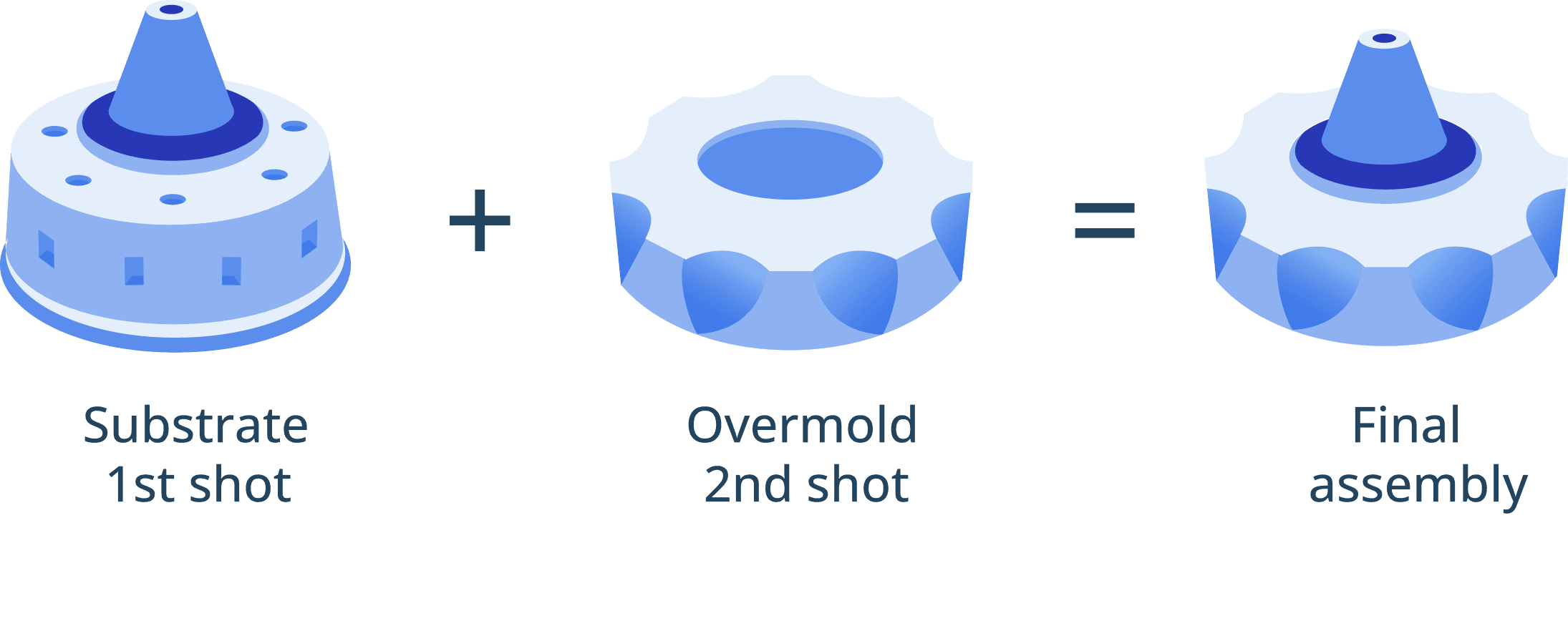

TPE overmolding is a key technology that involves encapsulating a soft thermoplastic elastomer (TPE) onto a hard substrate (such as plastic or metal) through injection molding. It is far from a simple combination of materials, but a complex system involving materials science, mold engineering, process technology, and failure analysis. The core of successful overmolding design lies in achieving stable and durable physical and chemical bonding between the substrate and TPE, and ensuring that the final product meets functional and aesthetic requirements throughout its lifecycle.

As the experienced plastic injection molding company in China, KingStar compiled this post which will systematically outline the core points for you.

1. Core Structure Composition and Substrate Treatment

1.1 Substrate Types and General Requirements

The substrate is usually made of plastic or metal materials, commonly including polymers such as ABS, PC, and nylon. Plastic substrates require chemical surface treatment to enhance adhesion, while some models use sandblasting or primer processes to treat the surface. In most cases, the substrate carries mechanical support and structural integration functions. For example, in the shock absorption and buffering of vacuum cleaner handle steel pipes wrapped in rubber, the combination of rubber and hard plastic needs to consider the transmission of deformation stress. The position of the logo printed with ink and the reserved adhesive port of the mold need to reserve offset compensation space in the structural design.

