As a leading TPU injection molding company, we receive inquiries every week about TPU overmolding process and problem solving. That’s why we work this post out for our clients and small and medium-sized injection molding factories.

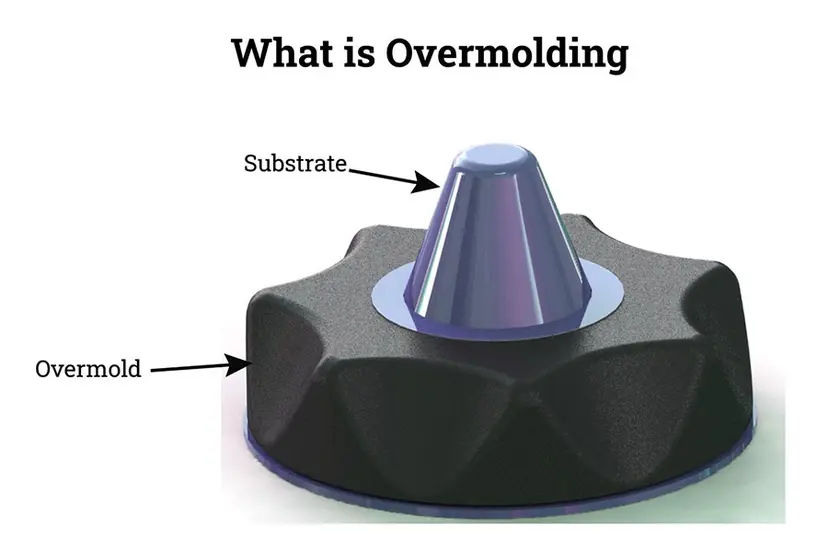

In the injection molding industry, TPU (thermoplastic polyurethane) overmolding is a process that offers both advantages and challenges. It can provide rigid substrates (such as nylon + 10% fiber or ABS materials) with an elastic, comfortable-touch overmolded layer, widely used in products like tool handles, electronic device protective cases, smart home suction cups, and seals. However, during actual production, many practitioners-especially beginners-often face difficulties such as “multiple mold adjustments still failing to meet standards and high scrap rates.”

In fact, the root cause of such issues lies not in material quality or equipment performance but in insufficient understanding of TPU’s material properties—TPU is significantly more sensitive to temperature, pressure, and mold structure than conventional plastics. From material selection to process parameter setting, every detail in each step directly impacts the final molding quality. Based on the practical experience of frontline technicians, this article first systematically analyzes the fundamental logic of TPU overmolding, then breaks down key mold adjustment parameters (correcting common misconceptions in temperature and pressure settings). Finally, it provides actionable solutions for the typical challenge of “80 Shore A TPU overmolding on nylon fiberglass substrates,” helping practitioners reduce trial-and-error costs and improve production efficiency.

1. Why TPU Overmolding is Prone to Issues?

The hardness range of TPU (thermoplastic polyurethane) can cover Shore A60 to Shore D80, with excellent elasticity and wear resistance. Therefore, it is often used as an overmolding material and compounded with rigid substrates such as nylon and ABS, and applied to suction cups, electronic components, and other products. However, the material properties determine the strictness of the process parameters, and even temperature fluctuations of 10 ℃ and pressure deviations of 5MPa may lead to product rejection.

From the perspective of mold design, the shrinkage rate of TPU has a significant hardness correlation. Taking 80 Shore A TPU as an example, its shrinkage rate is usually from 1.3% to 1.5%, and the lower the hardness, the higher the shrinkage rate. Therefore, during the mold design phase, it is necessary to compensate for the size based on the shrinkage rate of the target TPU, while reserving sufficient exhaust channels (to avoid gas retention in the mold cavity leading to missing glue or bubble defects), and accurately design the sealing structure size to prevent material leakage and flash in later production.

The material selection process also needs to comprehensively consider multi-dimensional requirements, and cannot only focus on hardness parameters. If the product needs to meet certain temperature resistance (such as outdoor or high temperature environment use), high crystalline TPU should be preferred; If the thickness of the overmolded layer is thin (e.g., less than 1mm), a low viscosity model should be selected to ensure the fluidity of the melt; For suction cup products, 80 Shore A TPU can balance tactile feel and structural support, but it is important to verify the interface compatibility between this model of TPU and nylon+10% fiberglass substrate – this is a key prerequisite that is often overlooked in most production processes.

