TPU (Thermoplastic Polyurethane Elastomer), with its outstanding wear resistance, elasticity and weather resistance, is widely used in automotive, electronic, medical, packaging and other fields. This post provides a detailed explanation of the basic characteristics and special grades of TPU, for both practitioners and learners.

1. Basic Characteristics

TPU is a material with -NH-COO- groups in its molecules. The long-chain diols and isocyanate components constitute the soft segment, while the short-chain diols and isocyanate components constitute the hard segment. Many properties of TPU depend on the type of long-chain diol, and its hardness can be adjusted by the proportion of the hard segment. Its light aging property can be improved by adding light stabilizers. It also depends on whether the isocyanate is aromatic or aliphatic. Its superior properties compared to other thermoplastic elastomers is as follows:

(1) Excellent wear resistance

Its Taber abrasion value is 0.5 – 0.35 mg, which is the smallest among plastics. If MoS2, silicon oil graphite, etc. are added, the friction coefficient can be reduced and the wear resistance can be improved.

(2) Tensile strength & elongation

When it comes to tensile strength, TPU delivers 2 to 3 times better performance than both natural and synthetic rubbers. Polyester-based TPU hits around 60 MPa in tensile strength, boasting an elongation rate of nearly 410%. Polyether-based TPU, on the other hand, comes in at 50 MPa for tensile strength and delivers an elongation rate over 30%.

(3) Oil and gasoline resistance

The oil resistance of TPU is superior to that of Nitrile Butadiene Rubber(NBR), and it has an extremely long oil resistance lifespan.

(4) Low temperature resistance, weather resistance, and ozone resistance

TPU’s weather resistance and aging resistance are superior to those of natural rubber and other synthetic rubbers. Its ozone resistance and radiation resistance make it particularly useful in the aerospace industry.

(5) Medical Health Properties

TPU exhibits biocompatibility and anticoagulant properties, making its medical applications increasingly widespread. These include artificial hearts, artificial kidneys, blood transfusion tubes, plasma bags, ureters, and fixation materials for surgical techniques.

(6) Hardness range

The hard segment of TPU ranges from Shore A10 to Shore D80, while the hardness range of ordinary rubber is generally between Shore A60 and A100. All elastomers with a Shore hardness below A15 in TPU exhibit similar compression deformation characteristics.

TPU maintains its elasticity when its Shore hardness is between A85 and above. This is a unique characteristic that other elastomers do not possess. Therefore, TPU exhibits high load-bearing capacity and excellent vibration absorption effect.

2. Special grades

(1) ESTANE® – Produced by BF Goodrich (United States)

ESTANE® is one of the earliest commercial TPU brands, developed by BF Goodrich (now part of Lubrizol). It is widely known for its excellent abrasion resistance, flexibility, and toughness over a wide temperature range. ESTANE® grades are commonly used in applications such as cables, films, hoses, and footwear components.

(2) Desmopan® – Produced by Bayer (Germany)

Desmopan®, manufactured by Bayer (now under Covestro), represents another major family of TPU products. It offers a broad hardness range, outstanding transparency, and high resilience. Desmopan® grades are used extensively in automotive parts, electronics, and sports equipment due to their excellent mechanical and aesthetic properties.

Learn more about Bayer TPU in one of our earlier posts: Bayer TPU Two-color Injection Molding Process: A Practical Guide from Material to Production

(3) Miractran® – Produced by 日本ミラクトラン株式会社(Nippon Miractran Co., Ltd.)

Among these 3 special grades, Miractran grade is divided into two series, E-type and P-type, due to the different ratios of the equivalent of diol hydroxyl to isocyanate. The E-type, with excess isocyanate forming some cross-linked structures, exhibits excellent mechanical strength, resistance to permanent compression deformation, and permanent elongation. The P-type has a linear structure due to equal proportions of the two components, and its viscosity has little dependence on temperature, with good fluidity and good processing properties, and is easily soluble in solvents.

Recently, Miractran has developed new functional materials such as electronic components for human body anti-static protection, fast-adaptive moisture-permeable materials for clothing and housing, antibacterial materials for medical and food safety requirements, wear-resistant materials for shoe soles, especially matting materials, foaming materials, light-storing materials, and antithrombotic catheters.

