Selecting the appropriate mold steel is a crucial strategic decision that will have an impact on various aspects ranging from part quality, production efficiency to mold lifespan and total cost. Although standard steel grades like P20 and 718 are still suitable for general applications, for high-precision, high-volume, or corrosive plastic materials, advanced options are also becoming indispensable.

This post breaks down the key categories of modern injection mold materials including Pre-Hardened Steels (e.g., P20, 718); Age-Hardening Steels (e.g., NAK80, PMS), Stainless & High-Polish Steels (e.g., S136, 1.2316) and some Composite Frontier Materials.

1. Performance Characteristics of Different Mold Materials

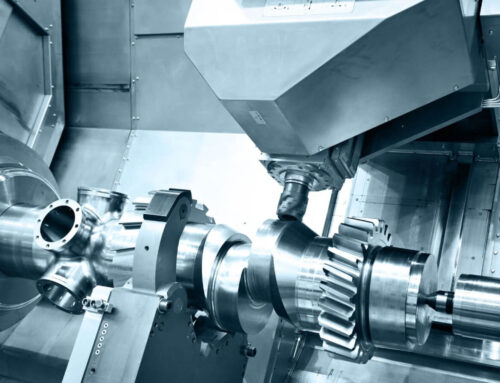

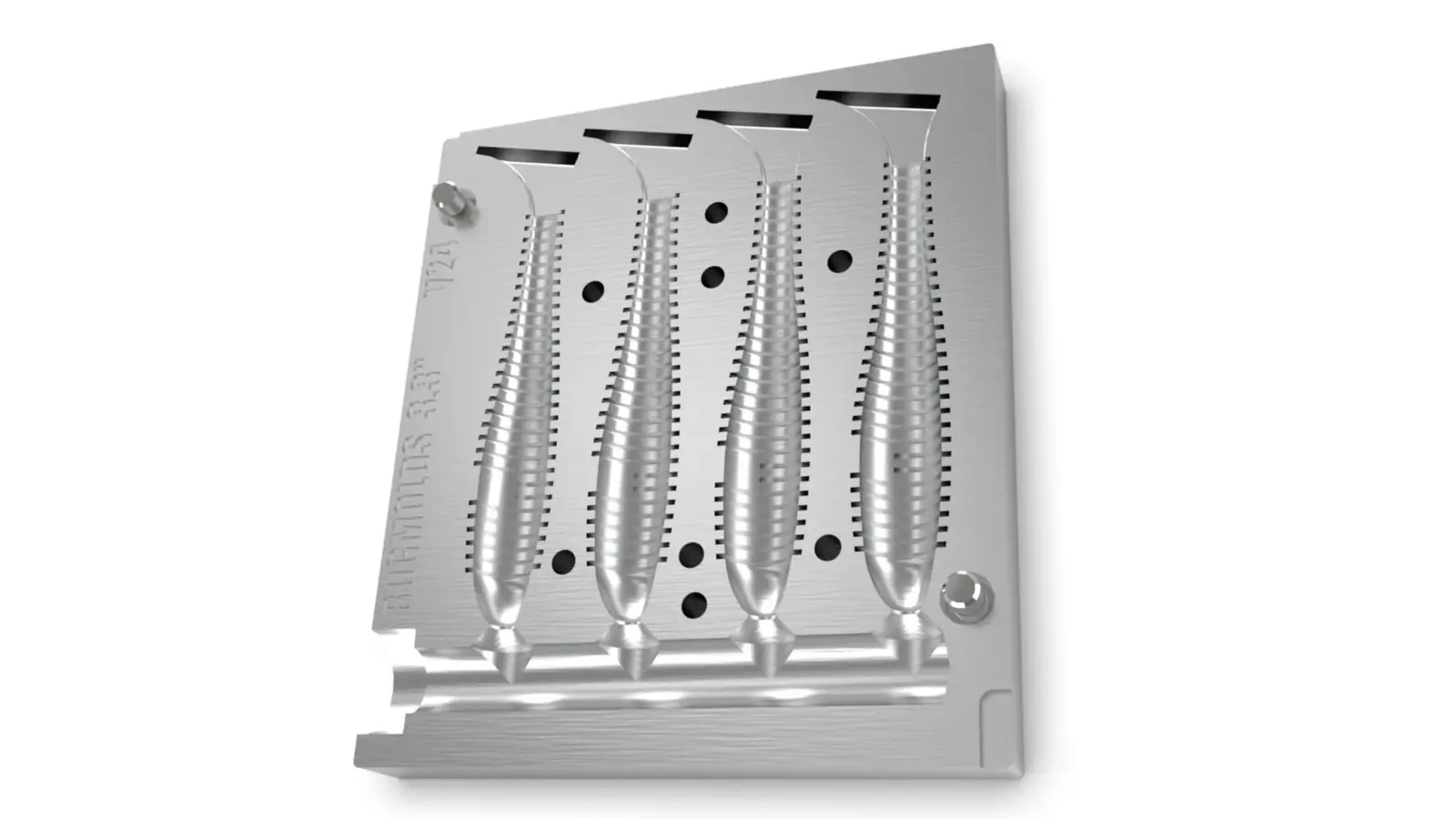

The selection of mold materials is of vital importance to the performance and lifespan of the mold, as different materials possess their own unique physical and mechanical properties. For instance, high-speed steel (HSS) is renowned for its excellent wear resistance and hardness, and is suitable for working environments with extremely high temperatures and pressures, as shown in Figure 1. The outstanding characteristics of high-speed steel enable it to ensure the stability and durability of the mold when it is subjected to high loads and impact forces. Additionally, hard alloy is known for its extremely high hardness and wear resistance, and is thus favored in mold manufacturing where it needs to withstand extremely high pressure and wear. However, the processing difficulty of such hard alloys is relatively high, requiring more precise processing techniques and equipment, which inevitably leads to an increase in manufacturing costs. Nevertheless, for applications with extremely high durability and performance requirements, this material is indispensable.

In production processes with lower requirements for temperature and pressure, traditional carbon tool steel and alloy tool steel can meet basic needs. These materials provide a good balance, meeting both the requirements for production efficiency and cost control, and are typically used to manufacture molds with less stringent performance requirements, such as plastic processing, low-pressure casting, and some light industrial applications. Although these molds are not suitable for the most demanding environments, their performance remains very reliable, maintaining stable output over time. For example, in the automotive industry, molds used for interior components would choose these materials, ensuring the precision of mass production without causing excessive production costs. Moreover, in the production of standard parts in the construction industry and the manufacturing of the shells of electronic products, solutions that balance performance and cost are widely adopted. By optimizing material selection, manufacturers can enhance their market competitiveness while ensuring product quality.