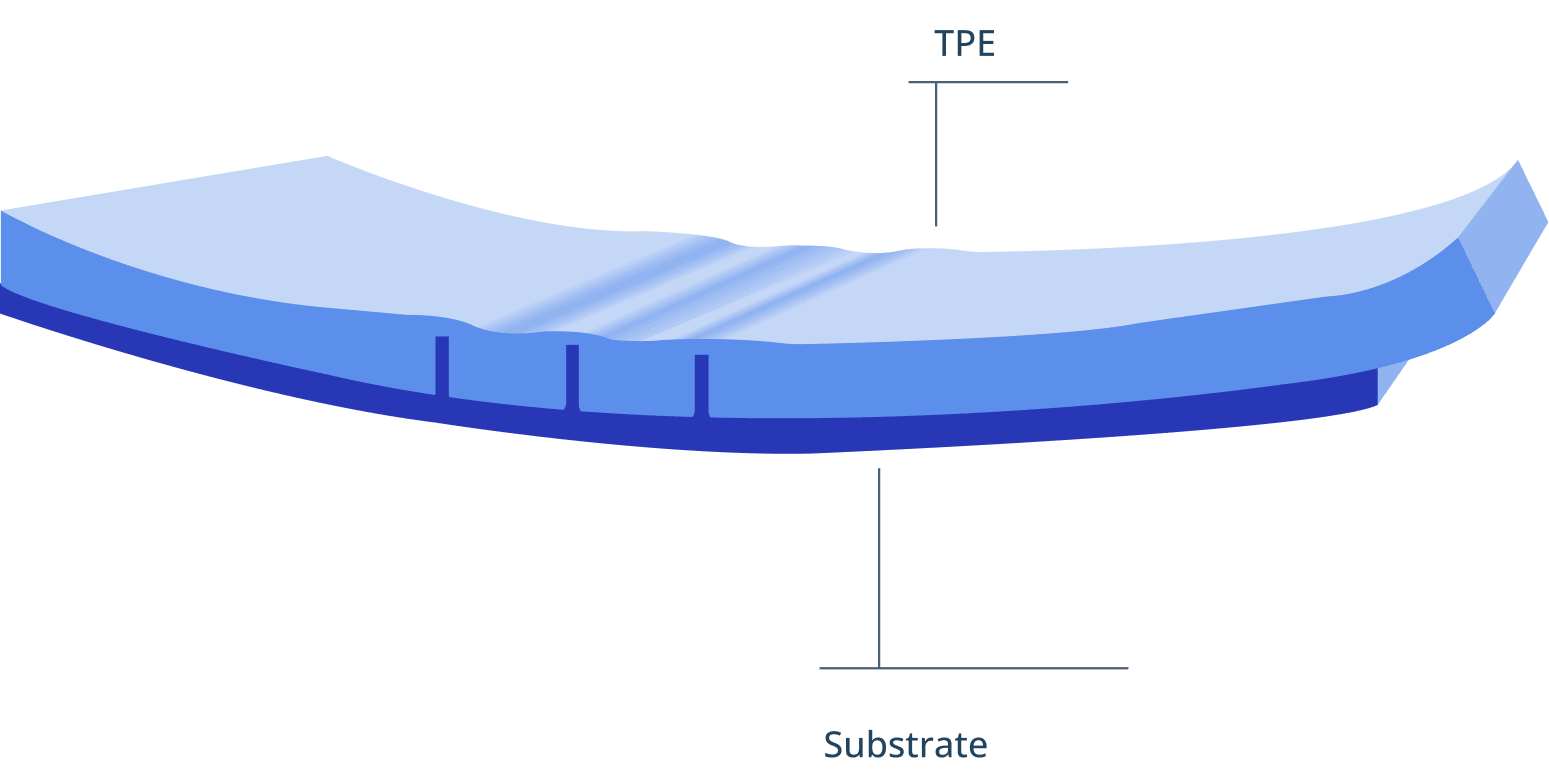

1.2 Structural Implementation and Process Control

Special structures require consideration of melt flow characteristics. TPE materials have different flowability, and the injection point and overflow well should be controlled according to the shape of the parts. The thickness design should be 0.8-2.0mm for the core functional area, as excessive thickness can affect cooling efficiency and cause sink marks. The development of fixtures in overmolding directly affects the morphology of the bonding layer, and automated instruments compatible with multiple material demolding are usually produced. The mold cooling channel adopts multi-circuit circulation to ensure uniform cooling in the TPE area, and the ejector pin layout avoids the joint surface to prevent fracture under stress. The common problem of burrs on the parting line needs to be simulated during the development stage to optimize the mold polishing process based on the material flow shape. The handle area of industrial screwdrivers usually has grip ribs to increase the friction coefficient, and using a fan gate instead of an edge gate can improve the problem of obvious bonding lines.

