Plastic storage boxes have become indispensable for both daily life and industrial use, and their quality and performance depend heavily on the materials they’re made of. Different types of plastic boxes differ greatly in durability, safety, use cases, and price. We’ve put together some practical tips to help you navigate this space.

We’ll start by breaking down several common plastic materials, including polypropylene, high-density/low-density polyethylene, polystyrene, and polycarbonate. From there, we’ll dive into key details about food-grade and food-safe plastic standards, eco-friendly and sustainable plastics, industry innovations and future trends, as well as practical guidance for consumers on choosing the right storage boxes.

1. Common Plastics & Characteristics

The storage box industry has been around for many years. Most of the materials that have survived in the market have undergone a process of selection and elimination, balancing costs and benefits according to different uses: polypropylene (PP), high/low-density polyethylene (HDPE/LDPE), ABS (acrylonitrile-butadiene-styrene copolymer), and polycarbonate (PC).

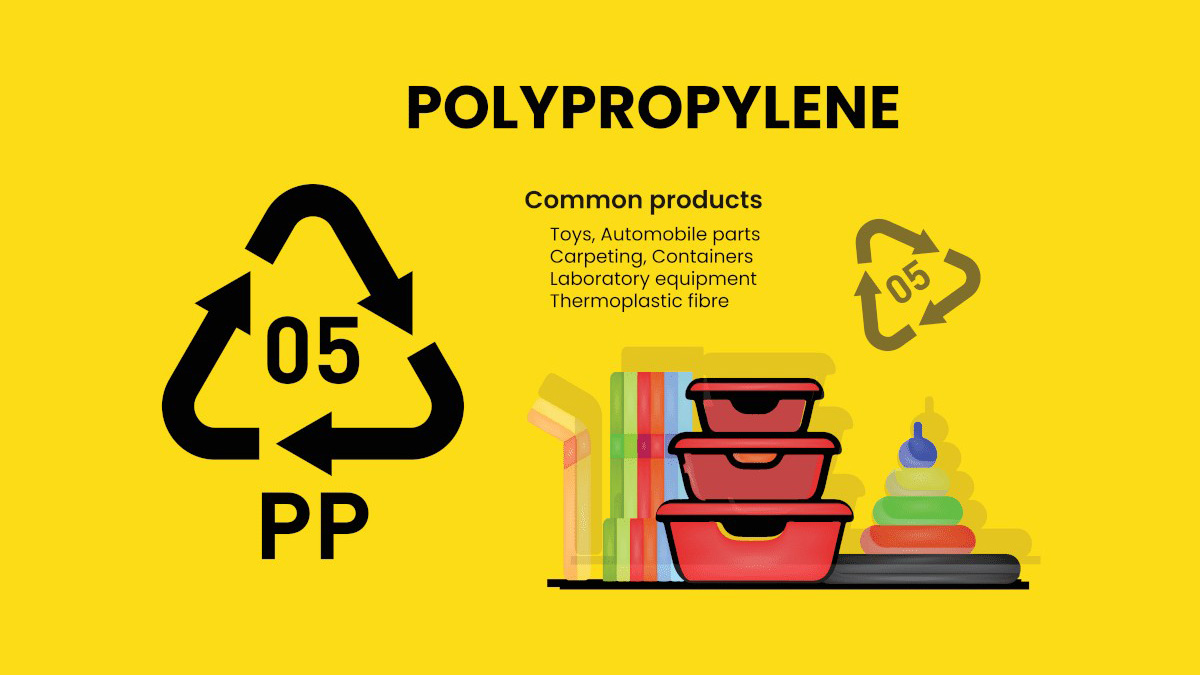

PP (around $3.50 per kg) is a semi-crystalline thermoplastic prized for its low density -roughly 0.9 g/cm³, making it one of the lighter plastics available. It’s highly resistant to chemicals like acids, alkalis, and organic solvents, plus it offers solid electrical insulation. Generally non-toxic, odorless, and corrosion-proof, PP can handle temperatures up to around 120°C, which is ideal for high-heat scenarios like sterilization. That said, it has a few drawbacks: it tends to get brittle in cold temperatures and degrades under UV light, so modifiers are usually added to address these issues.

