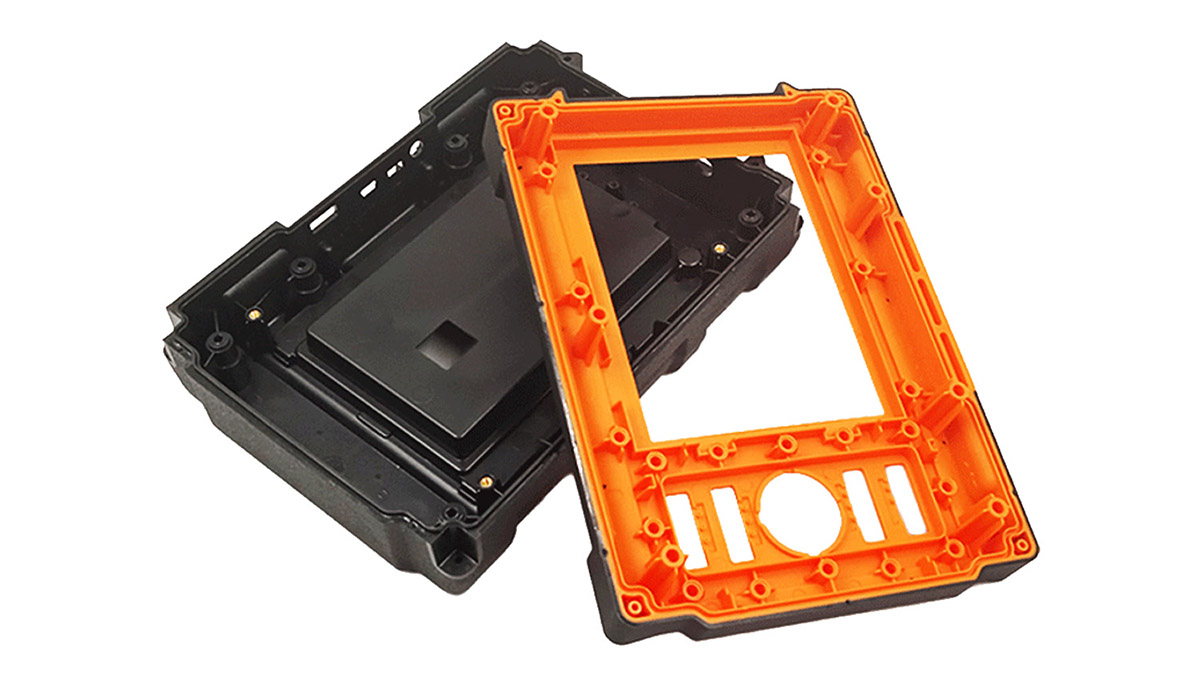

In modern manufacturing, thermoplastic injection molding technology, with its advantages of efficient mass production and controllable precision, can stably produce complex shaped components. In addition, the material itself has good processing fluidity, reliable mechanical strength, and economic cost advantages, so it is widely used in multiple industries.

