High-Quality Molding & Precision Engineering

Custom Manufacturing Solutions for Your Plastic and Metal Needs

At KingstarMold, we provide high-quality custom manufacturing solutions tailored to your needs and budget. Our diverse services ensure precision parts that are both cost-effective and efficient.

With a state-of-the-art production facility and optimized manufacturing processes, we serve various industries, including automotive, aerospace, consumer products, lighting, and electronics. Our dedication to quality and customer satisfaction means you can count on us for outstanding service and top-tier products.

Don’t compromise on your custom manufacturing needs. Contact us today to discover how First Mold can help turn your ideas into reality.

KingStar’s Custom Manufacturing Services

Enjoy various manufacturing processes, flexible order volumes, and experienced engineers. From prototyping to custom part mass production, we deliver quality with good price. Scale your production with KingStar now!

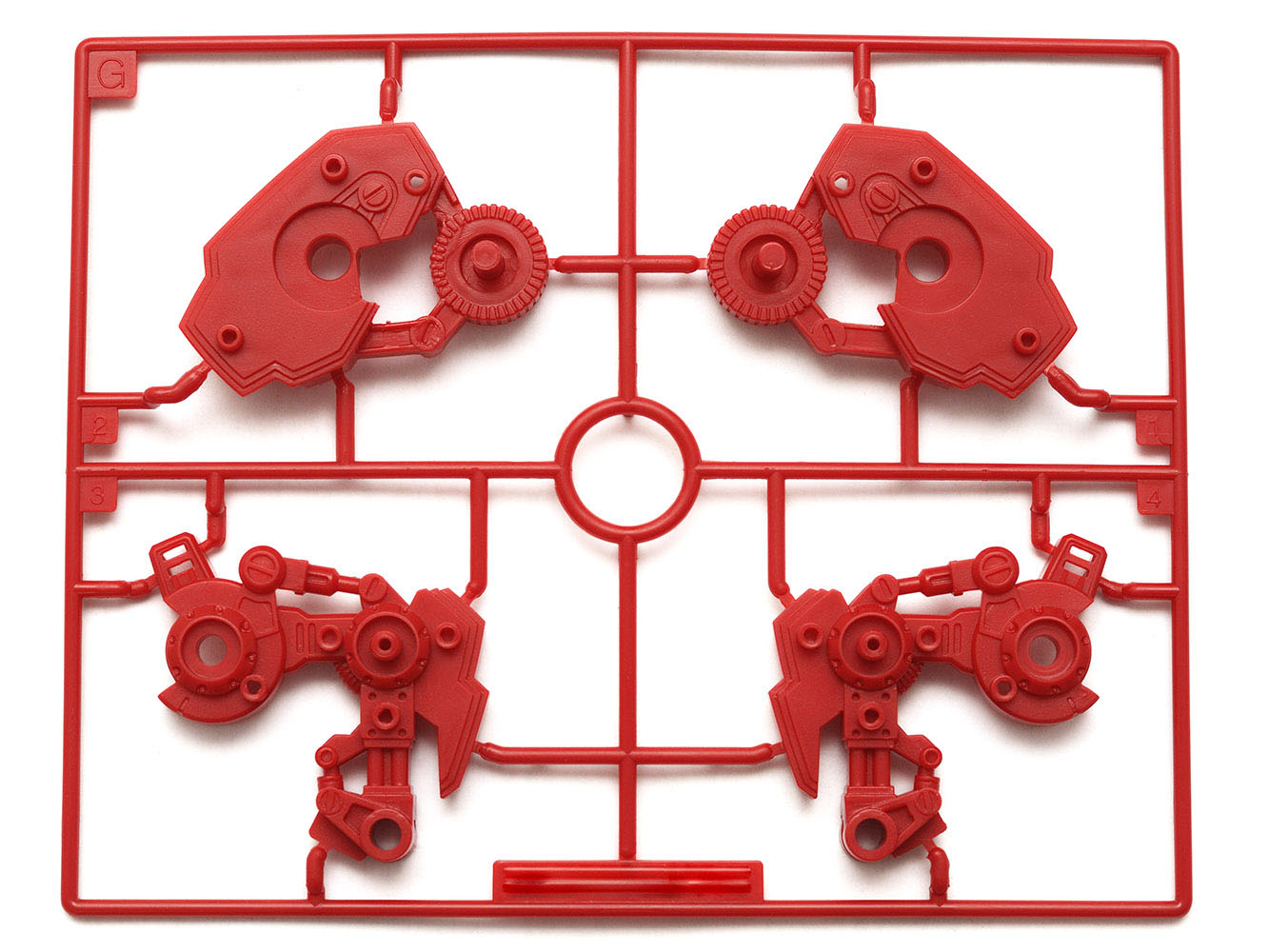

Injection Molding

KingStar offers comprehensive services of injection molding, producing a wide range of parts through two-shot molding, overmolding and custom molding techniques.

