Rapid Prototype At KingStar Mold

Providing High-precision Prototypes

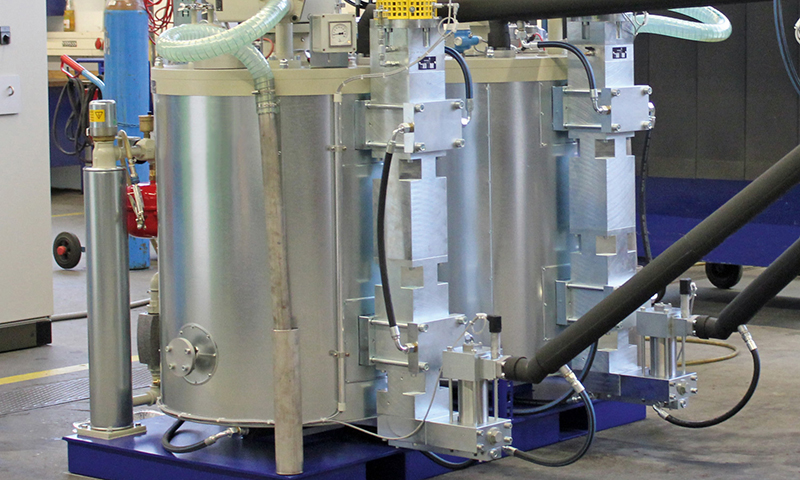

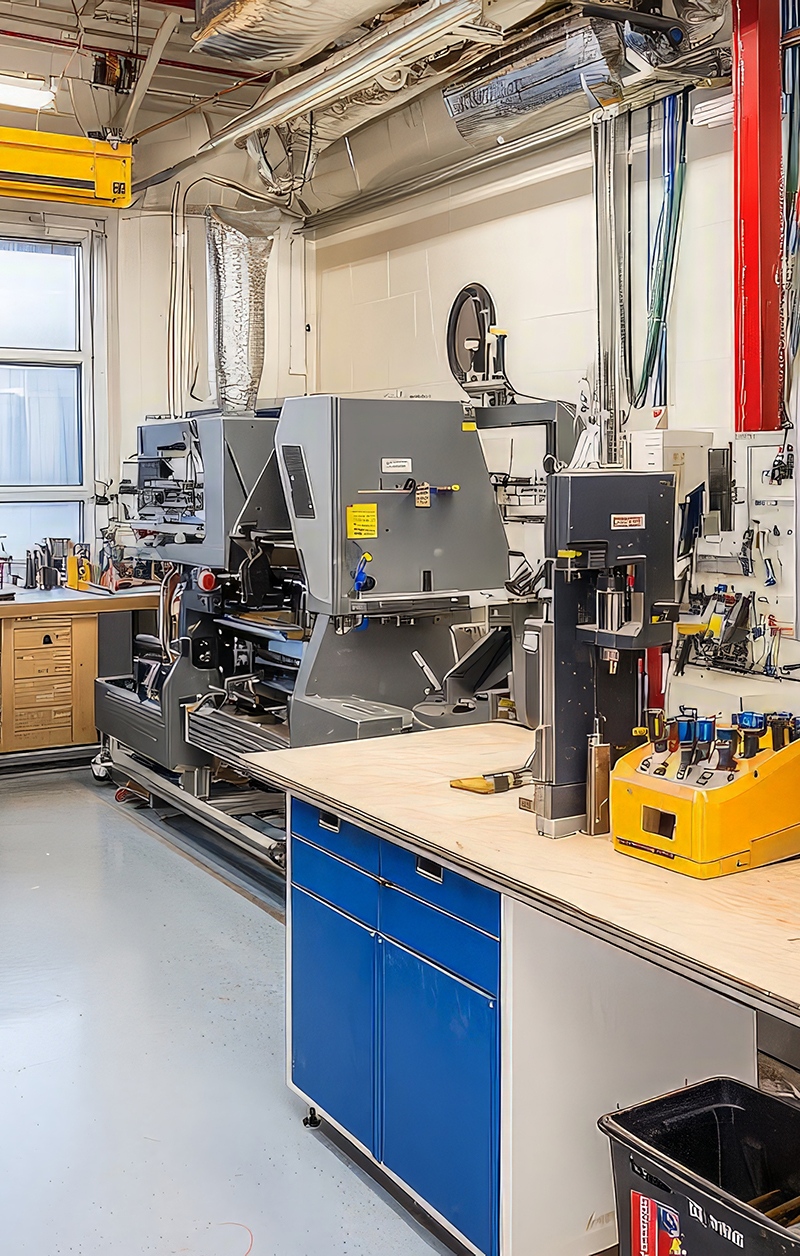

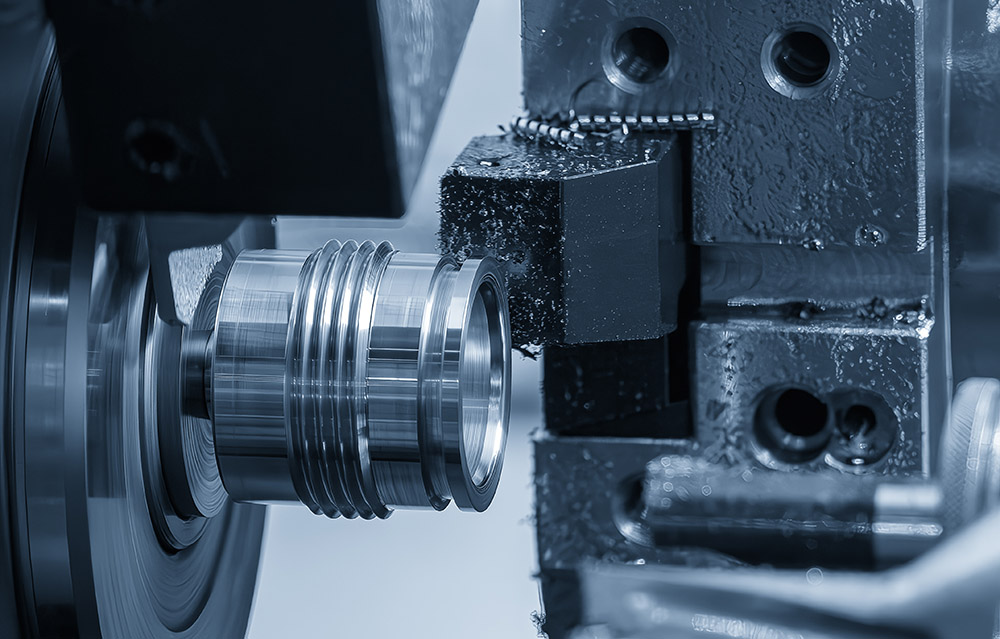

