SPI Surface Finish Service

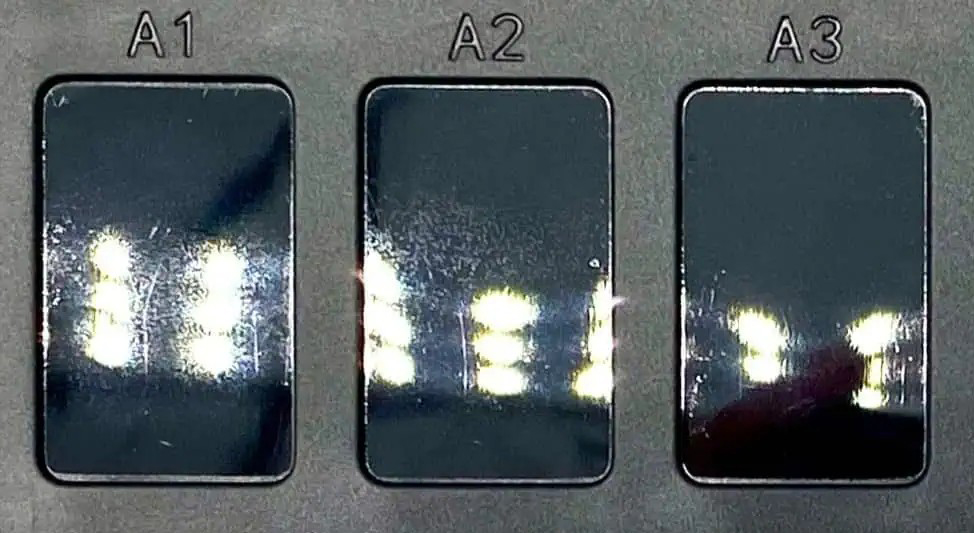

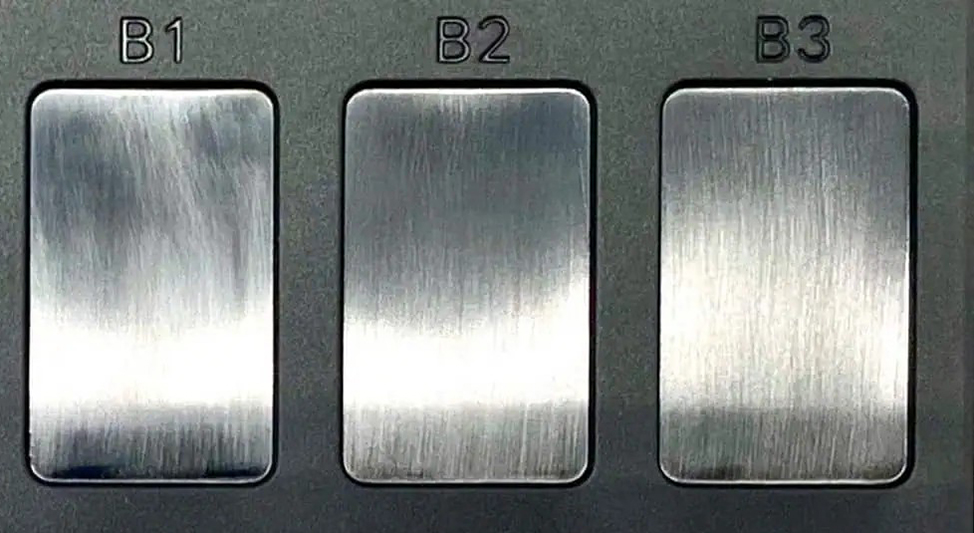

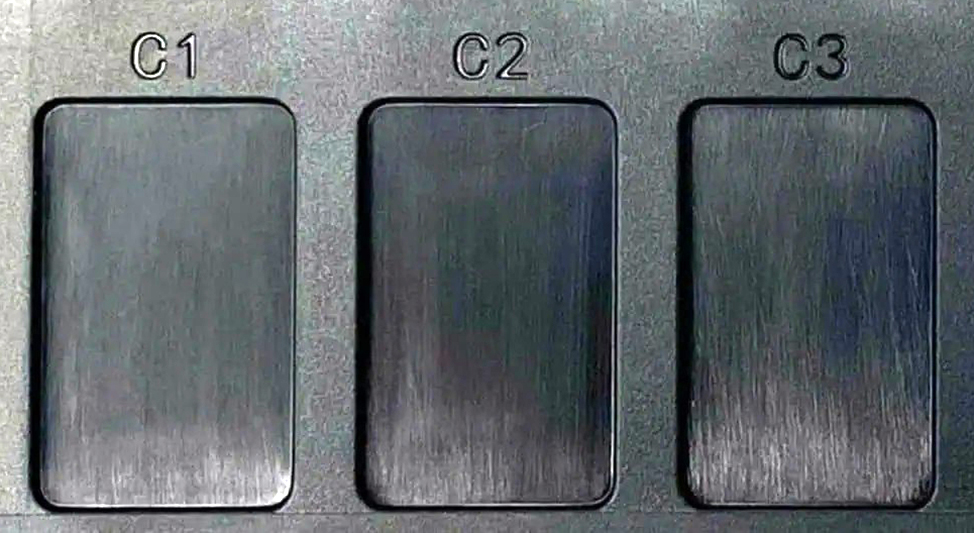

SPI Surface Finish is a set of widely recognized industry standards developed by the Society of the Plastics Industry (SPI) in the United States, specifically designed to define the surface smoothness and texture of injection-molded plastic parts. This standard includes 12 grades from A1 to D3, covering everything from ultra-smooth, high-gloss surfaces (such as the mirror-like effect of grade A1) to rough, textured surfaces (such as the heavy texture of grade D3), providing a clear reference for the surface quality of plastic parts with different requirements.

