Injection Molding Company for Solar Panel Parts

KingStar Mold’s Injection Molding Services

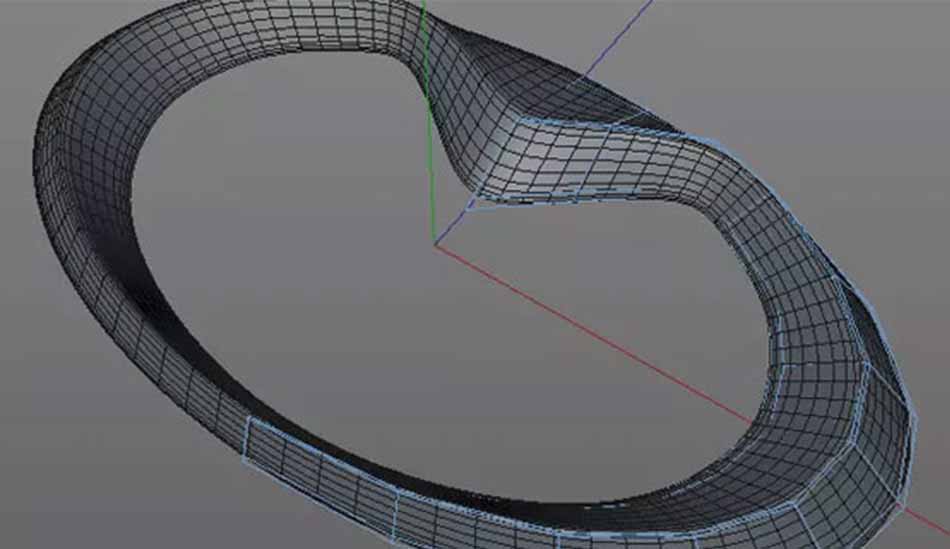

CAD Engineering

KingStar Mold offers advanced CAD engineering services to create precise 3D models and prototypes for solar panel parts. Our team utilizes cutting-edge CAD software to design and optimize components for enhanced performance and manufacturability.

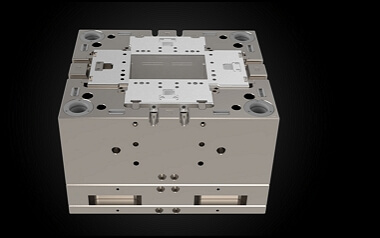

Mold Flow Analysis

Our mold flow analysis service simulates the injection molding process to identify potential defects and optimize design efficiency. By using state-of-the-art mold flow analysis, we ensure the perfect distribution of materials and prevent issues like warping and air pockets.

3D Printing

We use 3D printing technology to rapidly prototype and test solar panel parts before full-scale production. 3D printing allows for high-precision, complex designs, accelerating the development of solar panel components with reduced lead times.

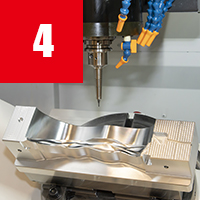

CNC Machining

KingStar Mold provides CNC machining services that produce high-precision, complex solar panel parts with tight tolerances. Our CNC machining capabilities ensure consistent quality and efficient production of metal and plastic components for the solar panel industry.