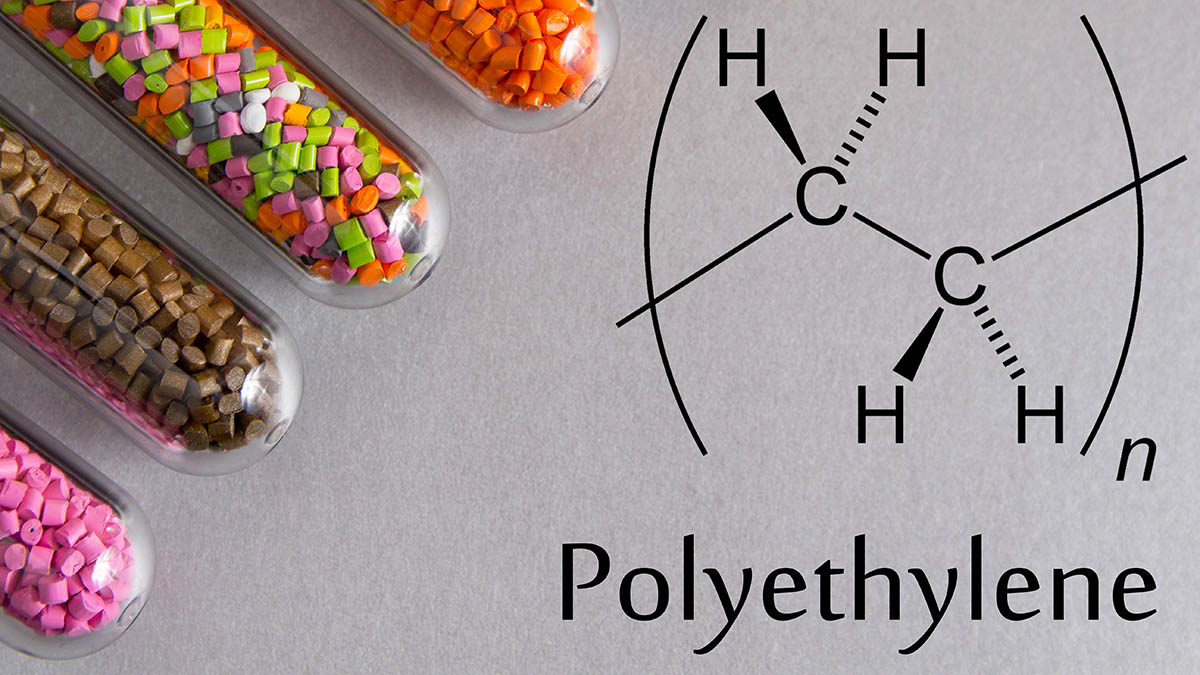

Polyethylene (PE) comes in two main variants: high-density (HDPE) and low-density (LDPE). HDPE boasts better impact resistance, so it’s perfect for storage boxes that need to stand up to rough handling. LDPE, by contrast, is more flexible, which is great for applications that require a little give. In terms of cost, PE is usually budget-friendly to mid-range: HDPE typically runs $0.77 to $0.87 per kg. But specialized forms like LDPE films can command higher prices, depending on their use case and quality.

ABS plastic stands out for its excellent impact resistance, heat resistance, and low-temperature resistance, making it an ideal choice for high-end equipment boxes. ABS plastic boxes have good wear resistance and anti-aging properties, making them suitable for storing items that are prone to wear. However, ABS has a relatively low heat distortion temperature and is flammable, with poor weather resistance, which limits its application in certain environments. Its cost is influenced by factors such as raw material price fluctuations (acrylonitrile, butadiene, and styrene), grade differences (e.g., general-purpose vs. flame-retardant or high-impact grades), and the application sector (consumer-grade ABS is typically cheaper than industrial-grade). ABS is generally considered a mid-cost material, offering a good balance of performance and price, typically costs $1.42-1.48/kg.

For scenarios requiring extremely high durability and professional protection, special engineering plastics such as polycarbonate (PC) offer better solutions, but thus costs higher.

These materials are typically used in professional fields such as military, medical rescue, and precision instrument packaging, and can pass strict test standards, including water and dust resistance, impact resistance, and extreme temperature tests. Below is a quick reference chart involving related characteristics of each plastics mentioned above, about differences between food-safe and food-grade, keep reading our next section:

| Material Type | Heat Resistance | Impact Strength | Food Contact Safety | Primary Application Scenarios | Cost (Approx. USD/kg) |

|---|---|---|---|---|---|

| PP (Polypropylene) | Up to 120°C | Good | Typically Food-Safe (Compliant with standards like FDA; widely used for containers in direct food contact.) | Home storage, food preservation, logistics containers | Low ($3.50) |