It is worth noting that achieving these surface effects is inseparable from the precise processing of metal molds – the mold surfaces are processed through techniques such as diamond polishing, sandpaper grinding, stone grinding, and sandblasting, and finally, the surface state of the mold is accurately “replicated” onto the plastic parts during injection molding. Therefore, SPI Surface Finish essentially measures the surface quality of plastic parts, but the processing technology of the mold is a key prerequisite for meeting this standard, providing reliable consistency guarantees for the appearance design and functional realization of plastic products.

However, SPI Surface Finish usually only involves smoothness and roughness. If your project need to achieve a specific surface effect for your parts (such as coating, coloring, etc.), then a post-surface treatment is required. Our team is equipped with experienced engineers who are capable of customizing surface treatments tailored to your project, whether it’s custom-level SPI mold surface treatment, other post-surface treatment or combined.

Our SPI Surface Finishing Services

SPI vs. VDI: Key Differences

VDI (Verein Deutscher Ingenieure, or German Association of Engineers) surface finish standards focus on quantifying surface roughness and texture through numerical ratings (typically VDI 18 to VDI 60), with higher numbers indicating coarser surfaces. Unlike SPI, which emphasizes aesthetic and functional categorization (glossy, matte, etc.) tied to mold polishing techniques, VDI provides a standardized scale based on measured roughness parameters, making it widely used in industrial manufacturing for specifying texture uniformity, especially in automotive and mechanical components.

| Feature | SPI Surface Finish | VDI 3400 Finish |

|---|---|---|

| Focus | Aesthetics (gloss, smoothness) | Functionality (texture, grip) |

| Grades | 12 grades (A1-D3, alphanumeric) | 45 grades (0-45, numeric) |

| Finishing Methods | Diamond buffing, grit paper, stone abrasives, dry blasting | EDM machining, chemical etching, dry blasting |

| Regional Use | Widely used in the Americas | Predominantly used in Europe |

| Best For | High-gloss, visually critical parts | Textured, functional parts (grip, adhesion) |

