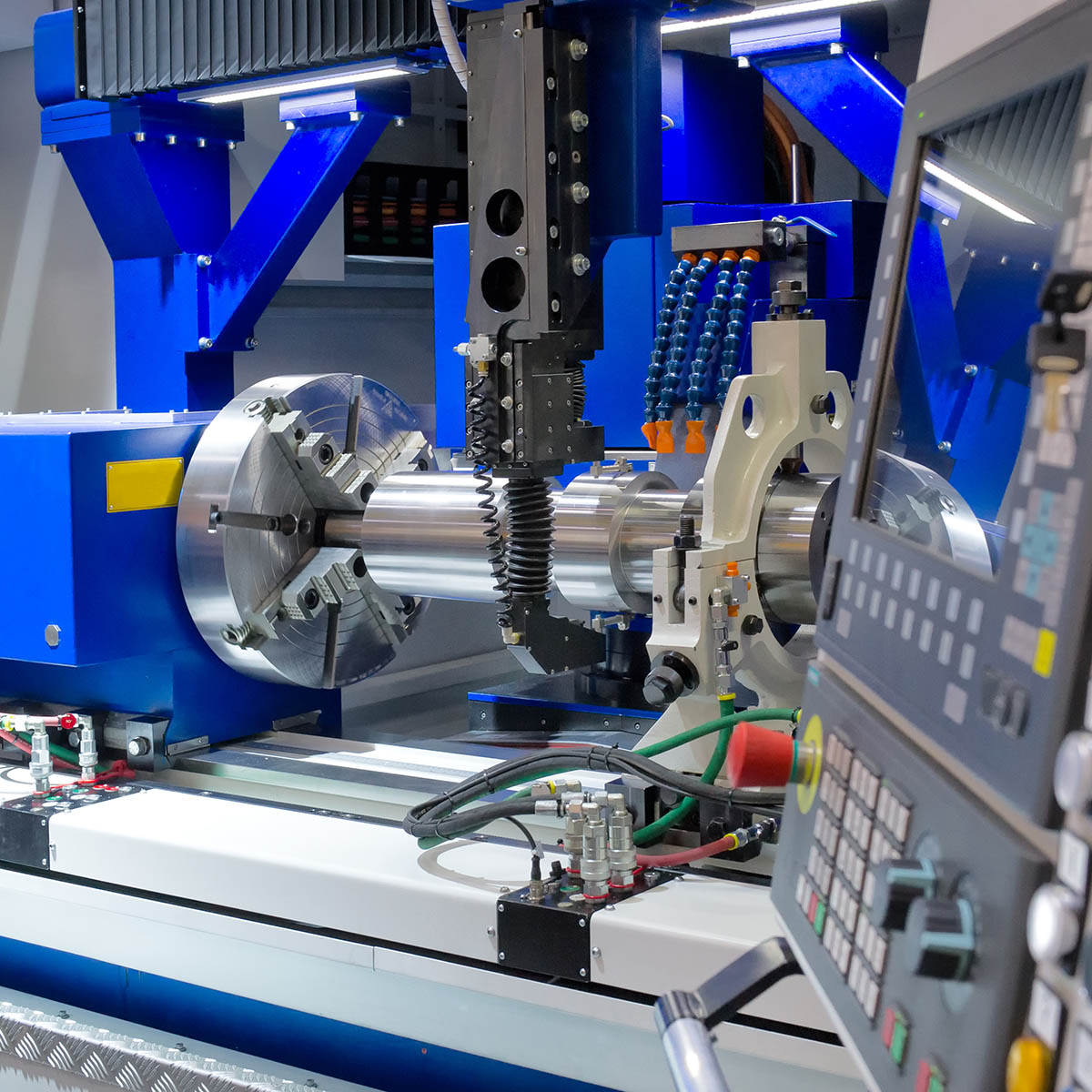

KingStar’s Expertise in Tools & Equipment Manufacturing

10+ Years of Tools & Equipment Manufacturing Experience

Certified Material Selection & Traceability

Fast Turnaround for Custom Orders

Injection Molding

Producing ergonomic handles and tough tool casings that combine user comfort with long-term performance