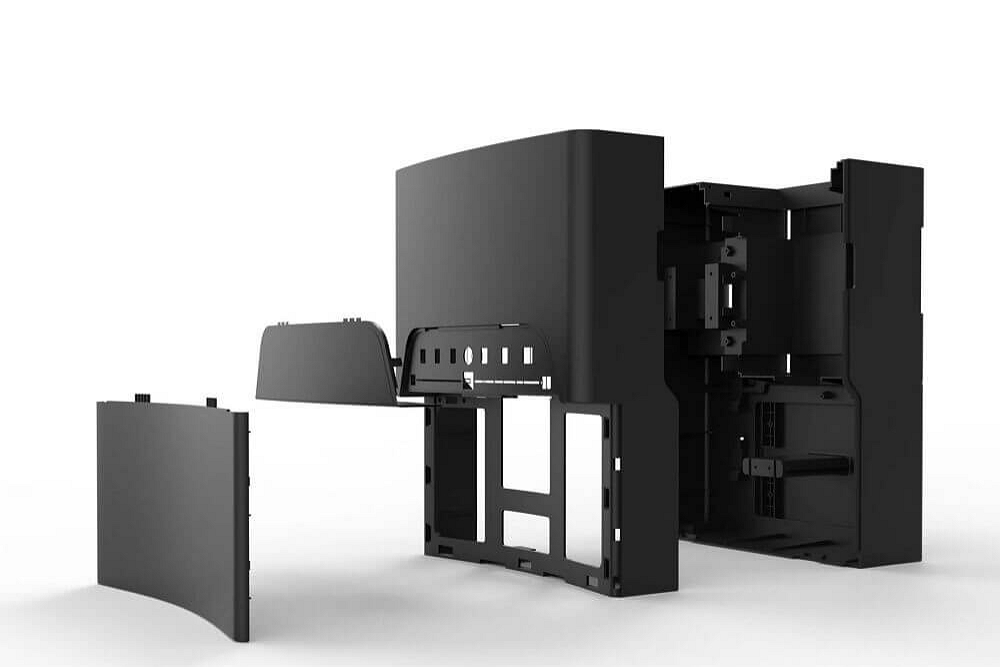

Injection Molding

Our injection molding services allow for the mass production of high-quality solar panel parts with complex shapes and fine details. We specialize in delivering fast and cost-effective solutions for producing durable, high-volume solar panel components.

Surface Finishing & Assembly

We offer a range of surface finishing services, including polishing, coating, and more, to enhance the performance of solar panel parts. Our assembly services ensure that all components are accurately assembled and ready for integration into the final solar panel design.

Orders Workflow

Initial Consultation & Design Review

We begin by discussing your project’s goals and reviewing the design to ensure it’s optimized for the specific manufacturing process. At this stage, we suggest improvements or adjustments to enhance efficiency, functionality, and manufacturability.

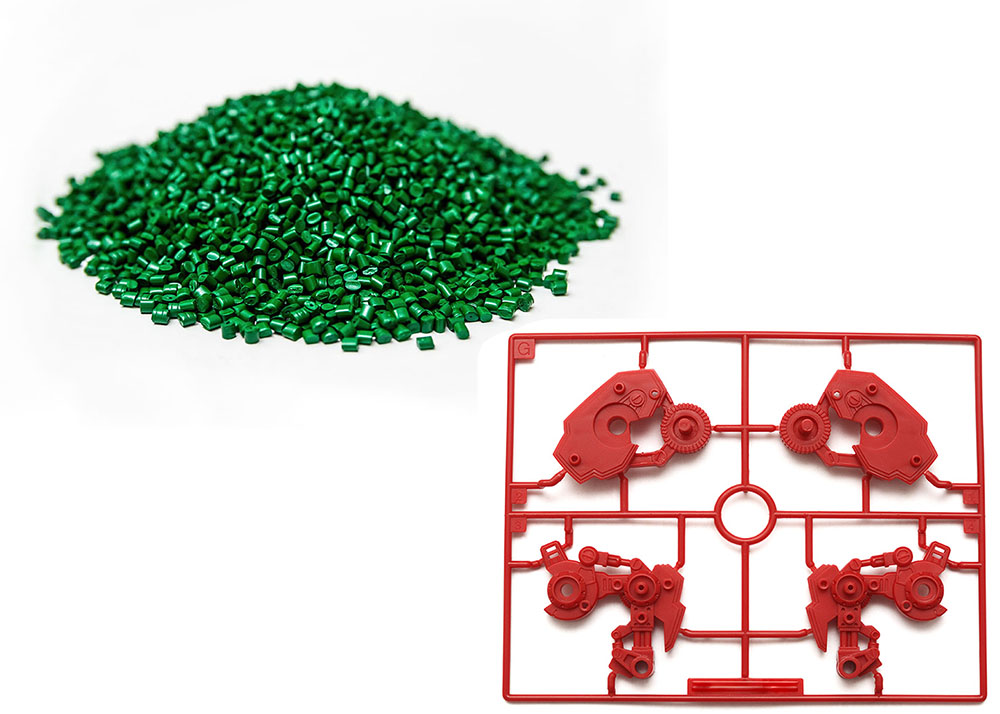

Material Selection

Our experts assist in selecting the right materials for your product based on performance requirements and compatibility with the manufacturing process. The correct material choice ensures durability, cost-effectiveness, and the desired product functionality.

Design & Engineering

Using advanced CAD and simulation tools, we develop a custom design for your project. This step ensures precise details and identifies potential challenges early in the process, optimizing the design for efficient manufacturing.

Prototyping & Sample Testing

A prototype or sample is created to verify design accuracy, functionality, and performance. Rigorous testing is conducted to ensure the product meets your specifications before moving into full-scale production.

Production Setup & Initial Production

We set up the required machines, molds, or tools for the manufacturing process. The initial production run is performed to confirm the setup, assess quality, and fine-tune settings for optimal results.

Final Production & Quality Control

After final approval, we proceed with full-scale production, ensuring continuous quality checks. Comprehensive inspections at each stage ensure that every part meets the highest standards before delivery.

