What is the Difference Between PLA/PHA VS PBS/PBAT? Can KingStar Mold produce parts and complete products using injection molding technology and PLA/PHA/PBS/PBAT raw materials? These are questions that customers often ask us.

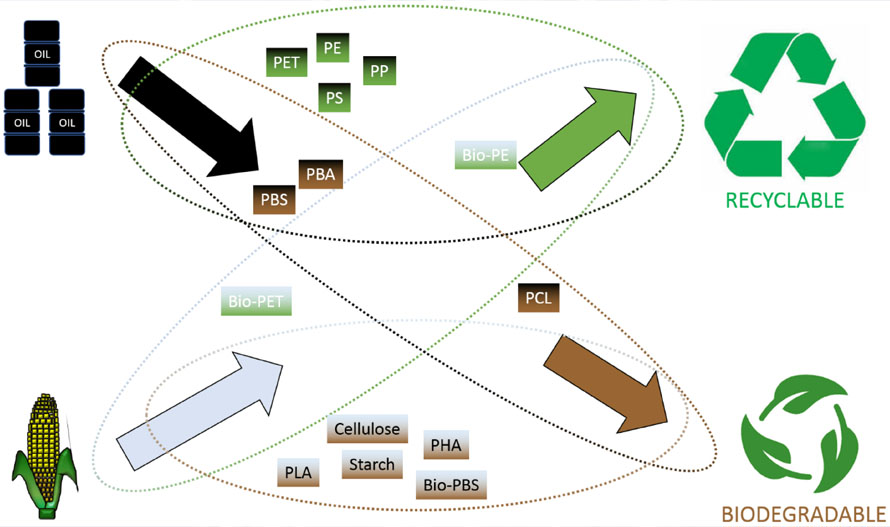

In the global promotion of “white pollution” control and the strategic process of replacing traditional non-biodegradable plastics, biodegradable plastics have become a key support for achieving sustainable environmental development. Among them, PLA/PHA (bio-based biodegradable plastics) and PBS/PBAT (petrochemical-based biodegradable plastics) are two mainstream categories that occupy important positions in industrial applications. Although both meet the core requirements for biodegradability, there are significant differences in dimensions such as raw material sources, performance characteristics, application scenarios, and market prospects. Clarifying these differences in the system is of great practical significance for enterprise procurement decisions, production process optimization, and rational consumer choices.

- 1. Core Classification of PLA/PHA & PBS/PBAT

- 2. Performance Comparison Between PLA/PHA & PBS/PBAT

- 3. How to Choose Biodegradable Plastics for Different Applications

- 4. Market Status and Prospects of PLA and PHA

- 5. Quotation and Cooperation Details for Injection Molding of Small Plastic Parts

- 6. Conclusion: How to Choose Suitable Materials Between PLA/PHA VS PBS/PBAT

1. Core Classification of PLA/PHA & PBS/PBAT

The fundamental difference between PLA/PHA and PBS/PBAT lies in the raw material supply system, which directly determines the environmental footprint, supply chain stability, and carbon reduction potential of the two types of materials, and is the core basis for classification and definition.

1.1 Bio-based Source of PLA and PHA

As a representative of bio-based biodegradable plastics, the production process of PLA/PHA uses renewable biomass resources as the core raw material, significantly reducing dependence on fossil fuels and aligning with the concept of circular economy development, possessing outstanding ecological advantages.

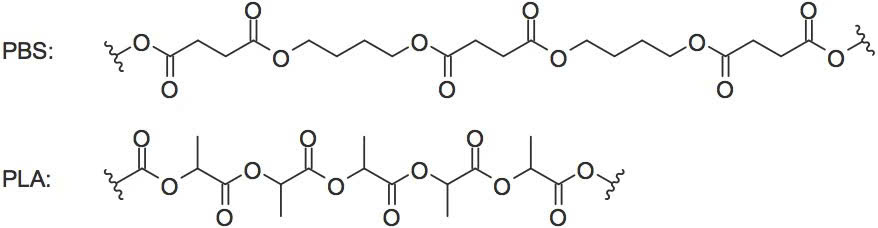

- PLA (Polylactic Acid): Its raw materials mainly come from renewable plant resources such as corn, cassava, and sugarcane, and agricultural waste such as sugarcane bagasse can also be used as supplementary materials. The production process adopts a mature “indirect synthesis method”: firstly, the raw materials are converted into lactic acid through biological fermentation technology. Lactic acid is polymerized to form low molecular weight oligomers, which are further cracked into lactide. Finally, high molecular weight PLA is generated through lactide ring opening polymerization reaction.

