True Silicone Overview

True Silicone 3D printing utilizes advanced additive manufacturing techniques to produce high-quality, fully crosslinked silicone parts without molds. This process enables the creation of flexible, biocompatible, and highly durable components with intricate geometries that traditional methods struggle to achieve. Ideal for applications in medical, automotive, and consumer goods industries, True Silicone offers superior performance in demanding environments.

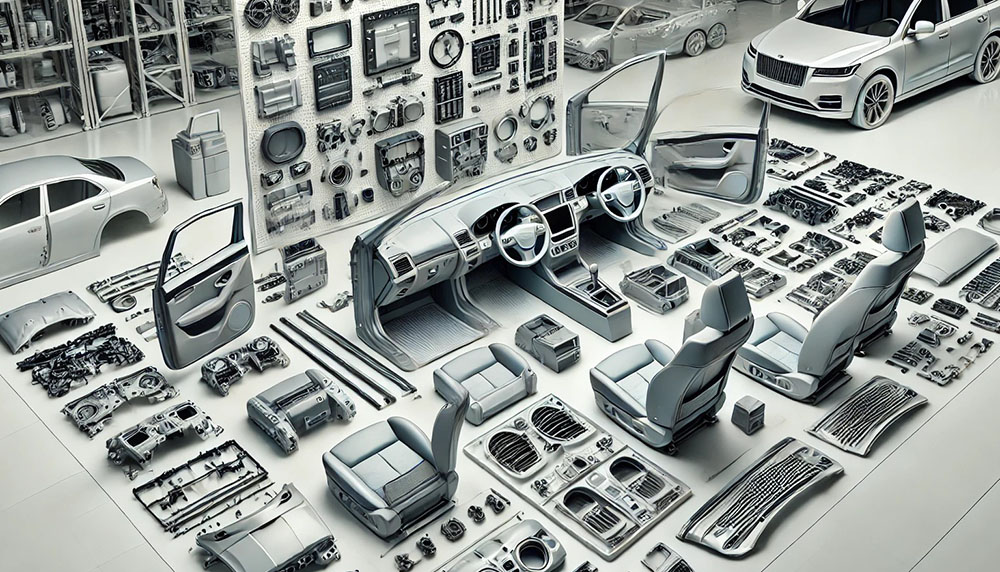

Automotive Components

Consumer Products

Industrial & Robotics

Medical & Healthcare

Properties of Silicone 3D Printing

| Property | Test Method | Value(US | Metric) | ||

|---|---|---|---|---|

| Shore-A Hardness | ISO 7619-1 | 60 | 50 | 35 |

| Tensile Strength | ISO 37 Type 4 | 1,160 psi | 8 MPa | 1,233 psi | 8.5 MPa | 1,450 psi | 10 MPa |

| Density | ISO 1183-1 A | 2.19 lb/in³ | 1.13 g/cm3 | 2.15 lb/in³ | 1.11 g/cm3 | 2.10 lb/in³ | 1.08 g/cm3 |

| Tear Strength | ASTM D624 Type C | 80 lbf/in. 14 N/mm | 51.4 lbf/in. | 9 N/mm | 60 lbf/in. | 10.5 N/mm |

| Elongation at Break | ISO 37 Type 4 | 320% | 550% | 950% |

Comparison Between True Silicone and Other Common Elastomers

30-35A (Soft) material comparison

60-70A (Harder) material comparison

Design Considerations for 3D-Printed Silicone Parts

To achieve high-quality, manufacturable silicone parts, consider the following guidelines:

General Design Guidelines:

| Specification | Imperial (in.) | Metric (mm) |

|---|---|---|

| Maximum Part Size | 4.7 x 2.8 x 3.9 | 119.4 x 71.1 x 99.1 |

| Minimum Feature Size | X-Y: 0.01, Z: 0.016 | X-Y: 0.25, Z: 0.40 |

| Minimum Wall Thickness | Supported: 0.012, Unsupported: 0.02 | Supported: 0.30, Unsupported: 0.50 |

| Dimensional Tolerance | ±0.004 for first inch + 0.1% | ±0.1 for first inch + 0.1% |

Unlike traditional molding, 3D-printed silicone allows for complex geometries without tooling costs, making it ideal for prototypes and custom designs.

Yes, medical-grade silicone is available for applications such as prosthetics, wearables, and surgical models.

Our process supports parts up to approximately 4.7 x 2.8 x 3.9 inches (119.38 x 71.12 x 99.06 mm).

We use true silicone elastomers with varying shore hardness, offering flexibility, durability, and biocompatibility.

Silicone 3D printing is best suited for low-to-medium production volumes and may have design constraints related to wall thickness and feature size.

Yes, we offer cleaning, surface treatment, and bonding solutions to enhance the performance and appearance of printed parts.

We follow strict process controls, ensuring consistency in material properties, accuracy, and surface finish.

KingStar Mold offers high-precision silicone 3D printing with fine detail resolution, suitable for prototypes and low-volume production.