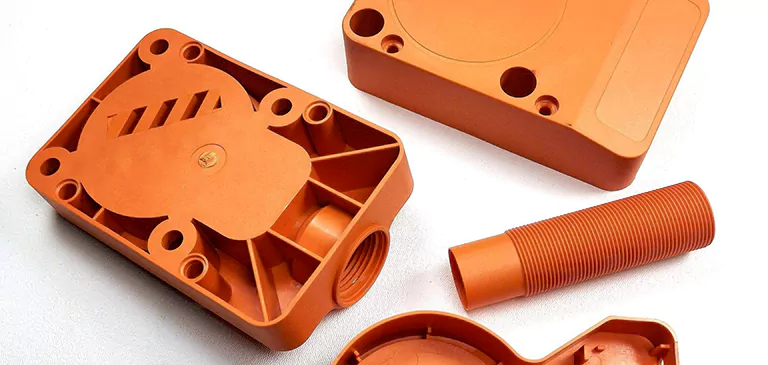

In the modern injection molding industry, thin-walled products have gained widespread application in sectors such as electronics, medical devices, and packaging due to their advantages of lightweight design, material efficiency, and high performance. The production of thin-walled products is a concentrated manifestation of technical precision and process innovation—requiring both high-volume manufacturing efficiency and the assurance of uniform wall thickness (typically ≤1mm), smooth surfaces, and stable performance. The key lies in the comprehensive coordination of equipment, materials, processes, and quality control. This post will discuss how to effectively manufacture thin-wall products in the injection molding process and the key requirements and technical details for practical application.

1. Core Prerequisite: Precision Equipment and Mold Design

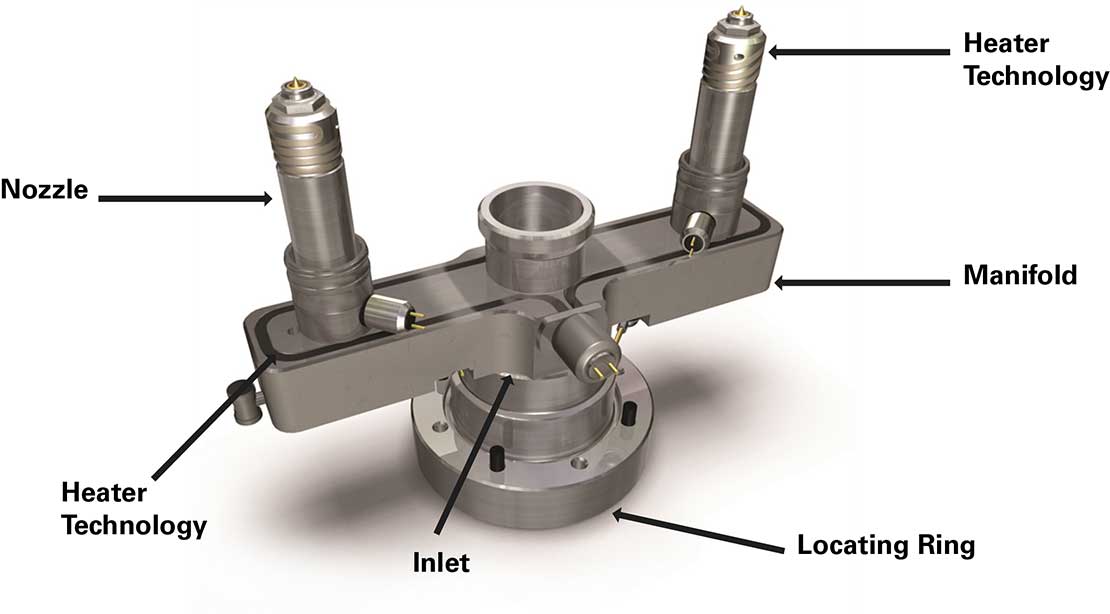

Thin-wall injection molding imposes far higher precision requirements on equipment and molds than conventional injection molding processes. The injection molding machine must possess high-precision control over injection pressure and speed to ensure molten plastic fills the mold cavity in an extremely short time, avoiding short shots caused by long flow paths and thin walls. Mold design is even more critical: KingStar Workshop optimizes the runner system and employs hot runner technology to achieve rapid distribution and uniform filling of molten plastic. Coupled with high-precision cavity machining, it strictly controls product wall thickness consistency, reducing defects such as warping and shrinkage from the source.

2. Key Link: Scientific Selection of Compatible Materials

Material properties directly determine the forming effect and service quality of thin-walled products, necessitating the prioritization of categories with excellent fluidity, strong heat resistance, and stable forming characteristics

• Polypropylene (PP): High cost performance, good fluidity, suitable for mass production of thin-walled packaging;

• Polystyrene (PS): Excellent transparency and fast molding, commonly used for electronic accessory casings;

• Polycarbonate (PC): High impact resistance and thermal stability, suitable for thin-walled products in medical and high-end electronic fields.

Additionally, the formulation ratio and particle size of the material must be precisely controlled to prevent issues such as melt fracture and voids during high-speed filling, ensuring both production efficiency and product quality.

3. Process Optimization: Precise Control of Temperature Control and Parameters

The temperature control system is the lifeline of thin-walled injection molding. By accurately controlling the mold temperature and barrel temperature, premature solidification or excessive flow of the melt can be avoided, effectively reducing the risk of product deformation. KingStar introduces advanced heat flow analysis tools and efficient cooling technology to dynamically optimize injection pressure, filling speed, holding time and other parameters based on material characteristics and product structure, achieving “fast filling and stable molding”, which not only improves production efficiency but also ensures molding accuracy.

4. Quality Assurance: Real Time Monitoring of the Entire Process

The quality control of thin-walled products needs to run through the entire production process. The KingStar injection molding production line is equipped with a real-time monitoring and data acquisition system, which dynamically tracks key parameters such as temperature, pressure, and filling speed for each injection molding cycle. Through data analysis and real-time feedback, production personnel can quickly adjust process parameters to ensure that each product meets design standards and customer expectations, achieving the goal of “zero defect” mass production.

Thin walled product injection molding is a technology intensive process, and its core lies in “precise matching” – precise adaptation of equipment and molds, scientific matching of materials and processes, and full process coordination of production and quality control. With the continuous innovation of injection molding technology, thinner, lighter, and more complex product molding will be achieved in the future, providing more possibilities for the lightweight upgrade of various industries. KingStar will also continue to deepen its expertise in precision injection molding technology, empowering high-quality production of thin-walled products with professional capabilities.

At KingStar, a leading injection molding company in China, we have rich experience in one-stop custom manufacturing. If you want to learn more about the thin-wall product injection molding process or want to source a reliable custom manufacturing company for your thin-wall product, please feel free to contact us by email (sales@kingstarmold.com) or fill out a form on our contact page.