Vapor Smoothing for 3D Printing

What Is Vapor Smoothing & How Does It Work?

Vapor smoothing, also called chemical vapor smoothing, vapor polishing, or vapor fusion, is a post-processing technique for enhancing 3D printed parts’ surface finish. It targets flaws like visible layer lines and “sugar cube-like” textures by exposing parts to vaporized solvents, and is widely used for parts from processes such as Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS). By partially melting and dissolving the material surface, it creates a smooth, glossy finish—ideal for cosmetic and functional uses, and valuable in industries like automotive and aerospace where smoothness and precision matter.

Vapor smoothing relies on controlled chemical reactions between vaporized solvents (e.g., acetone, ethanol) and part surfaces. A cleaned part is placed in a sealed chamber with solvent, which is heated to vaporize. The vapor fills the chamber, condenses on the surface, and interacts with the material—melting and smoothing the outer layer (with surface particles’ peaks flowing into valleys to boost smoothness) to eliminate imperfections, resulting in a polished finish. And that is to say, in vapor smoothing, no material is removed like other traditional surface treatments; instead, a controlled chemical melt refines the surface. After processing, the part is dried and cooled, with duration depending on size and complexity, up to several hours.

Improved Surface Finish

Vapor smoothing significantly reduces surface roughness, resulting in a much smoother, more polished appearance. This process enhances the overall aesthetics of 3D printed parts by minimizing visible layer lines and imperfections. Some studies have shown that chemical vapor polishing can increase the surface finish of materials by 800% to 1000%. The smoother surface(with roughness reduced from over 250 μin RA as-printed to 64–100 μin RA or even under 40 μin RA after smoothing) is ideal for applications requiring high-quality visuals, such as consumer products or prototypes.

Retention of Mechanical Properties

Vapor smoothing improves the visual appeal and surface quality without compromising the part’s mechanical strength or functionality. Tests have shown minimal changes in the mechanical properties of parts after smoothing.

Benefits of Chemical Vapor Smoothing

Standard Finished | Vapour Smoothed

Maintain Features & Dimensional Accuracy

Typical dimensional changes are kept within ±0.1%–±0.3% of the original size, ensuring critical details and tolerances remain intact.

Repeatable Processing Results

The process achieves closed-loop operation through controlled parameter settings, ensuring highly consistent results for different batches or identical parts with minimal repeatability errors.

Enhanced Hygiene and Moisture Resistance

Vapor smoothing cuts down on both bacterial growth and the absorption of moisture by reducing porosity, which is a big plus for parts used in settings where cleanliness matters. For example, tests on Nylon 12 parts showed that after vapor smoothing, the growth of MRSA bacteria dropped by 60%. This makes it a strong fit for uses in healthcare or food processing, where keeping things sterile is non-negotiable.

Uniform Coverage for Complex Geometries

Unlike methods that coat surfaces, vapor smoothing can reach every nook and cranny of a part—including hard-to-reach spots or areas you can’t easily see. This means even the most complex designs, with internal features or tight spaces, get a consistent, smooth finish all over. Its a key benefit for parts with intricate shapes that are tough to polish evenly with other techniques.

Design Guide for Vapour Smoothing

Vapour Smoothing for Health & Safety Industry

| Test | Details | Normative Reference |

|---|---|---|

| Food Contact Test | KingStar's SLS-printed PA-12 parts, after vapor smoothing, do not pose risks to consumer health or affect food quality. | (EC) 10/2011 Annex V, Chapter 3, Table 3, OM 3, 2 hours at 70°C; DS/EN1186-01:2002; DS/EN1186-03:2002; DS/EN1186-14:2002 |

| Skin Irritation Test | KingStar's SLS-printed PA-12 parts, after vapor smoothing, show no skin-irritating effects. | ISO 10993-10 (2013); ISO 10993-1 (2018); OECD TG 439 |

| Cytotoxicity Test | KingStar's MJF-printed PA-12 parts, after vapor smoothing, produce no cytotoxic effects. | ISO 10993-5 (2009); ISO 10993-1 (2010); ISO 10993-12 (2012) |

| Microbiological Test on MRSA Bacteria | KingStar's MJF-printed PA-12 parts, after vapor smoothing, reduce MRSA bacterial growth by 99.88%. | MOD ISO 22196: 2011 |

| Microbiological Test on E. coli Bacteria | KingStar's MJF-printed PA-12 parts, after vapor smoothing, reduce E. coli bacterial growth by 99.78%. | MOD ISO 22196: 2011 |

