In the growth process of injection molding engineers and mold designers, injection molding is a necessary subject to learn. However, the teaching of internship courses in schools is different from the processing and production of factories and enterprises. From equipment variety, scale, tooling to product quantity, it cannot be compared. Internship teaching fully utilizes limited class hours, equipment, and molds to enable internship engineers to come into contact with and practice more practical and typical mold structures and plastic product production and processing. Especially in modern society, lightweight, durable, and economical electronic product components are widely used, many of which have a wall thickness of less than 1 millimeter. Therefore, the injection molding of these thin-wall plastic parts is an indispensable topic in mold internship teaching. This post will introduce the detailed process of thin-wall injection molding.

1. Common Quality Defects and Causes in the Thin-Wall Plastic Parts

(1) Short Shot (Incomplete Filling)

There are forms such as incomplete filling of plastic parts and edge collapse. The cause is the low temperature of the filling material during injection molding, poor plastic melt flowability, and insufficient supply; The preset injection pressure of the injection molding machine is low, resulting in blockage of the steam tube nozzle or too small injection nozzle aperture; Poor lubrication of the inner surface of the mold, low mold temperature, small gate or runner size, improper gate location, improper or lack of venting, or cold slugs blocking the runner or gate.

(2) Poor Surface and Shadows

Mainly due to abnormalities in local surface color and gloss. The causes are high volatility of the filling material, mixed with foreign objects, insufficient drying, insufficient supply, low injection pressure of the molding machine, clogged or small diameter of the nozzle, slow injection speed, small mold gate or runner size, improper or lack of venting.

(3) Silver Streaks and Bubbles

The main reasons include low machine injection pressure, fast injection speed, small injection capacity, short holding time of the forming machine, high temperature and volatility of the filling material, insufficient drying, improper mold venting, uneven wall thickness of the forming shell, and small gate or runner size.

(4) Sink Marks

Caused by plastic deformation after ejection. The causes are high temperature of the filling material, insufficient supply, excessive shrinkage rate, low machine injection pressure, short holding time, slow injection speed of the forming machine, high surface temperature of the mold, short cooling time, uneven wall thickness of the forming shell, small gate or runner size, improper ejection, etc.

(5) Flow Marks

There are also many causes, such as low temperature and poor flowability of the filling material, poor lubrication, low machine injection pressure and slow injection speed of the forming machine, small nozzle orifice, poor lubrication and temperature of the inner surface of the mold, and small gate or runner size.

(6) Weld Lines

The main causes are low temperature of the filling material, rapid hardening, insufficient drying, poor lubrication, low machine injection pressure and slow injection speed of the molding machine; Due to factors such as low surface temperature, poor lubrication, low temperature, small gate or runner size, improper gate location, improper or lack of venting in the mold.

(7) Warpage and Deformation

There are many reasons for this, such as insufficient rigidity of the filling material, poor flowability, and high shrinkage rate; The injection molding machine is set to have high injection pressure and long holding time; High mold temperature, poor ejection structure, large gate size, etc.

2. Requirements for Thin-Wall Injection Moulding

In the processing of the thin-walled plastic parts, higher injection pressure and speed, shorter cooling time of plastic parts, as well as the arrangement of gates and the setting of part ejection mechanisms are required in terms of technology, which puts greater demands on injection molding machines and molds. At present, the performance of new injection molding machines has been greatly improved. Hydraulic injection molding machines used for thin-walled plastic injection molding have high speed and high pressure performance. Now all electric injection molding machines have injection molding speeds of up to 600mm/s, and the minimum clamping force is controlled within the range of 5-7 tons per square inch (projection area). This helps to control the filling and holding of the mold under high pressure and speed, and inject the molten thermoplastic materials into mold cavity at a high speed to form rapid filling and high pressure, thereby preventing solidification of the gate and improving the yield of plastic parts.