2. Core Mold Tuning Parameters

2.1 Temperature: Actual Need for Segmented Control

TPU has limited high temperature resistance and is prone to thermal degradation when the temperature exceeds 230℃. Therefore, a segmented control strategy is required for the temperature of the barrel:

- Feed Zone (Hopper End): 170-190 ℃, the temperature does not need to be too high during this stage to avoid raw material adhesion at the feeding port;

- Plasticizing Zone (Middle Section): 190-210 ℃, ensuring that TPU raw materials are fully melted to form a uniform melt;

- Nozzle Zone (Mold End): 200-220 ℃. Increasing the temperature appropriately can ensure smooth entry of the melt into the mold cavity and avoid nozzle blockage caused by premature cooling and solidification of the melt.

2.2 Pressure and Speed: Core Parameters for Balancing Shrinkage and Flash

Insufficient injection pressure leading to shrinkage and excessive pressure leading to flash is a typical problem of TPU overmolding, and the core lies in optimizing parameter balance based on product design:

- Injection Pressure: mainly medium high pressure, with a conventional range of 80-120MPa. For suction cup products (with a moderate thickness of the overmolded layer), an initial pressure of 90MPa can be set first. If shrinkage defects occur, gradually increase the pressure by 5-10MPa to avoid sudden pressure increases that may cause bulging;

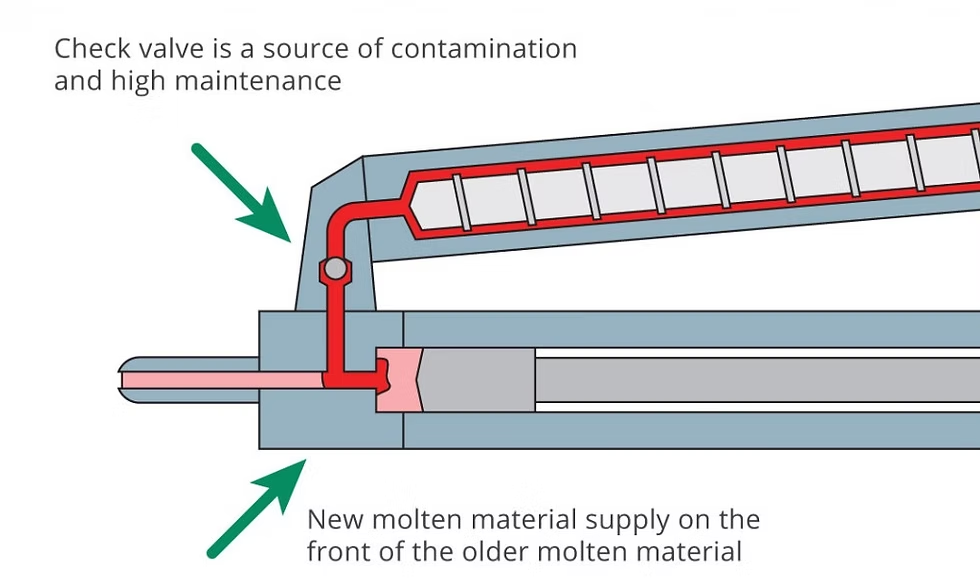

- Back Pressure: It can be controlled within 0.3-4MPa. The main function of this parameter is to discharge gas from the melt and ensure uniform dispersion of colorants. Excessive back pressure can actually exacerbate the thermal degradation of TPU;

- Injection Speed: It is recommended to use a medium low speed setting (20-50mm/s). TPU melt itself has good fluidity, and high-speed injection is prone to air entrapment and the formation of bubbles. Low speed may lead to insufficient filling, so it is recommended to adjust it with an initial speed of 30mm/s.

The mold temperature needs to be controlled within the range of 30-50 ℃. Excessive temperature can easily cause TPU melt to adhere in the mold cavity, increasing the difficulty of demolding; If the temperature is too low, it will reduce the fluidity of the melt, not only affecting the filling performance, but also weakening the interfacial bonding strength between TPU and the hard rigid substrate. In addition, it should be noted that if the equipment is shut down for more than 1 hour, the heating system of the material cylinder should be turned off in a timely manner to prevent continuous thermal degradation of TPU in the cavity; Before restarting, it is necessary to clean the material cylinder with PS or ABS materials to avoid degradation residues affecting the quality of the finished product.

2.3 Other Key Process Details

- Material Drying: TPU has strong moisture absorption, and if used directly without drying, it can easily cause defects such as water streaks and bubbles on the surface of the finished product. Drying at a temperature of 80-90℃ for 2-4 hours is required to ensure that the moisture content of the raw materials is below 0.07% (in practice, the drying effect can be judged by the non stick texture of the particles);

- Cycle Time: The conventional range is 20-60 seconds, and for small suction cup parts, it can be controlled within about 30 seconds. It is necessary to extend the cooling time appropriately to avoid deformation caused by internal stress release after demolding;

- Post-Processing: If the thickness of the overmolded layer exceeds 3mm, annealing treatment (2-4 hours of insulation at 60-80℃) is required after molding to eliminate internal stress and reduce the risk of cracking during long-term use;

- Mold Cleaning: TPU is highly sensitive to contaminants such as oil and mold release agents. Before each production, a clean cloth should be used to wipe the mold cavity. Release agents should be used sparingly or not to prevent them from affecting the bonding performance between TPU and the rigid substrate.