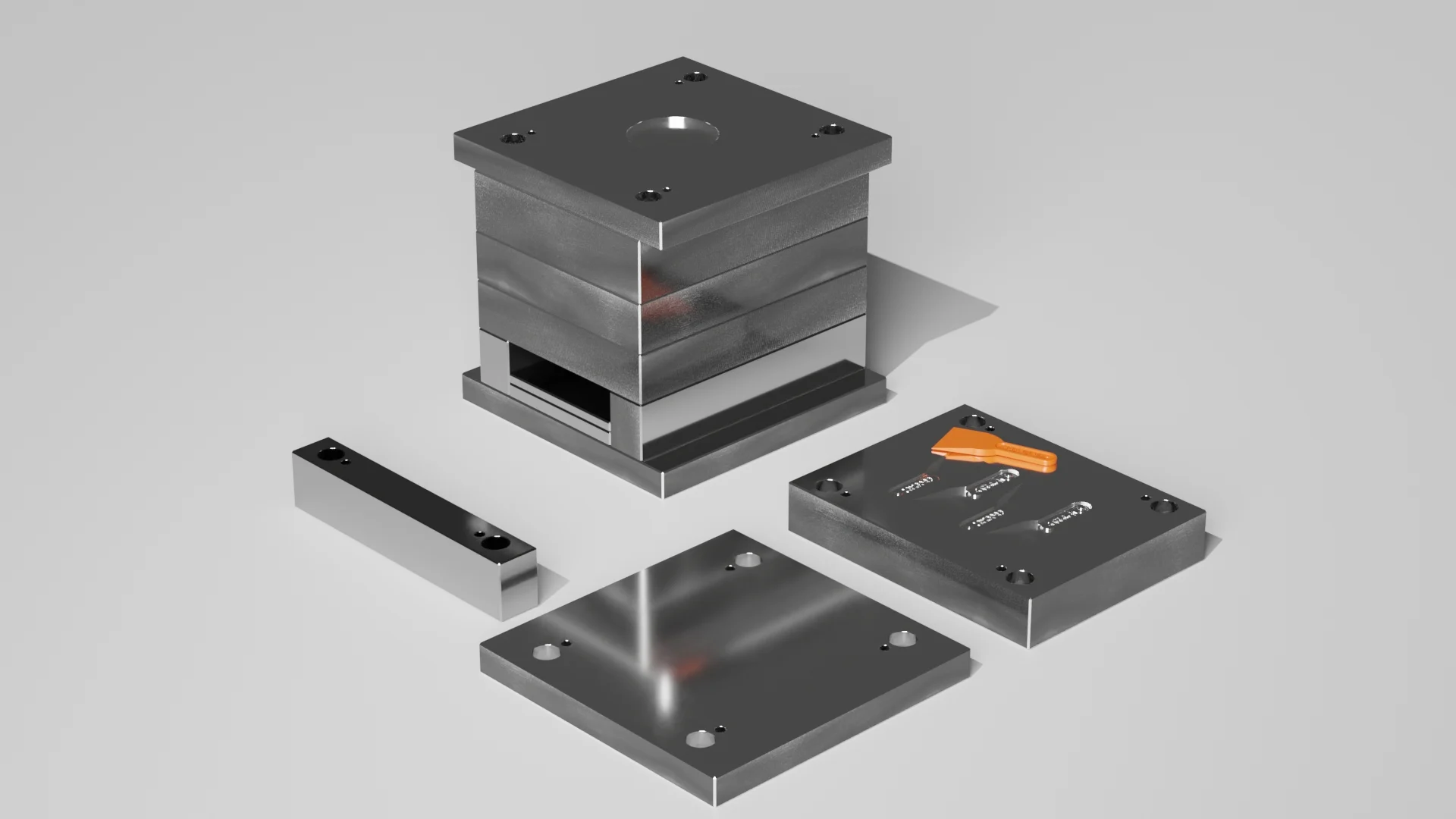

2. Common Materials for Injection Molds

The selection of materials for injection molds directly determines the mold’s lifespan, processing efficiency, and the quality of the final product. In the 1990s, domestically produced molds primarily used heat-treated steels such as 45 steel and 40Cr, as well as tool steels like CrWMn and Cr12MoV. However, as the plastics industry advanced toward higher precision, efficiency, and durability, these materials were gradually replaced by a new generation of mold steels due to their low hardness, poor wear resistance, or significant deformation during heat treatment. Currently, the commonly used base materials for injection molds, both domestically and internationally, can be categorized into pre-hardened steels, age-hardening steels, cold extrusion molding steels, and corrosion-resistant/high-polish steels.

2.1 Pre-hardened Steel

The carbon content of this type of steel ranges from 0.3% to 0.55%, with chromium (Cr), nickel (Ni), manganese (Mn), molybdenum (Mo), vanadium (V) and other elements as the most commonly used alloying components. To improve the machinability of the material, elements such as sulfur (S) and calcium (Ca) can also be added specifically. Typical grades in this category include 3Cr2Mo (internationally known as P20 steel) and its modified versions, 718/718H (corresponding to 3Cr2NiMo steel), and 5NiSCa steel.

P20 steel enjoys the widest application among pre-hardened plastic mold steels globally. It has well-defined heat treatment specifications: the quenching temperature should be controlled between 830-870°C, followed by oil quenching, and then tempering at 550-600°C. After this series of processes, the steel achieves a pre-hardened state of 30-35 HRC, making it highly suitable for manufacturing large and medium-sized molds, such as those used for home appliance casings and automotive interior parts.

718/718H (3Cr2NiMo steel) is an enhanced version with superior performance developed based on P20 steel. By incorporating an additional 1% nickel, the hardenability and core toughness of the material are significantly improved. Among them, 718H steel features a stable delivery hardness of 35-39 HRC. It combines excellent machinability and polishability, thus becoming the preferred material for molds with complex cavities and high surface quality requirements.

