistics company upon your request. If you are selling on Amazon, we also offer FBA service.

Conclusion

The manufacturing layout of Igloo is a successful example of “local-scale production + global flexible procurement”. Its Katy factory in Texas demonstrates its strong capabilities in quality control and supply assurance. For market participants, the essence of choosing a manufacturing location is to strike a balance among cost, quality control, delivery speed, and your brand story.

Whether you are a buyer seeking to build your own brand or a partner requiring reliable production capacity, the key lies in selecting an ODM/OEM manufacturer with mature processes, transparent test data, sustainable options, and a stable supply chain. This is precisely the core value that a professional hard cooler manufacturer like KingStar can offer. Contact us at anytime at sales@kingstarmold.com, and we’ll get to you with further inquiries or quotes tailored to your project.