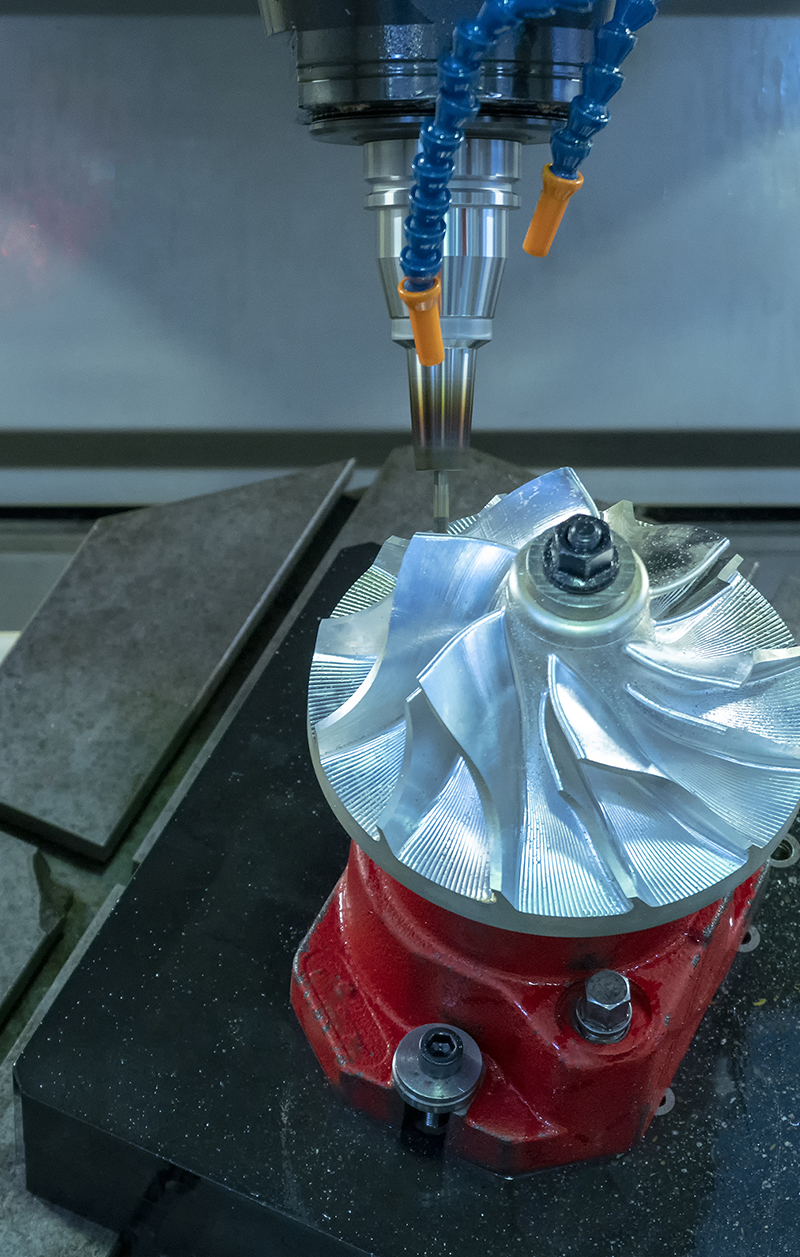

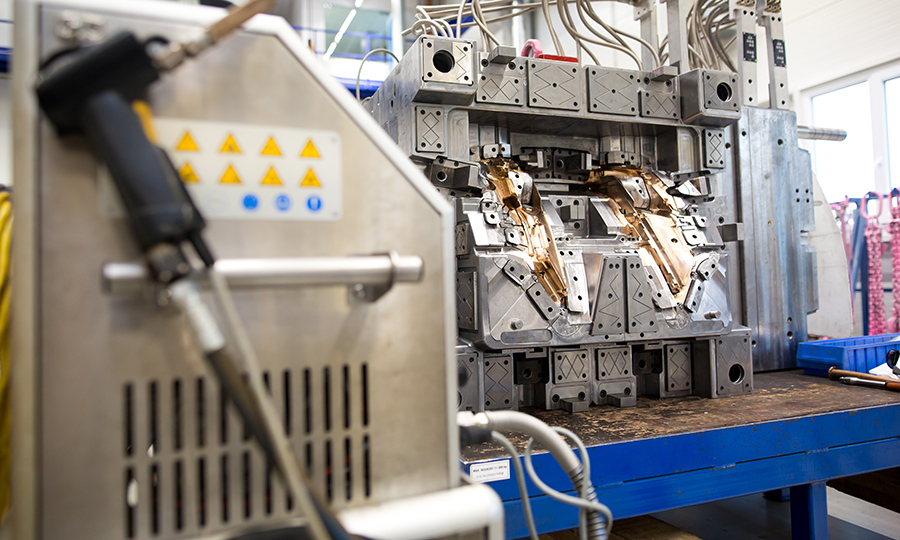

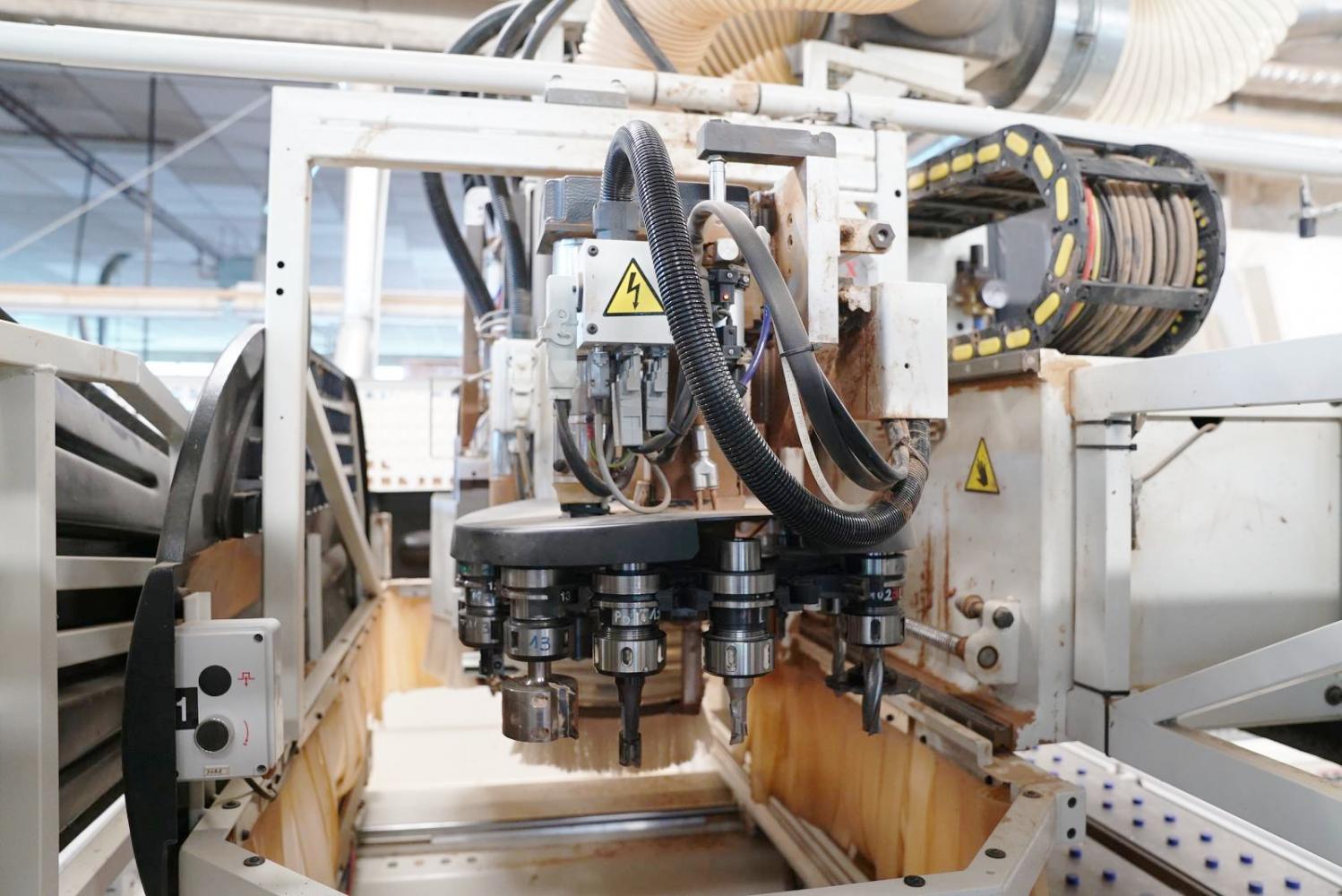

KingStar Mold’s Rapid Prototyping Capabilities

Fast Production and Turnaround

Rapid prototyping accelerates the product development process by quickly producing prototypes, allowing for faster design validation and reducing time-to-market.

Enhanced Design Iteration

This service enables multiple iterations of a design to be created and tested in a short period. It provides flexibility for designers to make improvements and refine the product based on real-world testing and feedback.