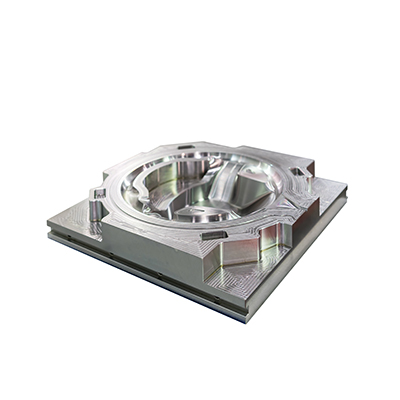

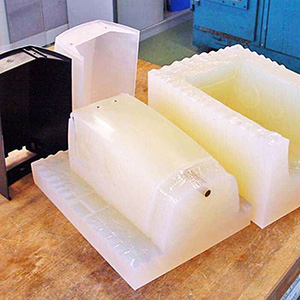

Mold Making

At KingstarMold, we develop and produce precision injection molds, die casting molds, stack molds, liquid silicone rubber(LSR) mold and two-color molds using state-of-the-art equipment.

Sheet Metal Fabrication

We provide precise sheet metal fabrication solutions, offering custom-made parts with exceptional durability, tailored to meet the specific requirements of your project.

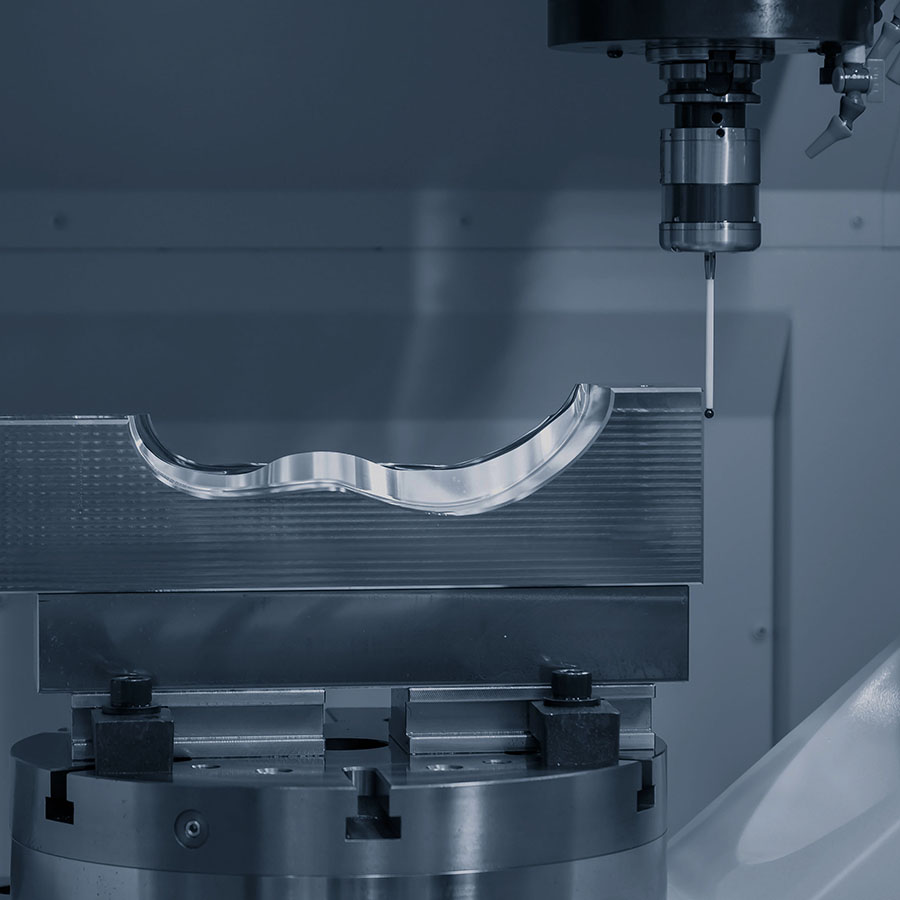

CNC Machining

CNC milling, turning and EDM. Our CNC machining includes both 4-axis and 5-axis capabilities, with a focus on optimizing equipment arrangement to enhance efficiency. Faster, easier and cheaper.