3. Molding processing technology

3.1 Advisories and Precautions

The typical molding methods for TPU are extrusion molding and injection molding. The following points should be noted for these molding methods:

(1) Due to the strong moisture absorption of TPU, it must be fully dried before processing;

(2) Due to the slow dependence of viscosity on temperature, it is necessary to improve the accuracy of temperature control;

(3) The structure and aspect ratio of the screw should be considered based on the characteristics of the material (such as compression ratio, screw channel depth, L/D, etc.);

(4) Design the mold structure based on the fluidity of the material (nozzles, runners, gates, etc. that do not cause stagnation);

(5) The power setting of the molding machine should be slightly higher (1.5 to 2 times that of general-purpose resin);

(6) Anneal the molded product to restore its original characteristics (especially for materials that have not been fully plasticized).

3.2 Molding processing technology and application

TPU processing is not less difficult than general plastics and other thermoplastic elastomers (TPE), but recently, due to improvements in molding machines and processing technology, various molding methods have been adopted to produce various products.

(1) Tubing, film, and sheet materials

TPU tubing, by virtue of its inherent softness, coupled with good tensile and impact strength, high and low temperature resistance, and the ability to withstand 1.5 MPa without expansion, has a burst pressure of up to 2-5 MPa and good oil resistance. Therefore, it is an ideal material for gas and oil tubing, are utilized in airplanes, tanks, cars, motorcycles, machine tools, etc. for gas and oil transmission tubing. TPU tubing is mainly processed by extrusion molding. However, due to the tendency of TPU to absorb water, which reduces the strength of the product, the raw material should be dried at 100-120°C for 4 hours before processing to ensure that the moisture content in TPU is below 0.05%. During extrusion, attention should be paid to temperature adjustment. Adding 1-4 PHR of lubricant to pure TPU helps stabilize the material flow and improve the surface finish of the tubing. Desmopan grades 786, 385, 392, and ESTANE grades 58311, 58092, 58409 can be used for extrusion tubing.

TPU film and sheet have a wide range of applications due to their toughness, thin-walled nature, unique feel, and good environmental friendliness. This product is produced using T-extrusion, blow molding, and calendering methods, and the appropriate grade must be selected for each molding method during production.

The standard grades in the Miractran range, such as E100, E300, and ESTANE grades 58206, 58887, and 58315, are suitable for T-die extrusion molding and can produce films with thicknesses down to tens of micrometers. The blow molding process can utilize grades E885PFAA and E390PFAA from Miractran, as well as grades 58277, 58409, 58630, and 58315 from ESTANE, to produce non-stick, soft, very thin, and lubricious films. The calendering method can be used to process grades E585MSOH, E660MSOH, and E380MSNT from the Miractran product range, with hardness ranging from 60A to 95A.

(2) Hot melt film and coating field

The application of this field is to utilize the adhesive property, elasticity, and good appearance characteristics of TUP. It is not only used simply as an adhesive material, but also widely used as a film for thermal transfer printing and copying of clothing patterns such as T-shirts. These films can be produced using T-extrusion and blow molding methods. The thickness is about 10μm, and the non-yellowing and hot melt grades in the Miractran grade can be used. Recently, “nonwoven fabrics” made from the same raw materials and controlled at 25~100g/㎡ have attracted attention as novel clothing materials due to their moisture permeability function, in addition to the above-mentioned characteristics, due to their porous structure. In addition, spherical powder hot-melt materials can also be used in the field of coating for automotive parts.

(3) Low compression set, heat deformation resistance

Miractran low compression set/heat resistant H grade has undergone significant improvements based on the original product. This is mainly achieved through material preparation technology, processing technology, and appropriate annealing. It is mainly used in industrial pressure and heat-resistant components.

(4) Electron beam crosslinking field

In fields with high requirements for heat resistance, chemical resistance, and friction resistance, standard grade TPU cannot meet the performance requirements. The improved method is to use electrons for crosslinking to form a crosslinked layer on the surface, which can meet the above requirements and can be made into grommet, diaphragms, sheaths, flexible conduit, etc.

In summary, TPU has found widespread applications in various fields such as automobiles, industrial components, flexible conduit, grommet, seals, wires and cables, as well as medical applications.