3. Key Solution: Technical Challenges in Overmolding Nylon Substrates with 80 Shore A TPU

In response to the issue of “insufficient pressure, shrinkage, and cracking due to excessive pressure after more than ten trial molds and 15 material replacements”, the core issue lies in the insufficient compatibility of materials and the matching of process parameters. The optimization can be carried out according to the following steps:

3.1 Enhancing Compatibility and Bond Strength Between TPU and Nylon Fiberglass Substrate

The polarity difference between nylon+10% fiberglass and TPU is significant, and the intermolecular binding force is weak. Targeted measures are needed to improve the interfacial bonding performance:

- Material Selection Optimization: Prioritize the use of polyester-based TPU, whose solubility parameter (8.5-10.5) is closer to nylon (about 10.5), which can significantly improve the interfacial bond strength;

- Substrate Pre-treatment: Two treatment methods can be used to address the insufficient adhesion caused by the smooth surface of the nylon substrate: ① using ethanol wiping to remove surface oil stains; ② By sanding with sandpaper or laser etching, a micro rough surface is formed to increase the contact area; If the above methods have limited effectiveness, polyurethane special primer can be applied to enhance the bonding effect.

3.2 Collaborative Optimization of Mold Structure and Process Parameters

- Mold Modification: ① Optimize the right angle structure at the base of the substrate to rounded corners of R0.5-R1.0 to avoid cracking caused by stress concentration during high-pressure injection; ② Add sealing lands (with a width of no less than 2mm) on the parting line to prevent excess melt from overflowing and reduce the generation of flash;

- Temperature Parameter Adjustment: Increase the temperature of TPU melt to 210-220 ℃ and the mold temperature to 45-50℃ to ensure the filling effect by improving the fluidity of the melt, while enhancing the interface adhesion with the substrate;

- Injection Process Optimization: Adopting a two-stage injection process instead of single-pressure injection: the first stage is quickly filled to 80% of the mold cavity with low pressure (70-80MPa) to avoid insufficient initial filling; The second section uses high pressure (90-100MPa) to slowly compensate for shrinkage and eliminate sink marks; The holding pressure is set to 60% of the injection pressure (approximately 50-60MPa), and the holding time is extended to 5-8 seconds to ensure that the melt is fully compacted.

3.3 Easily Overlooked Control Details

- Color Masterbatch Selection: For black TPU, it is necessary to use color masterbatches with TPU as the carrier, avoiding the use of PP or PE carrier color masterbatch – these incompatible carriers not only impair adhesion between TPU and nylon substrate, but also may lead to the embrittlement of TPU mechanical properties;

- Flow Ratio Control: The ratio of TPU flow length to product thickness should be controlled within 150:1. If the suction cup product has a longer flow channel, an auxiliary gate can be added to shorten the melt flow path;

- Equipment Condition Verification: Verify whether the clamping force of the injection molding machine meets the production requirements, and control the parallelism error of the template within 0.02mm to avoid mold overflow and flash during high-pressure injection due to insufficient clamping force.

4. Veteran Technician’s Summary: Three Typical Issues that Need to be Avoided

(1)Omit the Drying Process: 90% of surface defects in finished products (such as splay marks and bubbles) are caused by insufficient drying of raw materials. Even for newly opened TPU raw materials, the drying process must be strictly followed and this process should not be omitted;

(2)Indiscriminate Material Substitution: The performance difference of 80 Shore A TPU mainly depends on the molecular weight distribution, and the more types of materials to be replaced, the better the problem can be solved. Therefore, solubility parameter testing should be prioritized to screen for models that are compatible with nylon fiberglass substrate;

(3)Neglecting Exhaust Design: Some shrinkage defects are not caused by insufficient injection pressure, but by gas retention in the mold cavity that hinders the filling of the melt. It is necessary to open exhaust channels (with a depth of 0.01-0.02mm) in the last filling area of the melt to avoid material leakage caused by excessive depth.

The core of TPU overmolding injection molding lies in “targeted measures” – first identifying the root cause of the problem through fault symptoms (e.g., material incompatibility, unbalanced process parameter), and then adjusting and optimizing accordingly.

To gain systematic information of TPU overmolding, theoretical support is needed to facilitate the summarization and discovery in practice. KingStar welcomes any corrections or discussions, and please feel free to send us an email(sales@kingstarmold.com) for professional suggestions on the solutions for TPU overmolding for your project.