Plastics have become fundamental components in contemporary life, serving critical functions in nearly every sector from healthcare to consumer goods. Their ubiquitous nature demands rigorous quality assurance measures to guarantee various aspect from product safety, environmental sustainability, to performance reliability. For a Plastic Injection Molding Factory in China like us, ensuring consistent product quality is essential not only for safety and performance but also for staying competitive in the global market. The production process of plastic products involves many steps, and the processing procedures for some products are quite long. The raw materials, equipment and molds used in the production process are diverse. The appearance and performance of the products are affected by various factors such as molding temperature, pressure, time and processing operation conditions. Therefore, quality fluctuations during the production process are inevitable.

As a leading OEM/ODM part on-demand manufacturer, KingStar Mold explores a comprehensive framework for plastic product evaluation, systematically addressing five key dimensions: material specifications, manufacturing protocols, implementation systems, performance benchmarks, and ecological compliance standards. Whether you are a professional or a researcher in a related field, this article is for your reference.

- I. Quality Inspection Standards for Raw Materials

- II. Quality Inspection Standards for Production Processes

- III. Quality Inspection Implementation System

- IV. Inspection Standards for Performance Requirements of Plastic Products

- V. Environmental Compliance Inspection Standards for Plastic Products

I. Quality Inspection Standards for Raw Materials

The quality of plastic products is directly affected by raw materials. Conducting strict inspection and control of the quality of plastic raw materials is the basis for ensuring the quality of plastic products. The quality inspection standards for raw materials include but are not limited to the following aspects:

- Appearance requirements: Inspect the surface of raw materials for obvious cracks, bubbles, foreign objects and other defects, and evaluate their color, luster, etc.

- Density inspection: Check whether the density of raw materials meets the requirements by the water immersion or other methods for density measurement.

- Melt flow rate inspection: Based on the type and application of plastic raw materials, the melt flow performance is tested through equipment such as melt flow index testers to determine their adaptability to processing and molding.

- Mechanical property inspection: This includes testing of tensile strength (measuring resistance to pulling forces), impact strength (evaluating shock absorption capacity) and hardness (assessing surface resistance to indentation), along with other mechanical characteristics to verify whether the products’ structural integrity and durability are adequate for intended applications.

- Weather resistance performance inspection: Conducted through controlled exposure testing (outdoor weathering) or laboratory simulations (accelerated aging chambers) that replicate various environmental conditions including UV radiation, temperature fluctuations, and moisture exposure, ensuring material performance stability over the product’s expected lifespan.

II. Quality Inspection Standards for Production Processes

The production process of plastic products is directly related to the structure and performance of the products. Conducting quality inspection on the production process is an important link to ensure the quality of plastic products. The quality inspection standards for production processes include but are not limited to the following aspects:

- Temperature control: By detecting and recording the temperature changes during plastic processing, the temperature is ensured to remain within a reasonable range to prevent overheating and other defects caused by plastic thermal decomposition during processing.

- Pressure control: By detecting and recording pressure changes during the plastic processing, it ensures the stability and rationality of processing pressure, avoiding product defects caused by abnormal pressure.

- Injection molding speed control: By adjusting the injection speed, the plastic can be fully and evenly filled in the mold, avoiding defects such as warping, shrinkage, etc.

- Cooling time control: The cooling time should be reasonably controlled according to the type (and accordingly, the structure) of the plastic to ensure that the plastic products are fully cured and maintain the stability of their shape during the cooling process.

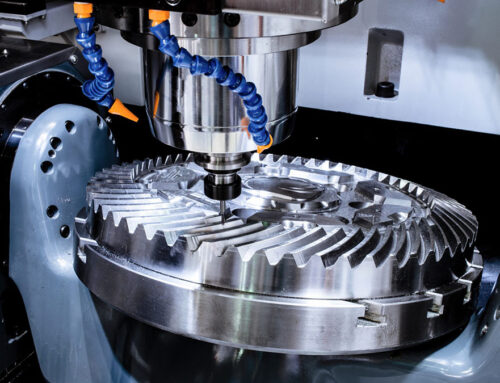

- Mold design and Maintenance: Ensure regular maintenance of reasonably designed molds to reduce wear and deformation during use to improve accuracy and surface quality of products.

