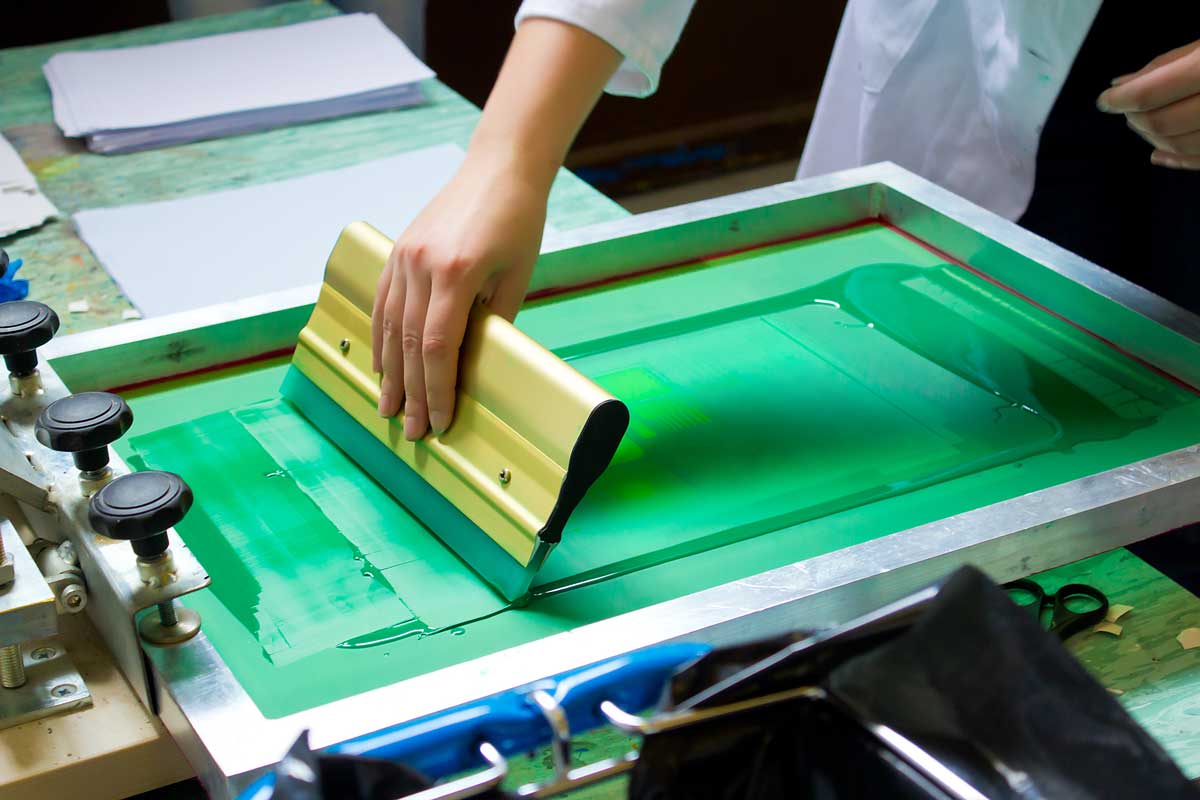

What is Silk Screening?

Silk screening, also known as screen printing, is a dynamic printing technique that brings your designs to life with exceptional clarity and vibrancy. This method involves creating a stencil on a mesh screen, allowing ink to be pressed through onto various surfaces such as textiles, plastics, and metals. With its ability to produce bold colors and intricate details, silk screening is perfect for a wide range of applications, including custom apparel, promotional items, and artwork. Whether you’re looking to promote your brand, design unique merchandise, or create personalized gifts, silk screening offers a versatile solution that meets your creative needs.

At KingStar Mold, we take pride in our state-of-the-art silk screening process, which combines traditional craftsmanship with modern technology. Our team of skilled professionals is dedicated to ensuring that each print meets the highest quality standards and accurately represents your vision. With our commitment to detail and color accuracy, we guarantee that your products will not only look stunning but also stand the test of time. Let us help you make a lasting impression with our exceptional silk screening services!

