The shrinkage rate of plastics directly relates to the shape and dimensional accuracy of the product. The characteristics of plastic products, mold design, process condition control, and other factors that affect molding shrinkage and post shrinkage significantly impact injection molded products and their stability. At present, the design of mold dimensions is usually calculated using tolerance zones or average shrinkage rates. After trial molding, the mold is adjusted based on the size of the trial produced product, but some have high hardness. The surface size correction of low roughness molds is quite difficult and time-consuming, sometimes even impossible to correct, resulting in huge losses. Therefore, in order to obtain precision injection molded parts of the required size while minimizing the need for mold modifications, it is necessary to fully understand the variation law of molding shrinkage rate with process conditions and accurately measure the molding shrinkage rate in advance.

Acrylonitrile-Butadiene-Styrene (ABS) terpolymer combines the chemical resistance, oil resistance, rigidity, and hardness of acrylonitrile, the toughness and cold resistance of butadiene, and the electrical properties of styrene. It is widely used in the automotive, electronics, and machinery industries and is currently one of the most widely used varieties of general engineering plastics.

Research on plastic molding shrinkage rate started earlier in foreign countries and has achieved relatively rich research results, while there are not many specialized researchers in plastic molding shrinkage rate in China. Therefore, the author used the ASTM D 955-89 standard to measure the molding shrinkage rate of plastic injection molding under different process conditions, and obtained the variation law of the molding shrinkage rate of ABS plastic with process conditions.

KingStar, as a leading plastic injection molding company, we compiled this article as an important basis for formulating reasonable process conditions, conducting correct process control and mold design, and producing qualified sized products.

1. What Materials and Equipment Are Used for ABS Shrinkage Testing?

(1) Main Raw Materials

ABS:IH-100, Shanghai Gaoqiao Petrochemical Company.

(2) Main Equipment

Drying hopper: FNH-A type, Nichirei Chemical Co., Ltd., Japan;

Mold temperature regulator: NT-55 type, manufactured by Nichirei Chemical Co., Ltd. in Japan;

Injection molding machine: PS40SESASE type, Nisshin Resin Co., Ltd., Japan;

Mold: Made according to ASTM D 955-89, including long and round molds, self-made.

(3) Testing Method

The samples are long strip door (127.045mm x 10.000mm x 3.200mm) and a disc (Φ101.975mm). During testing, a prototype with a dial indicator with an accuracy of 0.01mm is used to measure the dimensional changes of elongated specimens parallel to the flow direction and circular specimens parallel and perpendicular to the flow direction. The measurement times are 2, 24, and 48 hours after demolding. Calculate the molding shrinkage rate (S) of the sample according to formula.

In the formula, S represents the shrinkage rate of the sample during molding,%;

L0- the size of the mold cavity in any single direction, mm;

L1- The size of the specimen in the corresponding unidirectional direction at different testing times, mm.

(4) Basic Process Conditions

Dry ABS raw materials for 4 hours, inject them into standard samples, and then conduct testing within the specified time.

2. How Do Different Factors Affect ABS Injection Molding Shrinkage?

The molding shrinkage of plastics mainly consists of four parts: thermal shrinkage, phase change shrinkage, orientation shrinkage, compression shrinkage, and elastic recovery. There is no phase transition shrinkage for amorphous ABS plastic. The following discusses the effects of testing standards and molding process parameters on the shrinkage rate of ABS molding.

2.1 Why Use the ASTM D 955-89 Standard for Measuring Plastic Shrinkage?

There are many standards for determining the shrinkage rate of plastic samples, such as the international standard ISO2557/1-1989 (E), German standard DIN, Soviet standard GOST [СТ СЭВ 890-78], and American standard ASTM D955-89. Among them, international standards determine the “maximum shrinkage rate” and “partial shrinkage rate”, and the testing scope is limited to amorphous thermoplastic plastics, which cannot determine glass fiber reinforced and crystalline plastics. The German standard for determining the “maximum shrinkage rate” is limited to amorphous thermoplastic materials. Although the former Soviet standards can measure the “shrinkage rate”, “post shrinkage rate”, and “anisotropic shrinkage” of various plastics (with a wide ratio of transverse and longitudinal shrinkage), the measured “shrinkage rate” was only applicable to compression molding.