CNC Machining

Crafting complex metal parts for machinery and instruments with exceptional dimensional accuracy

3D Printing

Enabling rapid prototyping of advanced tool concepts and intricate equipment components to shorten development cycles

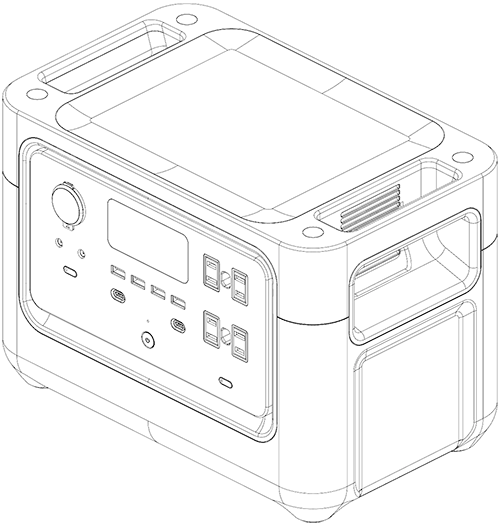

Die Casting

Manufacturing strong yet lightweight aluminum housings optimized for portable and high-efficiency equipment

Our Advantages in Industrial Parts Production

1

Diversified Supply Chain Support

Establish a reliable backup manufacturing source to safeguard against line-down scenarios and unexpected supply chain disruptions.

4

MRO Parts on Demand

Minimize downtime by ordering tailored replacement components for maintenance, repair, and operations—all delivered fast.

2

Agile, On-Demand Production

Boost responsiveness by sourcing rapid-turn industrial components exactly when needed—no overstock, no delays.

5

Engineered Durable Materials

Access 40+ metal alloys and a vast selection of industrial plastics and elastomers, including silicone rubber and TPU, for rugged parts like seals, gaskets, and housings.

3

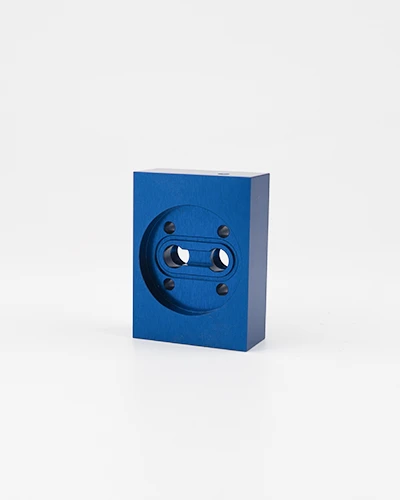

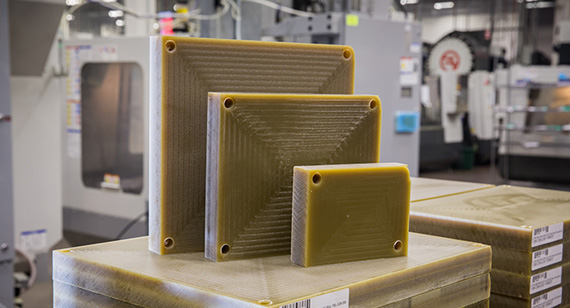

Precision Jigs & Fixtures

Enhance assembly efficiency and reduce production costs with high-strength, custom-built jigs and fixtures.

6

Low-Volume Manufacturing for Pilots & Pre-Production

Validate designs and processes with low-volume runs before scaling, ensuring quality and functionality without committing to full production.

What We Can Make for You

Tools & Equipment Parts Manufacturing Capabilities

Equipment & Tools for Daily Use

Equipment & Tools for Industry

Materials That Perform in Industrial Manufacturing

Aluminum

Despite weight being a lesser concern in many industrial applications, aluminum is frequently chosen for its outstanding machinability and low production costs. It offers a practical balance of strength, corrosion resistance, and efficiency—ideal for large-scale equipment components.