5NiSCa (full name: 5CrNiMnMoVSCa) and 8Cr2MnWMoVS steels are pre-hardened steels independently developed in China, primarily to enhance machinability. After quenching at 860-900°C and tempering at 575-650°C, 5NiSCa reaches a hardness of 35-45 HRC, with significantly better machinability than traditional P20 steel. The heat treatment process for 8Cr2MnWMoVS steel involves quenching at 860-880°C and double tempering at 550-620°C, resulting in a final hardness of 44-48 HRC. As an air-cooled, micro-deformation steel, it plays an irreplaceable role in the production of precision mold bases and plates.

Representative Grades: Sweden’s ASSAB 718, Germany’s 1.2311, USA’s P20+Ni.

2.2 Age-Hardening Steel

Age-hardening steels have relatively low hardness (approx. 28-32 HRC) after solution treatment, facilitating machining. Subsequently, hardness increases to 40-45 HRC through low-temperature aging, which precipitates intermetallic compounds, with almost no deformation. Commonly used types are low-nickel age-hardening steels. PMS and 25CrNi3MoAl belong to this category.

PMS Steel’s composition is similar to Japan’s NAK55. It contains 1% Cu for age hardening reinforcement, and 0.1% S is added to improve machinability. Solution heating temperature is 850-900°C, resulting in a hardness of 30-32 HRC. After aging at 490-510°C, hardness can reach 40-42 HRC. It offers excellent mirror polishability, making it suitable for high-gloss molds like those for transparent parts and optical lenses.

On the other hand, 25CrNi3MoAl Steel’s composition is similar to N3M steel. After solution treatment at 880-900°C and aging at 680°C, hardness is 25–30 HRC, allowing machining. Subsequent aging at 520-540°C precipitates coherent NiAl intermetallic compounds with the matrix, increasing hardness to 40-45 HRC. This type of steel offers better corrosion and wear resistance than pre-hardened steels and can be used for complex, precise plastic molds or long-life molds for mass production.

Representative Grades: Japan’s NAK55, NAK80.

2.3 Cold Extrusion Forming Plastic Mold Steel

Molds with complex cavities can be manufactured using these steels through cold extrusion methods. These steels have a carbon content of 0.05%–0.08%, a chromium content of 2%–5%, along with appropriate amounts of Ni, Mo, and V. China’s developed LJ steel is a dedicated cold extrusion forming mold steel. Its chemical composition (wt%) is: ≤0.08 C, <0.30 Mn, <0.20 Si, 3.50 Cr, 0.5 Ni, 0.4 Mo, 0.12 V. After annealing, hardness is 85–105 HB. After cold extrusion forming, followed by carburizing, quenching, and tempering, surface hardness reaches 58–62 HRC with a core hardness of 28 HRC. The mold exhibits good wear resistance, no collapse or surface peeling, and significantly increased service life.

2.4 High Corrosion-Resistant / High-Polish Steel

With the proliferation of corrosive plastics like PVC, fluoroplastics, and flame-retardant ABS, and the demand for mirror-like surface finishes in medical, optical, and food packaging applications, high-chromium martensitic stainless steels have become essential.

- S136 (1.2083): A classic martensitic stainless steel developed by Sweden’s ASSAB, containing 12-14% Cr. Delivery hardness is≤250 HB, reaching 50-54 HRC after heat treatment. It possesses excellent corrosion resistance (withstands HCl gas released from PVC decomposition), mirror polishability (Ra≤05μm), and wear resistance. Widely used for molds in medical devices, food packaging, optical lenses, etc.

- X36CrMo17 (1.2316): A high-chromium, molybdenum pre-hardened corrosion-resistant steel with a delivery hardness of 32-34 HRC. It withstands 500 hours of salt spray testing without rusting and can be polished to Ra≤05 μm. Suitable for molds working long-term in damp, corrosive environments.

- BÖHLER M390/M398 MICROCLEAN: Ultra-high purity steels produced via powder metallurgy, with extremely uniform carbide distribution. They combine high corrosion resistance, high wear resistance, and super mirror polishability, suitable for optical-grade and micro-structure molds.

Representative Grades: Sweden’s S136, Germany’s 1.2316, Austria’s BÖHLER M300 series.

