KingStar Mold’s Quality Management Overview

At KingStar Mold, our quality management system ensures full compliance with ISO 9001:2015 standards for all precision manufacturing services. We focus on preventing issues before they arise through regular maintenance, feasibility studies, process capability assessments, and ongoing quality training for our team. Equipped with advanced measurement tools and software, our inspection department ensures part accuracy and consistent precision.

We balance big-picture goals with attention to the fine details, ensuring that every part meets strict compliance standards. Our continuous process improvements, from design to production, set us apart from competitors, delivering exceptional quality and cost-effective solutions at every stage.

Importance of Our Quality Management

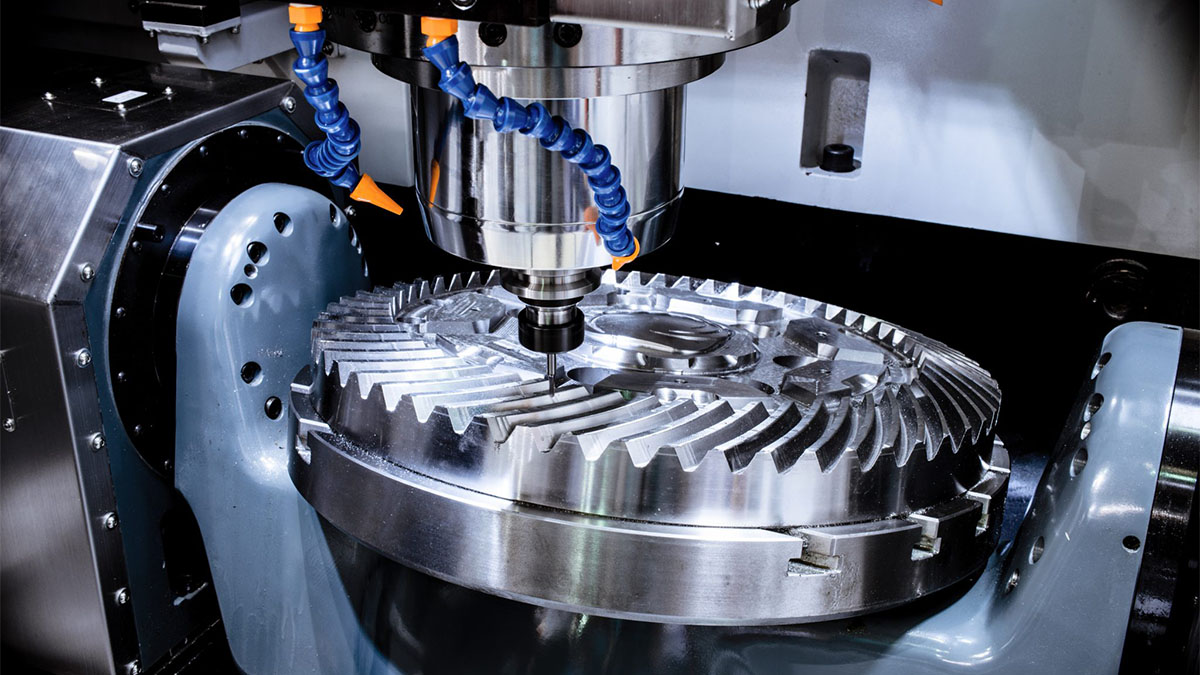

At KingStar Mold, our robust quality management system is critical to ensuring the highest standards in both injection molding and CNC machining. By rigorously adhering to ISO 9001:2015 standards, we minimize the risk of defects and inconsistencies in every product. Our proactive approach, including preventive maintenance and continuous process reviews, helps prevent common errors such as material warping, poor dimensional accuracy, or improper mold filling. This attention to detail ensures that each part meets strict specifications and performs reliably in its intended application.

Despite our best efforts, potential errors can still occur during production, such as misalignments in CNC machining or air bubbles in injection molding. To mitigate these risks, our quality management system emphasizes thorough inspections, real-time process monitoring, and the use of state-of-the-art equipment. By catching issues early in the production cycle, we ensure that even the most complex parts are manufactured to the highest standards, maintaining both quality and cost-effectiveness throughout the process.