| PE (Polyethylene) | Approx. 80-100°C | Excellent | Typically Food-Safe (Compliant with standards like FDA; a common material for food packaging and fresh-keeping boxes.) | Storage bins, anti-static boxes, food packaging | Low to moderate (HDPE: $0.77-0.87) |

| ABS Resin | Approx. 80-100°C | Outstanding | Typically Food-Grade (Most grades are not designed for food contact; specific certified grades can meet Food-Safe standards.) | Equipment cases, protective boxes, electronic component packaging | Medium($1.42-1.48) |

| PC (Polycarbonate) | Up to 130°C | Excellent | Specific Grades are Food-Safe (Traditional PC is controversial due to BPA; now, BPA-free PC materials with strict certifications are available for food contact.) | High-end fresh-keeping boxes, precision instrument packaging | Higher($1.25-3.60) |

In addition to the basic material properties, the production process of plastic storage boxes also directly affects the quality of the final product. The mainstream molding methods include injection molding, extrusion molding, blow molding, and rotational molding, etc. Injection molding is suitable for manufacturing complex-structured and precisely-sized boxes, and is the preferred process for most household storage boxes; while rotational molding is more suitable for producing medium-sized and large-sized boxes, such as industrial safety equipment boxes. For scenarios with special functional requirements, such as storage of electronic components, anti-static performance needs to be considered. At this time, HDPE or PP materials with conductive carbon powder added are used to keep the surface resistance within the anti-static range of 10^6 – 10^9 Ω or the conductive range of 10^4 – 10^6 Ω.

With the advancement of material science, the material formula of plastic storage boxes is also constantly being optimized. In recent years, the successful development of high-transparent polypropylene materials has broken the limitations of traditional opaque plastic boxes. Combined with its high impact resistance, high fluidity, and low processing temperature characteristics, it meets the market’s demand for visual content and high-quality appearance. This innovative material is causing a revolution in daily household packaging, allowing consumers to avoid making a compromise between aesthetics and durability.

2. Safety Standards for Food-grade & Food-safe Plastic Storage Boxes

Many small-sized storage containers (such as lunch boxes) are designed to hold food items including fruits and grains. The safety of the materials that come into contact with food is closely related to the health of consumers. Therefore, they have stricter standards and requirements than ordinary containers. Food-grade plastic containers must meet strict regulatory standards to ensure that no harmful substances are released when in contact with food, and ideally, they should maintain the original quality of the food. In the global market, different regions have their own food safety certification systems. For example, the FDA standards in the United States, the (EU) Regulation No. 10/2011, and the Chinese GB 4806.1-2016 standard. All these regulations strictly limit the types of plastics and additives that can be used for food contact materials.

When understanding these standards, it is crucial to clarify the difference between the two often-confused concepts of “food-grade” and “food-safe”. “Food-grade” typically refers to materials that meet safety specifications, such as BPA-free, low chemical concentration, and not releasing excessive harmful substances when in contact with food. These are commonly found in kitchen tools or conveyors that do not have direct or long-term contact with food. On the other hand, “food-safe” is a more comprehensive and stricter concept. It requires that the final product (such as storage boxes) be designed from materials, through the design process, and in the manufacturing process specifically for direct contact with food, and undergo strict testing and certification (such as by the FDA) to ensure that no harmful substances migrate to food under any usage conditions, or affect the smell and taste of the food. A product may use “food-grade” materials, but only if its final design and certification ensure comprehensive safety for food, can it be called “food-safe”.

Currently, the plastic materials widely recognized for food storage include PP, PE, polyethylene terephthalate (PET), and PC, among others. Among them, PP is selected as the preferred material for food storage containers due to its excellent comprehensive performance. It is non-toxic and odorless, has good heat resistance, and can be disinfected with boiling water without releasing harmful substances. It is worth noting that polycarbonate materials were once controversial due to the issue of bisphenol A (BPA). Nowadays, most well-known brands on the market use polycarbonate materials without BPA or switch to safer alternatives.

The sealing performance of food-grade plastic storage boxes is one of the key indicators for evaluating their quality. Excellent sealing performance can effectively prevent moisture from escaping, providing a sealing effect, and isolating air to prevent food oxidation and contamination. The international standard for measuring sealing performance is determined by humidity permeability tests. High-quality preservation boxes have 200 times lower humidity permeability than similar products, allowing food to remain fresh for a longer time. This is particularly important for scenarios where food needs to be stored for a long time or carried outside.