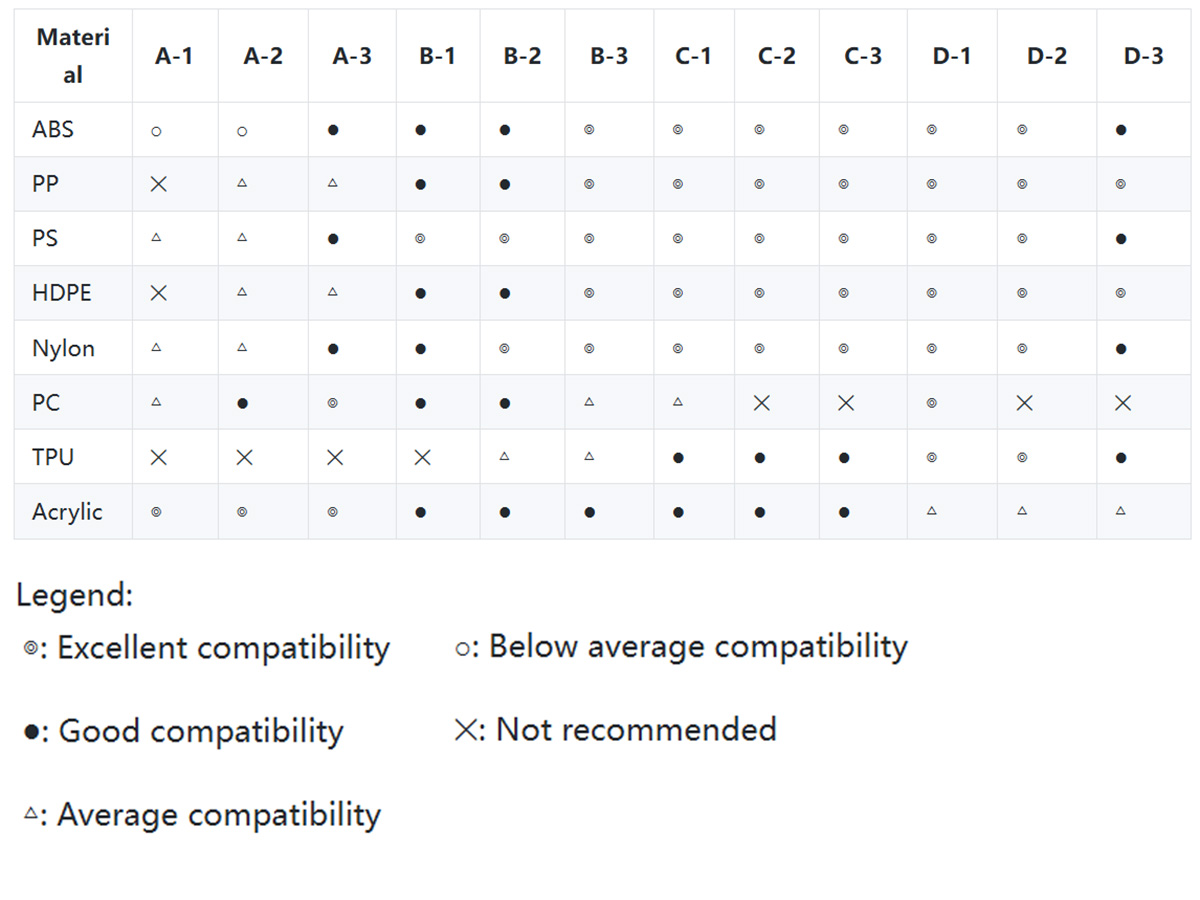

SPI Surface Finish Grades: Recommended Plastic Materials & Applications

| SPI Finish Category | Key Grades | Best-Performing Materials | Suitable Materials | Not Recommended Materials | Typical Applications |

|---|---|---|---|---|---|

| Glossy (A Series) | A1-A3 | Acrylic (Excellent across all grades) | ABS (A3: Good), PC (A3: Excellent), PS (A3: Good), Nylon (A3: Good) | PP (A1), HDPE (A1), TPU (all) | Lenses, mirrors, clear packaging, high-gloss casings |

| Semi-Glossy (B Series) | B1-B3 | Polystyrene (Excellent across all grades) | ABS (B3: Excellent), PP (B3: Excellent), HDPE (B3: Excellent), Nylon (B3: Excellent) | TPU (B1) | Appliance panels, clips, medium-shine trims |

| Matte (C Series) | C1-C3 | ABS, PP, PS, HDPE (Excellent across all grades) | Acrylic (Good), TPU (Good) | PC (C2-C3) | Laptop frames, keyboards, fingerprint-resistant parts |

| Textured (D Series) | D1-D3 | PP, HDPE (Excellent across all grades) | ABS (D1-D2: Excellent), PS (D1-D2: Excellent), TPU (Good) | PC (D2-D3) | Tool handles, grips, rugged industrial parts |

SPI Grade and Applicable Materials

Frequently Asked Questions

In brief, it can be understood as follows: SPI focuses on the smoothness of the surface, while VDI focuses on the roughness of the surface.

SPI focuses on aesthetic and functional categorization for plastic parts, with 12 grades (A1-D3) defining finishes like glossy, matte, or textured, tied to specific mold polishing techniques. VDI (German Association of Engineers) uses a numerical scale (18-60) to quantify surface roughness, emphasizing measurable texture uniformity (higher numbers = coarser surfaces).

SPI is design-centric, ideal for consumer products where appearance matters; VDI is industrial-focused, used in mechanical/automotive parts where precise roughness metrics drive performance (e.g., friction, wear resistance).

SPI/VDI finishes are mold-based—achieved by machining or polishing the mold itself, so the surface texture is replicated directly onto the part during injection molding. This ensures consistency across all parts and eliminates secondary steps but is limited to textures achievable through mold tooling. Post-surface treatments (e.g., painting, plating, anodizing, or laser etching) are applied after molding, enabling effects SPI/VDI can’t replicate—such as color layering, conductive coatings, or intricate patterns. Use SPI/VDI for high-volume production where uniformity and cost-efficiency matter (e.g., consumer electronics). Choose post-treatments when unique aesthetics, functional coatings, or small-batch customization are needed (e.g., adding a metallic finish or chemical-resistant layer).

Material properties directly impact finish results: Acrylic excels in A-series gloss, PP performs well in D-series textures, while PC works best for mid-range grades. Notably, glass- or mineral-filled materials—though offering unique benefits like enhanced strength—require caution for parts with high aesthetic demands. These fillers can cause material streaks, making it difficult to distinguish between SPI grades even after polishing. While not all filled resins exhibit this issue, we recommend consulting our application engineers or requesting sample panels of your intended material to verify compatibility with your desired finish. Our material guidance ensures you select plastics (ABS, nylon, etc.) that optimize finish consistency and durability.

Yes. Although we focus on replicating standard SPI grades (A1 – D3), our professional capabilities enable us to customize unique surface treatment effects according to unique aesthetic or functional requirements. For instance, when a certain surface needs a certain degree of roughness that SPI cannot meet, we will first consider the replicable VDI standard; if the standard VDI also fails to meet the requirements, we can still specially customize the surface treatment according to the project requirements. With our own material knowledge and surface treatment matching technology, we can meet your specific design requirements.