Different bonding treatment solutions are worth noting. When using thermal fusion processes, it is necessary to match the difference in shrinkage coefficients between the substrate and the overmold layer. Controlling the temperature difference between ABS and TPE within 30-50 ℃ can reduce the risk of interface cracks. The corona treatment has a maximum time limit of 150 seconds for the nylon substrate. If the interval for changing the molding production line exceeds the time limit, a retest of the treatment strength is required. The adhesive layer commonly used in medical applications is halogen-free UV curing adhesive to avoid chemical corrosion of medical device shells. During operation, it is necessary to isolate the UV lamp from light leakage to prevent the adhesive from curing prematurely and forming virtual adhesion. Some food grade products require the steel shell to be anodized before being fused with TPE, and the residual sulfide concentration in the treatment solution should not exceed 0.8ppm to prevent leakage and contamination. Upon disassembling the failed samples of two-color injection molding, it was found that 70% of the interface detachment issues were caused by polarity mismatch.

1.3 Chemical Bonding and Micro Mechanical Interlocking

The adhesive nature at the chemical level involves van der Waals forces and the interweaving of molecular chains. The introduction of glycidyl methacrylate graft onto PP substrate increases the carboxyl group reaction rate from 33% to 86%. Some modified formulas may introduce peroxide induced free radical cross-linking, which requires the temperature difference between each section of the twin-screw mixer to not exceed 18 ℃. The secondary injection molding process often requires preheating the metal core to 65% -75% of the TPE melting temperature in advance to promote the infiltration reaction. For tool grips made of all steel material, it is now widely recommended to use laser engraved lattice micro holes to allow molten TPE to penetrate and achieve mechanical interlocking structure. A test of a certain car gear lever showed that a microstructure with a lattice aperture of 0.15mm and a depth of 0.25mm increased the thrust demolding strength by three times and reduced the fracture displacement by 42%. During extreme weather verification, it is necessary to simulate a -40 ℃ freezing and high humidity salt spray environment to check for signs of thermal stress cracking.

2. Typical Cases and Structural Applications

In a typical case, the grip of a medical catheter is made of a three-layer structural substrate PP+copolymer primer+silicon modified SEBS composite material, achieving a balance parameter of hardness 75A and friction coefficient 0.3. The dental adhesive components of baby toys are made of water foam TPE and food grade PVC dual material injection, and the corners of the mold are rounded with R ≥ 0.3mm to avoid material stagnation at small angles.

In the development case of sports equipment handles, the prefabricated concave convex tooth shape of the steel lining resulted in a 55% increase in overall torsional strength compared to conventional designs. This type of structure requires load verification in computer-aided simulation to prevent local shear deformation from exceeding the design limit.

3. Testing System and Common Solutions

The testing system needs to establish a quantitative evaluation of interface bonding force, using T-shaped peeling test, and the bonding strength should meet the production standard of ≥ 12N/cm. During immersion verification, different acid-base solutions were continuously maintained for 48 hours, and the allowed swelling rate was less than 5% of the total thickness. The lifespan simulation requires a change rate of elastic modulus of less than 14.3% after 2 million cycles of pressure pulse impact. During the aging testing phase, it is necessary to perform alternating cold and hot experiments to discover micro cracks caused by differences in material shrinkage rates.

Common Solutions:

(1)Adding a cooling zone retainer on the low melting point TPE production line, can reduce the temperature curve error from ± 14 ℃ to ± 3.7 ℃.

(2)The vacuum degassing program on the production line is strictly regulated to have a minimum duration of no less than 7 seconds.

(3)At least five sets of cross-sectional tissues of key parts shall be sampled from each production batch for analysis to confirm sufficient wetting and spreading of the substrate.

(4) The protective film applied to the contact area during the packaging process must meet the VHB standard of 3M adhesive 903 test specification to avoid scratches caused by turnover and handling.

(5)The final quality inspection will implement infrared thermal wave imaging scanning technology to identify and locate gas hole defects in the bonding surface.

4. Conclusion

These structural development experiences indicate that functional overmolded products need to coordinate material compatibility, process window parameters, and failure prevention measures. The design process should not only consider static structural mechanics, but also pay attention to the differential damage of multi-layer materials caused by dynamic loads. Key processes need to simultaneously import digital monitoring data modeling to prevent major defects. When dealing with multi-material composite products, more attention should be paid to the cross comparison of parameters in the material database, and a process compatibility prediction module including 23 indicators, such as shear flow rate matching degree and curing activation energy difference should be constructed. This systematic development approach can significantly improve the market competitiveness of TPE overmolded components and reduce post-sales maintenance rates.

To gain systematic information of primary structural composition of TPE overmoldings, theoretical support is needed to facilitate the summarization and discovery in practice. KingStar, the best custom manufacturing company, welcomes any corrections or discussions, and please feel free to send us an email(sales@kingstarmold.com) for professional suggestions on the solutions for primary structural composition of TPE overmolding for your project.