2.5 Emerging Trends – Powder Metallurgy & Customized Alloys

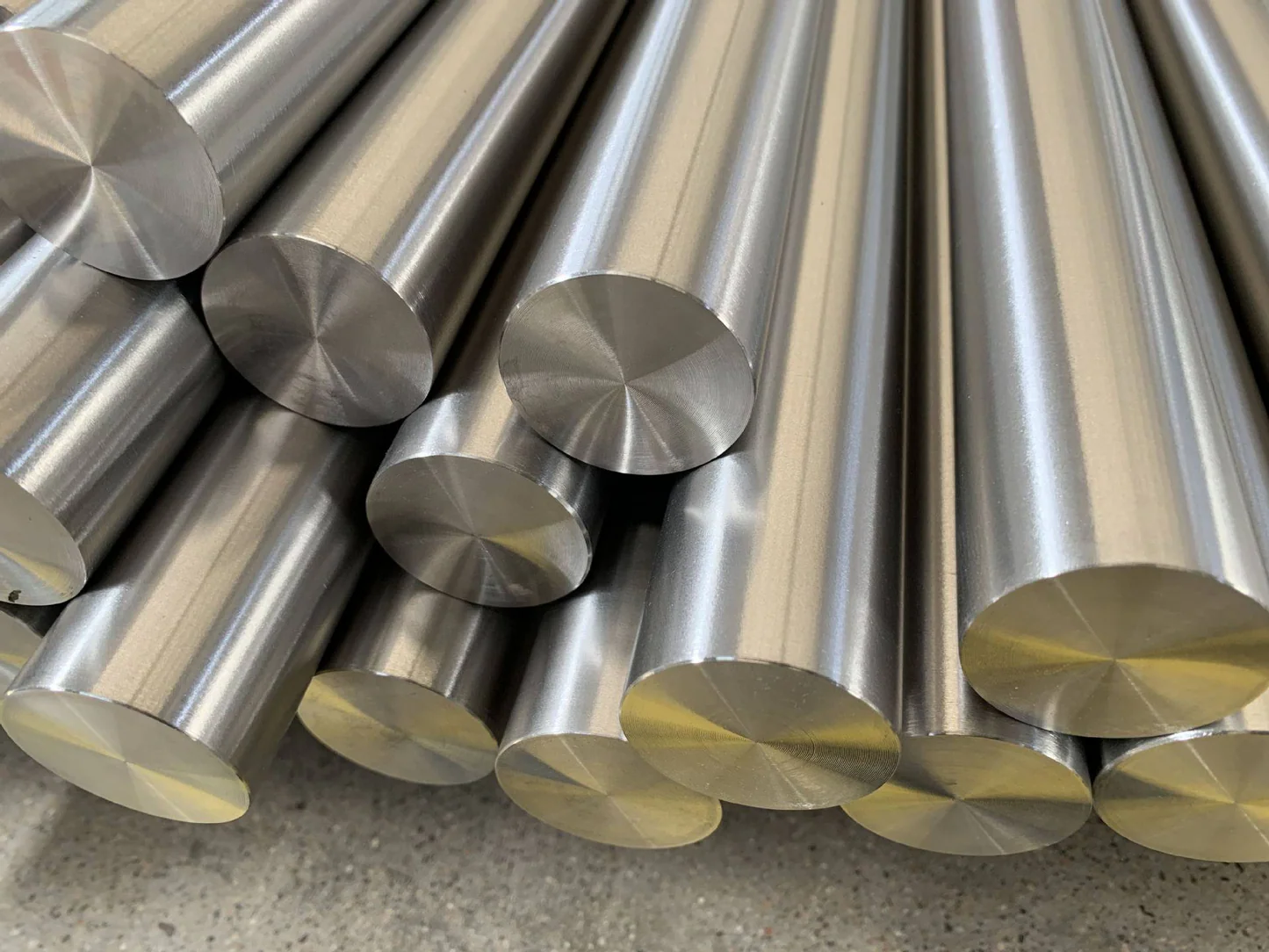

To meet demands for higher wear resistance, better polishability, and more uniform microstructure, the application of powder metallurgy (PM) mold steels is gradually expanding.

- Powder High-Speed Steel / Tool Steel: Examples include CPM 10V, CPM 3V, etc. The PM process eliminates macrosegregation, resulting in carbide sizes≤1μm and wear resistance 2-3 times that of conventional steels. Suitable for highly abrasive conditions like glass-fiber reinforced plastics.

- China’s Domestic R&D Progress: Companies like Daye Special Steel and TianGong International have achieved domestic production of PM plastic mold steels and launched grades like PMB42 and PM558 in 2024-2025 for high-end electronics and automotive lens molds.