Material Compatibility of Vapor Smoothing

| Material | Printing Process | Solvent | Cost | Notes |

|---|---|---|---|---|

| Polyamides (PA11, PA12, etc.) | Powder Bed Fusion (SLS, MJF), FDM | IPA, Formic Acid, etc. | Medium | Carbon/glass fiber-filled variants require controlled processing time to avoid over-etching of reinforcing materials |

| Acrylonitrile Butadiene Styrene (ABS) | FDM | Acetone, MEK | Low | Highly volatile solvents require strict temperature control and ventilation to prevent excessive part shrinkage. |

| Acrylonitrile Styrene Acrylate (ASA) | FDM | Acetone, MEK | Low | Yields high surface gloss but may experience UV stability issues with prolonged exposure (but still more stable than ABS) |

| Thermoplastic Polyurethane (TPU), Thermoplastic Elastomers (TPE) | FDM, SLS | Ethyl Acetate, Cyclohexanone, THF | Medium-High | Elastic materials prone to solvent-induced over-swelling; requires shorter processing time and lower temperature |

| Polypropylene (PP) | MJF, FDM | Heptane, Hexane | Medium | Non-polar solvents have weak etching effect on PP; extended processing time needed for optimal results |

| Polycarbonate (PC), PC-ABS Blends | FDM, SLS | Dichloromethane, Chloroform | High | Solvents are highly toxic, requiring specialized equipment and protective measures; PC-ABS blends may show uneven results due to compositional variations |

| Polyether Ether Ketone (PEEK), Polyether Ketone Ketone (PEKK) | High-Temp FDM, SLS | Specialty Fluorinated Solvents | Very High | Requires matched high-temperature and high-pressure environment; only suitable for industrial-grade equipment; high solvent cost and processing difficulty |

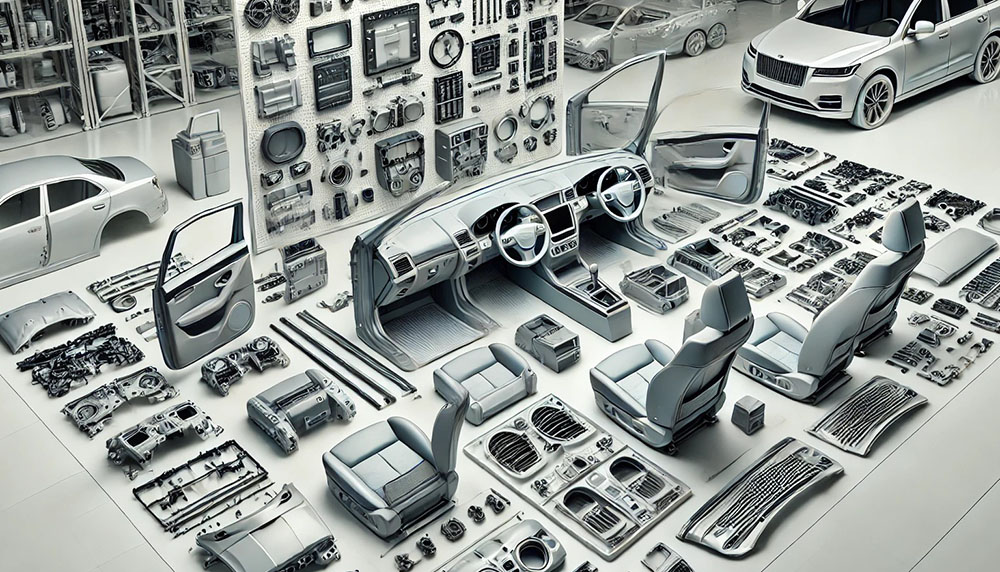

Automotive Components

Consumer Goods

Aerospace

Medical Devices

Cost Example of Vapor Smoothing

| Part | Automotive Hose | Eyewear Frames | Rigid Orthotic Insole |

|---|---|---|---|

|  |  |

|

| Model Dimensions (mm) | 180 x 25 x 70 | 144 x 36 x 47 | 157 x 23 x 80 |

| Material | TPU 92A Powder | Nylon 12 Powder | Nylon 11 Powder |

| Quantity | 40 | 80 | 50 |

| Cost of Vapor Smoothing (per part) | $1.10 | $0.49 | $0.98 |

| Cost of Sintered Powder (per part) | $4.50 | $0.62 | $3.98 |

| Total Cost Per Part | $5.60 | $1.11 | $4.96 |

*From past projects for a rough reference. The cost of vapor smoothing depends on several variables, including part size, material type, surface complexity, and order quantity. Typically, the cost correlates with the part’s dimensions and quantity, with larger or more intricate parts requiring more processing time and resources.

Frequently Asked Questions

Unlike traditional surface treatment processes, vapor smoothing achieves smoothness by melting and redistributing the material surface, using the raised peaks to compensate for the depressed valleys. In contrast, traditional surface processing smooths the surface by removing the raised peaks, bringing each part to the lowest point of the depressed valleys. Therefore, vapor smoothing has a much smaller impact on the size of the components compared to other traditional methods.