3. Selection Experiment of Process Parameters During Injection Molding Process

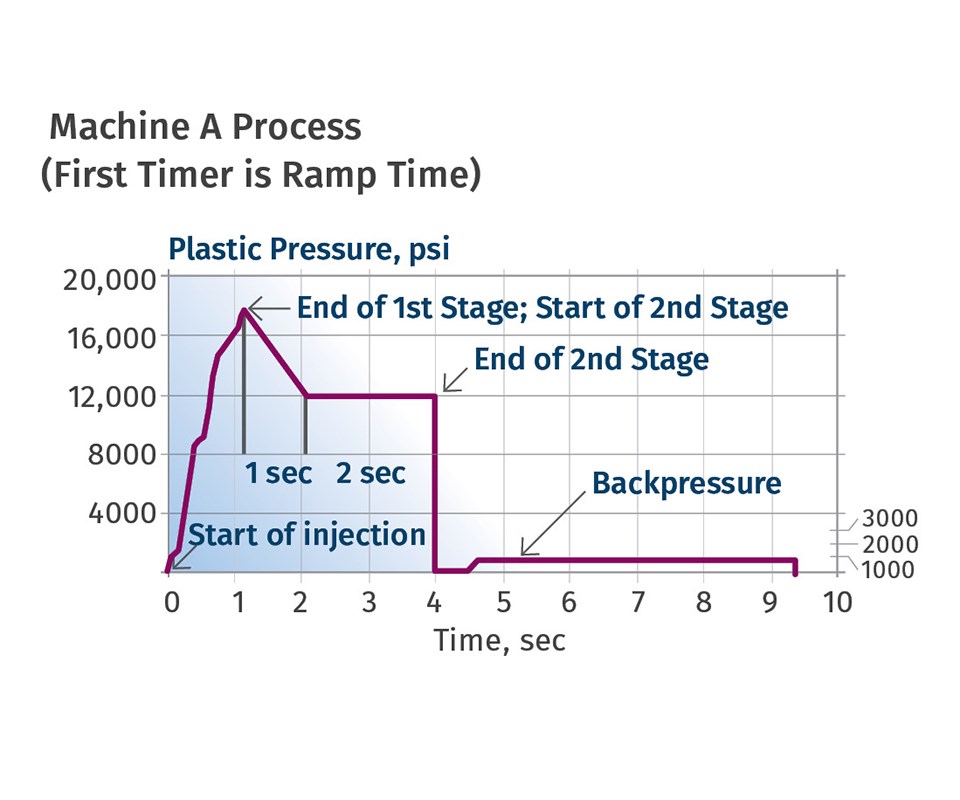

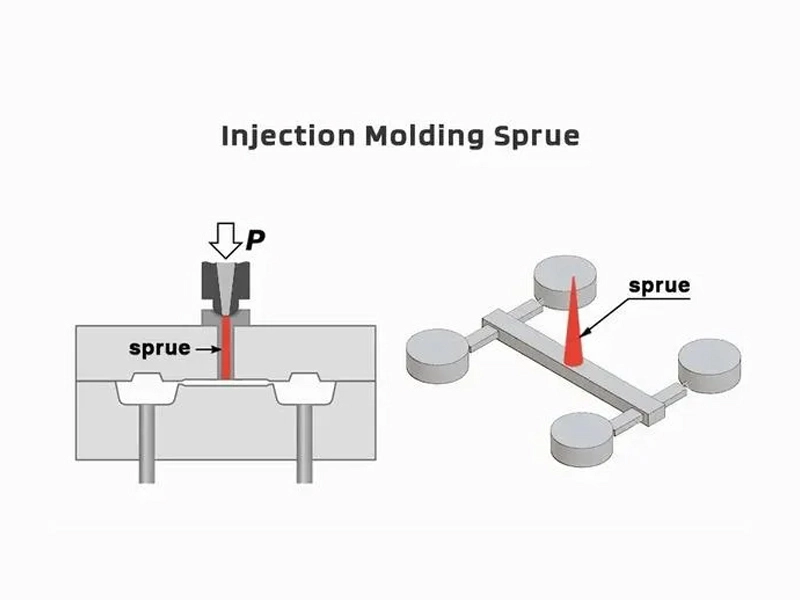

Under normal circumstances, when the injection molding machine enters the mold cavity along the gate, the molten thermoplastic material will come into contact with the cooler core or inner wall of the cavity, and form a solidified thin skin. This pre solidified skin accounts for approximately 20% of the entire wall thickness. Just like a plastic part with a wall thickness of 1mm, its solidified skin is 0.2mm thick, leaving only 0.6mm thick in the flow channel. To overcome this problem, injection molding machines are usually required to apply injection pressures of up to 300MPa and injection speeds of 1000mm/s. However, the injection pressure of ordinary standard universal injection molding machines is around 100mm/s. To achieve “thin-wall injection molding” on ordinary injection molding machines, it is necessary to optimize the mold structure and modify the injection molding machine. The author conducted production experiments on existing equipment, materials, and process selection, and mastered some practical parameters.