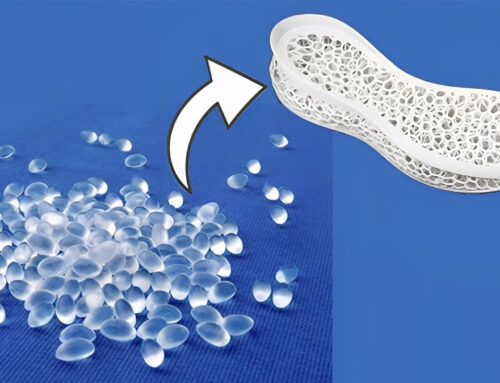

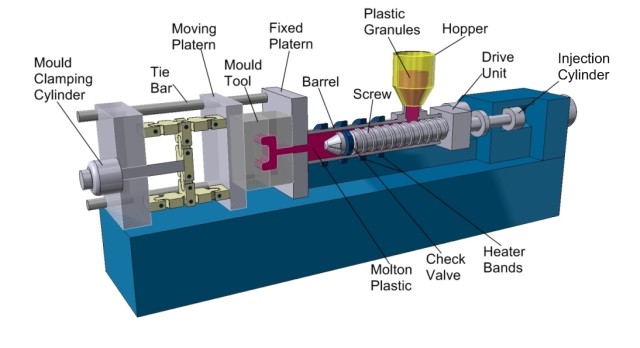

There are various methods for TPU molding processes, including injection molding, blow molding, compression molding, extrusion molding, etc., with injection molding being the most commonly used. The function of injection molding is to process TPU into the required parts, which is a discontinuous process divided into three stages: pre-plasticization, injection, and ejection. Injection molding machines are divided into plunger-type and screw-type, with screw-type injection machines being recommended because they provide uniform speed, plasticization, and melting.

4. Design of injection machine

The barrel of the injection machine is fitted with a copper-aluminum alloy liner, while the screw is chrome-plated to minimize wear. The optimal aspect ratio (L/D) for the screw is between 16 and 20, with a minimum of 15; the compression ratio should range from 2.5/1 to 3.0/1. The length of the feeding section is 0.5L, the compression section is 0.3L, and the metering section is 0.2L. The check ring should be installed near the top of the screw to prevent backflow and maintain maximum pressure.

When processing TPU, it is advisable to use a self-flow nozzle with an inverted conical outlet. The nozzle diameter should be at least 4mm, but smaller than the inlet of the main runner collar by 0.68mm. The nozzle should be equipped with a controllable heating band to prevent the material from solidifying. From an economic perspective, the injection volume should be 40% to 80% of the rated volume. The screw speed is 20 to 50 r/min.

4.1 Mold design

When designing molds, pay attention to the following points:

(1) Shrinkage rate of molded TPU parts

Shrinkage is influenced by molding conditions such as the hardness of the raw material, the thickness, shape, molding temperature, and mold temperature of the part. The typical shrinkage rate ranges from 0.005 to 0.020 cm/cm. For example, a rectangular test piece measuring 100×10×2mm with a gate in the length direction will shrink in the flow direction, and the shrinkage rate will be 2 to 3 times greater for a hardness of 75A compared to 60D. Figure 1 shows how TPU hardness and manufacturing thickness affect the shrinkage rate. A negative correlation is observed between part shrinkage rate and thickness for TPUs with hardness values between 78A and 90A.

(2) Runner system and cold slug well

Sprue is the channel in the mold that connects the injection machine nozzle to the runners or cavities. Its diameter should increase inward with a taper of over 2 degrees to facilitate the ejection of the runner slug.

Runners are the channels in a multi-cavity mold that connect the sprue to each individual cavity. They should be arranged symmetrically and equidistantly on the mold plate. Runners can be circular, semi-circular, or rectangular in cross-section, with a diameter preferably between 6–9 mm. The runner surface must be polished like the mold cavity to reduce flow resistance and provide faster filling speed.

A cold slug well is a cavity located at the end of the sprue, designed to capture the cold material that forms at the nozzle tip between injection cycles. This prevents the runners or gates from becoming blocked. If cold material enters the cavity, it can easily cause internal stresses in the molded part. The cold slug well typically has a diameter of 8–10 mm and a depth of about 6 mm.

(3) Gate and exhaust ports

The gate is the channel that connects the sprue or runner to the mold cavity. Its cross-sectional area is typically smaller than that of the runner, making it the narrowest part of the runner system, and its length should be as short as possible. Gates are usually rectangular or circular in shape, and their dimensions increase with the wall thickness of the product:

- For products with a wall thickness below 4 mm, the gate diameter should be 1.0 mm.

