Sandblasting is a technique that bridges the old and the new. Dating back to the early 1870s, its core idea – using a stream of abrasive material to clean or treat surfaces – has remained unchanged, even as the technology itself has evolved. Back then, and for decades after, people simply called it “sand blasting” or “air blasting”.

Nowadays, sandblasting technology is no longer merely used for cleaning. It is often employed as a pre-treatment step before surface treatment of steel structures (removing rust, oxide layers or old coatings to ensure better adhesion), but its applications go far beyond this. It is also widely used to enhance mechanical components, add decorative coatings, and even for creating precise etched patterns.

In this guide, as a leading custom manufacturing company, we’ll break down everything you need to know about sandblasting: how the workflow works, the key equipment involved, the different abrasives to choose from, and the most common ways it’s used across industries. Whether you’re new to the process or looking to refine your technique, this is your starting point.

1. Principles and Purposes

Sandblasting uses compressed air as its power source to propel abrasive materials—such as copper ore sand, quartz sand, carborundum, iron sand, and Hainan sand—at high speed in a focused jet onto the surface of a workpiece. The impact and cutting action of these abrasives alter the workpiece’s surface appearance or shape, leaving it with a controlled level of cleanliness and specific roughness. This process enhances the mechanical properties of the surface, improving the workpiece’s fatigue resistance, boosting adhesion with subsequent coatings, extending the coating’s durability, and even aiding in the smooth application and aesthetic finish of paints.

The purpose of sandblasting: The primary condition for ensuring that the coating can effectively protect steel components for a long time is that the coating must have a firm bond with the base material of the steel structure. This requires two conditions to be met: The gap between the coating and the base material should be less than 0.5 micrometers (equivalent to the sum of the diameters of three oxygen atoms) to ensure a firm bond; there must be a sufficient contact area between the coating and the base material surface. There is no better way to achieve this except for improving the roughness; one is to thoroughly remove impurities on the surface of the workpiece and expose the base material as much as possible; the other is to generate a certain degree of roughness on the surface to expand the actual surface area of the workpiece and increase the bonding force of the coating on the unit surface area of the workpiece.

2. Sandblasting Equipment

2.1 How to Choose the Right Sandblasting Equipment

a. Generally, the blasting effect depends largely on the workpiece material and the abrasive used. For different materials, you’ll need to pick abrasives ranging from aggressive metal types to milder resin-based ones. Additionally, choosing between dry blasting and wet blasting is a key consideration.

b. Production efficiency dictates the type of equipment. Based on your processing capacity, opt for automated blasting lines, semi-automatic systems, pressure-blast machines, or suction-blast machines.

c. Workpiece size determines the equipment specifications. Select a cabinet size that provides enough space to handle your parts comfortably during processing.

d. Compressed air requirements: Match the air compressor capacity to the equipment’s specifications, with a 20% buffer to extend the compressor’s service life.