- PHA (polyhydroxyalkanoates): Belonging to microbial synthetic polymer materials, PHA is synthesized and stored in the body by bacteria and other microorganisms under nutrient imbalance growth conditions, serving as a reserve substance for energy metabolism. Its production substrates come from a wide range of sources, including conventional raw materials such as glucose, starch, and vegetable oil. It can also utilize organic waste such as kitchen waste to achieve the environmental value of “waste resource utilization”. In the PHA category, PHB (polyhydroxybutyrate) and PHBV (Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) are the most widely used, among which PHBV effectively improves the high brittleness defect of PHB through copolymerization modification, expanding the scope of processing applications.

1.2 Fossil Material Sources for PBS and PBAT

This type of material belongs to the category of petrochemical-based biodegradable plastics, and its production process relies on petrochemical derived raw materials. Its cost fluctuations and supply chain stability are closely related to the global petroleum industry. Although it has biodegradable properties, it has natural limitations in terms of resource renewability.

- PBS (Polybutylene Succinate): Synthesized by the condensation reaction of succinic acid and 1,4-butanediol. Although succinic acid has a biological fermentation preparation pathway, considering the cost control and technological maturity of industrial scale production, the mainstream still adopts the petrochemical raw material route. The production process is mainly based on the “direct esterification”: the monomers are fully reacted in a high-temperature vacuum environment, and the molecular weight is regulated by adding chain extenders to ensure product performance. This process was first industrialized by Japan Showa Polymer in 1993. After digestion, absorption and technical improvement by scientific research institutions such as the Chinese Academy of Sciences, a complete industrial application system has been formed in China.

- PBAT (Poly(butylene adipate-co-terephthalate)): Using adipic acid, terephthalic acid, and 1,4-butanediol as comonomers, the product combines the biodegradability of aliphatic polyester with the mechanical strength of aromatic polyester through precise control of polymerization reaction parameters. Due to its highly correlated molecular structure with PBS, it is often classified as a “PBS series material”.

2. Performance Comparison Between PLA/PHA & PBS/PBAT

The difference in performance indicators is the core driving force behind the differentiation of application scenarios for two types of materials, forming clear technical boundaries from degradation conditions, mechanical properties to processing adaptability, providing a basis for targeted selection. The specific performance comparison is shown in the following table:

| Core advantages | key Advantages | Key Limitations | Core Technical Parameters |

|---|---|---|---|

| PLA | Excellent biosafety (FDA certified, suitable for the food/medical field); Excellent transparency and mechanical strength (close to PS); Low cost in bio-based materials; Mature processing (suitable for injection molding, film extrusion and other processes) | Stringent degradation conditions, requiring an industrial composting environment (≥ 55 ℃, high humidity), while the natural environment (soil/ocean) degrades slowly; Poor heat resistance, softening at about 60 ℃ (not suitable for hot food containers); High brittleness and insufficient impact resistance | Melting point: 175-180 ℃; Glass transition temperature: 57-58 ℃; Tensile strength: about 60MPa; Degradation rate: moderate |

| PHA | The degradation has strong universality and can be decomposed in soil, ocean, and household compost without the need for industrial conditions; Outstanding biocompatibility (suitable for medical implants); Heat resistance is superior to low-density polyethylene, and flexibility can be adjusted through copolymerization | High production cost, $8,520–$9,940/ton, about 2x the price of PLA Narrow processing window, easy to decompose at around 130 ℃ (requires specialized equipment); Poor storage stability and easy degradation after long-term storage | Melting point (PHB): 173-180 ℃; Tensile strength: 20-50MPa; Degradation rate: relatively fast; Elongation rate: 10-300% |

