SLA 3D Printing Overview

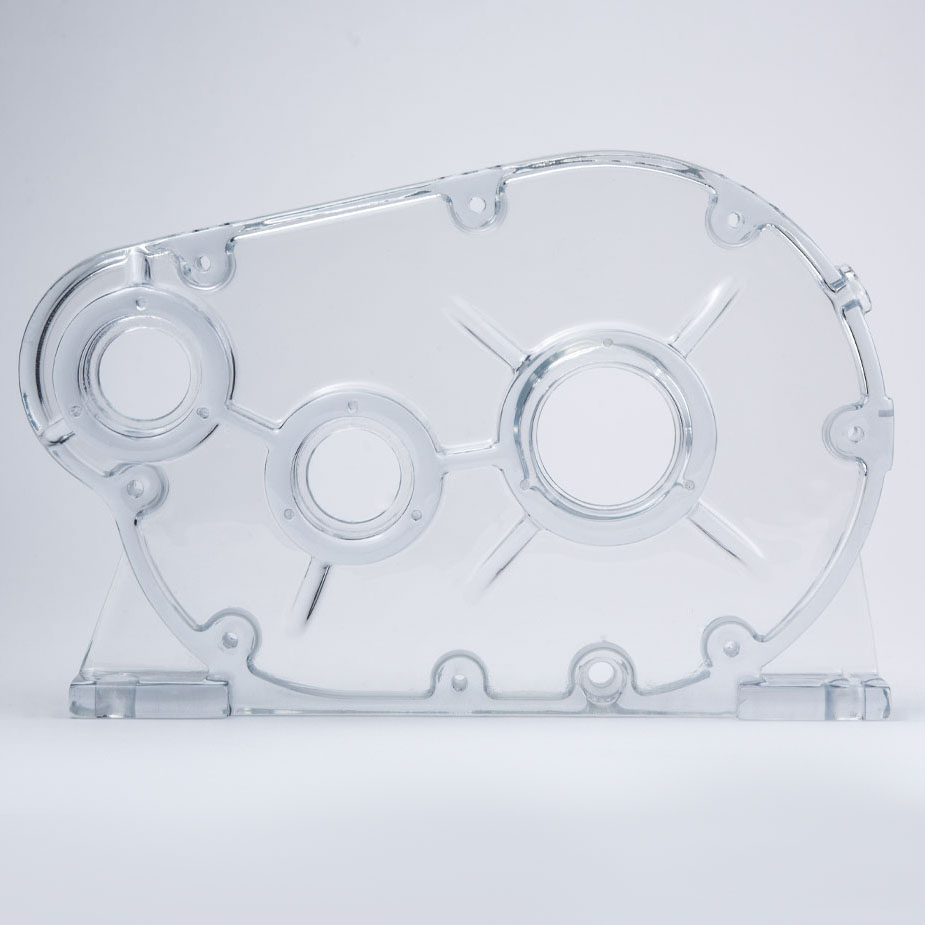

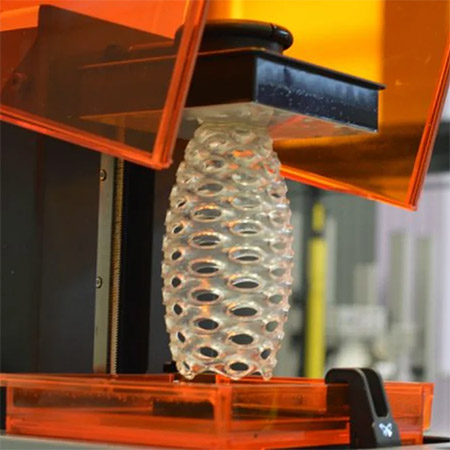

As one of the methods of 3D printing, SLA 3D printing is a form of additive manufacturing that employs a laser to solidify liquid resin, building up objects one thin layer at a time. This process allows for the creation of parts with exceptional detail and accuracy. By precisely controlling the laser, SLA can produce highly intricate designs with smooth finishes. It is known for its ability to produce smooth surface finishes and intricate geometries, making it ideal for applications requiring fine detail and high accuracy. It is commonly used in industries such as aerospace, automotive, and healthcare for rapid prototyping, functional parts, and small-batch production. The process is valued for its speed, precision, and versatility in producing complex designs.

