TPU (Thermoplastic Polyurethane Elastomer), with its outstanding wear resistance, elasticity and weather resistance, is widely used in automotive, electronic, medical, packaging and other fields. However, different types of TPU have significant performance differences. Correctly understanding its classification logic is the core prerequisite for matching actual application requirements. This post provides a detailed explanation of the classification and key features of TPU from multiple core perspectives, for both practitioners and learners.

TPU can be classified according to different standards, and the performance and applicable scenarios corresponding to each category are clearly distinct:

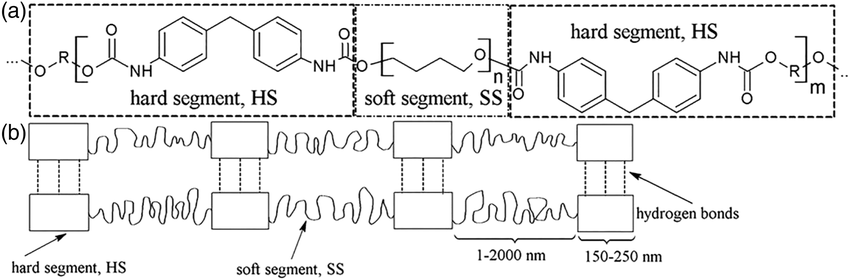

1. By Molecular Chain Structure (Soft/Hard Segment)

Soft Segment

This is the most common classification method for TPU. The soft segment structure directly determines the key properties of the material such as its resistance to hydrolysis and oil. They can be classified as polyester, polyether and butadiene types, which respectively contain ester groups, ether groups or butenyl.

As for their properties and practical applications, polyester-based TPU exhibits excellent oil resistance, aging resistance and mechanical strength, but has relatively poor hydrolytic resistance. It is suitable for manufacturing mechanical parts, automotive seals and other load-bearing or wear-resistant components in non-humid environments. Polyether-based TPU has hydrolytic resistance and excellent low-temperature elasticity, and can maintain stable performance even in humid or low-temperature environments. It is commonly used in medical catheters, underwater equipment sheaths, etc. On the other hand, butadiene-based TPU has outstanding weather resistance and chemical resistance, but its application range is relatively narrow and is mostly used in special industrial coatings or high-strength adhesives.

Hard Segment

Based on the structural characteristics of hard segments, thermoplastic polyurethanes (TPUs) fall into two main categories: urethane-type and urethane-urea-type. These two types are synthesized through the use of diol chain extenders and diamine chain extenders, respectively. Among which, urethane type has better elasticity and flexibility, and is suitable for scenarios that require frequent deformation, such as the elastic components of sports equipment; while the urethane-urea type has higher tensile strength and heat resistance, and is often used in pipes or mechanical special-shaped parts with high strength requirements.

2. By Crosslinking Presence

Based on the presence or absence of crosslinking, TPUs can be classified into pure thermoplastics and semi-thermoplastics.

Pure thermoplastics TPU has a purely linear structure without any crosslinking bonds, and thus possess good processing fluidity and can be repeatedly melted and molded or extruded, making it suitable for large-scale mass production of standardized products (such as conventional pipes and films), and has a relatively high recycling rate.

Semi-thermoplastics TPU contains a small amount of crosslinking bonds such as allophanate. Although it has better temperature resistance and dimensional stability than pure thermoplastic TPU, its processing difficulty is slightly higher. For application, it is suitable for components that need to be used in medium-high temperature environments (such as sealing parts around automotive engines).

3. By Synthesis Process

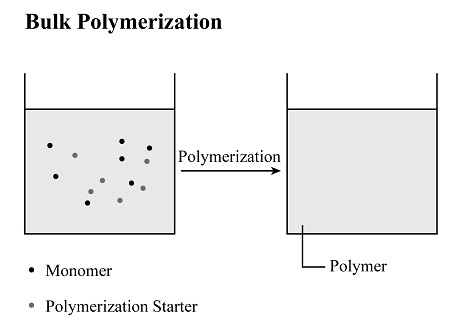

According to the synthesis process, they can be divided into bulk polymerization and solution polymerization.

Bulk polymerization

In bulk polymerization, it can be further classified into pre-polymerization method and one-shot method: the former involves the reaction of diisocyanate with a large molecule diol for a certain period of time and after that, a chain extender is incorporated into the system to generate TPU; the latter consists of blending macromolecular diol, diisocyanate, and a chain extender together in one step, with the mixture then undergoing a reaction to generate TPU.