Real Scene in KingStar Mold Factory with Workers Inspecting Plastic Products

III. Quality Inspection Implementation System

To keep the quality of plastic products within a certain range, in addition to strictly controlling the selection and design of materials for the products, the design and manufacture of molds, the selection and commissioning of equipment, and the setting of process flow and process parameters, it is also an important condition to strengthen quality inspection at each process during the production process. In the production process of plastic products, it is often emphasized that “quality is guaranteed by manufacturing process”, which indicates that high-quality products are mainly achieved through strict process management. However, in order to ensure that the management measures of quality guarantee by process can be reflected in the production process, it is necessary to set up necessary quality inspection points in the production process of the products, and appropriate inspection methods and means should be adopted.

3.1 Setting of Quality Inspection Points

In the production process of plastic products, the places where inspection procedures are set up according to the process flow or where dedicated inspection devices are installed and quality checks are conducted by inspectors are called quality inspection points. The task of quality inspection points is to promptly identify and remove substandard products generated in each molding process to avoid waste in subsequent processing or adverse effects on the quality of the final product. The setting of quality inspection points after which molding processes requires careful consideration, as a reasonable arrangement not only enhances the efficiency of quality inspection work and accurately reflects the quality situation during the production process of the products in a timely manner, but also helps to achieve the quality management policy of ” prioritizing prevention over remediation” for the products. A large amount of production practice indicates that quality inspection points are generally needed to be set up after the following molding processes.

3.1.1 Initial Process

The initial process in the production of plastic products is mostly the preparation process for the raw materials used for mixing and molding. Common mixing processes, involve, for example, in the production of polyvinyl chloride products, blending powdered PVC resin with plasticizers, stabilizers, fillers, and colorants to form a powder that can be directly used for molding or is extruded and granulated before being used for molding. After this mixing process, a quality inspection point should be set up to focus on checking whether the composition of the powder and the molding process meet the requirements specified in the formula. Using powders with composition errors or those whose molding process does not meet the specified requirements is obviously difficult to produce qualified products through molding. Common preparation processes for molding materials include the drying operation of various granular thermoplastic plastics. After this initial process, the quality inspection point should be set up to focus on checking whether the moisture content of the dried granules has been reduced to the allowable limit. Granules with poor drying quality are often the main reason for defects such as lack of luster, silver fibers, and bubbles in the products.

3.1.2 Molding Process

During the entire process of plastic product manufacturing, molding is generally the most crucial process as it transforms the plastic raw materials into products with specific shapes and dimensions. The appearance and strength of the products, to a large extent, are related to the reasonable process control and correct operation during the molding process. Quality inspection points are set after the molding process to promptly test the appearance and dimensions of the products. This not only enables the removal of defective products but also helps to assess the implementation of the process operation procedures.

3.1.3 Processes with Significant Impact on Final Product Quality

Among the multiple processes in plastic product manufacturing, apart from the molding process, there are some processes that have a significant impact on the final product quality, such as the sizing process for hard pipes in thermoplastic extrusion molding, the painting and baking process for thermosetting plastic molded products, and the foaming process for foam plastic products. Setting quality inspection points after these processes and promptly testing technical indicators such as the diameter size of the hard pipes, the moisture absorption of the molded products, and the density of the foamed products is of great significance for ensuring the quality of the final products.

3.1.4 Processes Prone to Quality Fluctuations

In the plastic product manufacturing process, some processes often experience significant fluctuations in product quality due to complex influencing factors or relying mainly on the operators’ experience. For example, the process of connecting products with adhesives, where the bonding strength is affected by various factors such as the type of adhesive, surface treatment methods of the products, gluing techniques, drying conditions, and curing process parameters of the glue, and the glue application techniques are not advanced enough, thus causing significant fluctuations in the quality of adhesive products. The coloring process of powdery and granular thermoplastic plastics, where the color control currently mainly relies on the operators’ experience, makes the color of the products prone to fluctuations. Setting quality inspection points after these processes, promptly identifying the main factors causing quality fluctuations and taking measures to improve them is very necessary to ensure the consistency of product quality.

