Sandblasting

With 10+ years specializing in sandblasting for mold and metal parts, we craft customized abrasive solutions, from steel grit to glass beads, tailored to your material type and precision needs. Our 0.05mm micro-precision control ensures consistent surface quality, helping 200+ clients reduce rework rates by 30%+ while balancing efficiency and long-term reliability.

Our Machines & Equipments

Below are our core sandblasting systems—each chosen to tackle specific industrial needs. They’re supported by a full suite of blast chambers, abrasive recovery systems, and precision calibration tools to ensure seamless, efficient operations for mold and metal part processing.

Functions of Sandblasting

Surface Cleaning

Sandblasting is a powerful way to strip away built-up grime, grease, rust, and old paint. It clears the surface down to its clean, raw state—perfect for prepping metal or other materials before applying a new finish.

Surface Preparation for Coating

When a surface needs to hold onto paint or primer for the long haul, sandblasting helps. It creates a slightly roughened texture that allows coatings to grip better, reducing the chance of peeling, chipping, or flaking over time.

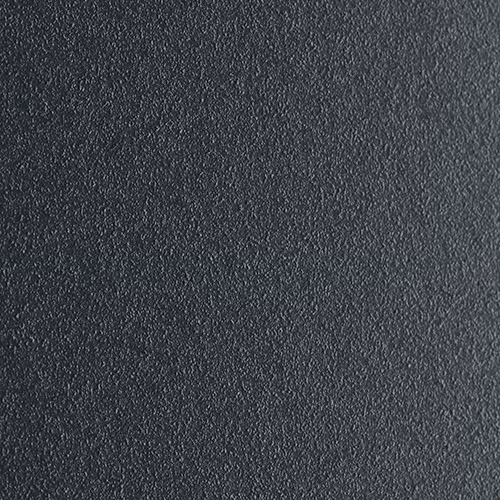

Surface Texturing

Need a specific texture or decorative look? By tweaking the blasting pressure or the type of abrasive, sandblasting can create just the right finish no matter it’s for slip resistance, visual appeal, or better handling on tools and parts.

Rust Removal

Sandblasting cuts through corrosion fast, exposing clean metal underneath. This not only restores strength but also gets the surface ready for repainting or protective coating.

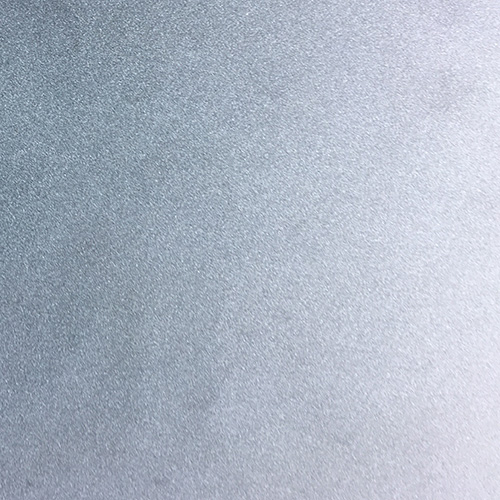

Smoothing Rough Surfaces

Got a surface that’s too rough or uneven? Sandblasting can even things out, creating a smoother, more uniform finish. It’s great for prepping concrete, stone, or metal before painting, polishing, or sealing.

Restoration and Refinishing

When materials start to look old or worn, sandblasting can breathe new life into them. It strips away years of wear by removing stains, blemishes, and coatings, so the surface is ready for a fresh finish or just to shine on its own.

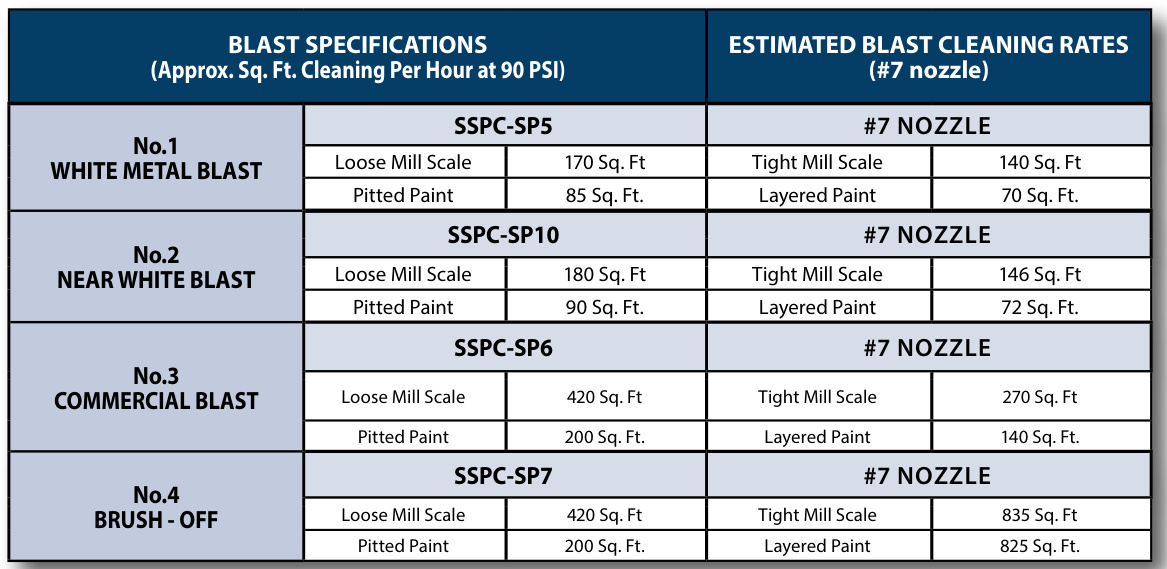

Sandblasting Service Standards and Cleaning Rate Table

*Resource: BLASTING TECHNICAL INFORMATION

Advantages of Sandblasting With KingStar

Common Applicable Materials for Sand Blasting

*For these type of material, we usually only undertake the individual surface treatment work and do not provide any production services other than the surface treatment. For other materials, including plastics and various metals, we offer a one-stop service, including a complete series of workflows from molding/cnc machining/die casting/extrusion… to post-processing (coatings/chemical treatments to change the appearance or mechanical performance).