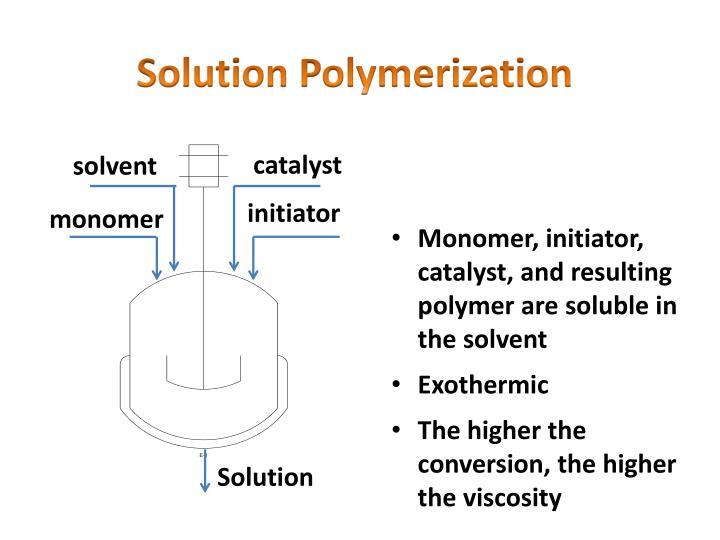

Solution Polymerization

Solution polymerization is to first dissolve the diisocyanate in a solvent, then add the large molecule diol to allow it to react for a certain period of time, and finally add the chain extender to generate TPU.

Among them, the one with the most stable performance is the TPU synthesized by pre-polymerization, as its molecular weight distribution is uniform. The one-shot method of TPU has a shorter production process, higher production efficiency and lower cost, so it is more widely used. While for the solution polymerization method, it is easier to control the reaction rate and is suitable for preparing low-viscosity TPU (such as adhesives and coating resins), but requires additional solvent recovery, which results in higher environmental protection costs.

4. By Processing Technology

According to the processing method, they can be divided into melt processing and solution processing.

Melt processing refers to the molding process through hot melt processes such as injection molding, extrusion, and blow molding, which has high processing efficiency and is suitable for manufacturing three-dimensional components, such as special mechanical parts, wire sheaths, and rod-shaped materials;

While solution processing involves dissolving TPU into a solution and then molding through coating, casting, and impregnation processes, it is suitable for preparing films, coatings, or bonding layers, such as food packaging films and coating protection layers for electronic components.

5. By End-Use Applications

According to the end-use applications, they can be classified into several categories: those used for special-shaped parts (such as various mechanical components), tubing (such as sheaths, rods), and films (such as thin sheets and plates), as well as those applied in adhesives, coatings and fibers, etc.

For a quick reference, we’ve concluded a table below:

| Product Category | Specific Examples | Recommended TPU Type | Key Considerations |

|---|---|---|---|

| Profiled Parts | Automotive seals, electronic connectors, mechanical buffers | High-strength polyester-based TPU; Urethane-urea TPU | Wear resistance & deformation resistance |

| Pipes | Wire & cable sheaths, medical catheters, industrial fluid transfer tubes | Polyether-based TPU (for humid environments); Urethane-urea TPU (for high-strength needs) | Moisture adaptability; High strength |

| Films | Food cling film, sports equipment skins, electronic insulation films | Solution-processed polyether-based TPU; Melt-cast pure thermoplastic TPU | Flexibility & light transmittance |

| Other Categories | Adhesives; Coatings; Fibers | Solution-polymerized TPU (adhesives); Butadiene-based/polyether-based TPU (coatings); High-elastic polyester-based TPU (fibers) | Matching specific needs (bonding, protection, textiles) |

The classification of TPU is not an isolated theory. When making a selection for application based on it, a comprehensive judgment needs to be made based on “structural characteristics – process cost – application scenarios” – for example, in the medical field, a hydrolysis-resistant polyether type and solution-processed films are chosen; for automotive mechanical parts, high-strength polyester type and pre-polymer method non-standard parts are selected. Clearly defining the classification logic can help match requirements more efficiently and avoid performance waste or selection errors.

If you have any more questions or need us to make professional suggestions for your specific project, you’re welcomed to contact us by email (sales@kingstarmold.com) or fill out a from on our contact page. KingStar is a leading injection molding company in China. We have rich experience in one-stop custom manufacturing.