On the other hand, the American standards were applicable to various types of plastics and could measure the “1-2 h”, “24 h”, and “48 h” molding shrinkage rates. Therefore, their testing range is wide, and there are many types of plastics that can be measured. They can measure the “anisotropic shrinkage” that reflects the difference in longitudinal and transverse shrinkage rates, and can also reflect the changing law of plastic shrinkage rate over time. This is something that the above three standards cannot achieve. Therefore, the author chooses the American ASTM D 955-89 standard as the standard for determining the shrinkage rate of ABS specimens during molding.

2.2 Influence of Injection Molding Key Process Parameters on ABS Molding Shrinkage Rate

1. Injection Pressure

The effect of injection pressure on the shrinkage rate of ABS molding is clear. It can be seen that the molding shrinkage rate decreases with the increase of injection pressure. This is because increasing the injection pressure will increase the compactness of ABS products, reduce the coefficient of linear expansion, decrease thermal shrinkage, and increase the elastic recovery, thereby reducing the molding shrinkage rate. At the same time, with the increase of injection pressure, the orientation of ABS molecular chains will also increase, which will increase the shrinkage rate. However, comparing the two effects, the former dominates.

2. Holding Pressure

The holding pressure has the greatest impact on the shrinkage rate of ABS molding. This is because during the injection molding process, the cavity is not yet filled with molten material, and the injection pressure does not significantly compact the molten material. However, when the holding pressure acts, the mold cavity is already filled, so the holding pressure compensates for the shrinkage of the product. The compaction effect is significant, resulting in a significant reduction in the shrinkage rate of the product during molding. It can also be seen that when the holding pressure increases to 80 MPa, the effect of pressure changes on the forming shrinkage rate is no longer significant.

3. Screw Speed

The relationship curve between the shrinkage rate of ABS molding and the screw speed is as follows. It can be seen that as the screw speed increases, the molding shrinkage rate decreases. This is because as the screw speed increases, the shear effect inside the barrel increases, causing the material temperature to rise, the viscosity of the melt to decrease, and the flow resistance to decrease, promoting the transmission of pressure and reducing the forming shrinkage rate. On the other hand, the thermal shrinkage rate of the product also increases, and the result are obtained by combining the above two effects. When the screw speed is low, the factor that reduces the shrinkage rate dominates with the increase of speed, but when the speed is increased to 120r/mi. Above, the factors that reduce and increase the shrinkage rate tend to balance, and their impact on the shrinkage rate of product molding slows down.

4. Injection Rate

An increase in injection rate can promote the orientation of ABS molecular chains, but during rapid mold filling, the product will be maintained at a higher temperature for cooling, and the relaxation time of molecules at high temperatures will be prolonged, which is significantly beneficial for de orientation and reduces the degree of orientation and molding shrinkage. On the contrary, if injected at low speed, the temperature of the molten material entering the mold is relatively low, resulting in more frozen orientation structures. At the same time, the ability of polymer chains to undergo Brownian motion is weakened, and the effect of disorientation is small, leading to an increase in molding shrinkage.

5. Holding Time

Extending the holding time can reduce the backflow of molten metal to the gate, enhance the shrinkage compensation effect, make the product compact, and thus reduce the molding shrinkage rate of the product. However, extending the holding time after the gate is closed will not have the effect of compensating for shrinkage. With the increase of holding time, a plateau appears in the molding shrinkage rate, indicating that the sealing time of the injection sample gate is 15 seconds.