3.2 Inspection Methods

If the inspection method is chosen appropriately, it not only helps to ensure that the inspection results truly reflect the quality status of the products, but also helps to reduce the cost of quality inspection and shorten the inspection cycle. An appropriate inspection method should not only ensure the required inspection effect but also facilitate production management, and should also minimize the workload of dedicated inspectors. During the production process of plastic products, for different types of products and different production processes, different inspection methods can be adopted.

The quality inspection work in the plastic product production process, in addition to having dedicated inspectors responsible for it, from the perspective of all-round production management, it is more important to widely involve production operators in quality inspection and quality management, that is, the more appropriate inspection method is to combine the inspection of dedicated personnel with the self-inspection and mutual inspection of each process operator.

3.2.1 Self-inspection

Self-inspection refers to the quality inspection conducted by the operators of the forming process on the products they have manufactured. Production operators not only need to proficiently carry out the production operations within their responsibilities to ensure the normal operation of the production process; but also have an important responsibility for the quality of the products they have processed. In order to truly take responsibility for the quality of the products, production operators are required to carefully read the process documents before production, carefully check the molds and their accessories, the types and specifications of the plastic raw materials used for molding, and the related metal inserts, and adjust the various process parameters according to the provisions of the process card; during the production process, they must strictly follow the drawings, process cards or relevant standards to carry out production operations, and promptly make production records; after the products are processed, they should inspect each product according to the quality requirements of each process, and promptly separate the defective and substandard products from the qualified products. Only when the products processed by each process are qualified by the operators, can they be sent to the next process for processing or submitted to the dedicated inspectors for inspection.

3.2.2 Mutual Inspection

Mutual inspection mainly refers to the quality inspection conducted by the operators of the next process on the products submitted by the operators of the previous process. Since the quality inspection in the plastic product production process is mainly an appearance inspection, especially the inspection of the appearance defects produced during the processing. During the self-inspection of the products processed by each production operator, due to lack of experience, incorrect judgment and incomplete understanding of the allowable degree of appearance defects in the next process, they may still send the products that are not suitable for further processing to the next process. Therefore, the operators of the next process still need to re-inspect the products improved by the operators of the previous process before processing. Through re-inspection, defective products that cannot be further processed can be promptly discovered, thereby avoiding the waste of manpower and material resources caused by processing the already defective products again.

3.2.3 Professional Inspection

To ensure that the quality inspection work in the plastic product production process achieves effective results, in addition to widely mobilizing the participation of production operators in self-inspection and mutual inspection of product quality, it is also necessary to attach great importance to the role of professional inspectors. This is primarily because, when production operators conduct self-inspection and mutual inspection, due to certain psychological factors of their subjective consciousness, they are prone to overlook some quality issues. However, professional inspectors, having undergone specialized training and strong sense of responsibility, are more likely to detect various quality problems, including systematic errors, by reminding production operators to pay attention, thereby overcoming these problems.

During the plastic product production process, professional quality inspectors should conduct inspections on the products produced in each process at fixed points or on a rotating basis. When inspecting the products along the prescribed route, items and standards, the professional quality inspectors should focus on inspecting the quality issues that production operators are prone to overlook during self-inspection and mutual inspection. Moreover, after the introduction of new products, after machine and mold maintenance, and after changes in molding process conditions, they should promptly conduct comprehensive and careful quality inspections on the first-piece products produced. When professional quality inspectors discover quality problems, they should help production operators identify the causes of the problems and collaborate with process personnel to propose improvement measures to avoid large-scale quality accidents.

