Keeping an injection molding machine running smoothly isn’t just about fixing problems when they happen — it’s about preventing them in the first place. To ensure their regular operation, reduce the occurrence of faults, maintain their high performance, service life, safe operation and shorten the downtime caused by faults, regular maintenance and inspection work for the injection molding machine must be carried out. Whether you’re running a small shop or managing a high-volume molding factory, having a clear schedule and checklist helps keep everything under control, they can be divided into weekly, monthly and annual intervals. In this post, we’ll walk through these injection molding machine maintenance tasks, along with what to check and how to fix when error occurs.

I. Weekly maintenance and inspection items:

- Check and tighten all connecting bolts (toggle linkage bolts, fasteners on moving parts, mold clamping bolts, bolts or screws on moving mold components, and locking screws for limit switches…).

- Inspect the cooling system of hydraulic oil and lubricating oil, including all cooling and oil lines. Check for any leakage (both oil and water). And if necessary, tighten connections or replace sealing gaskets.

- Carefully inspect all lubrication points and oil supply lines for changes in grease or oil quality. Check if there are water, metal particles, or other contaminants in the oil. Replace or filter the lubricating oil if needed.

II. Monthly Maintenance and Inspection Items:

- Check the quality of hydraulic oil. If contaminated, insufficient, or contained water, take immediate action to address the issue and replenish the oil as needed.

- Inspect all electrical wiring and connectors for any looseness.

- Check the ventilation filters on the electrical control cabinet, remove any debris, and clean them thoroughly if necessary.

- Clean the hydraulic oil filter screen.

- Clean all sliding or moving surfaces (such as tie bars and the sliding guide rails of the injection unit), then reapply fresh lubricating oil.

III. Annual Maintenance and Inspection Items:

- Inspect the quality of the hydraulic oil. Generally, the oil should be replaced every 12–18 months. For new machines, drain the hydraulic oil after the first 3 months of operation. And all components in the hydraulic system (control valves, pipelines, oil tank…) need to be cleaned to remove iron particles or contaminants introduced during the break-in period. Filter the drained oil through a 150-mesh filter and refill the tank with clean oil.

- Calibrate the thermocouple and temperature controller by comparing its reading to an actual thermometer at the measurement point. Remove any dirt at the thermocouple contact and verify correct positioning for accurate measurement.

- Inspect the firmness of all wire connections inside the control cabinet. Check if the rubber insulation on the wires shows signs of aging to prevent electrical leakage. Replace wiring if needed.

- Check the mechanical transmission and reduction system, including bearing cleaning and wear inspection. Replace bearings if necessary.

- Inspect the gear tooth surfaces and assess the condition of the lubricant in the gearbox. Record wear and oil quality for future reference.

- Examine the screw and barrel for wear. Perform minor polishing for light wear or scratches. If wear is severe, plan for repair or replacement and keep detailed records.

- For drive motors, hydraulic pumps, and motors, inspection should be applied after disassembly. Check wear on components such as bearings and pump housings. Clean and reapply lubricating oil or grease. Record wear status and prepare maintenance or replacement plans.

- Inspect seals and other easily worn components and replace them as needed.