For different types of food, the design and material selection of food-grade storage boxes also have specific focuses:

- Dry snacks storage: It is recommended to use transparent or semi-transparent PP material boxes, which facilitate intuitive viewing of the contents and avoid frequent opening that causes contamination. The box cover should ensure basic sealing to prevent moisture from entering and causing food to deteriorate.

- Cold food preservation: It is advisable to use PE or PP materials with cold resistance up to -25℃ to ensure that they do not become brittle in low-temperature environments. The design of the preservation box should fully consider sealing performance to reduce cross-contamination of odors in the refrigerator and facilitate the preservation of food humidity.

- Liquid food storage: High-sealing box bodies are required, usually using PP or HDPE materials, to ensure that the box body does not leak during transportation and storage. The inner wall should be smooth and seamless to facilitate thorough cleaning and prevent bacterial growth.

With the growing global awareness of environmental protection, the sustainable development of plastic storage containers has become a key issue of great concern in this industry. The production and use of traditional plastic containers do indeed impose certain pressure on the environment, but the industry is gradually reducing its impact on the environment through material innovation, process optimization, and the establishment of recycling systems. Moreover, up to now, consumers are increasingly inclined to choose products that conform to environmental protection concepts, which is driving the entire industry towards a greener direction.

The recyclability of plastic storage containers is a key indicator for evaluating their environmental performance. Most commonly used plastic container materials, such as polypropylene (PP), polyethylene (PE), and acrylonitrile-butadiene-styrene copolymer (ABS), are theoretically recyclable; however, the actual recycling efficiency and effectiveness vary depending on the region and the recycling system. Polypropylene (PP) and polyethylene (PE) are considered relatively easy to recycle because they can be transformed into recycled plastic through classification recycling and melting and regrinding, which can be used to produce plastic products with less stringent requirements for raw materials; however, the recycling process of ABS is more complex, usually requiring classification first, and then through injection molding, extrusion, vacuum, blow molding, and rolling processes to form plastic. To improve recycling efficiency, many manufacturers have begun to label the material type codes on the packaging, so that consumers and recycling enterprises can correctly classify and handle these materials.

3. Sustainable Development and Environmental Choices

With the increasing global awareness of environmental protection, the sustainable development of plastic storage boxes has become a key issue of concern in the industry. The production and use of traditional plastic boxes do indeed impose certain pressure on the environment, but the industry is making efforts through material innovation, process optimization, and the establishment of a recycling system, gradually reducing their ecological footprint. Nowadays, consumers are increasingly inclined to choose products that align with environmental protection concepts, driving the entire industry towards a greener direction.

The recyclability of plastic storage boxes is a key indicator for evaluating their environmental performance. Most commonly used plastic box materials, such as PP, PE, and ABS, are theoretically recyclable, but the actual recycling efficiency and effectiveness vary depending on regions and recycling systems. Polypropylene (PP) and polyethylene (PE) are considered relatively easy to recycle, and they can be transformed into recycled plastic through classification recycling and melt regrinding to be used in the production of plastic products with less stringent requirements on raw materials. However, the recycling process of ABS is more complex, usually requiring sorting, then processing through injection molding, extrusion, vacuum, blow molding, and roll pressing to form plastic. To improve recycling efficiency, many manufacturers have begun to mark the material type code on the boxes to facilitate correct classification and handling by consumers and recycling enterprises.

Biobased plastics and degradable materials are another important direction for the environmental transformation of plastic storage boxes. Although most plastic storage boxes are still non-degradable at present, the industry has begun to explore the use of biobased materials such as polylactic acid (PLA) as a supplement. However, these materials still face challenges in durability, heat resistance, and cost, and cannot completely replace traditional materials. A more practical approach is to use biobased materials in appropriate scenarios or blend traditional materials with biobased materials to achieve a balance between environmental performance and practicality.

For consumers, if you are concerned about the environment, when choosing plastic storage boxes, you can consider the following points:

- Prioritize storage boxes built by single material: If the box body and accessories made of the same material, it is more convenient for subsequent recycling and disposal process.

- Choose durable designs: High-quality plastic boxes can be used for many years, reducing the resource consumption caused by frequent replacements.

- Pay attention to products containing recycled components: Some forward-looking enterprises have already been adopting a certain proportion of recycled plastic in their products’ material recipe.

It is worth noting that whether a storage box is environmentally friendly is not solely determined by the material itself, but also determined by the efficiency optimization in the transportation and storage processes. Designs aiming to optimize these processes such as slotted or staggered style logistics box can reduce storage volume when the box is empty, facilitating the cost of logistics turnover and reducing carbon footprint.