We at KingStar use the Haitian injection molding machine HTF series model and the commonly used polycarbonate (PC) material for comparative testing. The production tests are as follows:

3.1 Improvement of Mold Structure

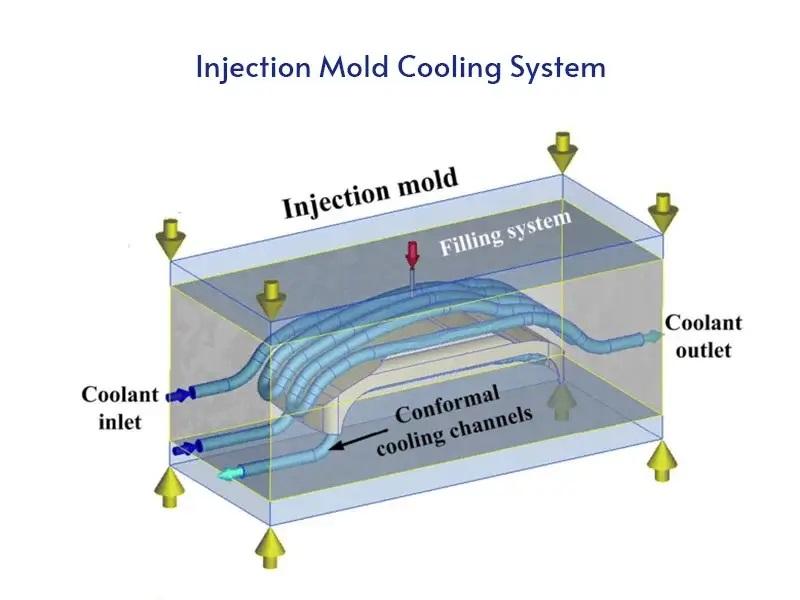

Designing larger or more gates on the mold structure helps to reduce the pressure in the hot runner system for thin-walled products. The diameter of the melt runner is 25% to 40% larger than that of a typical standard mold to reduce pressure loss. And try to use a single gate as much as possible to reduce the number of weld lines. Adding venting to the mold can avoid burn marks and enhance the strength of the weld lines. Increasing the number of ejector pins avoids piercing and sticking of molds. Strengthen the cooling of the mold to ensure balanced cooling, minimize shrinkage and warpage as much as possible, and ensure dimensional stability.

3.2 Parameter Selection and Result Analysis

(1) The increase in melt temperature will result in higher thermal energy of the material and a decrease in melt viscosity, making it easier for the molten material to flow, forming a longer flow length and filling the mold cavity more smoothly. But if the melt temperature is too high, it will cause material degradation. So, this parameter can only be used to ensure the filling of the cavity within the upper limit allowed by the resin;

(2) The increase in mold temperature will reduce the condensation layer of resin in the mold cavity, making it easier for the melted material to flow in the mold cavity, thereby obtaining greater part weight and better surface quality;

(3) The machine injection volume should be maximized as much as possible, as this can also help reduce the residence time of melted materials in the container;

(4) Shorter cooling time can shorten the residence time of molten material in the container and reduce the possibility of degradation;

(5) The increase in injection speed may decrease the viscosity of PC material and cause an increase in part weight, but the increase in part weight is less than when the melt temperature increases. However, as it can also make the material less prone to degradation, improving injection speed still has its merits;

(6) The optimization of mold structure has improved the quality and efficiency of thin-wall injection molding.

Based on the comprehensive experiments, melt temperature, mold temperature, cooling time, and injection speed are all key parameters that affect the weight of the parts. When processing thin-walled parts on traditional injection molding machines, changing some process parameters has achieved the effect of increasing the weight of the parts, reflecting the increase in the resin’s ability to fill the LMM cavity in the melted state, which improves the ability of thin-wall molding. Injection molding of thin-walled products can be completely achieved under traditional injection molding machine conditions. When operating, in addition to optimizing the mold structure, the injection speed can also be adjusted to the maximum allowable limit. Based on this, the recommended maximum melt temperature limit for the material and the maximum mold temperature standard can be used to increase these two temperature parameters as much as possible. This can save equipment modification costs and facilitate the smooth progress of thin-wall injection molding projects.

If you want to learn more about thin-wall injection molding or source a custom manufacturer, please contact us, the leading injection molding company in China, by email (sales@kingstarmold.com) or fill out a from on our contact page. We will provide detailed suggestions on your projects.