| PBS | Balanced performance, with mechanical strength close to PP/PE; Good heat resistance, with a thermal deformation temperature of about 100 ℃ (modifiable to above 100 ℃); Stable daily use, only degraded in composting environment (to avoid premature failure); Strong versatility in processing (injection molding, blown film, foaming) | Poor barrier properties, weak ability to block water vapor and oxygen (food packaging requires coating); Dependent on petrochemical raw materials, with a carbon footprint higher than that of biobased materials | Melting point: 115 ℃; Heat deformation temperature: About 100 ℃; Tensile strength: 40MPa; Elongation rate: 400%; Degradation rate: Faster |

| PBAT | Excellent ductility, with a fracture elongation of up to 120 times that of PLA (suitable for flexible films); Mature processing, compatible with existing plastic equipment (no need for modification); Balance between impact resistance and degradability | Insufficient tensile toughness (lower than low-density polyethylene, not suitable for high impact scenarios); Poor barrier properties (similar to PBS, requiring a barrier coating); Stone based source, with carbon emissions higher than PLA/PHA | Melting point: 110-120 ℃; Glass transition temperature: -30 ℃; Tensile strength: ≥ 15MPa; Elongation rate: 750%; Degradation rate: moderate |

3. How to Choose Biodegradable Plastics for Different Applications

Based on the performance differences mentioned above, PLA/PHA and PBS/PBAT have formed a clear application market division, demonstrating technological adaptability advantages in different fields, covering the entire industry chain demand from daily consumer goods such as custom coolers and wholesale pill organizers to high-end medical equipment.

3.1 Sustainability and High-End Applications of PLA and PHA

PLA: With its cost advantage and mature technology, it has become the core choice for large-scale applications, mainly covering the following areas:

- Packaging Industry:Accounting for 65% of the total usage of PLA, mainly used for disposable tableware, beverage cups, food trays, shopping bags and other products, relying on its food contact safety to achieve widespread application;

- Textile Industry:Used to produce biodegradable fiber clothing, non-woven fabrics, and sanitary products, and has played an important role in disposable protective equipment such as masks;

- Agricultural Application:Suitable for plastic film and seed coating in areas equipped with industrial composting systems, achieving environmental upgrades in agricultural production;

- Medical Field:As a raw material for drug carriers and low-cost medical devices (such as disposable syringes), its biocompatibility has been clinically validated.

PHA: Positioned in high-end application scenarios due to its unique performance advantages, including:

- Biomedical:Used for absorbable surgical sutures (degradation in vivo without secondary removal), tissue engineering scaffolds, and controlled release drug carriers. PHBV can achieve precise control of degradation rate by adjusting the copolymerization ratio;

- Environmental Protection:In response to the problem of marine plastic pollution, we have developed marine degradable fishing nets, ocean transportation packaging, and soil remediation films that can achieve efficient degradation in saltwater environments;

- High-End Packaging: Targeting the organic product market, we have launched packaging materials with home composting function to enhance the environmental attributes of our products.

3.2 PBS and PBAT as Leading Materials for Flexible Packaging and Agricultural Film

PBS: With heat resistance and durability as its core advantages, its application scenarios are concentrated in:

- Packaging Field:Used for foam cushioning materials, daily chemical product bottles (shampoo, detergent), and pharmaceutical packaging, its chemical stability can effectively avoid the risk of drug contamination;

- Agricultural Field:We produce heat-resistant plastic films (capable of withstanding high temperatures of up to 100 ℃ in the field) and slow-release carriers for pesticides and fertilizers, achieving precise nutrient release through controlled degradation;

- Medical Field:Gradually expanding to the production of surgical implants (such as artificial cartilage), whose biocompatibility and adjustable degradation rate meet clinical needs.

PBAT: With high ductility as its core feature, it is often blended with PLA to improve the toughness of composite materials, mainly used for:

- Flexible Packaging:including garbage bags, thin-walled cosmetic bottles, and stretch films, with high elongation characteristics effectively improving product tear resistance;

- Agricultural Field:Used for large-scale plastic film (with outstanding wind erosion resistance) and greenhouse covering film, which has the advantages of easy installation and efficient disassembly;

- Disposable Products:Produce medical disposable wipes, gloves, and food contact products that can be adapted to high-speed automated production lines.