- For a wall thickness of 4–8 mm, the gate diameter should be 1.4 mm.

- For a wall thickness above 8 mm, the gate diameter should range from 2.0 to 2.7 mm.

The gate location is generally selected at the thickest section of the product where it does not affect appearance or functionality. It should be positioned at a right angle to the mold wall to prevent sink marks and avoid flow lines.

The exhaust port is a slot-shaped air outlet designed into the mold to prevent gas from being entrapped in the molten material entering the mold. It expels gas from the mold cavity, ensuring the molded product is free from gas pores, poor weld lines, incomplete filling, or even burns and internal stress caused by high temperatures due to compressed air. The exhaust port can be positioned at the end of the molten material flow within the mold cavity or on the mold parting surface, and it is typically a 0.15mm deep and 6mm wide pouring slot. It is essential to ensure uniform temperature control in the mold to prevent warping and distortion of the molded parts.

4.2 Molding conditions

The most important molding conditions for TPU are temperature, pressure, and time, which affect plasticizing flow and cooling. These parameters will affect the appearance and performance of TPU parts. Good processing conditions should result in uniform white to beige parts.

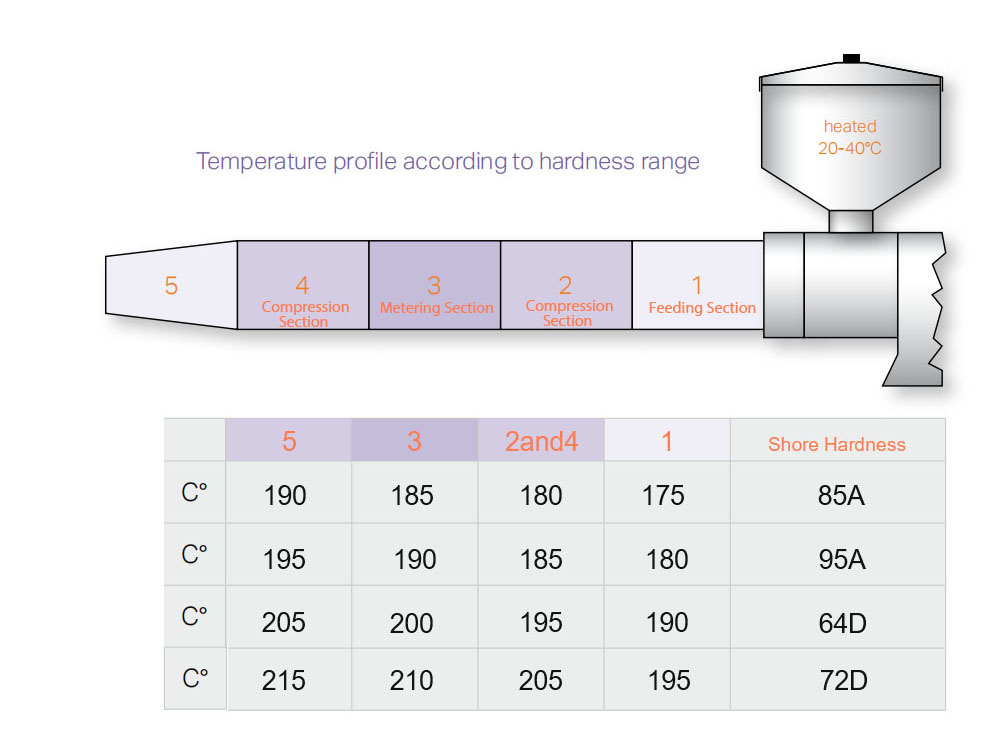

(1) Temperature

The temperature control of the molding TPU process includes barrel temperature, nozzle temperature, and mold temperature. The first two temperatures mainly affect the plasticization and flow of TPU, while the latter temperature affects the flow and cooling of TPU.

a. Barrel temperature: The hardness of the TPU determines the appropriate barrel temperature. Higher-hardness TPU necessitates a higher melting temperature, which correspondingly demands a higher maximum temperature at the barrel’s end. The temperature range of the barrel used for processing TPU is 177~232℃. The distribution of barrel temperature generally increases gradually from the hopper side (rear end) to the nozzle (front end), so that the temperature of TPU can rise steadily to achieve uniform plasticization.

