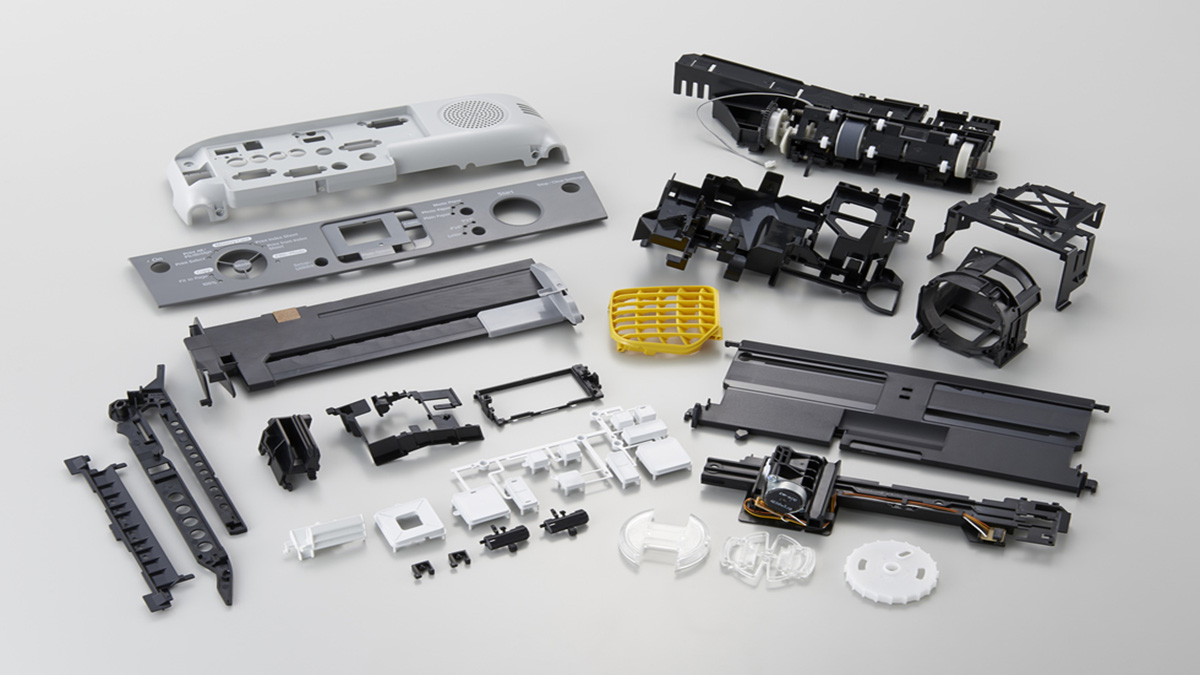

In current industrial production, thin-wall injection molding materials are widely used in various fields such as packaging and electronics due to their unique advantages. From daily food packaging to precision mobile phone accessories, their presence can be seen. Understanding the prominent characteristics and design advantages of thin-wall materials is of great significance for optimizing product production and improving product quality. KingStar, as a leading injection molding company in China, we have rich experience in thin wall injection molding. The following will provide a detailed introduction for you.

1. Three Prominent Characteristics of Thin-wall Materials

1.1 Selection of High Fluidity Materials for Thin-Walled Injection Molding

In terms of material selection, due to the fact that the thickness of packaging thin-walled products is usually below 0.6mm and the flow length ratio is generally greater than 200, this results in a short injection molding cycle for thin-walled products and a very fast cooling rate during the molding process. In order to achieve rapid injection molding and filling, the material must have extremely high fluidity. At present, thin-walled injection molding mainly uses polyolefin materials, such as PP (polypropylene) and PE (polyethylene), which are commonly used types. In addition, PET (polyethylene terephthalate), PS (polystyrene), PA (polyamide), ABS (acrylonitrile butadiene styrene), PC (polycarbonate) are also suitable.

1.2 Gate Layout in Thin-Walleded Injection Molded Products

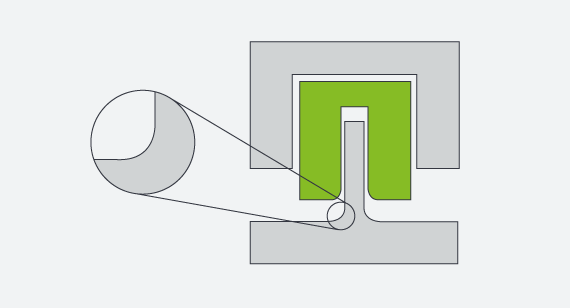

When designing thin-walled injection molded products, the layout of the gate is a key focus, and it is necessary to ensure a balanced gating to ensure uniform filling of the entire product. At the same time, venting design cannot be ignored. For products with large width and thin walls, venting pins can be used, and the arrangement of these venting pins should be as perpendicular as possible to the final weld line, which can maximize venting efficiency. Taking mobile phone battery covers as an example, as mobile phones become thinner, mobile phone battery covers also pursue thinner designs. Therefore, venting pins are usually designed on the back of the battery cover, which can effectively discharge gas from the mold when trapped gas occurs during filling.