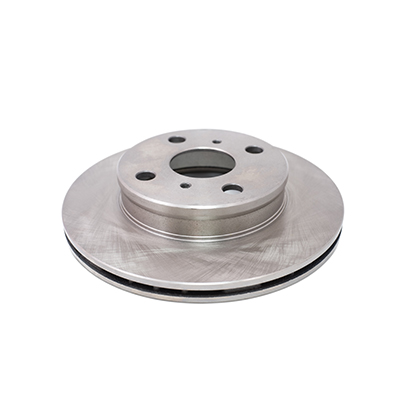

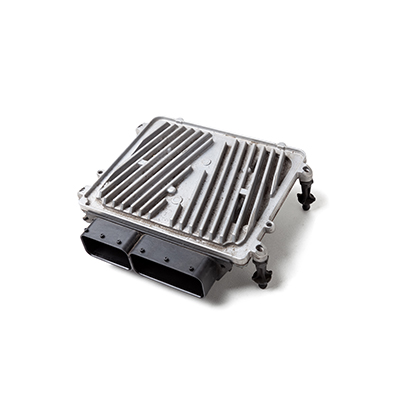

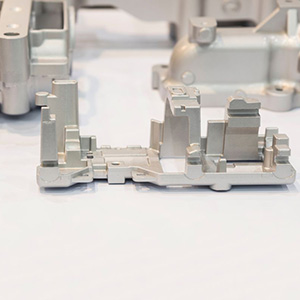

Die Casting

Our die casting service ensures high-precision, high-volume production of metal parts with excellent surface finishes and tight tolerances.

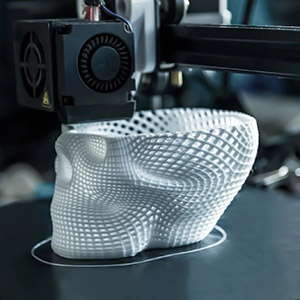

Vacuum Casting

With vacuum casting, we produce high-quality, detailed prototypes and low-volume parts with exceptional accuracy.

Who Can Benefit From Our Manufacturing Services?

KingStar Mold offers a diverse range of manufacturing services, including rapid prototyping and mass production. Here’s how various groups can benefit:

- Startups and Innovators

Fast part creation and small-batch customization allow startups to conduct initial testing and multiple design iterations before scaling up production. With no strict minimum order quantities, ordering specific products is seamless.

- Small and Medium Enterprises (SMEs)

SMEs can enhance their manufacturing capabilities by accessing cost-effective solutions for small to medium-volume production of high-quality parts and components. Our precision manufacturing and mold-building services ensure that even the most complex designs are accurately replicated, helping SMEs stay competitive in their niches.

- Major Corporations

We support large corporations across industries such as automotive, aerospace, electronics, and consumer goods by providing high-volume production. Our investment in advanced machinery and techniques enables us to produce thousands of parts while maintaining consistent quality.

Whether you need small runs or high-volume production, KingstarMold is ready to help your company grow by delivering the reliability and expertise needed to bring your products to market.

Yes, our team provides design assistance, including Design for Manufacturing (DFM) services, to optimize your product designs for cost-effective and efficient production.

Lead times vary depending on the complexity of the project. For rapid prototyping, we offer fast turnaround times, and for full-scale production, we work with you to meet your deadlines.

Yes, we specialize in both low-volume and high-volume production. Whether you need a small batch or large-scale manufacturing, we have the capacity and flexibility to deliver.

We work with a variety of materials including metals, plastics, composites, and more. From CNC machining to injection molding, we handle different materials to meet your project’s requirements.

We provide services to industries such as automotive, medical, electronics, consumer goods, packaging, and more. Our experience covers a wide range of sectors, delivering high-quality, reliable parts.

We offer precision manufacturing services, including CNC machining, injection molding, mold building, 3D printing, and rapid tooling. Our expertise spans various industries, ensuring tailored solutions for every project.

To get a quote, simply contact us with your project details, including design files and requirements. Our team will review your specifications and provide a competitive and accurate quote based on your needs.

We provide various 3D printing services, including SLA, FDM, and SLS, tailored to meet the specific needs of your project, whether it’s for prototypes, small batches, or intricate designs.

We offer high-precision CNC machining for a wide range of materials, providing custom parts with tight tolerances. Our state-of-the-art machines can handle both simple and complex designs.

Absolutely! We specialize in custom mold building for injection molding, ensuring that your molds are designed to meet the specific needs of your parts, whether for prototyping or large-scale production.

Yes, we offer rapid prototyping to help you test and refine designs before full-scale production. Our 3D printing, CNC machining, and rapid tooling services are ideal for prototyping.

At KingStar Mold, quality is a top priority. We implement strict quality control processes, using advanced inspection tools and techniques to ensure each part meets your specifications.