What is Reverse Engineering?

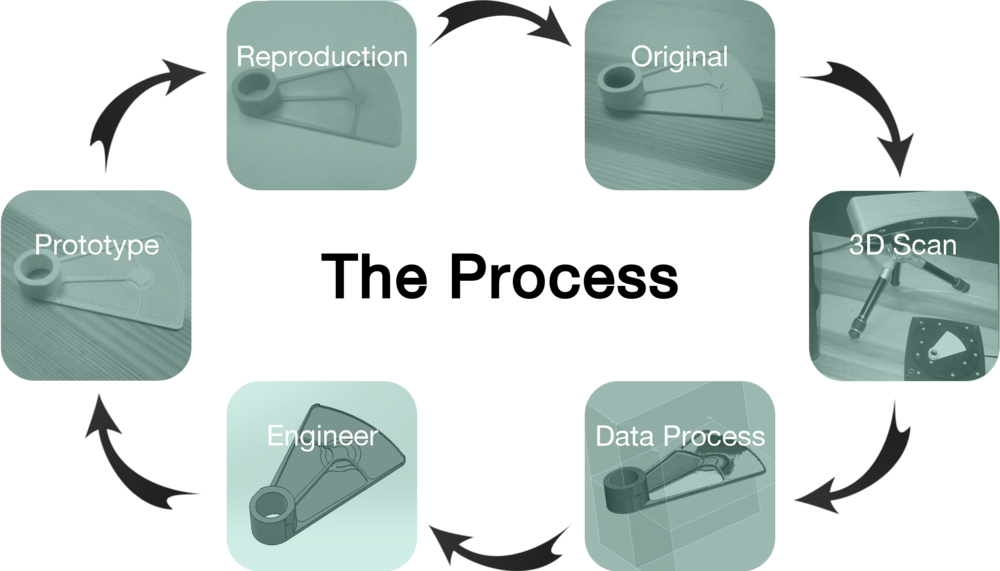

Reverse engineering is the process of analyzing an existing part or product to recreate its design and functionality, often when original drawings or specifications are unavailable. Using advanced 3D scanning and CAD software, we capture the precise geometry of the object, enabling us to generate accurate digital models. This service is essential for reproducing obsolete parts, improving component design, or making modifications to existing products. Whether you need to replicate an OEM part, analyze a component, or repair damaged items, reverse engineering provides the solution to bring your ideas to life with precision and efficiency.

3D Scanning Technical Specifications

If you’re looking to inspect an existing product, replicate a part without drawings, analyze a component, or recreate OEM parts for outdated models, our reverse engineering services are here to help! At KingStar Mold, we utilize the advanced Peel 2-S 3D CAD scanner to ensure precise part scanning.

| Part size range | 0.05 - 0.5 m (2 - 20 in) |

| Accuracy | up to 0.1 mm (0.004 inch) |

| Mesh resolution | 0.100 mm (0.004 inch) |

| Measurement rate | 550,000 measurements/s |

| Volumetric accuracy (base on part size) | 0.3 mm/m (0.0036 in/ft)1 |

| Scanning area | 143 x 108 mm (5.6 x 4.3 inch) |

| Depth of field | 100 mm (4 inch) |

| Texture resolution | 50 to 250 DPI |

| Dimensions | 154 x 178 x 235 mm (6 x 7 x 9.2 inch) |

| Output formats | .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .iges, .step, .dxf |