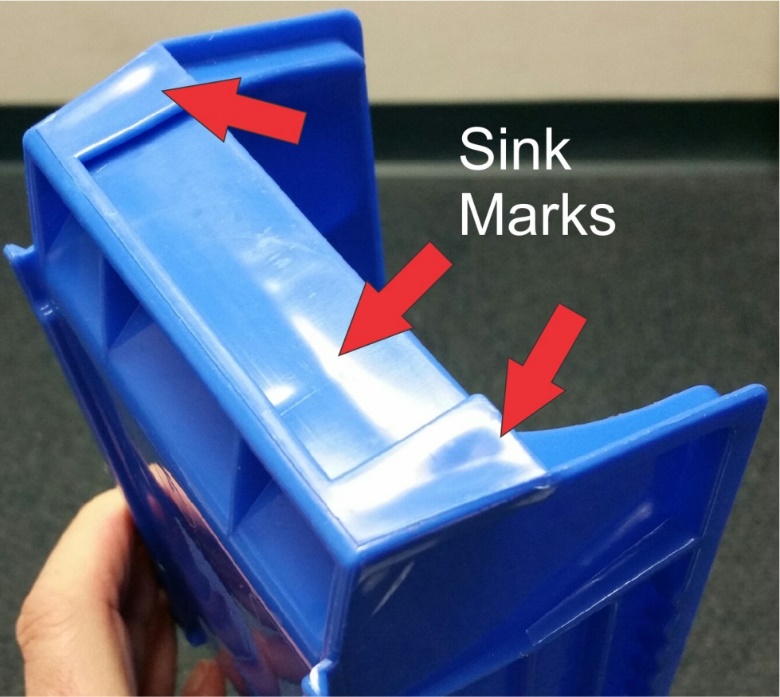

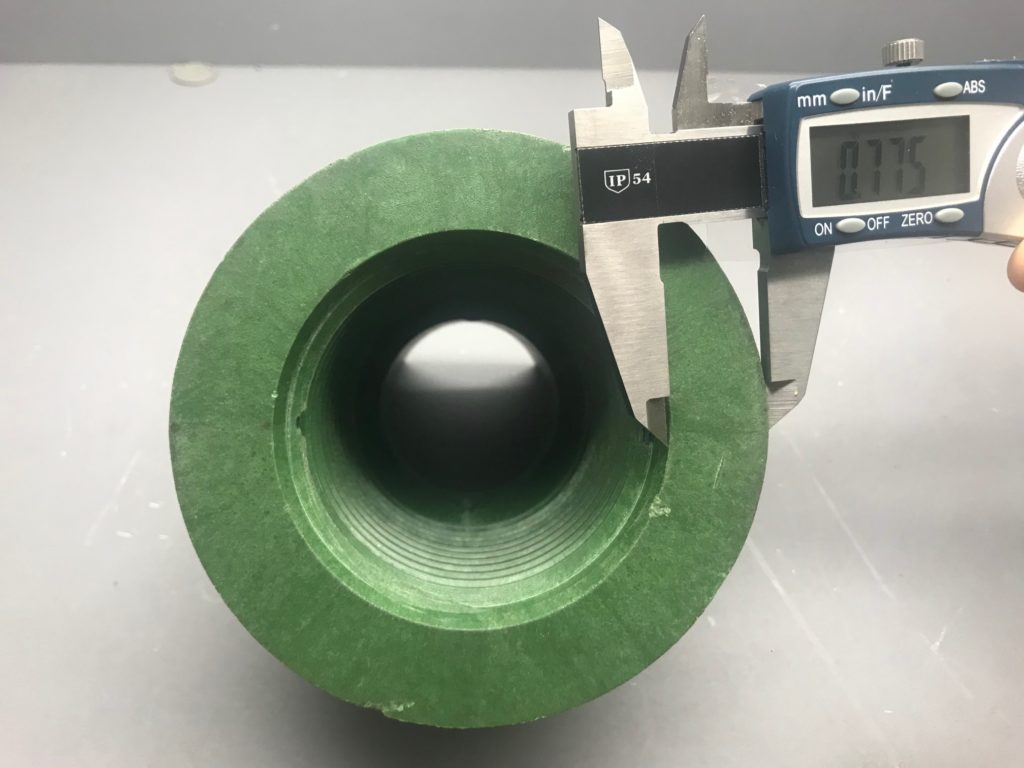

Wall thickness is one of the most critical structural indicators in injection molding design, which directly affects whether the product can be formed smoothly, and also determines the mechanical strength, durability, and final production cost of the product. In actual production, improper wall thickness design can lead to a series of problems: being too thin may result in incomplete filling of the melt, obvious weld lines, and thus affect product strength; Excessive thickness can easily lead to defects such as shrinkage marks and internal bubbles, as well as increase material usage and cooling cycles, resulting in increased costs.

1. Data Description

This table systematically compiles the core wall thickness parameters for 18 types of commonly used thermoplastic plastic injection-molded parts in industry. It covers the minimum feasible wall thickness (the critical minimum value ensuring molding integrity), general application wall thickness (a conventional choice balancing performance and production efficiency), and maximum feasible wall thickness (the upper limit to avoid defects such as shrinkage and bubbles). The data is presented in dual units of millimeters (mm) and inches (in), suitable for both domestic and international production scenarios.

2. Table of Wall Thickness Parameters for Common Thermoplastic Injection Molded Parts

| Plastic Abbreviation | Minimum Feasible Wall Thickness |

General Application Wall Thickness

|

Maximum Feasible Wall Thickness | |||

| mm | in | mm | in | mm | in | |

| POM | 0.4 | 0.016 | 1.5 | 0.06 | 3.18 | 0.125 |

| ABS | 0.75 | 0.03 | 2.25 | 0.09 | 3.18 | 0.125 |

| PMMA | 0.75 | 0.03 | 2.3 | 0.092 | 6.35 | 0.25 |

| CA./CAB/CAP | 0.65 | 0.026 | 2.4 | 0.076 | 17 | 0.669 |

| PA | 0.35 | 0.014 | 1.5 | 0.06 | 3.18 | 0.125 |

| PC | 0.75 | 0.029 | 2 | 0.079 | 9.53 | 0.375 |

| PBT | 0.6 | 0.024 | 1.5 | 0.06 | 10 | 0.4 |

| LDPE | 0.5 | 0.02 | 1.5 | 0.06 | 6.35 | 0.25 |

| HDPE | 0.75 | 0.029 | 1.5 | 0.06 | 6.35 | 0.25 |

| EVA | 0.5 | 0.02 | 1.5 | 0.06 | 3.18 | 0.125 |

| PP | 0.55 | 0.022 | 2 | 0.08 | 7.5 | 0.295 |

| PES/PSU | 1 | 0.04 | 2.5 | 0.1 | 9.53 | 0.375 |

| PPO-M | 0.75 | 0.03 | 2 | 0.08 | 9.53 | 0.375 |

| GPPS/HIPS | 0.5 | 0.02 | 1.5 | 0.06 | 6.35 | 0.25 |

| SAN | 0.75 | 0.03 | 1.5 | 0.06 | 6.35 | 0.25 |

| TPU/PUR | 0.6 | 0.024 | 12.7 | 0.5 | 38 | 1.5 |

| UPVC | 1 | 0.04 | 2.4 | 0.094 | 9.53 | 0.375 |

3. Supplementary Explanation

- Data limitations:The values in the table are only for general reference, and the actual determination of wall thickness needs to be flexibly adjusted according to specific circumstances. For example, different plastic grades have different requirements. Special materials such as reinforced and flame-retardant materials usually require an appropriate increase in wall thickness; If the product structure is complex or has thin-walled areas, the flowability of the material should be considered for adaptation; In addition, the locking force and injection pressure parameters of the injection molding equipment, as well as the melt temperature and cooling time settings in the molding process, will all affect the final wall thickness selection.

- Expansion suggestion: If you need more detailed information, such as wall thickness parameters for specific plastics (such as PA66, PC/ABS alloy), or wall thickness standards for special application scenarios such as high temperature resistance and impact resistance, or if you want to export data to Excel/CSV format for subsequent calculations, please let us know at any time and we will further improve according to your needs.

If you want to gain systematic insights into thermoplastic injection molded parts, theoretical support is needed in practical discovery. KingStar, the leading custom manufacturing company in China, sincerely welcomes corrections or further discussions, and we look forward to receiving your email at sales@kingstarmold.com regarding your specific project.