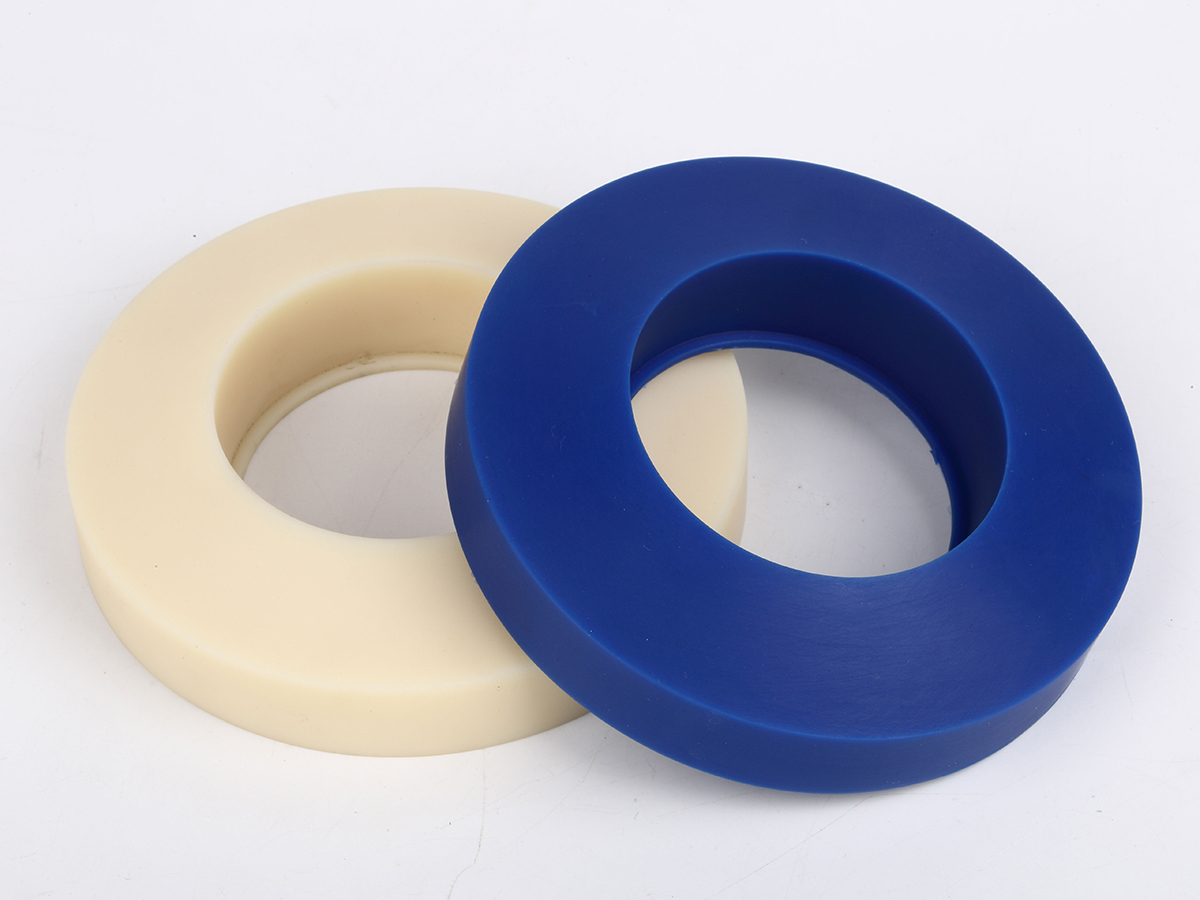

Wide Material Options

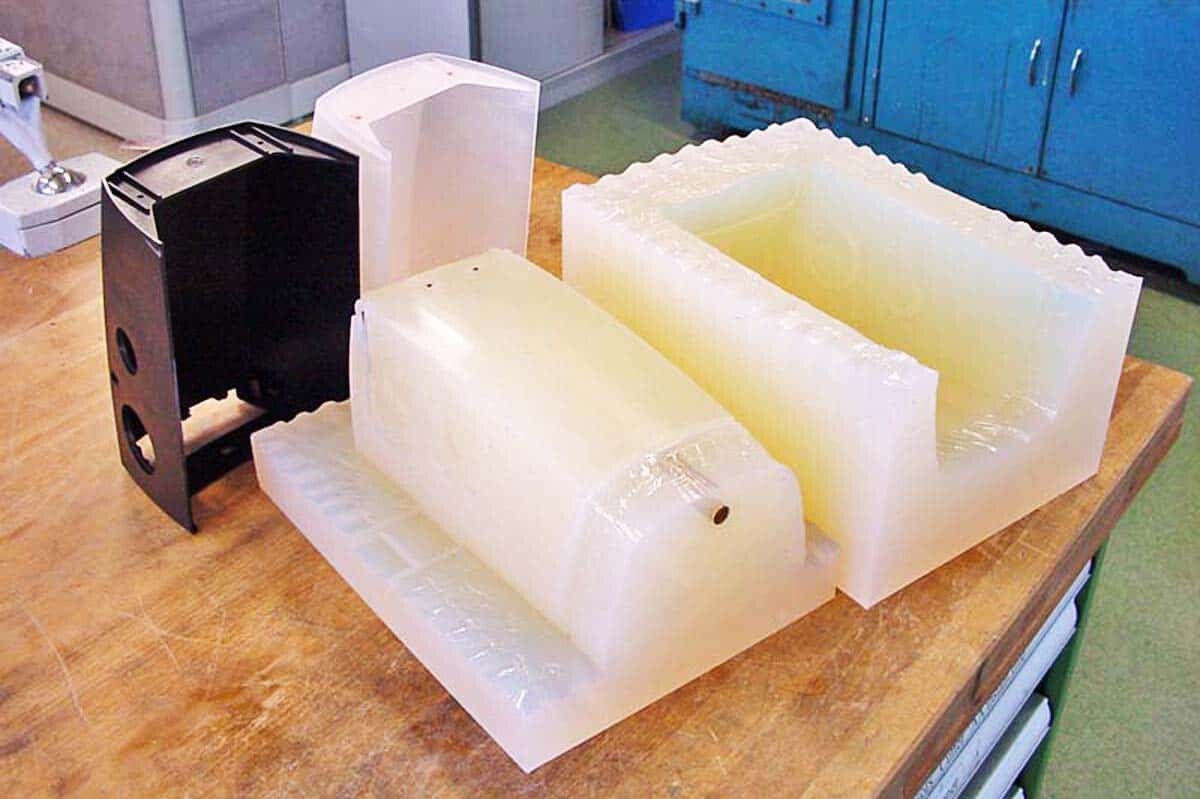

Rapid prototyping supports a variety of materials, such as plastics, metals, and composites, to create prototypes that closely resemble the final product in terms of function, durability, and appearance, making it ideal for different industries and applications.