2.2 Standard Equipment Diagram & Workflow

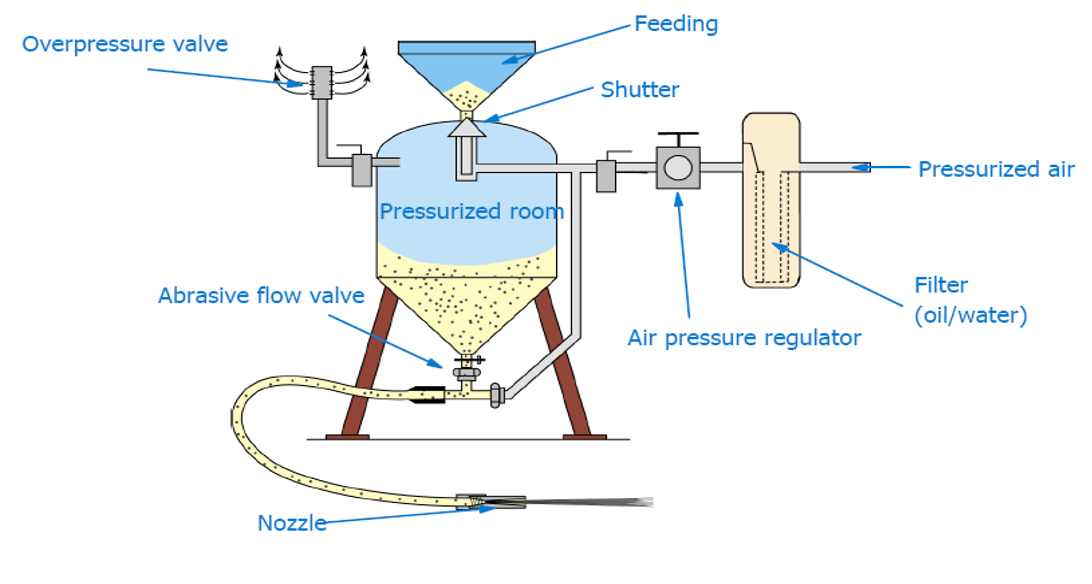

This chart illustrates the typical installation layout of a sandblasting equipment. The abrasive material is sent into the pressurized chamber through the feed port. The compressed air, which has been filtered by the oil/water filter to remove contaminants, enters the system. The pressure regulator controls the pressure, while the abrasive flow valve controls the flow of the abrasive material. The overpressure valve releases the excess pressure to ensure safety. Finally, the mixture of pressurized air and abrasive material is directed through the nozzle to perform the sandblasting operation.

However, it should be noted that this is only the most basic schematic illustration. In reality, there are various types of sandblasting equipment, and their structures are much more complex.

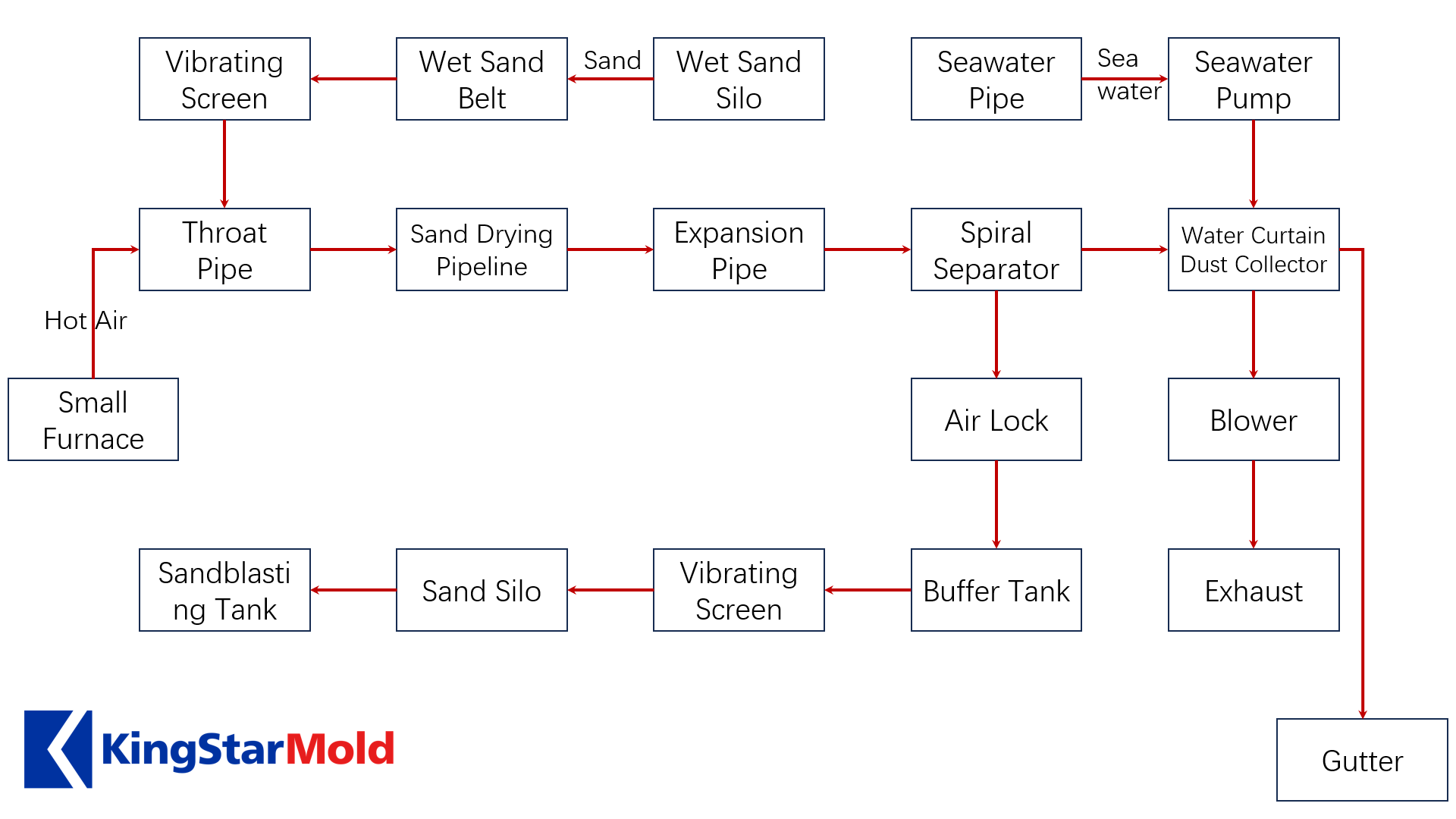

The above is the standard working procedure of the sandblasting machine. However, before officially starting the sandblasting process, material pre-treatment is required. Using an air flow drying equipment, the moisture, excessive solid particles and dust and other impurities in the sand are removed. The process is as follows:

Wet sand is conveyed via a belt to a vibrating screen, where stones and debris are removed. It then enters a throat, mixing with 250°C hot air from a small furnace. Driven by the negative pressure of a fan, the sand flows rapidly in a suspended state through the sand-drying pipeline for drying. After slowing down in an expander, it enters a cyclone separator. The separated dry sand passes through an air lock and buffer tank to a dry sand vibrating screen, which sifts out standard sand smaller than 5mm. This qualified sand is stored in a sand silo and supplied to the sandblasting tank for use.

Dust-laden hot air exiting the spiral separator is routed to a water film dust collector for purification before being discharged by an exhaust fan. Seawater, pressurized by a seawater pump, is split into two paths: one enters the water distribution pipe of the dust collector, spraying to form a uniform, enclosed water film; the other is injected through a sprinkler in the collector’s inlet pipe, creating an inverted cone-shaped water film. The seawater used for dust removal accumulates at the bottom of the collector and is directed into a drainage ditch via an outlet pipe.

2.3 Types of Sandblasters

Sandblasters are the most widely used products in abrasive jet applications. They are generally categorized into two main types: dry sandblasters and wet sandblasters. Dry sandblasters can be further divided into suction-type and pressure-fed models.

2.3.1 Suction-Type Dry Sandblasters

A complete suction-type dry sandblaster consists of six systems: structural system, media power system, pipeline system, dust collection system, control system, and auxiliary system.

It uses compressed air as its power source. The high-speed airflow generates negative pressure inside of the sandblasting gun, thereby sucking the abrasive material through the sand delivery tube into the sandblasting machine. Then, these abrasive materials are sprayed onto the surface of the workpiece through the nozzle. In this type of sandblasting machine, the compressed air not only serves as the power to create the negative pressure that sucks the abrasive material into the system, but also acts as the driving force to accelerate the abrasive material towards the workpiece. This design is typically suitable for small-scale operations or when dealing with more delicate components that require a lighter abrasive impact.

2.3.2 Pressure-Fed Dry Sandblasters

A complete pressure-fed dry sandblasting unit comprises four systems: pressure tank, media power system, pipeline system, and control system.

The pressure-type dry sandblasting machine is the opposite of the suction-type. Although both use compressed air, the difference between them is that the pressure-type sandblasting machine uses compressed air as the driving force, rather than suction. This driving force pushes the abrasive through the sand outlet valve into the conveying pipeline, and then the nozzle sprays it onto the surface of the workpiece to achieve certain effect. This setup can provide a more powerful and stable sandblasting effect – it is highly suitable for large workpieces, deep rust removal, or situations requiring faster material removal.

2.3.3 Wet Sandblasters

Compared to dry sandblasters, wet sandblasters offer a key advantage: they effectively control dust pollution during blasting, significantly improving the working environment.

A complete wet sandblaster includes five systems: structural system, media power system, pipeline system, control system, and auxiliary system.

The wet sandblasting machine uses a liquid pump as the power source for supplying the grinding liquid. The uniformly mixed grinding liquid, a mixture of abrasive and water (typically water, and rust inhibitors or detergents may be add into it if necessary) is transported to the spray gun by the liquid pump. Compressed air serves as the acceleration power for the grinding liquid, and it enters the spray gun along the air pipe. In the spray gun, the compressed air accelerates the grinding liquid that enters it and then it is ejected through the nozzle and sprayed onto the workpiece’s surface to achieve the expected processing purpose. In the liquid sandblasting machine, the liquid pump is the power source for supplying the grinding liquid, and the compressed air is the acceleration power.

In the following scenarios, you might need to use a wet sandblasting machine: The surface of the workpiece requires a slightly smooth finish rather than a particularly rough one; The working environment requires low levels of dust. The workpiece itself is prone to deformation (mainly due to its relatively thin wall thickness); Or if the material of the workpiece is an oxidizable metal (if using a dry sandblasting machine, it is very likely to oxidize rapidly within a short period of time)

3. Different Types of Sandblasting Abrasives

3.1 Types

Steel grit/steel shot: High hardness and high impact force, suitable for removing oxide scale, coatings or strengthening the surface of metals. Applicable to heavy industrial scenarios such as cast iron and steel, reusable, and highly efficient.