3. Considerations for Selecting Mold Materials

Selecting the right mold material greatly affects part quality, how fast parts are made, and how long tools last. This decision must account for working conditions, stress levels, number of units produced, also cost factors. What follows covers main points in choosing materials, along with common types of steel used for injection molds.

3.1 Operating Conditions & Environmental Factors

The service environment dictates the core properties a mold steel must possess. In high‑temperature applications such as hot‑runner systems or molding high‑temperature polymers, the material needs outstanding thermal stability and resistance to thermal‑fatigue cracking. H13 hot‑work steel, for example, retains high hardness and strength at temperatures up to 600 °C, making it a common choice for die‑casting and demanding plastic‑molding operations. Where rapid thermal cycling occurs, a low coefficient of thermal expansion and high thermal conductivity help minimize thermal stress and shorten cycle times.

Pressure affects choice of materials. Molds need to handle force during injection while avoiding damage or breaking. For parts facing sudden impacts – like cores, pins, or punches – strong and durable steels such as S7 are often picked. If working with gritty mixes, say glass-reinforced plastics, fighting surface wear matters most. In these cases, tool steels rich in carbon and chromium, for instance D2, perform well because they contain many tough carbide particles. When molds face harsh environments – like those from PVC or flame-retardant materials – resisting rust becomes critical. Steels like 420 stainless, especially when hardened and smoothed, hold up well against such tough conditions.

3.2 Key Material Properties

Several mechanical and physical properties guide the selection process:

- Hardness determines the material’s ability to resist indentation and wear. Prehardened steels like P20 are supplied at 30–34 HRC, ready for machining without subsequent heat treatment.

- Toughness indicates resistance to chipping and fracture under impact. S7 steel is renowned for its high impact toughness, making it suitable for heavily loaded components.

- Thermal conductivity governs cooling efficiency. Beryllium‑copper alloys (e.g., C17200) exhibit thermal conductivity 3–5 times that of tool steel, allowing them to serve as cooling inserts that drastically reduce cycle times.

- Thermal stability & oxidation resistance are vital in hot‑work conditions. H13 retains its hardness and resists oxidation at elevated temperatures, ensuring long service life in hot molds.

3.3 Production & Economic Considerations

The production volume and cost targets influence material choice. For prototyping and short runs, easily machined materials like aluminum or prehardened P20 provide a cost‑effective solution. For high‑volume production (millions of cycles), high‑performance steels such as H13 or S7 are justified by their extended service life, even at a higher initial cost.

Machinability affects both lead time and manufacturing expense. Prehardened steels (P20, 420 stainless) can be machined directly, avoiding post‑machining heat‑treatment distortion. Additionally, weldability and repairability are valuable for maintaining or modifying molds; P20 and 420 stainless are known for their good welding characteristics.

Ultimately, the decision involves a trade‑off between initial material cost, machining expense, expected tool life, and potential production losses from unscheduled downtime. Often, a higher‑grade steel with superior properties yields a lower total cost of ownership over the mold’s life.

3.4 Typical Material Selection Guide

| Mold Requirements | Recommended Materials (Common Domestic & International Options) |

|---|---|

| General Injection Molding (Small to Medium Batch) | P20 (3Cr2Mo), 718H (3Cr2NiMo) |

| High Surface Finish / Transparent Parts | PMS, S136, NAK80 |

| Long Life, High Wear Resistance (Fiberglass-Reinforced) | 8Cr2MnWMoVS, PM High-Speed Steel (e.g., CPM 10V) |

| Corrosive Plastics (e.g., PVC, Flame-Retardant ABS) | S136, 1.2316, BÖHLER M310/M390 |

| Complex Deep Cavities, Cold Extrusion Forming | LJ Steel, Domestic Low-Carbon Cr-Ni-Mo Cold Extrusion Steel |

| High Precision, Minimal Deformation (e.g., Precision Gears) | 25CrNi3MoAl, 06Ni6CrMoVTiAl |

4. Composite Material Injection Molds

Composite materials have gained popularity in various fields due to their excellent mechanical properties and inherent characteristics. With the development of composite materials, more and more composite parts have the characteristics of complex structures and high precision requirements. Traditional molds have begun to fail to meet the high requirements of components. Due to the similar thermal expansion coefficients and low density of composite materials, composite material molds have become the choice for component production. Research on composite material molds can better understand the development of composite material components.

