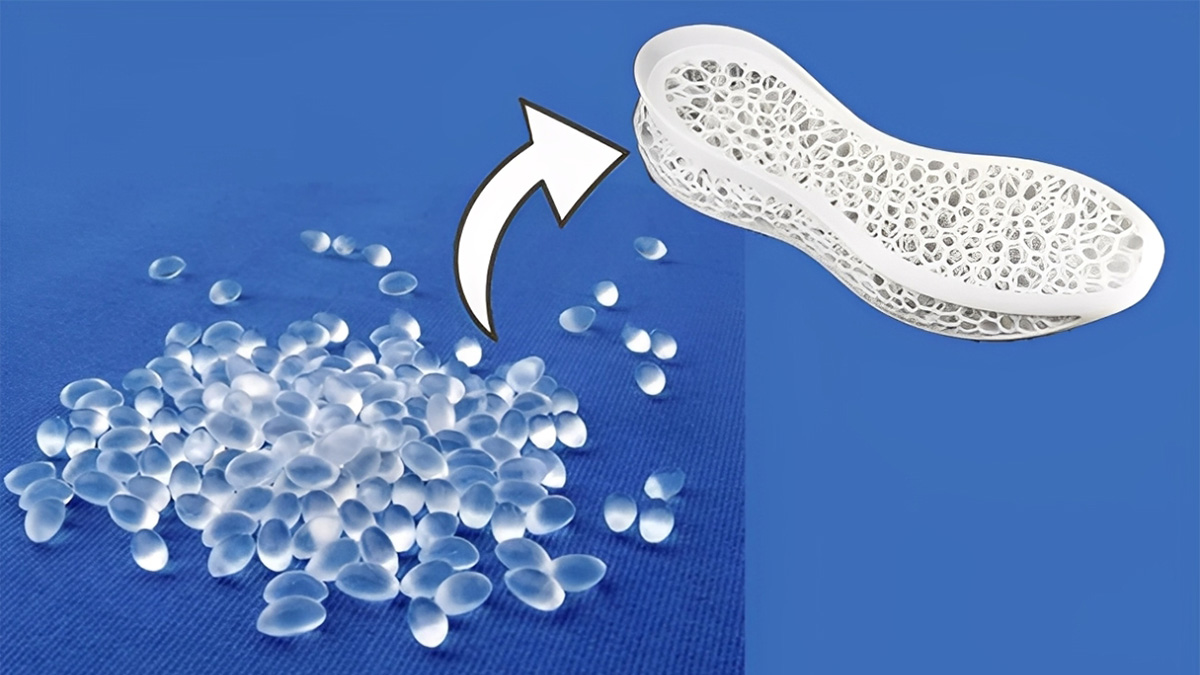

TPU Injection Molding Overview

TPU injection molding is a process that uses thermoplastic polyurethane to create durable, flexible parts with excellent abrasion, impact, and wear resistance. This molding technique is ideal for producing high-performance components that require both elasticity and toughness, such as automotive, medical, and consumer products. At KingStar Mold, we leverage advanced TPU injection molding technology to deliver high-quality, precise parts that meet the demands of various industries.