Why Choose Us

We Believe You Will Choose Us Again

Only companies with extensive market experience and a deep understanding of customer needs can offer the best service.

Skilled

High-precision production equipment, skilled production staff, and guaranteed delivery times.

Experienced

Over ten years of industry experience, with a mature quotation system and technical support.

Thoughtful

Customized processing options that save time and effort, with active support throughout pre-sales and post-sales.

Equipped

Engineers review designs to identify and resolve potential issues, backed by advanced testing equipment.

Why Choose Injection Molding For Solar Panel Parts Manufacturing?

One key benefit of our injection molding technology is the rapid production of prototypes. By utilizing both 3D printers and CNC machines, we ensure your solar panel part prototypes are created in the shortest time frame possible.

We take pride in being able to produce over 600 set molds in a year. This has garnered us a reputation for being able to fulfill any order, no matter how big it is. No matter how large the scale of the order, we are more than capable of fulfilling it.

KingStar Mold always adheres to a high standard of control. We follow the strictest quality control, and any plastic parts that we distribute, are tested by our specialized team of experts. Rest assured, any product you get from KingStar Mold is of the best quality possible.

By utilizing injection molding for your components of solar panels, you are assured that you will be saving money. Just one injection mold could be used to create a myriad of parts. This means that you will save on both material and production costs.

Over 10 Years of Experience as an Injection Mold Builder & Accessories of Plastic Solar Manufacturer

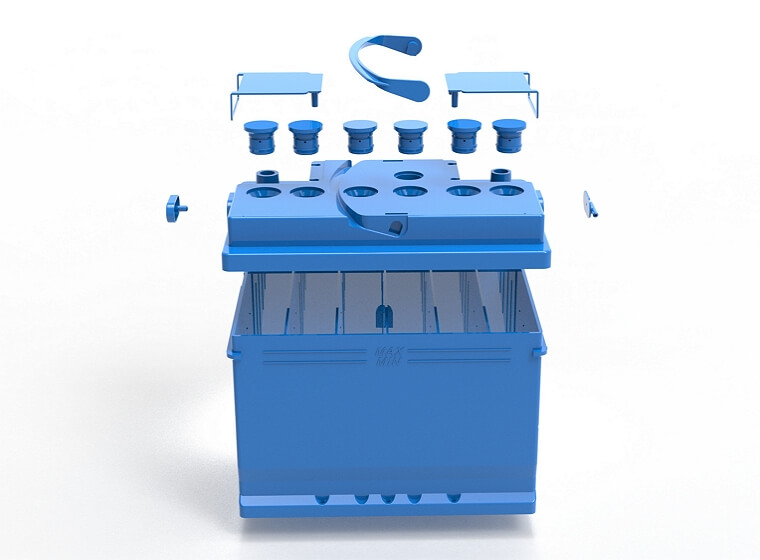

Battery Box

Connector

Double Cable Entry Gland

Previous Projects of Injection-Molded Plastic Solar Panel Parts

KingStar Mold is a leading and trusted manufacturer specializing in molds for plastic injection molded products, including solar panel components. With the production of 900-1000 molds annually, we possess extensive capabilities in manufacturing a wide variety of plastic parts.

We are highly regarded for delivering comprehensive, one-stop solutions for all plastic solar panel parts needs, including plastic part design, mold design, and injection molding. In addition to solar panel components, we also produce injection molded plastic products for industries such as home appliances, furniture, automotive, crate molds, and baby products.

Absolutely, our parts are designed for both grid-connected and off-grid solar systems, providing reliable performance in various setups.

Yes, our parts are designed to withstand UV exposure, high temperatures, and moisture, ensuring long-lasting performance.

We conduct rigorous quality control checks throughout the manufacturing process to ensure that all parts meet industry standards.

Lead time varies based on order complexity, but we strive for efficient production and typically deliver within a few weeks.

Yes, we offer customization options to meet specific requirements for sizes, shapes, and material preferences.

We use high-quality materials like PBT, PVC, ABS, and POM to ensure durability and reliability in harsh environmental conditions.

Yes, we provide comprehensive after-sales support to ensure the long-term success and functionality of your solar system.

Yes, all our parts meet or exceed international industry standards for quality and performance.

Yes, we are capable of managing bulk orders and offer competitive pricing for large-scale manufacturing.

Our parts are designed for durability, efficiency, and ease of installation, contributing to the overall performance and longevity of solar systems.

We provide technical support and installation guidance to ensure your solar system is set up correctly and efficiently.

Simply contact our sales team or visit our website to discuss your requirements and place an order.