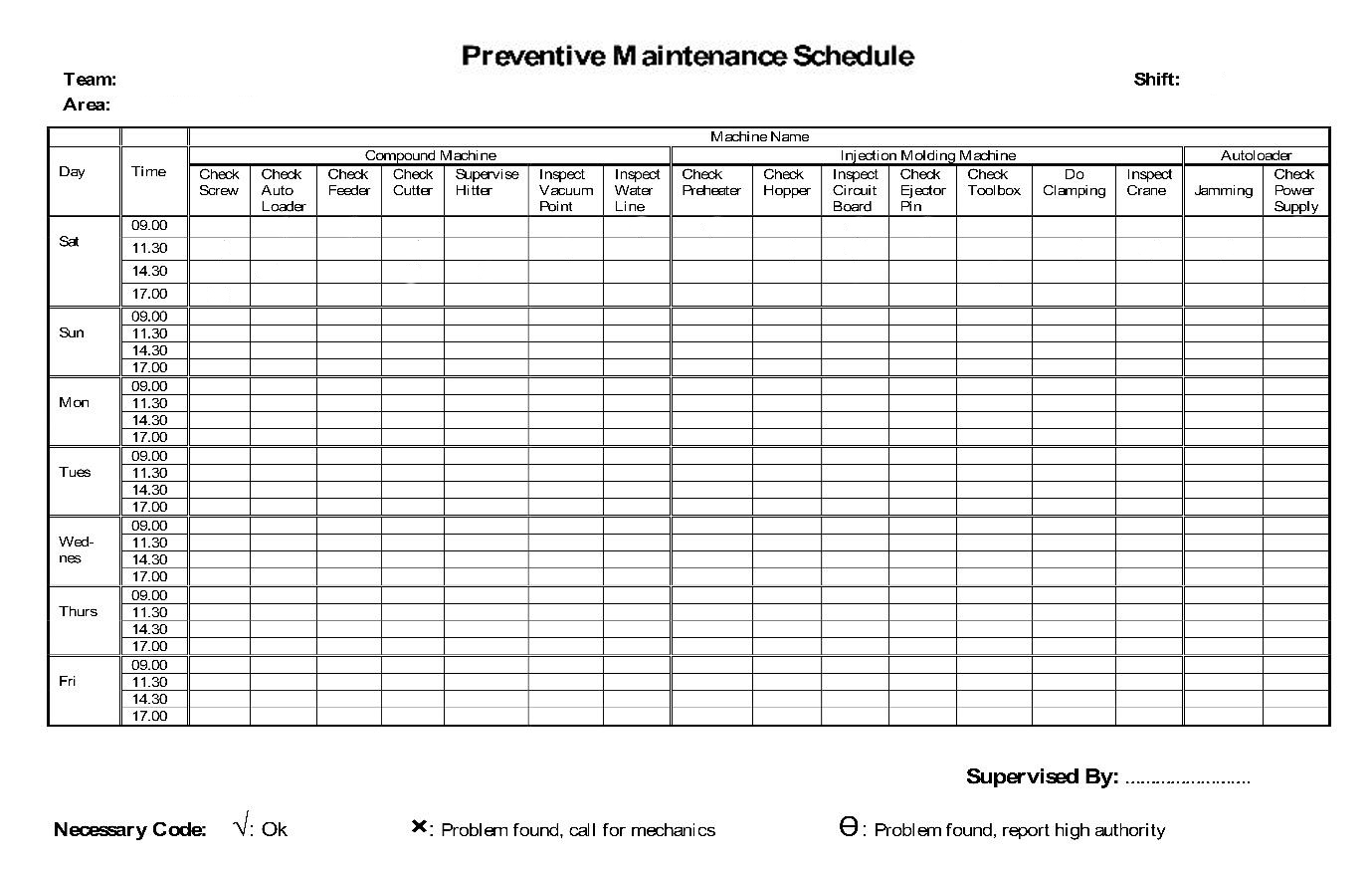

Below is a checklist we utilize in compound machine, injection machine and auto-loader in our factory, and you can refer to this table to customize a detailed table for your regular maintenance:

Preventive Maintenance Schedule Plan

Injection molding machines are long-term investments. And their performance depends majorly on how they’re maintained. Following this structured injection molding machine maintenance schedule and checklists (weekly, monthly, and annually) carried out by KingStar Mold—not only reduces costly downtime but also improves product consistency and machine life. If you’re looking for a molding company in China who follows strict standards for machine maintenance, parts production and quality assurance, we ensure every machine in operation is kept in peak condition. Our professional team applies the same care to your molds as we do to our own equipment—because quality starts with reliability.