Steel & Stainless Steel

With high strength, excellent machinability, and cost-efficiency, steel remains a foundational material in industrial production. Stainless steel, prized for its corrosion resistance, is commonly used in harsh environments such as oil and gas fields. For extreme-performance needs, 3D-printed superalloys like Inconel deliver superior heat and stress resistance.

Commodity Plastics

In applications such as electronics-integrated manufacturing systems, versatile thermoplastics offer an affordable and scalable solution. These materials are ideal for housings, panels, and components where flexibility, insulation, and cost-effectiveness matter most.

Thermoplastics & Thermosets

Materials like PEEK and PEI (Ultem) deliver high heat tolerance and mechanical strength, making them reliable alternatives to metal in specific use cases. Elastomers such as liquid silicone rubber are widely applied in environments requiring fuel and chemical resistance.

Surface Treatments for Equipment & Tools

At KingStar, we offer a comprehensive selection of surface finishing solutions designed to meet the functional and aesthetic needs of industrial and tool parts. Depending on the material—whether metal or plastic—and the client’s requirements, we select the most appropriate treatment method. In the absence of specific instructions, a high-gloss finish is generally used as the default.

Here are the common surface treatments we provide for industrial and tool components:

For Metal

For Plastic

Common Applications

We offer a broad range of services and manufacturing capabilities tailored for industrial applications. Common use cases include:

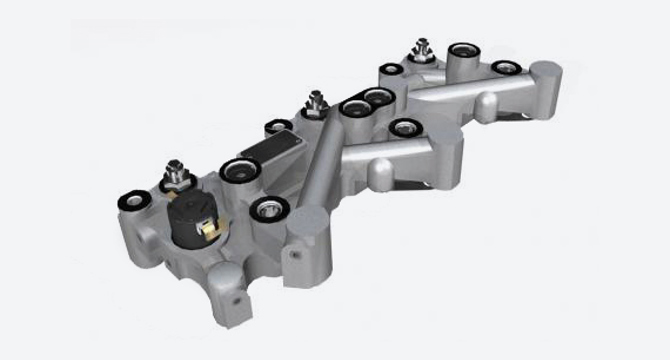

Accelerating Braking Innovation for Jacobs Vehicle Systems

Engine braking is essential to the safe and efficient operation of modern trucks, working alongside traditional braking systems to control speed when the accelerator isn’t engaged. But with space constraints varying across truck models, a universal brake design isn’t feasible. To address this challenge, Connecticut-based Jacobs Vehicle Systems partnered with us to rapidly develop and refine multiple prototype designs—each tailored to specific form factors. This flexible approach enabled seamless progression from prototyping to full-scale production.

Frequently Asked Questions

We support a range of industries, including construction, electronics, oil & gas, automotive, heavy machinery, and general industrial manufacturing.

Yes, KingStar Mold can assist in both product design and Design for Manufacturability (DFM). For example, we helped a client in the automotive industry design a custom plastic air filter housing. The original design had intricate undercuts and thin walls, making it difficult to mold effectively and increasing the likelihood of defects.

Our team analyzed the part’s design and suggested several changes to improve manufacturability. We recommended modifying the undercut shapes to incorporate draft angles, reducing wall thickness where possible, and adjusting gate placement for better material flow during injection molding. Additionally, we selected a more appropriate material that offered better moldability without compromising strength.

By implementing these DFM recommendations, we helped the client reduce production costs, minimize scrap rates, and accelerate time-to-market while ensuring the part met all performance requirements for the final product.

KingStar Mold ensures high precision and durability through a combination of advanced equipment and rigorous quality control. We operate high-speed CNC machining centers, precision EDM machines, and multi-axis milling systems that allow us to meet tight tolerances—often within ±0.002″. For plastic parts, we use high-tonnage injection molding machines equipped with real-time process monitoring.

Our quality assurance process includes in-house CMM (Coordinate Measuring Machine) inspection, first-article verification, material certification checks, and 100% dimensional reports for critical parts. Every component undergoes strict quality evaluation to ensure long-term performance in demanding industrial environments.

KingStar Mold produces a wide range of components, including machine parts, tool housings, jigs, fixtures, and precision accessories for both industrial and household applications.