By implementing our quality management procedures, these are part of the errors we can prevent:

CNC Machining

Injection Molding

KingStar Mold’s Quality Management

Rigorous Quality Control Process

We implement a thorough quality control process at every stage, from material inspection to final testing, ensuring every product meets the highest standards.

Advanced Equipment

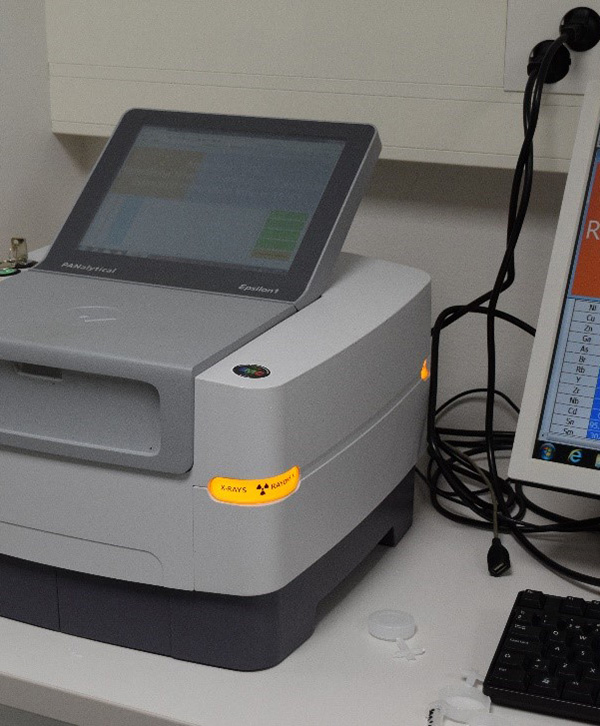

We use state-of-the-art measuring machines, like XRF Spectrometers and Profile Projectors, to ensure precise quality control and accurate results at every production stage.

Proactive Quality Control

We implement a thorough quality control process at every stage, from material inspection to final testing, ensuring every product meets the highest standards.

The main QC documents we follow are:

Nonconforming product control procedures

Corrective and preventive action procedures

Inspection and test status control procedures

Customer complaint control procedures

Supplier audit procedures

Product identification and plasticity process

Incoming material inspection procedures

Production process inspection procedures

Final and ex-works inspection procedures

We also provide Inspection Reports:

| Inspection Type | Quality Inspection | Digital Inspection | Conventional Inspection |

|---|---|---|---|

| Ideal For | Confirming the integrity of Protolabs’ manufacturing processes | Checking up to 50 critical dimensions in a cost-effective and timely manner | Measuring any number of dimensions, including non-critical aspects |

| Measurement Capabilities | Up to 4 plane-to-plane and outside diameter (OD) measurements | Up to 50 measurements, including OD/ID, plane-to-plane, hole location, and angles | Unlimited measurements utilizing most GD&T types |

| Special Features | Includes images highlighting quality checks | Digital reports featuring color mapping or a standalone color map option | None |

| Who Can Use It | Applicable to all injection molding and CNC machining orders | Suitable for on-demand manufacturing and injection molding orders | Also available for on-demand manufacturing and injection molding orders |

| Lead Time Requirements | No additional lead time | Usually requires an extra 3+ days | Typically takes 7+ days |

| Cost Structure | No extra charge required | Additional fees may apply; please consult your account representative for specifics | Additional fees may apply; consult your account representative for details |

| Sampling Plan | Molding: Initial part checked at start of the run and approximately every 12 hours for longer runs; Machining: All parts will be checked | Molding: Randomly selected parts per customer request; Machining: N/A | Molding: Random selection per customer request; Machining: N/A |

| Request Process | Automatically included with all on-demand manufacturing orders; for other inquiries, please contact customer service | Available with all on-demand manufacturing orders, or you can call your account representative to request | Accessible with all on-demand manufacturing orders or through your account representative |

Important Note: For parts that exceed 8 inches (203mm) in diameter or 5 inches (127mm) in height, a conventional inspection is required.