b. Nozzle temperature: The nozzle temperature is usually slightly lower than the maximum temperature of the barrel to prevent the possible occurrence of salivation in the straight-through nozzle. If a self-locking nozzle is used to eliminate salivation, the nozzle temperature can also be controlled within the maximum temperature range of the barrel.

c. Mold temperature: Mold temperature has a significant impact on the inherent properties and apparent quality of TPU products. It depends on many factors such as the crystallinity of TPU and the size of the product. Mold temperature is typically regulated via temperature-stabilized cooling media like water. TPU features high hardness and crystallinity, which translates to a relatively high required mold temperature. For example, Texin, with a hardness of 480A, has a mold temperature of 20-30°C; with a hardness of 591A, the mold temperature is 30-50°C; with a hardness of 355D, the mold temperature is 40-65°C. The mold temperature for TPU products is generally between 10-60°C. Low mold temperature can cause the melt to freeze prematurely, resulting in flow lines, and is not conducive to the growth of spherulites, which can lead to low crystallinity in the product, resulting in later crystallization processes, which can cause post-contraction and changes in product performance.

(2) Pressure

The injection molding pressure includes plasticizing pressure (back pressure) and injection pressure. When the screw retracts, the pressure applied to the melt at the top of the screw is the back pressure, which is adjusted through an overflow valve. Increasing the back pressure increases the melt temperature, reduces the plasticizing rate, homogenizes the melt temperature and colorant mixing, and discharges melt gases, but it extends the molding cycle. The back pressure for TPU is usually between 0.3 and 4 MPa.

Injection pressure refers to the pressure applied by the top of the screw to TPU, which acts to overcome the flow resistance of TPU flowing from the barrel to the mold cavity, give the rate of melt filling, and compact the melt. The flow resistance and filling rate of TPU are dictated by melt viscosity, which is governed by the material’s hardness and melt temperature. That is, the viscosity of the melt is not only determined by temperature and pressure, but also by the hardness of TPU and the deformation rate. The higher the shear rate, the lower the viscosity; if the shear rate remains unchanged, the higher the hardness of TPU, the greater the viscosity.

For TPU processing under constant shear rate, viscosity decreases progressively as temperature goes up. However, this temperature dependence is more pronounced at low shear rates than at high ones. The injection pressure of TPU is generally 20~110MPa. The holding pressure is about half of the injection pressure, and the back pressure should be below 1.4MPa to ensure uniform plasticization of TPU.

(3) Time

The time required to complete an injection process is called the molding cycle. The molding cycle includes filling time, packing time, cooling time, and other time (opening, demolding, closing, etc.), which directly affects labor productivity and equipment utilization. The molding cycle of TPU is usually determined by hardness, part thickness, and configuration. The higher the hardness of TPU, the shorter the cycle, the thicker the plastic part, the longer the cycle, and the more complex the plastic part configuration, the longer the cycle. The molding cycle is also related to mold temperature. The molding cycle of TPU is generally between 20 and 60 seconds.

a. Injection speed

The required injection speed is dictated by the product’s geometry: thick sections necessitate slower speeds, whereas thin sections require faster filling.

b. Screw speed

Processing TPU products usually requires a low shear rate, so a lower screw speed is appropriate. The screw speed of TPU is generally 20~80r/min, preferably 20~40r/min.

(4) Shutdown for maintenance

Due to the potential degradation of TPU at high temperatures over extended periods, it should be cleaned with PS, PE, acrylate plastics, or ABS after shutdown. If the machine is stopped for more than 1 hour, the heating should be turned off.

(5) Post-processing of products

Due to uneven plasticization in the barrel or different cooling rates in the mold cavity, Internal stresses in TPU products are frequently caused by uneven crystallization, molecular orientation, and differential shrinkage. This is more prominent in thick-walled products or products with metal inserts. Products with internal stress often experience a decrease in mechanical properties, silver streaks on the surface, and even deformation and cracking during storage and use. The solution to these problems in production is to perform annealing treatment on the product. The annealing temperature depends on the hardness of the TPU product. Products with high hardness require higher annealing temperatures, while products with low hardness require lower temperatures. Too high a temperature may cause the product to warp or deform, while too low a temperature may not achieve the purpose of eliminating internal stress. TPU annealing should be performed at low temperature for a long time. Products with lower hardness can be placed at room temperature for several weeks to achieve optimal performance. For products with hardness below Shore A85, annealing at 80°C for 20 hours is sufficient, while for products with hardness above Shore A85, annealing at 100°C for 20 hours is sufficient. Annealing can be performed in a hot-air oven, but care should be taken not to overheat the product in localized areas, which can cause deformation.