4. Industry Innovation and Future Trends of Plastic Storage Boxes

The plastic storage box industry is innovating along three main directions: material science, intelligence, and sustainability, driving the continuous upgrading of products.

In terms of material innovation, the high-transparency polypropylene technology has broken through the limitation of traditional PP materials being opaque, achieving the visualization of contents while maintaining excellent performance. At the same time, ergonomic handles, easily opening locks, and other detailed designs have significantly enhanced the user experience.

With the deepening of collaborative innovation in the industrial chain, plastic storage boxes are evolving towards greater safety, durability and environmental friendliness. While meeting the current storage needs, they also make positive contributions to sustainable development.

5. How to Choose the Right Plastic Storage Box

When faced with the wide variety of plastic storage boxes available on the market, consumers often find it difficult to make a choice. The materials of storage boxes are linked to many factors, such as safety, appearance, price, lifespan, and so on.

The usage scenario is the primary consideration when choosing a plastic storage box. The performance requirements of the box vary greatly in different scenarios:

- Storage of household clothes and toys: It is recommended to choose stackable drawer-style storage boxes made of PP material. The size should be selected based on the specific dimensions of the wardrobe compartments or storage space. For toy storage in children’s rooms, a box with a wide opening and handles that can be lifted by children is preferable, making it easy for them to take and put away items.

- Food preservation storage: It is essential to choose materials clearly labeled as “food grade”, such as PP or PE. Sealing performance is a key consideration. High-quality storage boxes have a 200-fold lower humidity permeability than ordinary models. For frequently accessed food, transparent box designs or those with viewing windows are more practical.

- Precision instruments and important document storage: Consider using protective boxes made of ABS or special engineering plastics. These boxes usually have dust-proof, waterproof, and even shock-proof functions. Some high-end products have passed international certifications such as ASTM IP67 and MIL-STD-810F.

- Logistics turnover and industrial use: Choose HDPE or PP-made logistics boxes. Prioritize stackable, plug-in, or folding designs to save storage and transportation space. In the electronics industry, use anti-static turnover boxes to avoid damage to electronic components from static electricity.

Next, we will provide some specific steps for consumers to identify the materials of storage boxes:

- Observe the label: Regular products usually clearly indicate the material type on the box or label, such as PP, PE, ABS, etc., as well as the recycling code.

- Examine the appearance: High-quality plastic boxes have a smooth surface, uniform color, and no obvious impurities or stains. The wall thickness is uniform, and the reinforcement design is reasonable.

- Smell the odor: High-quality plastic boxes should have no obvious odor, especially for food storage boxes. Strong, pungent odors may indicate the presence of residual additives or improper use of recycled materials.

- Test the toughness: Press the box moderately. High-quality materials should recover quickly after pressure release and should not leave white marks or cracks. Special attention should be paid to stress concentration areas such as corners and edges.

- Check the certification: For specific usage scenarios with special requirements, such as food contact or professional protection, check if the product has passed relevant industry certifications.

For specific usage environments, the weather resistance and durability of plastic storage boxes also need to be carefully considered. If the box will be placed in a place exposed to sunlight on the balcony or courtyard, choose materials that have been added with UV-resistant agents to prevent the box from cracking and fading. In humid environments, the mold resistance of the material and the anti-rust ability of the hardware accessories need to be taken into account.

In terms of balancing budget and quality, the plastic storage box market shows a distinct hierarchical structure. Economy products mainly use basic PP and PE materials to meet basic storage needs; mid-range products have improved in material formulation, structural design, and accessory quality; high-end products use ABS, engineering plastics, or specially modified materials, providing comprehensive protection functions and long service life. It is recommended that consumers allocate their budgets based on usage frequency and importance: for frequent use or storage of important items, investing in high-quality boxes is more economical; for occasional use or storage of non-precious items, cost-effective basic products may be more suitable.

As we have explored, the world of plastic storage boxes is rich with innovation, from advanced materials like high-clarity PP and food-safe certified plastics to smart features and sustainable designs. Selecting the right storage solution is crucial for protecting your belongings, ensuring food safety, and optimizing your space.

But you don’t have to navigate this complex landscape alone. As a leading manufacturer and supplier of plastic products, we are your dedicated partner for all your storage needs. We combine the material science and manufacturing expertise detailed in this article to deliver products that are not just containers, but reliable solutions. Contact us today at sales@kingstarmold.com or leave online message to discuss your requirements, request a catalog, or get a free quote for your next project.