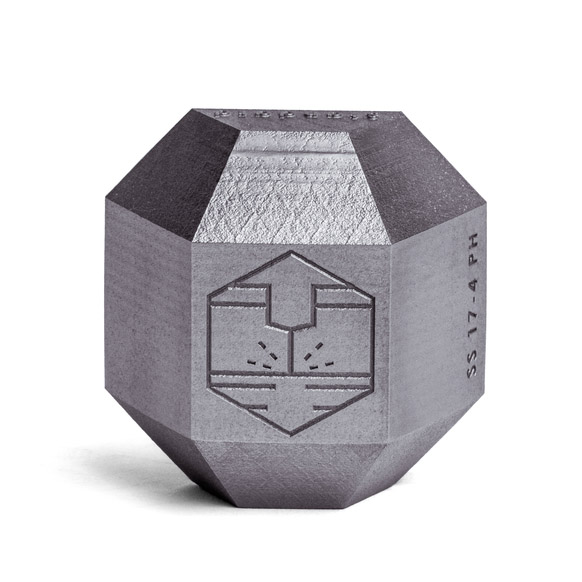

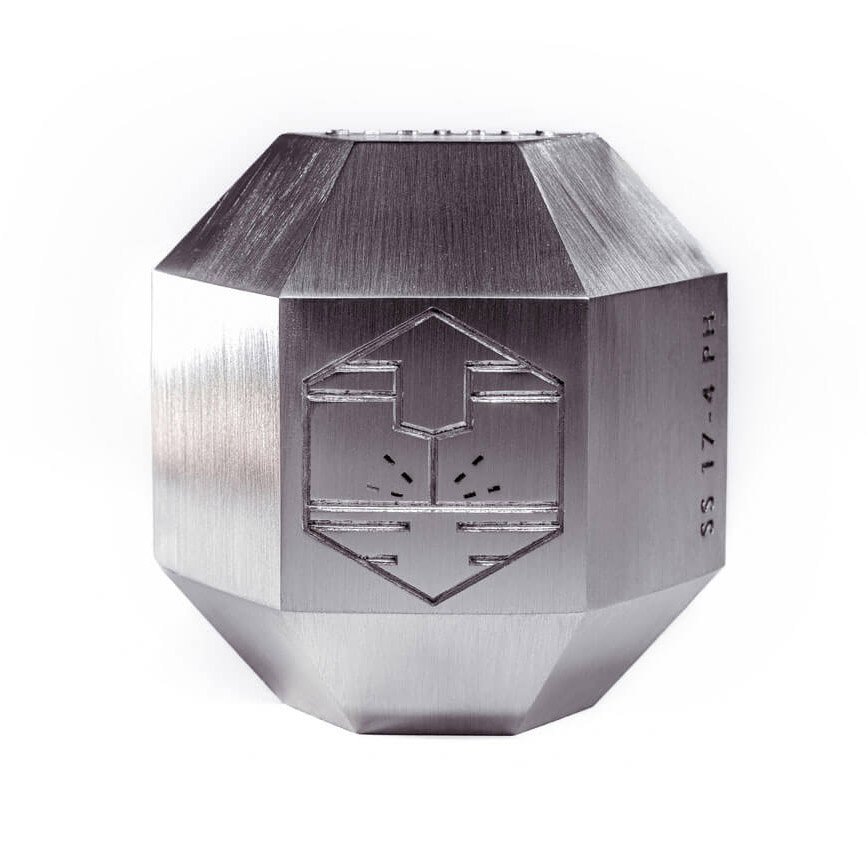

Stainless Steel 17-4PH

Machanical Properties Overview

| Condition | Yield Strength Rp0.2 (MPa) | Ultimate Tensile Strength RM (MPa) | Elongation at Break A (%) | Sample Count |

|---|---|---|---|---|

| As printed, vertical build | 930 – 970 | 1,020 – 1,070 | 14 – 17 | 150 |

| As printed, horizontal build | 920 – 960 | 990 – 1,040 | 15 – 18 | 60 |

| Heat treated, vertical build | 1,220 – 1,260 | 1,340 – 1,390 | 9 – 12 | 150 |

| Heat treated, horizontal build | 1,190 – 1,230 | 1,320 – 1,370 | 9 – 12 | 60 |

-

Maximum pore size: typically under 110 µm

-

Measured porosity: around 0.014% (based on 60 samples)

Mechanical tests conducted following DIN EN ISO 6892-1 B10 standards. The listed values are average ranges and can vary due to factors like build orientation, platform temperature, heat input, and part geometry. The manufacturing process in this case used a minimum layer exposure time of 40 seconds.

Heat Treatment Procedure (in Argon atmosphere):

-

Solution annealing at 1,040 °C (±15 °C) for 30 minutes, followed by air cooling below 32 °C.

-

Aging treatment at 460 °C for 1 hour, then air cooling under 32 °C.