4.1 Advantages and Disadvantages of Different Molds in Composite Manufacturing

Aluminum mold alloys are lightweight, dense enough, with strong heat transfer – this speeds warming, improving part shaping. Still, when crafting composite parts, mismatched expansion rates between the metal and material create inner tension, leading to warping that harms consistency. Alloy steel molds, shaped by cutting tools, last longer plus expand less – about half as much compared to aluminum – but they’re heavier, warm slowly, spread heat unevenly, also gather stress easily, which limits use in precision composite production.

Nickel electroformed molds have lower density than alloy steel molds, good thermal conductivity, efficient heating performance, and the advantage of being able to create complex geometries. However, the preparation and processing cycle for the molds themselves is long, part repair is difficult, and their coefficient of thermal expansion (12.3 × 10⁻⁶/°C) is far higher than that of composites. This makes them unsuitable for producing high-precision carbon fiber composites (coefficient of thermal expansion 2–4 × 10⁻⁶/°C) and aramid fiber composite products.

Graphite molds have high thermal conductivity and good heating performance. Although the thermal conductivity rate of graphite is not as high as that of aluminum alloy and other metal molds, the coefficient of thermal expansion of graphite molds matches that of aramid fiber composites and carbon fiber composites, making them suitable for processing composite components. Secondly, graphite molds have low thermal mass, similar to composites, meaning the heat required per unit volume for heating graphite molds is the same as for composites. However, graphite molds have low strength and wear resistance, high brittleness, poor impact resistance, and are easily damaged, making them unsuitable for producing large or complex geometries. Additionally, they have poor vacuum integrity, high cost, long manufacturing cycles, and pose difficulties in mass production processing.

4.2 Advantages of Composite Molds

4.2.1 Well-Matched Coefficient of Thermal Expansion

Due to the low coefficient of thermal expansion (CTE) of composite materials, using metal molds, which have a significantly higher CTE, can generate internal stresses during the heating and curing process. Since composite molds are also made from composite materials, the CTE difference between the mold and the composite component is minimal. This allows for better compatibility during curing and reduces the generation of residual stress.

This is because during heating and curing, as the temperature rises, the mold expands thermally, leading to dimensional changes and an increase in size. Consequently, the manufactured dimensions also change. After curing is complete, both the mold and the cured part contract as the temperature decreases. If the CTE difference between the mold material and the part material is too large, internal stress develops between the part and the mold, inevitably causing dimensional deviations between the two. When the mold is made of composite material, the matched CTE between the composite mold and the part means the dimensional changes of the composite mold during thermal expansion and cooling contraction have less impact on the part. For component manufacturing, the CTE not only affects the final dimensions of the part but can also lead to issues such as deformation and demolding difficulties.

Understanding the expansion of both the mold and the part during heating and curing reveals that an excessive CTE difference between them, due to the resulting internal stress, will negatively affect the part’s precision and dimensional accuracy. This can cause the manufactured part to deviate from the intended design, potentially leading to scrap. Table 1 shows the CTEs and the resulting thermal growth at 200°C for several common composite mold materials when producing a 7-meter-long composite component. The table demonstrates that a higher CTE leads to greater dimensional change in the mold during heating, consequently having a larger impact on the component. Furthermore, compared to mild steel and aluminum alloy, carbon fiber composites have a lower CTE, thus causing less influence on the component during its manufacture. Therefore, materials with a matched CTE should be selected for producing composite components. It has been reported that the 18-meter-long Delta-III launch vehicle fairing utilized composite molds to achieve its highly demanding shape accuracy and dimensional precision.

| Mold Material | Coefficient of Thermal Expansion /(×10⁻⁶ °C⁻¹) | Mold Dimensional Increase /mm |

|---|---|---|

| Low Carbon Steel | 12.1 | 14.28 |

| Aluminum Alloy | 24 | 26.67 |

| Glass Fiber Composite | 11.7 | 16.92 |

| Carbon Fiber Composite | 3.6 | 4.32 |

| INVAR Alloy | 1.7 | 3.16 |

Table 1 Coefficient of Thermal Expansion and Corresponding Mold Dimensional Increase for Common Mold Materials

Table 1 shows the thermal expansion coefficients of various material forming molds. From the table, it can be seen that the thermal expansion coefficient of aluminum alloy is the largest. While the thermal expansion coefficient of invar alloy is very small. Using invar alloy to make forming molds can well match the thermal expansion coefficient of composite material components, achieving better dimensional accuracy. This is the most competitive type of material forming mold. However, the disadvantage of invar alloy is that it is difficult to process and expensive.