4. Market Status and Prospects of PLA and PHA

The current development pattern of the biodegradable plastics market is shaped by three factors: production scale, cost competitiveness, and global “plastic ban” policies. The two types of materials present differentiated development paths and market potential.

4.1 Cost Challenges for PLA and PHA in the Bio-based Boom

- PLA: As the most technologically mature bio-based biodegradable plastic, its global production capacity has exceeded 3 million tons per year. China dominates the world with a production capacity of 1.2 million tons per year. Its market price is about 1704-2130 US dollars per ton, and it has significant substitution advantages in packaging, textile and other fields. However, the development of the industry still faces bottlenecks: the core intermediate propylene glycol relies on imports, and the cost of raw materials is easily affected by fluctuations in grain prices such as corn.

- PHA: With enormous development potential but limited by cost constraints, the global planned production capacity exceeds 50,0000 tons per year, while the actual annual output is less than 50000 tons per year. With technological breakthroughs, the cost reduction channel is gradually opening up: the “halophilic bacteria technology” developed by Tsinghua University uses seawater and waste as production substrates, reducing costs to about 4260 US dollars per ton.

4.2 Scale Advantage of Petrochemical-based PBS and PBAT

As the mainstream category of petrochemical based biodegradable plastics, PBS/PBAT occupies an important market share with its technological maturity and supply stability. The PBAT production capacity in China has reached 450,000 tons per year. This type of material can be directly adapted to existing plastic production equipment, with a complete raw material supply system, and is a popular choice for replacing disposable plastics. However, it should be noted that its carbon footprint is about 2.6 times that of traditional PP plastics, and under the background of the “dual carbon” policy, it faces increasing competition pressure from bio based materials.

5. Quotation and Cooperation Details for Injection Molding of Small Plastic Parts

In response to the core requirements of “prioritizing the use of PLA/PBS materials, possessing international biodegradable certification, and providing quotation/delivery time/MOQ/technical documents” in procurement needs, and in combination with industry standards and supply chain resources, the following solutions are provided:

5.1 Material Compliance and International Certification

The injection molding grade PLA/PBS materials used in this quotation meet 100% biodegradable requirements and hold international certification certificates issued by authoritative institutions to ensure product compliance. The specific certification information is as follows:

| Material | Biodegradability Compliance | International Certification Qualifications |

|---|---|---|

| Injection molding grade PLA (such as NatureWorks Ingeo) ™ 3251D) | Under industrial composting conditions, complete degradation into carbon dioxide and water within 180 days, in compliance with EN 13432 & ASTM D6400 standards | EN 13432 (EU composting certification, issued by DIN Certco); ASTM D6400 (American composting certification, issued by BPI); FDA 21 CFR § 177.1520 (Food Contact Safety Certification) |

| Injection molding grade PBS (such as Showa Polymer Bionolle) ™ 1001) | Completely degraded in soil/composting environment, residue non-toxic, in compliance with ISO 17088 bioplastic standard | EN 13432 & ASTM D6400; ISO 17088 (Degradable standard for medical devices); REACH (EU Chemical Safety Compliance) |

5.2 Quotation Scheme Based on MOQ

This quotation takes into account the costs of raw material procurement, injection molding processing, and certification document services, and is formulated with reference to the pricing systems and industry processing fee standards of core suppliers. The specific details are as follows:

| Minimum Order Quantity (MOQ) | Material Option | Unit Cost (per item) | Delivery Cycle | Cost Structure |

|---|---|---|---|---|

| 10,000 pcs | Injection molding grade PLA | $0.170–$0.213 | 15–20 work days | 1. Raw material cost: $0.114–$0.142 (PLA pellet market price ~$2,556/ton, 5% bulk discount for orders ≥10 tons); 2. Processing fee: $0.043–$0.057 (including mold debugging, energy consumption, and labor); 3. Certification/document fee: $0.014 |

| 10,000 pcs | Injection molding grade PBS | $0.213–$0.256 | 18–22 work days | 1. Raw material cost: $0.085–$0.107 (10% bulk discount for orders ≥50 tons); 2. Processing fee: $0.035–$0.043 (no additional equipment modification required); 3. Certification/document fee: Waived (covered by large order value). |

| ≥50,000 pcs | Injection molding grade PLA | $0.128–$0.156 | 25–30 work days | 1. Raw material cost: $0.121–$0.142 (8% bulk discount for orders over 50 tons); 2. Processing fee: $0.035–$0.043 (scale effect reduces unit cost); 3. Certification/document fee: Free (one-time fee covered for large orders) |

| ≥50,000 pcs | Injection molding grade PBS | $0.170–$0.199 | 28–35 work days | 1. Raw material cost: 0.85-1.00 yuan (8% bulk discount for orders over 50 tons); 2. Processing fee: $0.035–$0.042; 3. Certification/Document Fee: Waived (covered by large order value) |