Automotive Components

Medical Devices

Consumer Electronics

Sports and Recreation

TPU Injection Molding

KingStar Mold’s Capabilities

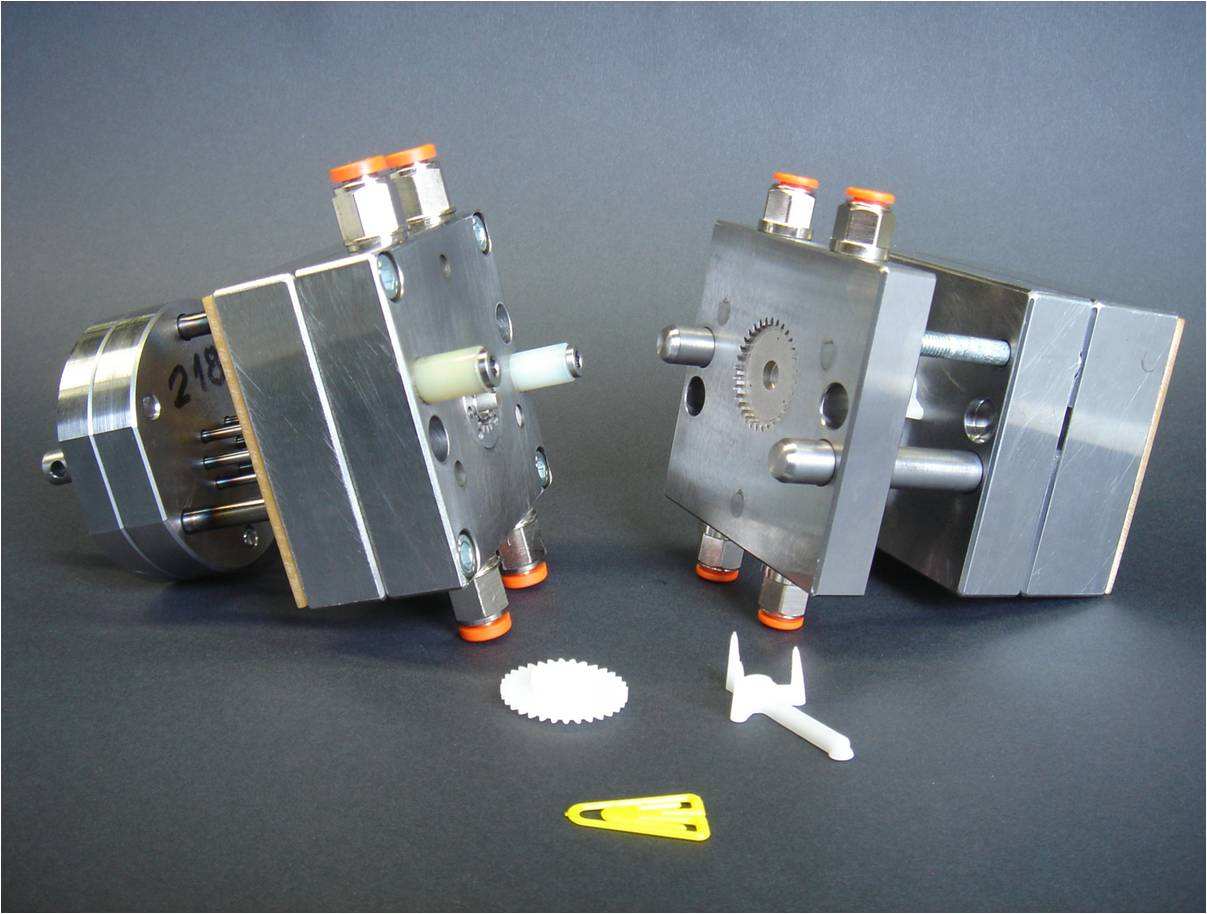

Expert TPU Mold Design

At KingStar Mold, our experienced designers focus on creating precise and optimized mold designs for TPU injection molding. Using advanced tools like mold flow analysis, we ensure optimal material distribution, reducing defects and enhancing production efficiency.

Our state-of-the-art CNC machining and injection molding technology allow us to produce TPU parts with exceptional accuracy and consistency. With rigorous quality control systems in place, we guarantee that every part meets the highest standards for clarity, durability, and performance.

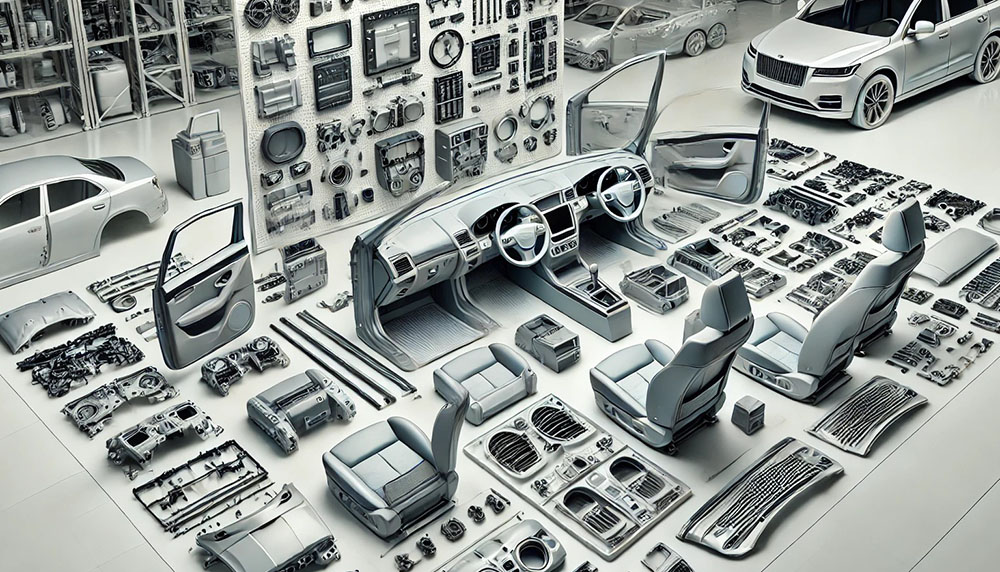

Versatility Across Industries

KingStar Mold’s TPU injection molding services cater to a wide range of industries, including automotive, consumer electronics, and signage. We provide tailored solutions to meet specific requirements, whether for transparent, impact-resistant components or high-end aesthetic parts.

Why Choose Us

Advantages of KingStar Mold

Tailored Solutions for Complex Designs

Advanced Technology Integration

Dedicated Customer Support

Competitive Pricing

TPU is used in automotive parts such as bumpers, seals, hoses, and trim components due to its durability and resistance to environmental stress.

Yes, TPU can be modified with additives to improve properties like flame resistance, UV resistance, and chemical resistance, making it adaptable for various industries.

Unlike many thermoplastics, TPU combines the properties of rubber and plastic, offering both flexibility and strength, which makes it suitable for a variety of applications.

TPU offers superior elasticity, abrasion resistance, impact strength, and flexibility, making it ideal for applications that require tough, flexible parts.

TPU injection molding is widely used across industries such as automotive, medical, electronics, sports, and consumer goods due to its flexibility, durability, and wear resistance.

TPU injection molding involves the use of thermoplastic polyurethane to create flexible, durable parts through a high-precision molding process.

Yes, TPU parts can be customized in terms of size, shape, and performance characteristics to meet the specific needs of different industries, including adding color, coatings, or additional properties like anti-static resistance.

KingStar Mold ensures quality through strict process controls, including the use of advanced mold flow analysis, CNC machining, and comprehensive testing procedures to deliver precise, high-quality parts.

The production time for TPU injection molded parts varies based on complexity, but the process is typically fast, with lead times ranging from a few days to a few weeks.

TPU is highly flexible, durable, and resistant to wear, making it an excellent choice for sporting goods like protective gear, grips, and exercise equipment components.

TPU is ideal for consumer electronics because it provides excellent shock absorption, wear resistance, and flexibility for products like phone cases, keypads, and wearable devices.

Yes, TPU is widely used in the medical industry for products like catheters, wound care devices, and seals due to its flexibility, biocompatibility, and resistance to sterilization.