4.2.2 Low Specific Heat Capacity

The specific heat capacity of composite material molds is high. Therefore, for a given mass, the amount of heat required to increase the temperature by one degree is greater. However, since the density of composite materials is much lower than that of metal materials, the mass of composite material molds is much smaller than that of metal material molds during the production process. This results in a lower specific heat capacity for composite material molds compared to metal material molds. In actual production, due to the lower specific heat capacity of composite materials, the amount of heat required for composite material molds is less, allowing for faster temperature rise and component curing. This enables the production process to be completed in a shorter time, reducing labor hours, saving energy, and lowering the production cost of components.

4.2.3 Low Density

Because the density of composite materials is low, it is approximately 1/4 of that of steel, as shown in Table 2. Therefore, the molds manufactured using composite materials are relatively lightweight. This makes them easy to transport during use. Moreover, carbon fiber composite materials have the characteristics of high strength, high modulus, and low density. Thus, the forming surface thickness of molds made with them is generally between 6 and 9 mm, which is very thin. Even large and complex molds are very lightweight, making them convenient for transportation and use.

| Mold Material | Density /(kg·m⁻³) | Tensile Strength /MPa | Tensile Modulus /GPa |

|---|---|---|---|

| Aluminum Alloy | 2.8 | 400 | 70 |

| Low Carbon Steel | 7.8 | 600 | 210 |

| Carbon Fiber Fabric Composite | 1.5 | 900 | 60 |

| INVAR Alloy | 8.2 | 450 | 140 |

Table 2 Density and Tensile Strength of Several Common Mold Materials

4.2.4 Good dimensional thermal stability

When the mold surface is very complex and the size is large, if a metal mold is used to produce large surface shapes, due to the large weight of the metal mold and its excessive bulkiness, the aluminum liquid filling time is too long, resulting in defects such as pores or porosity inside the produced components, which reduces the mechanical properties of the components and also affects the airtightness of the composite material components. If a composite material mold is used for production, since the composite material mold is made by duplicating the master mold and the production and processing difficulty of the master mold is much less than that of metal materials, in addition, the metal can be sprayed on the surface of the composite material mold, reducing the roughness of the surface of the composite material components.

4.3 Problems of Composite Material Molds

The composite material molds mainly have the following issues: Their manufacturing process is complex, requiring a master mold and demanding high stability of the materials under high temperature and high pressure; The surface hardness is relatively low, making them prone to mechanical damage, delamination of the gel coat, and degradation of accuracy due to collisions; Their service life is much shorter than that of metal molds, usually only a few dozen times, resulting in an increase in costs and possible inconsistency in product accuracy; Despite having many advantages, their cumbersome manufacturing process and complex technology ultimately lead to overall costs being higher than those of ordinary metal molds.

As we’ve seen, the landscape of mold materials is rich and specialized. The optimal choice always depends on a careful balance of your production volume, required part aesthetics, material being processed, and total life-cycle cost.

As we have discussed, the field of mold materials is highly specialized and complex. As a manufacturer with a full range of precision processing equipment and a materials laboratory, we understand that the correct material selection is the foundation for achieving high-quality production. From pre-hardened steel to age-hardened steel, from powder metallurgy to composite materials, we not only have a variety of standard grades in stock, but also can provide customized material solutions based on the characteristics of your products, ensuring the best balance between production efficiency, part accuracy, and mold lifespan.

We have equipped a vacuum heat treatment production line and a metallographic analysis system, which enables us to precisely verify the performance of each material under different working conditions. In practical cases, we have enhanced the mold lifespan by over 300% for our clients by optimizing the material combination. We welcome you to share the challenges and experiences in the application of mold materials. Our engineering technical team will provide you with professional advice – whether it is the mold selection for high-corrosive plastics or the surface treatment requirements for ultra-precise optical components, we have the corresponding technical reserves and successful cases. Contact us at sales@kingstarmold.com to obtain more professional knowledge, or get a customized quote for your project.