Annealing can not only eliminate internal stress, but also improve mechanical properties. Due to the two-phase morphology of TPU, phase mixing occurs during thermal processing of TPU. The phase separation in TPU is kinetically hindered by high viscosity during fast cooling, making sufficient time a critical process parameter for adequate separation and form microdomains, thereby obtaining optimal properties.

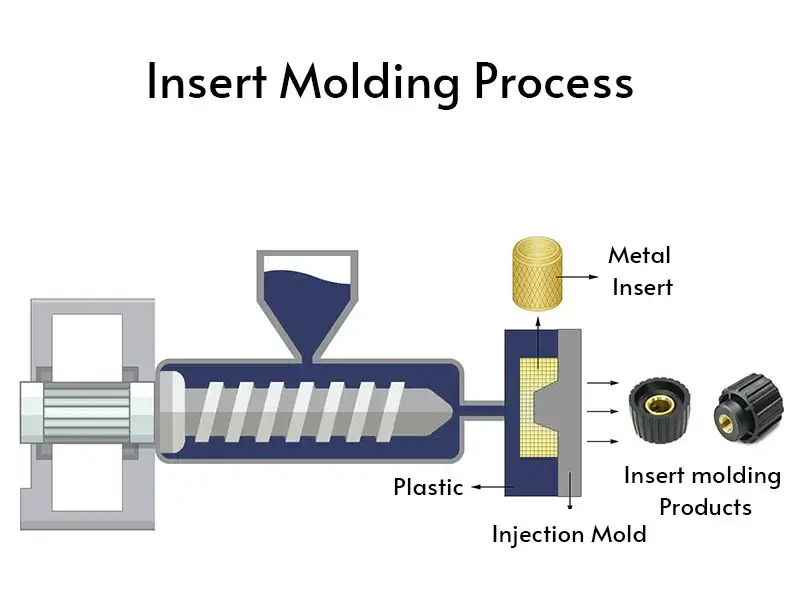

(6) Insert molding

To meet the requirements of assembly and use strength, metal inserts need to be embedded in TPU parts. The metal inserts are placed in a predetermined position in the mold and then injected into a single piece of product. Due to the significant difference in thermal properties and shrinkage rates between the metal inserts and TPU, the bonding between the inserts and TPU is not strong in TPU products with inserts. The solution is to preheat the metal inserts, as preheating reduces the temperature difference between the inserts and the melt, which can slow down the cooling of the melt around the inserts during injection, resulting in more uniform shrinkage and a certain degree of hot material shrinkage compensation, preventing excessive internal stress around the inserts. TPU insert molding is relatively easy, and the shape of the inserts is not limited. As long as the inserts are degreased and heated at 200-230°C for 1.5-2 minutes, the peel strength can reach 6-9 kg/25mm. To obtain stronger bonding, adhesive can be applied to the inserts, heated at 120°C, and then injected. In addition, it should be noted that the TPU used should not contain lubricants.

(7) Reuse of recycled materials

During the TPU processing, waste materials left in the sprue and runner, and unqualified products can be recycled and reused. According to experimental results, when 100% recycled material is used without mixing with new material, the mechanical properties of products do not decline significantly, making it fully usable. However, to maintain optimal physical and mechanical properties and injection conditions, it is recommended to use a proportion of 25% to 30% recycled material. It is important to ensure that the recycled material matches the specifications of the new material, and to avoid using contaminated or annealed recycled material. Recycled material should not be stored for extended periods and should be granulated and dried immediately for use. The melt viscosity of recycled material generally decreases, requiring adjustments to the molding conditions.

To gain systematic information of the basic characteristics and special grades of TPU, theoretical support is needed to facilitate the summarization and discovery in practice. As a leading injection molding company in China, KingStar welcomes any corrections or discussions, and please feel free to send us an email(sales@kingstarmold.com) for professional suggestions on the basic characteristics and special grades of TPU, or request a quote for your project.