KingStar Mold’s Vacuum Casting Service

At KingStar Mold, we provide top-tier vacuum casting services designed to meet the needs of diverse industries. Our state-of-the-art technology and skilled team ensure the creation of precise, high-quality prototypes with exceptional detail. Whether you need functional parts or intricate designs, we offer a broad selection of materials to suit your project requirements.

Our vacuum casting process delivers quick turnaround times without compromising on accuracy or durability. With a focus on cost-effective solutions, we work closely with clients to ensure timely delivery and the highest standards of quality. Trust KingStar Mold for reliable and efficient vacuum casting that brings your ideas to life.

Material Options for Vacuum Casting

| Material Type | Properties | Applications & Typical Uses | Pricing |

|---|---|---|---|

| Polyurethane (Rigid) | Strong, durable, impact-resistant, mimics plastic/metal. | Automotive parts, functional prototypes, enclosures. | $$ |

| Polyurethane (Flexible) | Soft, rubber-like, flexible, resilient. | Seals, gaskets, flexible prototypes. | $$ |

| Silicone Rubber | Highly flexible, heat-resistant, excellent finish. | Medical devices, seals, soft-touch parts. | $$$ |

| ABS-like Resin | Strong, heat-resistant, impact-resistant. | Consumer products, casings, functional parts. | $$ |

| Polyethylene (PE-like) | Tough, chemical-resistant, low friction. | Chemical-resistant parts, wear-resistant prototypes. | $$ |

| PVC-like Material | Rigid, excellent surface finish, machinable. | Electrical enclosures, industrial parts. | $$ |

| Transparent Resin | Clear, glass-like finish, precise molding. | Transparent covers, optical devices, lighting housings. | $$$ |

| Flame Retardant Resin | Fire-resistant, high-temperature stable. | Electrical components, automotive, aerospace parts. | $$$ |

| Rubber-like Resin | Soft, rubbery, strong elongation. | Gaskets, seals, overmolded parts. | $$ |

KingStar Mold’s Advantages On Vacuum Casting Service

High Precision and Detail

Our vacuum casting process captures even the smallest details with exceptional accuracy, ensuring that every prototype matches your design specifications. This precision is crucial for evaluating complex geometries and achieving high-quality results.

Fast Turnaround Time

We prioritize speed without sacrificing quality, providing rapid prototyping services that deliver results quickly. Our efficient process allows for faster iterations, helping you move from concept to production in record time.

Wide Range of Material Options

We offer a broad selection of materials, from rubber-like to rigid plastic, to match the unique requirements of your project. This flexibility allows us to create functional prototypes that mimic the final product’s properties.

Cost-Effective Solution

Vacuum casting is an affordable alternative to traditional manufacturing methods, reducing production costs while still delivering high-quality prototypes. Our service helps you save on tooling and setup costs, making it ideal for small batch production and testing.