1.3 Use of High-Speed Machines for Thin-Walled Injection Molding

Thin-walled injection molding requires the use of high-speed machines, and machines with speed-boosting mechanisms can be preferred. Among them, the screw plunger machine is a classic thin-walled injection molding equipment, which can achieve fast injection speed through screw material storage and plunger injection, and well meet the forming needs of thin-walled injection molding. In addition, equipment such as nitrogen boost systems and hydraulic cylinder boost systems can also be used as options for thin-walled injection molding machines. To meet the requirements of rapid filling, thin-walled injection molding machines need to have the following specific conditions:

- The injection pressure should reach above 200Mpa(usually the injection molding machine pressure is below 200Mpa);

- The clampingforce should be large, and the clamping mechanism provides a clamping force of 5-8 tons per square inch of the projected part area (conventional injection molding machines provide 3-5 tons);

- The response speed should be fast, with the highest known injection speed reaching 2200mm/s and a response time of only 11 milliseconds;

- In addition, the clamping mechanism of thin-walledinjection molding machines requires higher precision and stability in motion. In the commonly used In-Mold Labeling (IML) process in the packaging field, it is necessary to quickly and accurately place labels in the mold cavity before injection molding, and at the same time remove the molded product. This requires efficient mechanical arm movements, which in turn puts higher demands on the precision, response speed, and stability of the opening and closing mold actions.

2. Two Major Design Advantages of Thin-Walled Materials

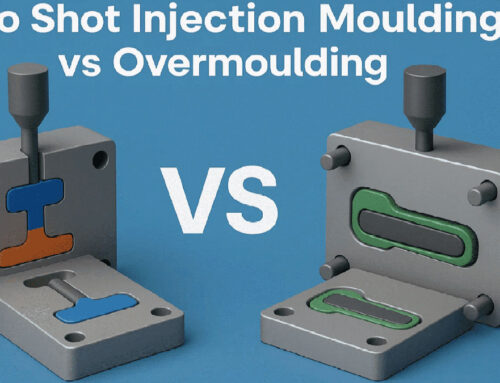

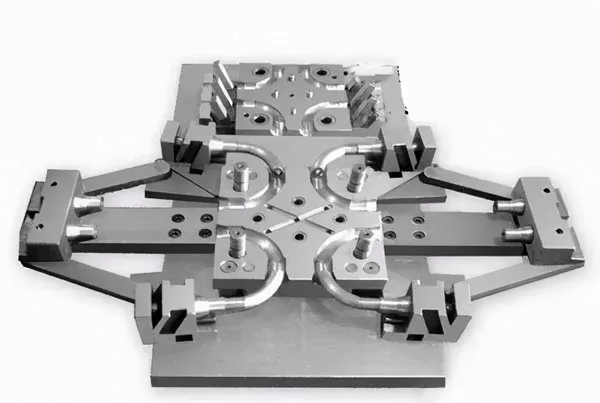

2.1 Mold Material, Venting Design and Gate Design for Thin-Walled Injection Molding

The mold design of thin-walled injection molded products needs to consider multiple factors, including mold material, mold venting, gates, etc. Firstly, it is the material of the mold. Due to the high-pressure rapid filling method commonly used in thin-walled injection molding, the impact of the material on the mold surface is relatively severe. Therefore, it is usually necessary to use steel with a hardness above HRC 55, and heat treatment of the steel to effectively prevent mold wear. The polishing work on the surface of the mold is also crucial, and the areas that can be polished should be polished as much as possible to reduce the flow resistance and friction during plastic filling.

Next is mold venting. In addition to designing venting fins on the product structure, a mold-internal vacuum valve inside the mold can also be used to first evacuate the mold cavity and then fill it, thereby reducing the resistance caused by air compression. For venting grooves at the end of the mold, it should be designed according to different materials to ensure effective venting without causing flash. At the same time, all venting channels should be led to the outside of the mold.

In gate design, it is necessary to consider using large gates or multiple gates for injection, and even use gate sequencing control for injection to ensure effective material filling. It should be noted that thin-walled products have a fast cooling time. To prevent the runner and gate from being closed due to cooling, it is necessary to increase the thickness of the runner and gate appropriately.

2.2 Controlling Pressure and Speed in the Thin-Walled Injection Molding Process

The filling time of thin-walled injection molding is very short, often less than 0.5 seconds. In such a short time, it is impossible to follow the conventional velocity profiles or transfer pressure points, so high-resolution microprocessors must be used to control the injection molding machine. During the entire injection molding process of thin-walled products, it is necessary to simultaneously and independently control pressure and speed. The conventional method used in standard injection molding machines – speed control during the filling stage and switching to pressure control during the packing stage – is no longer applicable.

Thin walled injection molding usually uses high-pressure rapid filling, but attention should be paid to possible issues such as burning, trapped gas, and discoloration during the injection process. This requires rational control of molding temperature, screw shear speed, and other parameters based on the thermal and shear sensitive properties of plastic. At the same time, combined with mold venting, filling resistance can be reduced to ensure product molding quality.

Thin walled injection molding technology, as an important branch of modern injection molding, can meet the needs of products in terms of structure, lightweight, molding cycle, and cost. It has been widely used in the field of injection molding. In practical production, we should start from the design source, comprehensively consider various factors such as machines, molds, and processes, continuously optimize the thin-walled injection molding process, further improve product quality, and promote the greater role of thin-walled materials in more fields.

If you want to gain more systematic information about thin-walled materials for your project, please feel free to contact us by email (sales@kingstarmold.com) or fill out a from on our contact page.