Comprehensive Quality Management System

At KingStar Mold, we are committed to maintaining the highest standards of quality throughout every stage of production. Our robust quality management system (QMS) integrates advanced technologies, detailed inspections, and continuous improvement practices to ensure that every product meets or exceeds client expectations. We emphasize proactive problem-solving, real-time data collection, and rigorous testing, all aimed at enhancing product performance and consistency.

Our comprehensive QMS is supported by a range of cutting-edge measuring machines that enable precise monitoring and control of product quality. From material composition analysis to dimensional verification and color consistency, our advanced equipment plays a crucial role in guaranteeing the reliability and accuracy of our molds and components. These machines, combined with our skilled team and attention to detail, allow us to deliver superior quality products efficiently and reliably.

Our Quality Management Machines

High-Precision Measurement Technology

Our measuring machine utilizes cutting-edge technology to ensure the highest level of precision in every component. Equipped with advanced sensors, it provides accurate measurements to tight tolerances, essential for maintaining product quality.

Versatile Measurement Capabilities

The machine is capable of measuring a wide range of materials and complex geometries, making it ideal for diverse manufacturing needs. From small, intricate parts to large components, it ensures consistent performance across various applications.

Automated Data Collection and Analysis

Our measuring machine is integrated with automated data collection systems that streamline quality control processes. The system provides real-time analysis and reports, enabling faster decision-making and continuous quality improvement throughout production.

Enhanced Quality Management Capabilities

More KingStar Mold shows will give you a deeper insight into our QM expertise

Color Controller

Accurately analyzes the composition of materials, ensuring that every mold and part meets the required material specifications.

Pressure Gauge

Monitors the pressure within molds during injection, ensuring optimal conditions for consistent part quality and performance.

Moisture Analyzer

Measures the moisture content in materials, helping to prevent defects caused by excess moisture during the injection molding process.

Profile Projector

Allows for precise measurement of molded parts’ profiles and contours, ensuring complex geometries meet the required specifications with high accuracy.

XRF Spectrometer

Accurately analyzes the composition of materials, ensuring that every mold and part meets the required material specifications.

XRF Analyzer

Be Used to non-destructively detect and measure the elemental composition of materials, providing fast and reliable analysis for quality control.

To ensure consistency, we conduct rigorous quality checks at every stage of production, including material inspection, in-process monitoring, and final product testing. This guarantees that each batch meets the same high standards.

We use a range of advanced measuring and testing equipment, including XRF Spectrometers, Profile Projectors, and Color Controllers. These tools help ensure the precision and accuracy of every product we manufacture.

When a quality issue arises, KingStar Mold follows a structured corrective action process. This includes root cause analysis, immediate resolution, and preventive measures to ensure that issues do not recur.

KingStar Mold is ISO 9001 certified, ensuring our quality management processes comply with international standards. This certification reflects our commitment to delivering products of the highest quality.

We implement rigorous quality control measures, including in-process inspections, final product testing, and continuous improvement practices. Our team uses advanced equipment and thorough analysis to detect and resolve any issues early.

KingStar Mold follows an ISO-accredited quality management system (QMS) to ensure that every stage of production meets the highest standards. Our QMS includes continuous monitoring, testing, and evaluation to guarantee consistency and reliability in our products.

KingStar Mold is committed to continuous improvement through regular employee training, process evaluations, and the implementation of feedback loops. This ensures we evolve and enhance our quality management practices to meet the changing needs of our customers.

We integrate sustainability into our quality management system by minimizing waste, optimizing energy use, and ensuring that our processes comply with environmental regulations. This contributes to producing high-quality products with minimal environmental impact.

We regularly evaluate our quality management system through internal audits, performance reviews, and customer feedback. This allows us to identify areas for improvement and ensure that our practices are always aligned with industry standards.

Our approach ensures that products are defect-free, meet specifications, and are delivered on time. By integrating advanced testing, continuous feedback, and proactive issue resolution, we maintain the reliability and excellence of our products.

Our measuring machines are calibrated regularly to ensure accurate readings. We follow a strict maintenance and calibration schedule to ensure our equipment continues to meet the highest standards of precision.

Yes, KingStar Mold provides comprehensive quality control documentation, including CPK, FAI, PPAP, and PFMEA reports, upon request. These reports help verify that products meet your specifications and quality standards.