6 Steps to Complete Your Project

Step 1

Initial Consultation & File Submission

Step 2

Creating the Master Model

Step 3

Mold Creation

Step 4

Duplication Process

Step 5

Quality Check & Final Adjustments

Step 6

Delivery & Feedback

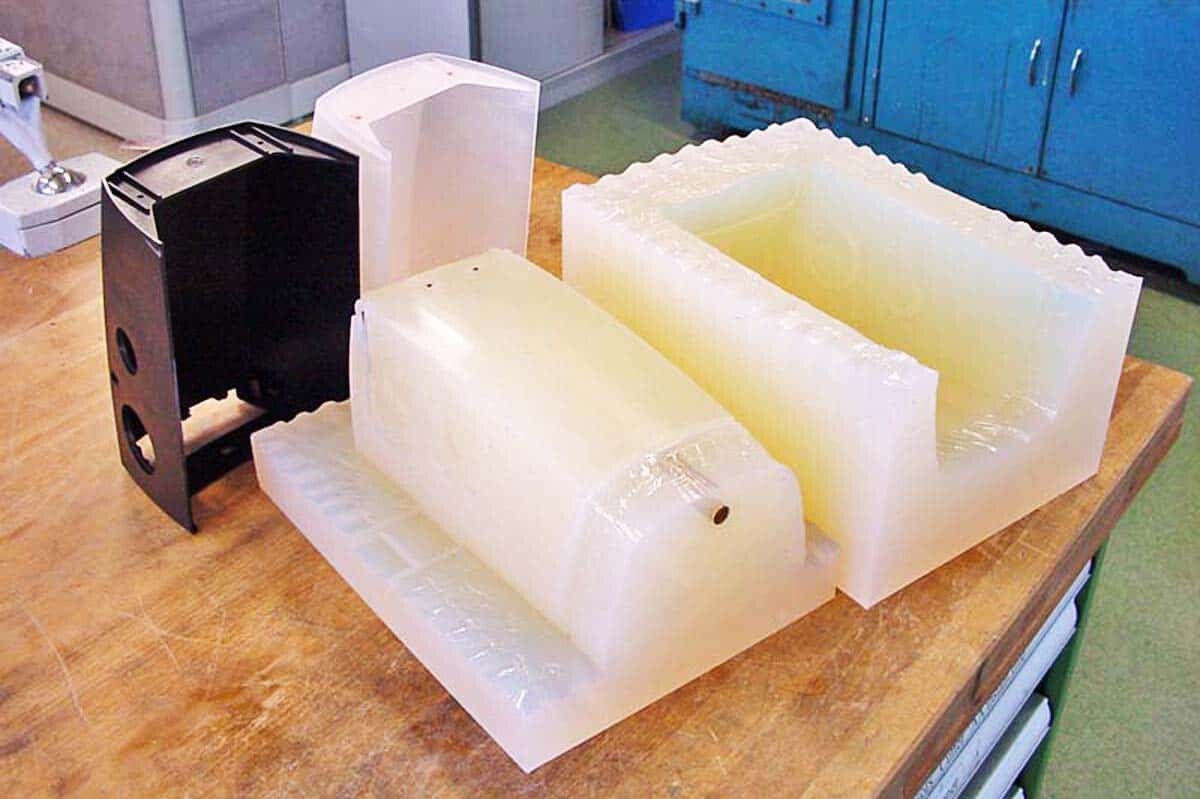

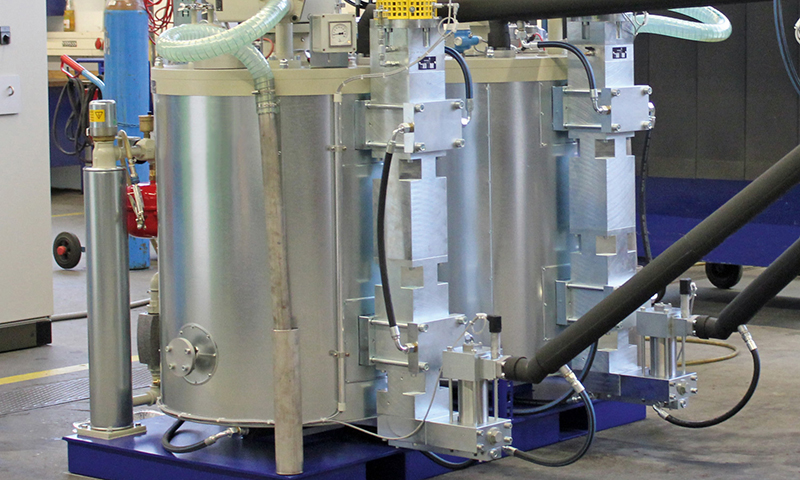

Vacuum Casting Product Gallery

Our vacuum casting process is highly precise, with tolerances typically within ±0.2mm. The level of accuracy depends on the complexity of the part, and we ensure the final product matches the design intent.

Polyurethane is rigid and suitable for hard, durable parts, while silicone rubber is flexible, soft, and often used for seals or soft-touch components. The choice depends on your specific part requirements.

Yes! Vacuum casting is ideal for small to medium production runs, making it perfect for testing prototypes, producing limited batches, or validating designs before moving to mass production.

We offer a variety of materials, including polyurethane, silicone rubber, ABS-like resin, transparent resin, and flame-retardant materials. Each material has unique properties, such as flexibility, heat resistance, and chemical resistance.

The lead time for vacuum casting typically ranges from 5 to 10 business days, depending on the complexity and quantity of the order. The process can be expedited if necessary.

Vacuum casting is a rapid prototyping technique used to create high-quality, low-volume parts. It involves creating a silicone mold from a master model, then casting materials like polyurethane into the mold to produce prototypes or end-use parts.

At KingStar Mold, we strive for 100% customer satisfaction. If you’re not satisfied with the final prototype, we’ll work with you to resolve any issues or make necessary adjustments to ensure the part meets your expectations.

We serve a wide range of industries, including automotive, aerospace, consumer electronics, medical devices, and more. Whether you need functional parts, visual prototypes, or end-use components, we tailor our services to meet your needs.

At KingStar Mold, we focus on delivering fast, reliable, and cost-effective solutions for your prototyping needs. Our team of experts uses advanced technologies to ensure high-quality results with quick turnaround times, and we offer personalized customer support throughout the entire process.

Yes! We accept orders for single prototypes, which are often used for testing, validation, or early-stage design feedback. Vacuum casting is perfect for low-volume, high-quality prototypes.

You can easily submit your 3D design files (STL, STEP, or other formats) through our online portal or via email. We’ll review your files and provide feedback or a quote based on your project’s requirements.

Yes, we offer a range of finishes including matte, glossy, textured, or painted finishes. Our finishing team can also apply graining, polishing, or even transparent coatings to mimic the final product appearance.