Sandblasting for Injection Mold Surface Treatment

As a critical step in your mold production and finishing workflow, our sandblasting service integrates seamlessly with our core capabilities—linking injection mold building, precision surface preparation, and SPI-compliant finishes to deliver consistent, production-ready molds.

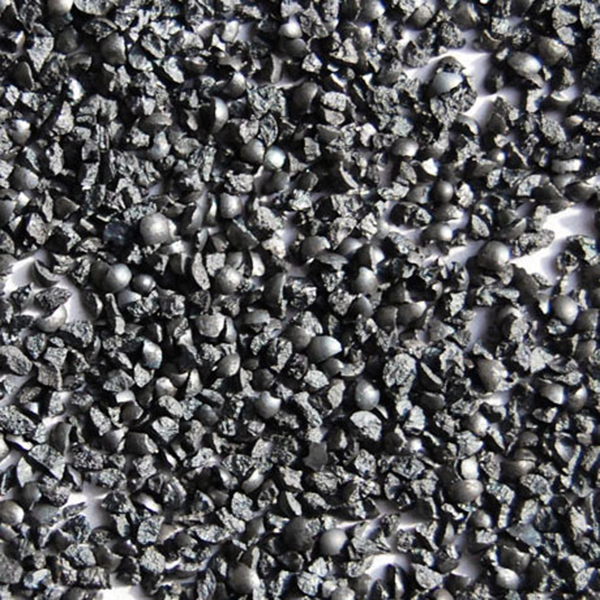

Various Options for Sand Blasting

| Type of Sandblasting | Duration | Cost | Typical Applications |

|---|---|---|---|

| Dry Sandblasting | Moderate to fast, depending on surface size | Low to Medium ($$) | Paint removal, rust cleaning, surface preparation for coatings |

| Wet Sandblasting | Moderate, slower due to water mixture | Medium ($$) | Delicate surface cleaning, dust-free environments, rust removal |

| Soda Blasting | Moderate | Medium ($$) | Paint removal, graffiti cleaning, grease and contaminant removal |

| Bead Blasting | Moderate to fast | Medium ($$) | Polishing, smoothing metals, removing light corrosion or coatings |

| Abrasive Blasting | Fast, depending on abrasive type | Low to High ($$-$$$) | Aggressive cleaning, surface roughening, etching, heavy-duty cleaning |

| Steel Grit Blasting | Fast | Medium to High ($$-$$$) | Heavy-duty rust removal, industrial equipment cleaning, abrasive etching |

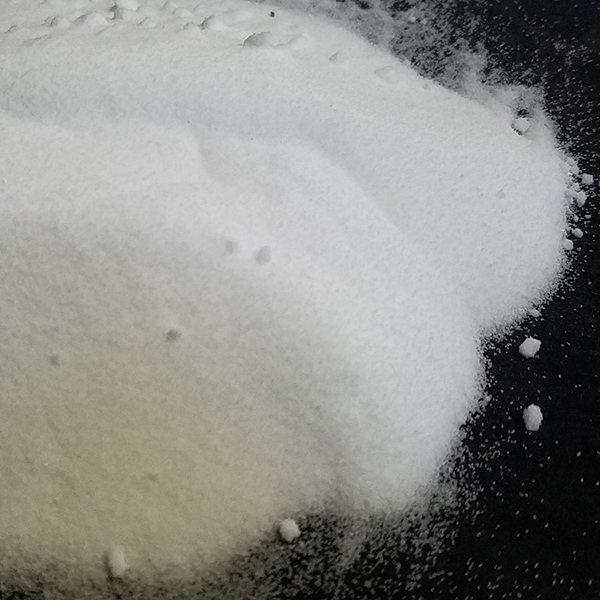

| Sandblasting with Ceramic Media | Moderate | High ($$$) | Delicate part cleaning, automotive, aerospace, and precision finishing |

Frequently Asked Questions

Project timelines vary depending on the size, material, and level of surface contamination. Small items like wheels or metal panels can often be completed in a few hours, while larger or more complex jobs may take a full day or more. We’ll provide a clear time estimate after evaluating your specific project.

Yes. We offer a range of abrasive media and pressure settings to match the sensitivity of each material. For delicate items like aluminum parts, sculptures, or vintage car panels, we use gentler media such as crushed glass, soda, or walnut shells to clean the surface without harming fine details or thin layers.

While traditional sandblasting did use sand, most modern methods have moved away from it due to safety concerns. Today, media like crushed glass, steel grit, walnut shells, and soda are much more common—and safer. With Dustless Blasting, you can use a wide variety of eco-friendly and effective media tailored to your project needs.

The traditional sandblasting process may pose serious health risks, especially when using materials containing silica sand, as this material releases harmful tiny dust particles into the air. However, the dust-free sandblasting technology, by mixing water with the abrasive, significantly reduces the amount of dust in the air, making it a safer alternative for both the operators and the surrounding environment.