Note:

- This quotation does not include mold costs. If a new mold is required, a special mold quotation can be issued after providing 2D/3D drawings of the parts;

- If customized colors or functional additives (such as antibacterial agents) are required, the unit cost will increase by $0.014–$0.028, and the delivery cycle will be extended by 3-5 working days;

- Logistics service: Next day delivery in the Pearl River Delta region, 3-5 days delivery in other parts of China, and free delivery service for orders over 50,000 pieces.

5.3 Supporting Documents Provided

After the order is officially confirmed, the following complete set of technical and certification documents will be provided within 3 working days to ensure the quality verification requirements of the purchaser:

- Material Datasheet:Includes complete technical parameters of the selected PLA/PBS model, covering melt flow rate, tensile strength, processing temperature range, and drying process requirements (such as PLA requiring 85 ℃ × 2h drying conditions);

- Certification Copy: Provide scanned copies of certifications such as EN 13432 and ASTM D6400, including official seals and expiration dates, to ensure the validity of the certification;

- Injection Molding Process Report: Clearly define the optimized molding parameters (injection temperature, pressure, cooling time) and the quality inspection standards for finished products (including dimensional tolerance range and appearance defect judgment basis).

5.4 Follow up Cooperation Guidelines

(1) To improve the accuracy of quotation, please provide 2D/3D drawings of small plastic parts (recommended STEP or IGES format) to optimize material consumption calculation and processing technology plan;

(2) 5-10 samples can be provided for performance testing, with a sample cost of $7.10–$11.36, which can be fully offset in subsequent bulk orders;

(3) Regarding technical issues such as material performance adaptability (such as the application stability of PLA in low-temperature environments) or the validity of certification documents, you can always contact the technical team for professional interpretation.

6. Conclusion: How to Choose Suitable Materials Between PLA/PHA VS PBS/PBAT

The selection of biodegradable plastics should be based on a precise understanding of their own needs, and there is no absolute optimal “universal material”. The core is to achieve the matching of material properties and application scenarios. The specific selection suggestions are as follows:

(1) If sustainability and natural environmental degradation capacity are given priority consideration (such as marine applications and household composting scenarios): PHA can be chosen for high-end demand, while PLA is recommended for cost sensitive and industrial composting scenarios;

(2) If the core requirements are flexibility and heat stability (such as agricultural films and flexible packaging bags): PBAT is chosen for ductility, and PBS is chosen for heat resistance, both of which have high cost-effectiveness advantages;

(3) If focusing on food contact or medical application safety: PLA is preferred in the food packaging field, while PHA is the core choice in the medical implant field, both of which have passed FDA biosafety certification;

(4) If we focus on cost control and feasibility of large-scale production: PLA (bio-based) and PBAT (petrochemical based) are currently the two categories with the lowest production costs and the most stable supply, which can be preferred according to environmental requirements.

With the continuous promotion of policies such as the EU’s “Disposable Plastics Directive” and China’s “14th Five-Year Plan for the Development of Bioeconomy”, as well as breakthroughs in low-cost PHA, modified PLA and other technologies, the biodegradable plastics market will enter a stage of high-quality development. Both PLA and PBS can meet the compliance requirements for the injection molding of small plastic parts, with PLA being more suitable for large-scale low-cost orders and PBS having advantages in scenarios with higher heat resistance requirements.

If you want to get more information regarding the PLA injection molding of plastic parts using biodegradable materials, please feel free to contact us at sales@kingstarmold.com. We will provide a detailed DFM from multiple dimensions and provide quotations and cooperation plans for injection molding and one-stop manufacturing solutions.