Showcase of Screen Printed Products

Digital Screen

Medal

Thermal Bottle

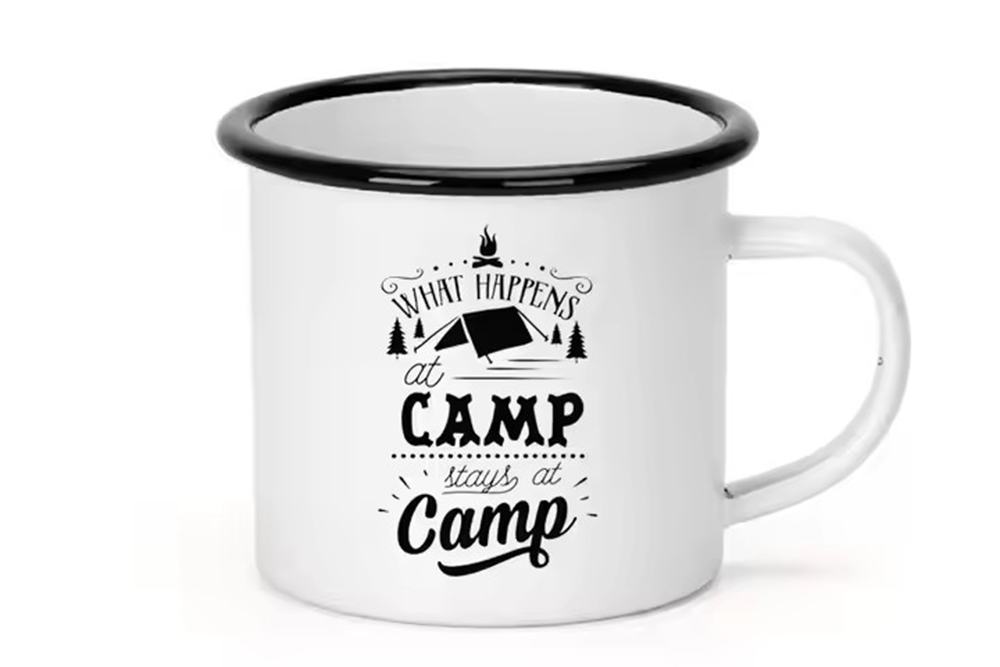

Metal Mug

Various Options for Silk Screening

| Spot Color Printing | Uses solid, opaque inks to print specific colors directly onto the substrate, ideal for limited color palettes and vibrant designs. |

| Process Color Printing | Combines four colors (CMYK) to create a wide range of hues, suitable for complex color gradients and photographic images. |

| Halftone Printing | Creates color gradients by varying the size and spacing of dots, often used for photographs to add depth and dimension. |

| Discharge Printing | Utilizes water-based ink that removes dye from fabric, offering a soft feel and a vintage appearance, especially on dark garments. |

| Water-Based Ink Printing | Eco-friendly inks that are absorbed into the fabric, providing a softer feel and breathability in prints. |

| Plastisol Printing | Commonly used for vibrant colors and durability, this ink becomes solid when heated, resulting in long-lasting prints. |

| Metallic and Specialty Inks | Includes reflective, glittery, and fluorescent inks that add unique visual effects to the prints for standout designs. |

| Sleeve or Tag Printing | Involves printing on the sleeves or tags of clothing items, utilizing special screens to accommodate unique shapes for high-quality results. |

KingStar Mold’s Silk Screening Working Process

Advantages of Silk Screening Your Product

Enhanced Durability

The inks used in silk screening, especially plastisol inks, create durable prints that can withstand multiple washes and wear without fading or cracking. This longevity makes silk screening a cost-effective option for items requiring repeated use.

Vibrant Color Quality

Versatility

Customizability

Frequently Asked Questions

Silk screening can be made more environmentally friendly by using water-based inks instead of traditional solvent-based inks. At KingStar Mold, we offer options that prioritize both quality and sustainability to meet your eco-conscious needs.

Absolutely! We encourage our customers to bring their own artwork and designs for silk screening. Whether you have a logo, graphic design, or custom artwork, you can submit it in high-resolution formats such as AI, EPS, or high-quality PNG and JPG files. This capability allows you to truly personalize your products, ensuring they align perfectly with your brand identity or personal vision.

At KingStar Mold, we understand the importance of protecting your creative assets. We treat all customer designs as confidential and recognize them as your intellectual property. Your artwork will never be used for any purpose outside of your specific order without your explicit permission. Our commitment to safeguarding your designs ensures that your unique concepts remain secure and exclusively yours throughout the entire printing process. If you have any questions about the submission process or design requirements, our team is here to assist you every step of the way!

The production time for silk screening varies based on order size and complexity. Generally, orders can be completed within 5 to 14 business days, but we will provide an estimated timeline when you place your order.