Main Advantages

Stainless Steel 254

Machanical Properties Overview

| Condition | Yield Strength Rp0.2 (MPa) | Ultimate Tensile Strength RM (MPa) | Elongation at Break A (%) | Sample Count |

|---|---|---|---|---|

| As printed, vertical build | 420 – 460 | 690 – 740 | 35 – 45 | 150 |

| As printed, horizontal build | 400 – 450 | 670 – 720 | 36 – 46 | 60 |

| Solution annealed, vertical | 400 – 440 | 650 – 700 | 40 – 50 | 150 |

| Solution annealed, horizontal | 380 – 430 | 630 – 680 | 42 – 52 | 60 |

-

Maximum pore size: typically below 80 µm

-

Measured porosity: approx. 0.015% (based on 60 samples)

Mechanical tests performed according to DIN EN ISO 6892-1 B10. Values represent typical ranges and may vary depending on build orientation, laser parameters, part geometry, and thermal history during production. For these datasets, a minimum layer exposure time of around 40 seconds was employed.

Heat Treatment Details (in Argon atmosphere):

-

Solution annealing at ~1,150 °C (±15 °C) for 30–60 minutes, followed by rapid water quenching.

Main Advantages

Stainless Steel 316L

Machanical Properties Overview

| Condition | Yield Strength Rp0.2 (MPa) | Ultimate Tensile Strength RM (MPa) | Elongation at Break A (%) | Sample Count |

|---|---|---|---|---|

| As printed, vertical build | 480 – 510 | 600 – 650 | 30 – 35 | 150 |

| As printed, horizontal build | 460 – 500 | 590 – 640 | 32 – 37 | 60 |

| Stress relieved, vertical | 470 – 500 | 590 – 630 | 28 – 33 | 150 |

| Stress relieved, horizontal | 450 – 480 | 580 – 620 | 30 – 35 | 60 |

-

Maximum pore size: typically under 80 µm

-

Measured porosity: approx. 0.02% (based on 60 samples)

Mechanical tests were performed in line with DIN EN ISO 6892-1 B10 protocols. The values represent typical averages and can be influenced by parameters such as build orientation, platform heating, part geometry, and scan strategies. For this production, a minimum layer exposure time of around 40 seconds was maintained.

Heat Treatment Details (in Argon atmosphere):

-

Stress relief annealing at approximately 900 °C for 1–2 hours, followed by air cooling below 40 °C.

Main Advantages

Stainless Steel PH1

Machanical Properties Overview

| Condition | Yield Strength Rp0.2 (MPa) | Ultimate Tensile Strength RM (MPa) | Elongation at Break A (%) | Sample Count |

|---|---|---|---|---|

| As printed, vertical build | 1,200 – 1,300 | 1,350 – 1,450 | 12 – 15 | 150 |

| As printed, horizontal build | 1,180 – 1,280 | 1,330 – 1,430 | 13 – 16 | 60 |

| Heat treated, vertical build | 1,300 – 1,400 | 1,400 – 1,500 | 11 – 14 | 150 |

| Heat treated, horizontal build | 1,280 – 1,380 | 1,380 – 1,480 | 12 – 15 | 60 |

-

Maximum pore size: generally below 100 µm

-

Measured porosity: approx. 0.015% (based on 60 samples)

Mechanical tests performed in compliance with DIN EN ISO 6892-1 B10. Reported values are typical ranges and can vary depending on build orientation, part geometry, scan strategies, and thermal conditions during production. In this dataset, a minimum layer exposure time of around 40 seconds was applied.

Heat Treatment Details (in Argon atmosphere):

-

Solution annealing at ~1,040 °C (±15 °C) for 30 minutes, followed by air cooling under 32 °C.

-

Aging process at 480–500 °C for 1–2 hours, then air cooling below 32 °C.

Main Advantages

Stainless Steel CX

Machanical Properties Overview

| Condition | Yield Strength Rp0.2 (MPa) | Ultimate Tensile Strength RM (MPa) | Elongation at Break A (%) | Sample Count |

|---|---|---|---|---|

| As printed, vertical build | 1,600 – 1,680 | 1,700 – 1,780 | 5 – 7 | 150 |

| As printed, horizontal build | 1,580 – 1,650 | 1,680 – 1,760 | 5 – 8 | 60 |

| Heat treated, vertical build | 1,650 – 1,720 | 1,720 – 1,800 | 5 – 7 | 150 |

| Heat treated, horizontal build | 1,630 – 1,700 | 1,700 – 1,780 | 6 – 8 | 60 |

-

Maximum pore size: typically below 90 µm

-

Measured porosity: approx. 0.010% (based on 60 samples)

Mechanical tests conducted according to DIN EN ISO 6892-1 B10. All values represent typical ranges and can fluctuate based on build orientation, heat input, part geometry, and thermal management during printing. For this dataset, a minimum layer exposure time of around 40 seconds was used.

Heat Treatment Details (in Argon atmosphere):

-

Solution annealing at ~1,040 °C (±15 °C) for 30 minutes, followed by air cooling under 32 °C.

-

Aging heat treatment at 480–500 °C for 1–2 hours, then air cooling below 32 °C.

Main Advantages

Automotive

Aerospace

Medical

Energy

Frequently Asked Questions

Yes. Upon request, we can provide material certificates, test reports (e.g. tensile strength, porosity), and conformity to standards like ASTM, EN, or ISO. Certifications vary by material and application.

We accept standard 3D model file types such as STL, STEP, IGES, and 3MF. For best results, provide a high-resolution file and specify any critical tolerances, surface finishes, or post-processing needs.

It depends on the alloy. Austenitic grades like 316L generally do not require heat treatment for corrosion resistance, though stress relief can improve mechanical properties. Precipitation-hardening steels (e.g., 17-4PH, PH1, CX) need solution annealing and aging to reach full strength and hardness.