It is mainly used for:

Our SLA 3D Printing Design Guidelines & Capabilities

| Metric | US | |

|---|---|---|

| Micro Resolution | 63.5mm x 127mm x 127mm | 2.5 in. x 5 in. x 5 in. |

| High Resolution | 254mm x 254mm x 254mm | 10 in. x 10 in. x 10 in. |

| Normal Resolution | 533mm x 635mm x 736mm | 21 in. x 25 in. x 29 in. * |

*Available Only for: ABS-Like Translucent/Clear, ABS-Like White and Gray, and PC-Like Translucent/Clear

| Metric | US | |

|---|---|---|

| Micro Resolution | 0.0254mm | 0.001 in. |

| High Resolution | 0.0508mm | 0.002 in. |

| Normal Resolution | 0.1016mm | 0.004 in. |

*Available Only for: ABS-Like Translucent/Clear, ABS-Like White and Gray, and PC-Like Translucent/Clear

| Metric | US | |

|---|---|---|

| Micro Resolution | X-Y: 0.0635mm Z: 0.203mm | X-Y: 0.0025 in. Z: 0.008 in. |

| High Resolution | X-Y: 0.1016mm Z: 0.406mm | X-Y: 0.005 in. Z: 0.016 in. |

| Normal Resolution | X-Y: 0.254mm Z: 0.406mm | X-Y: 0.010 in. Z: 0.016 in. |

| Metric | US | |

|---|---|---|

| Micro Resolution | 0.0635mm | 0.0025 in. |

| High Resolution | 0.1016mm | 0.004 in. |

| Normal Resolution | 0.254mm | 0.010 in. |

| Metric | US | |

|---|---|---|

| Micro Resolution | 0.381mm | 0.015 in |

| High Resolution | 0.508mm | 0.020 in. |

| Normal Resolution | 0.635mm | 0.025 in. |

For well-designed parts, tolerances of ±0.002 in. (0.05mm) in the X/Y dimensions for the first inch, plus 0.1% of the nominal length (0.001mm/mm), and ±0.005 in. in the Z dimension for the first inch, plus 0.1% of the nominal length, are typically achievable. Please note that tolerances may vary based on part geometry.

Surface Finish Options for SLA Parts

| Finishing Options | Description |

|---|---|

| Unfinished | Dots or standing "nibs" may remain visible on the bottom of the part due to support structure remnants. This finish is ideal when fast lead times or cost efficiency is a priority. |

| Natural | Supported surfaces are sanded to remove the support nibs, providing a smoother finish. |

| Standard | Supported surfaces are sanded, and the entire part is finely blasted for a consistent appearance. Keep in mind that layer lines may still be visible. |

| Custom | Options for custom finishes include soft-touch paint, clear part finishing, painting, masking, color matching, decals/graphics, and various texture finishes. |

Material: ABS-like Translucent/Clear

Unfinished

Standard

Natural

Custom

Material: MicroFine Gray™

Unfinished

Standard

Natural

Custom

Additional Finishing Options

Custom finishing combines science, technology, and craftsmanship to tailor a part to your precise specifications. Available finishes include:

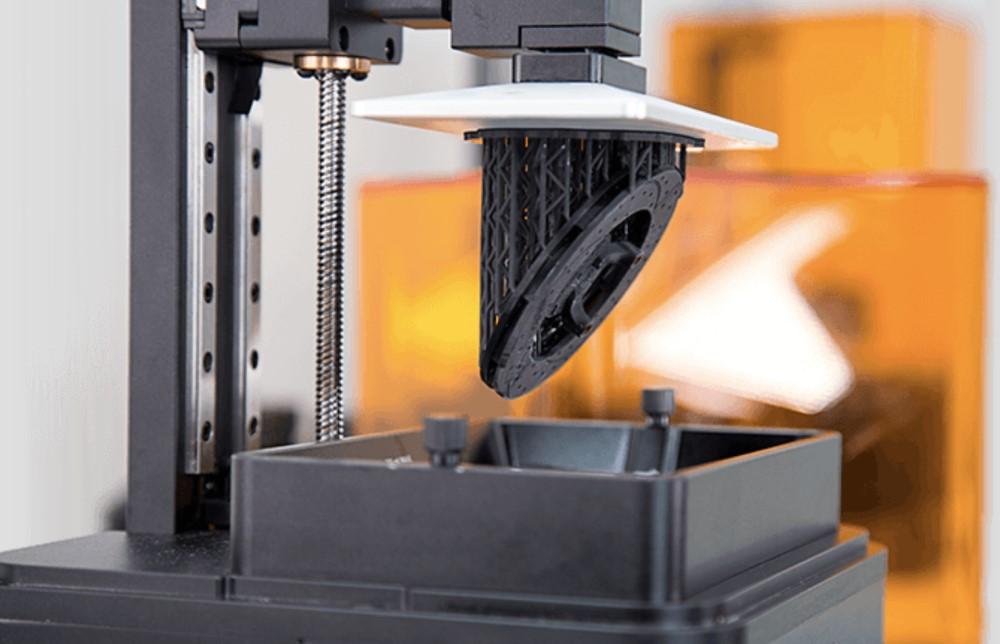

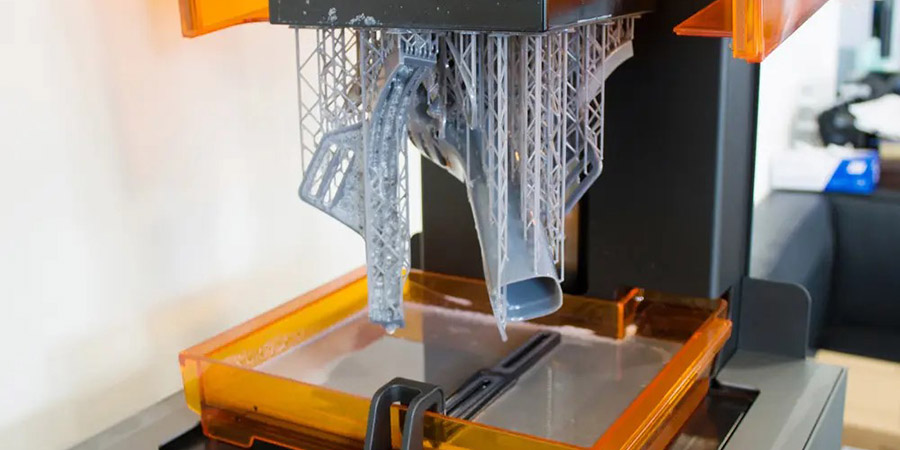

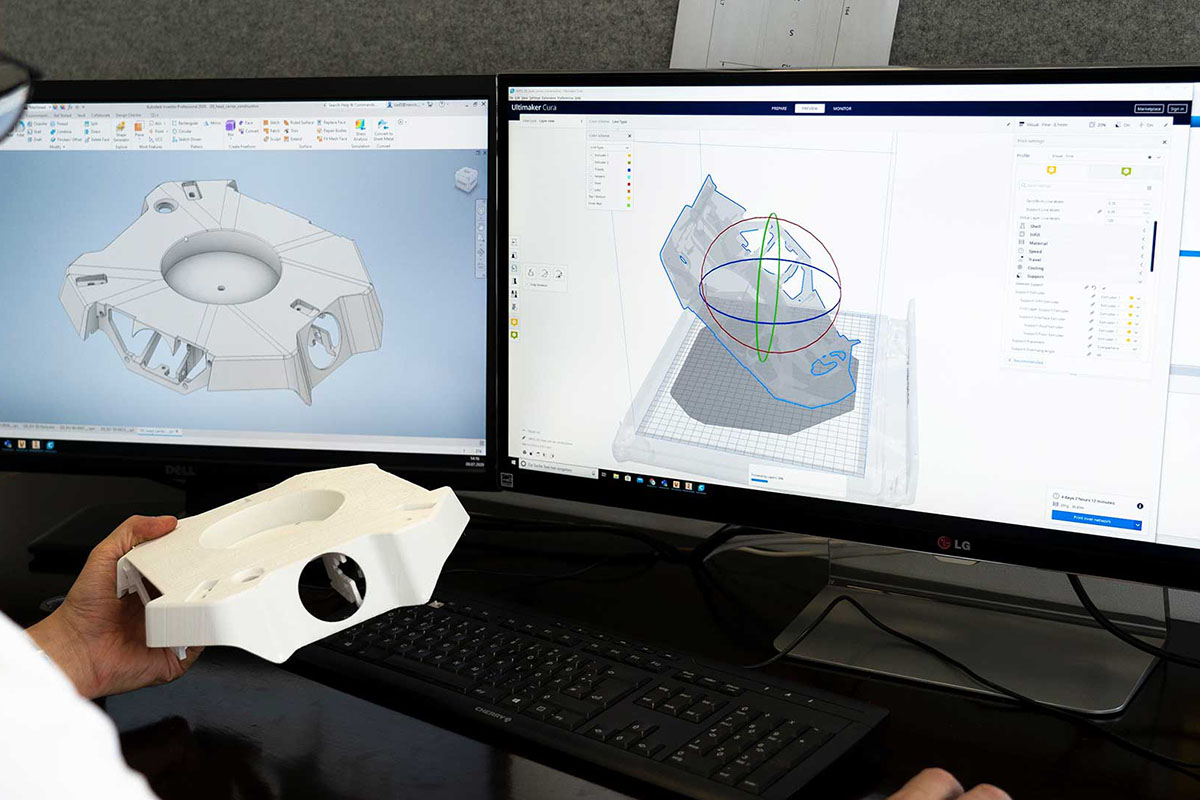

Our SLA Printers

At KingStar Mold, we utilize some of the most renowned SLA 3D printers to ensure high-quality and precise outputs for our clients. Here are parts of the machines we employ:

Formlabs Form 3

The Form 3 is a professional-grade SLA 3D printer known for its precision and reliability. It features Low Force Stereolithography (LFS) technology, delivering smooth surface finishes and detailed prints. This printer is ideal for artists, designers, and engineers seeking high-quality prototypes and end-use parts.

Formlabs Form 3L

The Form 3L offers a larger build volume compared to the Form 3, making it suitable for larger prototypes and production parts. It shares the same LFS technology, ensuring consistent quality across different print sizes. This printer is ideal for teams requiring scalability without compromising on detail.

Design Guidelines

At KingStar Mold, our SLA 3D printing design guidelines are focused on ensuring the highest quality and precision in every project. We emphasize factors like part orientation, support structures, and material selection to optimize strength, surface finish, and accuracy. Our goal is to provide clients with functional, cost-effective prototypes and end-use parts that meet their specific needs and specifications.

Advantages of Choosing SLA 3D Printing

High Precision and Detail

SLA 3D printing delivers exceptional accuracy, capable of printing parts with fine details as small as 0.002 in. This precision makes it ideal for creating intricate geometries and complex designs. Whether for prototypes or functional parts, SLA ensures the highest level of detail in every layer.

Smooth Surface Finish

The process results in smooth, polished surfaces without the need for additional post-processing. This is particularly advantageous for parts with visible surfaces or those requiring an aesthetic appeal. The fine layer resolution helps achieve a professional, high-quality look right from the printer.

Fast Prototyping

SLA 3D printing enables rapid prototyping, reducing the time between design and production. With quick turnaround times, you can test and iterate designs faster than traditional manufacturing methods. This speed allows for more efficient product development and quicker decision-making.

Versatile Material Options

SLA printing offers a wide range of resin materials, including those with specific properties like rigidity, flexibility, and heat resistance. This versatility makes it suitable for various industries, from automotive to medical. It allows for customization of parts to meet specific performance and environmental requirements.

The lead time for SLA 3D printing typically ranges from 2-3 days, depending on the complexity and size of the part. Our team at KingStar Mold works efficiently to ensure timely delivery of your parts without compromising on quality.

The maximum build size for our SLA 3D printing service is 800 x 800 x 550 mm (31.5″ x 31.5″ x 21.6″). This large build volume allows KingStar Mold to produce both small and medium-sized parts with high precision, catering to a wide range of customer needs.

SLA offers high precision, smooth surface finishes, rapid prototyping, and a wide selection of materials. It is ideal for creating detailed prototypes, low-volume production parts, and intricate designs with excellent accuracy. KingStar Mold leverages SLA to meet the demands of customers seeking both aesthetic and functional parts.

It is an advanced manufacturing technique that employs a laser to harden liquid resin, constructing objects layer by layer. This method is renowned for its remarkable accuracy, making it ideal for creating detailed, smooth-surfaced parts. At KingStar Mold, we harness this technology to produce complex, high-precision components for a wide range of industries.

SLA 3D printing offers high accuracy, with tolerances of ±0.002 in. (0.05mm) in the X/Y dimensions for the first inch, plus 0.1% of the nominal length, and ±0.005 in. in the Z dimension for the first inch, plus 0.1% of the nominal length. KingStar Mold ensures precision in every print for tight tolerances and high-quality results.

While SLA 3D printing excels in creating detailed and accurate parts, it is typically better suited for low to medium volumes. For high-volume production, other methods like injection molding may be more cost-effective. KingStar Mold can help you decide the best approach for your production needs.

SLA is ideal for high-precision prototypes, cosmetic parts, and low-volume, detailed production runs. It is commonly used for industries like automotive, healthcare, and consumer electronics where fine details and smooth finishes are essential. At KingStar Mold, we specialize in creating these high-quality parts.

SLA 3D printing uses various types of resin materials, including standard, flexible, and high-temperature resins. The choice of material depends on the specific requirements of your project, such as durability, flexibility, or heat resistance. KingStar Mold offers a wide selection of materials to suit different applications.