Brown corundum/white corundum: High hardness and strong grinding force, suitable for fine grinding or removal of hardened coatings of high-hardness metals such as stainless steel and alloy steel.

Glass beads: Low hardness and no sharp edges, suitable for occasions with high requirements for metal surface smoothness (such as aluminum polishing), does not damage the substrate and can enhance the glossiness.

Garnet sand: Natural abrasive, moderate hardness, suitable for sandblasting of brittle materials such as glass and ceramics, can form uniform matte effect.

Resin sand/nut shells: Soft texture, suitable for gentle treatment of precision instruments or fragile materials.

3.2 Advice On Choosing Abrasives

3.2.1 Surface Treatment Requirement

Simple rust removal and cleaning

- Quartz sand: High hardness and low cost, suitable for large-scale rust removal, but with large dust. Needs to be combined with dust removal equipment.

- Steel sand/steel balls: Highly efficient for removing thick rust layers or old coatings, suitable for maintenance of heavy industrial equipment.

- Garnet sand: Environmentally friendly abrasive, suitable for occasions with high dust control requirements (such as rust removal of food processing equipment).

Surface roughening/marking

- Carborundum (silicon carbide): Extremely high hardness, suitable for surface treatment requiring high roughness (such as pre-treatment before coating).

- Alumina sand: High hardness and uniform particle size, suitable for surface roughening of precision parts.

Surface polishing/mirror effect

- Glass beads: The only abrasive that can achieve mirror polishing, suitable for high-gloss requirements of automotive parts, decorative items, etc.

- Ceramic beads: High hardness and wear resistance, suitable for matte polishing of stainless steel and other metals.

3.2.2 Special Scenarios

Stone/Glass Engraving

Petroite sand can be selected: a natural abrasive with moderate hardness, which can produce fine engraving effects without damaging the substrate.

Ship/Bridge Rust Removal

Copper ore sand can be chosen: with high hardness and strong decontamination ability, it is suitable for long-term rust prevention treatment of large steel structures, but the dust is relatively large.

4. Key Applications of Sandblasting

- Pre-treatment: Sandblasting can remove all impurities such as rust scales from the surface of the workpiece, and establish an important basic pattern on the surface of the workpiece (that is, the so-called rough surface). Moreover, by changing the abrasive of different particle sizes, such as abrasive tools for fly grinding, different degrees of roughness can be achieved, greatly improving the adhesion between the workpiece and coatings, plating materials, and making the bonding of adhesive parts more firm and of better quality.

- Cleaning and polishing workpieces after heat treatment: Sandblasting can clean almost all impurities (including oxide scales, oil residues, etc.) on the surface of castings and workpieces after heat treatment, and polish the surface of the workpiece to improve the smoothness of the workpiece, allowing the workpiece to reveal a uniform and consistent metallic color, making the appearance of the workpiece more beautiful and attractive.

- Renovation of old parts: Renovation and cleaning of all moving parts of automobiles, motorcycles, electrical machinery equipment, etc. At the same time, it can eliminate fatigue stress and extend the service life.

- Enhancement of finish: Elimination of surface marks on all metal products and non-metal products, matte/foggy surface treatment, which enhances the grade of the product surface.

- Mold treatment: By sandblasting the surface of the mold, a certain degree of roughness or texture is formed. So that the plastic parts produced through subsequent injection molding no longer require post-surface treatment. This is also usually referred to as SPI surface treatment.

- Removal of burrs: Remove tiny burrs on machined workpieces, plus elimination of overflow edges of injection molded parts.

- Re-work of defective products: Remove defective coatings, coloring or printing on the surface.

- Improvement of mechanical properties of parts: After sandblasting, uniform and fine uneven surfaces can be generated on the surface of mechanical parts, allowing lubricating oil to be stored, thereby improving the lubrication conditions and reducing noise to extend the service life of the machinery.

So, sandblasting stands as a versatile and essential process across industries, from surface preparation to enhancing aesthetics and performance. At KingStar, we bring years of hands-on experience to every project (and we have completed countless sandblasting jobs for clients across manufacturing, automotive, aerospace, and more).

What sets us apart? We offer one-stop solutions tailored to your needs. Whether you’re looking for a standalone sandblasting or other surface finishing service to refine existing parts, or seeking end-to-end support from initial production through post-processing (including sandblasting, coating, and finishing), we’ve got you covered. Our team combines technical expertise with quality-focused execution, ensuring consistent results that meet even the strictest standards.

Ready to elevate your parts’ quality and efficiency? Partner with us – where precision meets convenience, every step of the way.