Key Benefits of Rapid Prototyping at KingStar Mold

Faster Time-to-Market

Cost Efficiency

Improved Design Accuracy

Enhanced Flexibility and Iteration

Production Capacity Gallery

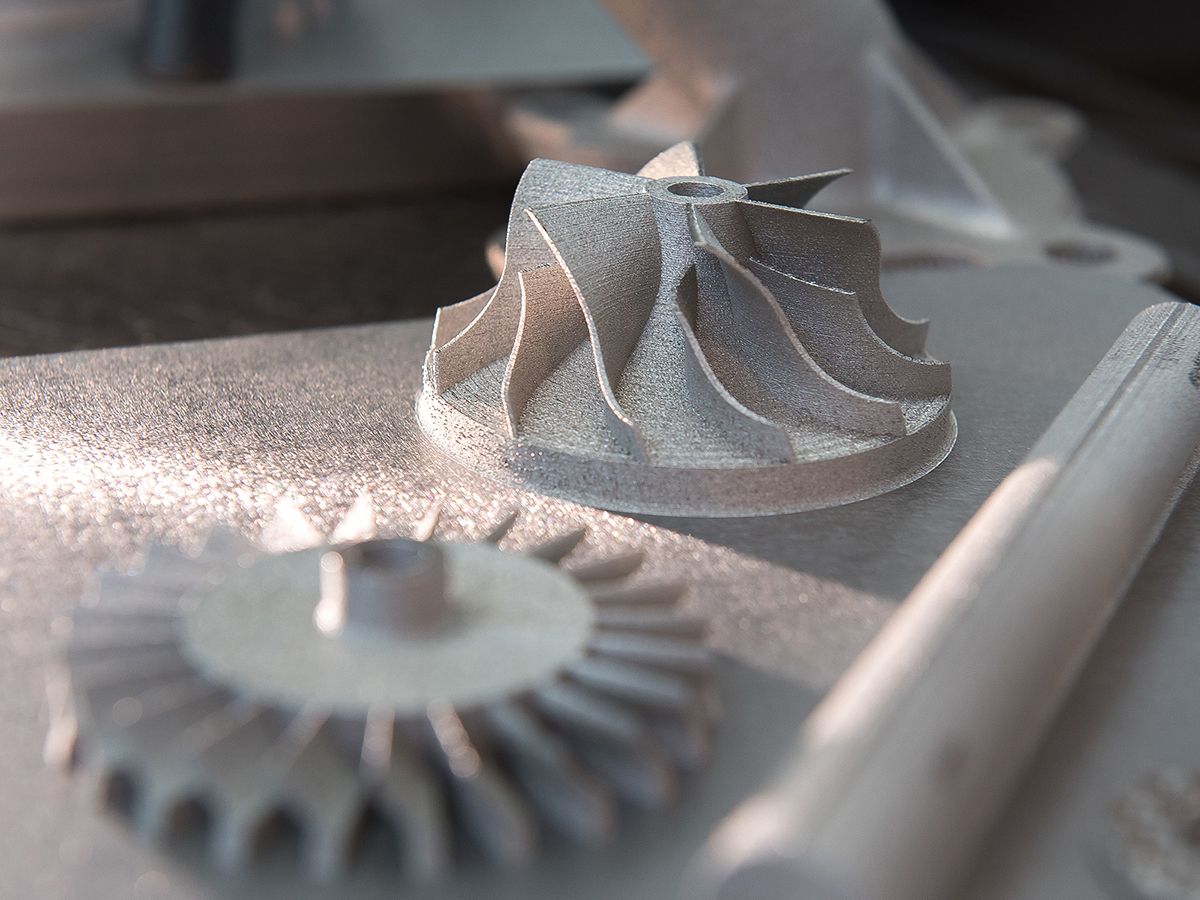

Rapid Prototyping

Development & Engineering Services

Engineering File Formats Accepted

Document File Formats Accepted

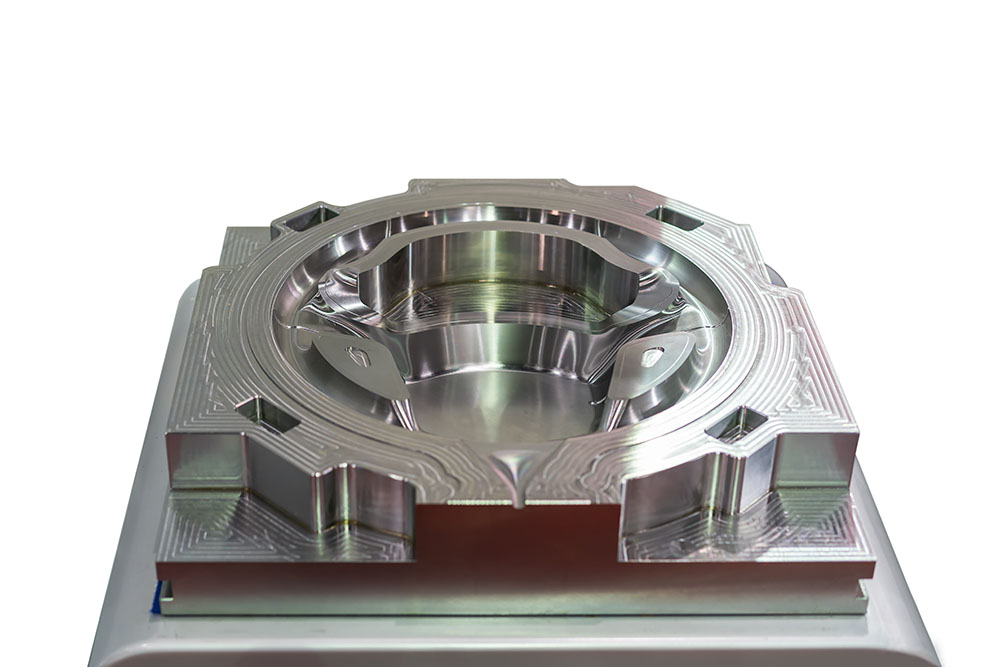

KingStar Mold ensures high precision in our rapid prototyping process, ensuring that prototypes closely match the final product’s specifications.

Our rapid prototyping service supports industries like automotive, consumer goods, electronics, medical devices, and more.

Rapid prototyping helps minimize the need for costly rework and tooling by allowing you to test and refine designs before full-scale production.

We offer a variety of materials such as plastics, metals, composites, and rubber-like substances for different applications and performance requirements.

The turnaround time for rapid prototyping can range from a few days to a few weeks, depending on the complexity of the design and material used.

Rapid prototyping is a fast process used to create a physical model or prototype from a digital design, enabling quick testing and validation of concepts.

Yes, we provide additional services like surface finishing, painting, and assembly, to ensure your prototype meets functional and aesthetic requirements.

KingStar Mold combines years of experience with cutting-edge technology to deliver high-quality prototypes with quick turnaround times and competitive prices.

Yes, KingStar Mold can provide prototypes for both small runs and large-scale production, helping you test your designs before committing to full manufacturing.

The cost depends on the material, complexity, and size of the prototype. We offer competitive pricing to ensure cost-effective solutions.

Rapid prototyping allows for multiple iterations, so you can refine your design based on testing and feedback without additional significant costs.

Yes, KingStar Mold specializes in producing prototypes with both simple and complex geometries, ensuring that intricate designs are accurately represented.