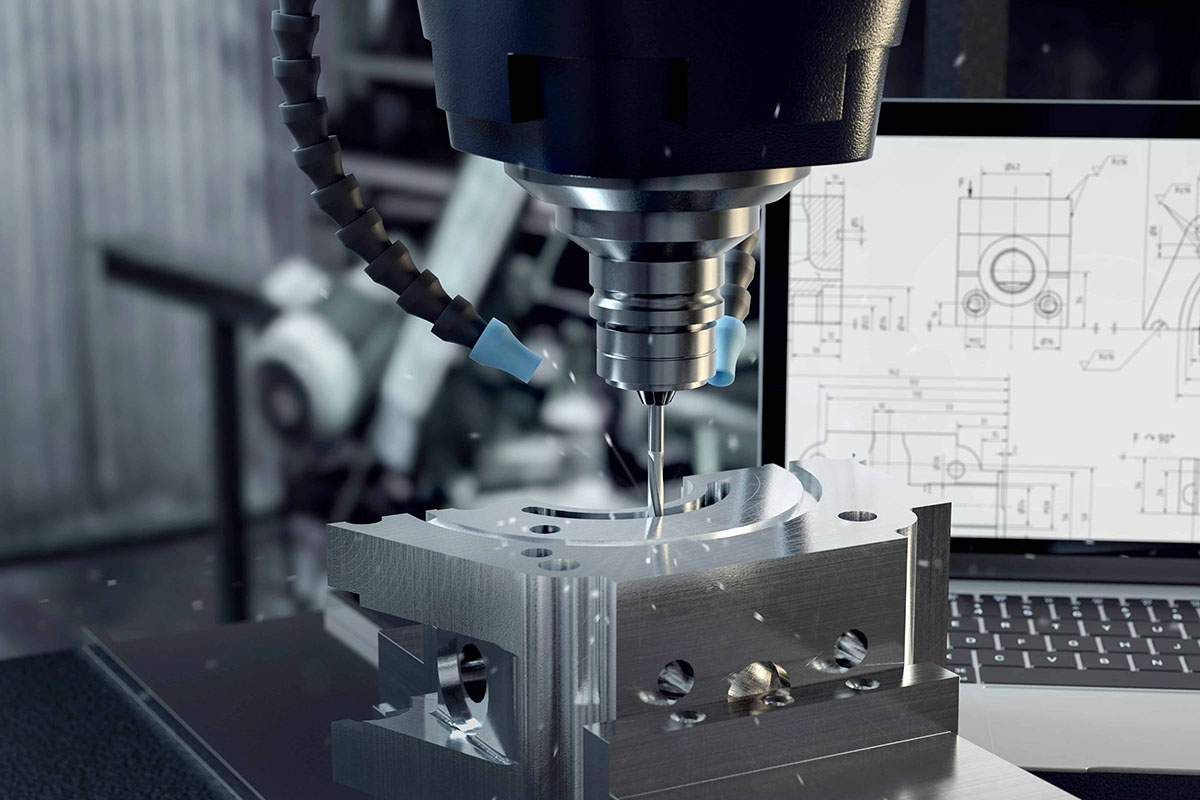

Combine reverse engineering with our rapid prototyping services to shorten your design process from months to days. We provide a variety of prototyping options, including 3D printing, CNC machining, vacuum casting, and more!

We can export scanned data into various CAD file formats, including STL, OBJ, and other industry-standard formats, based on your project requirements.

If you have a heavy, delicate, or large item, or prefer not to send it to us, we can visit your location to perform the scan.

Note: Travel and accommodation costs are not included in the service, so this option is usually more expensive, especially for distant locations. However, we’re happy to come to you if the additional costs are acceptable.

Yes, you can either send your item by mail or drop it off in person. This method often proves more cost-effective. Once we’ve completed the 3D scanning, we’ll return your object to you.

Note: Shipping arrangements can be made through us, but shipping costs are not covered.

We can scan a wide range of objects, from small components to large machinery parts, as long as they fit within our scanning capabilities. Please contact us if you’re unsure whether your item is suitable.

Yes, once your item is scanned, we offer rapid prototyping services, such as 3D printing and CNC machining, to create physical prototypes based on the digital model, helping you visualize the end product faster.

First, send us the object you need scanned. Once received, we’ll use advanced 3D scanning techniques, involving projected light and deformation patterns, to capture the dimensions and complexity of your item with precise accuracy. Afterward, we’ll convert the scanned data into your preferred CAD format and return both the digital file and your object.

Our reverse engineering service can still capture accurate scans even if your part is worn or damaged. The digital model can then be used for repairs, modifications, or reproducing a new part.

The time needed for scanning depends on the size and complexity of the object. Typically, small to medium-sized parts can be scanned within a few hours to a day, while larger, more complex objects may take longer.