6. Mold Temperature

The increase in mold temperature, although the cooling of the melt during mold filling is slow, has the effect of increasing the elastic recovery of the product. Moreover, the higher the mold temperature, the more significant the effect of disorientation, reducing the molecular orientation and the molding shrinkage rate. High mold temperature can also increase the thermal shrinkage of the product and increase the molding shrinkage rate. When the mold temperature is low, thermal shrinkage plays a secondary role, and therefore increases with the increase of mold temperature; The molding shrinkage rate of the product decreases; At higher mold temperatures, thermal shrinkage becomes the main influencing factor, and as the mold temperature increases, the molding shrinkage rate of the product increases. So, when controlling the mold temperature, excessively high mold temperature is not appropriate.

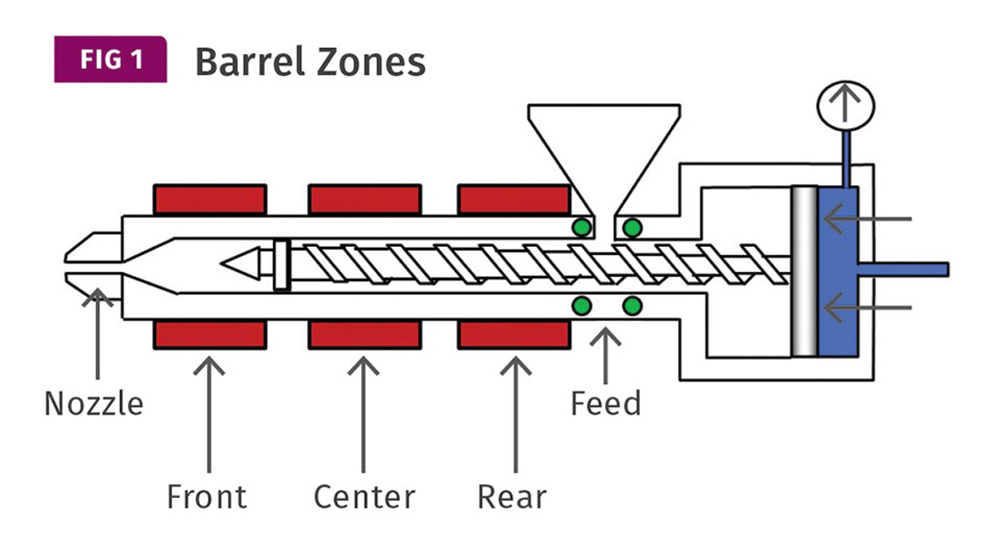

7. Barrel Temperature

The relationship curve between barrel temperature and ABS molding shrinkage rate is as follows. It can be seen that as the temperature of the barrel increases, the molding shrinkage of ABS products first decreases and then increases again. This is because the increase in material temperature reduces the viscosity of the melt and pressure loss, which has the same effect as increasing pressure. At the same time, when the material temperature is high, the disorientation effect of molecular chains is enhanced, resulting in a decrease in molding shrinkage rate. But as the material temperature continues to rise, the thermal shrinkage effect becomes more significant, resulting in an increase in the molding shrinkage rate of the product. Therefore, molecular orientation plays a major role in the low-temperature region, while thermal shrinkage is the main influencing factor in the high-temperature region.

3. Conclusion

By comparing different standards for measuring the molding shrinkage rate, the American ASTM D 955-89 standard was ultimately chosen to determine the molding shrinkage rate of ABS specimens. Under the conditions of this experiment, the molding shrinkage range of ABS is 0.29% -0.76%. The shrinkage rate of ABS molding is influenced by many factors such as injection pressure, holding pressure, screw speed, injection rate, holding time, mold temperature, and barrel temperature, among which holding pressure and holding time have the most significant impact.

Regarding the optimization of ABS injection molding process and the implementation of technology, or you are looking for a reliable professional custom part manufacturer, please contact KingStar at sales@kingstarmold.com or leave online message at any time to discuss cooperation and share professional solutions.