3.3 Inspection Methods

The quality inspection methods in the plastic product production process should be simple, feasible, and capable of obtaining inspection results in a short period of time. To this end, advanced detection technologies such as pneumatic, electric, laser, infrared, ultrasonic, X-rays, and β-rays have been widely adopted on modern plastic product production lines, enabling rapid and precise detection of the main quality indicators of products during the production process. β-rays are used for continuous measurement of the thickness of laminated films and sheet materials, and infrared is used for automatic measurement of the thickness of blown films. These are successful examples in this regard.

3.3.1 Visual Appearance Inspection

The characteristics such as surface color, gloss, texture, and surface defects that can be observed and judged by the naked eye are usually regarded as the basis for inspecting the appearance quality of plastic products. Currently, the inspection of the appearance quality of plastic products is mainly conducted through naked-eye observation. To better observe some appearance defects, magnifying glasses are often used for observation. The better inspection method for determining whether the color, gloss, and texture of the product meet the specified requirements and the allowable limits of surface dents, flow marks, bubbles, weld lines, silver threads, black spots, and warping deformation is to compare with the sealed physical samples as the standard.

The results of visual appearance quality inspection can not only serve as the basis for evaluating whether the product is qualified, but also through the statistics and analysis of the types and quantities of defects or non-conforming products, it can identify the causes of non-conformity and find targeted solutions.

3.3.2 Material Performance Inspection

In addition to visual inspection, the key performance indicators of raw materials are also important.

Density testing: Use immersion method or electronic density meter and other instruments to ensure that the material density meets the requirements of the formula. The stability of density directly affects the mechanical properties and dimensional stability of the product.

Melt flow rate determination: Use melt index instrument to accurately measure the flow performance of the material under specific temperature and pressure. This test is crucial for evaluating the processing adaptability of the material, especially for processes such as injection molding.

Mechanical performance monitoring: Conduct tensile strength, impact strength, and hardness tests by sampling to ensure that the raw material has the required mechanical properties. These data provide a basis for predicting the performance of the product during use.

Weather resistance assessment: Conduct laboratory accelerated aging tests or outdoor exposure tests to verify the durability of the material in the expected usage environment, ensuring that the product maintains stable performance throughout its life cycle.

3.3.3 Dimension Inspection

For injection-molded, compression-molded, and cast products used as industrial parts, extruded and rolled profiles with product specifications, and machined products, etc., during the production process, dimensional quality inspections are required. In the plastic product production process, the commonly used measuring tools are steel straight rulers, vernier calipers, depth gauges, micrometers, thread ring gauges, and dial indicators, etc. For single-piece plastic products produced in large quantities, it is best to use special measuring tools such as custom-made cardboards and plug gauges for dimension inspection. Although using these special measuring tools cannot provide the actual dimensions of each product, it can completely determine whether the measured dimensions are within the allowable tolerance range. When the dimensional accuracy demand of the product is very high, it is best to use optical measuring instruments for dimension inspection. The advantage of this type of instrument is that it does not directly contact the product during the measurement process, and it will not cause measurement errors due to contact pressure when the product deforms.

When measuring the dimensions of plastic products during the production process for quality inspection, first, attention should be paid to the influence of the product temperature on the dimension measurement. Products removed from the hot mold should be measured after cooling to room temperature. Secondly, the influence of aging on the dimension measurement should not be ignored. The dimensions of the product change with time after being removed from the mold. The dimensions of thermoplastic injection-molded products change significantly within 24 hours after demolding. The dimensions of thermoplastic products with high crystallinity change more significantly over time. Thirdly, the influence of the contact pressure during measurement should be considered. This is because plastics are more prone to deformation compared to metals. The contact pressure of precision measuring tools such as dial indicators is generally large, and using them for the dimension inspection of plastic products will result in large measurement errors. It is best to use plastic product dimension measuring special tools with smaller contact pressure.

For single-piece plastic products processed by injection molding, compression molding, casting, blow molding, and thermoforming, the dimensional deviation of each product can be easily determined from the measurement results of the dimensions. For continuously processed profiles such as those produced by extrusion or calendering, the dimensional conformity of an entire batch cannot be determined solely from measurements taken at a few points. Dimensional inspection of plastic continuous profiles typically requires multi-point measurements, followed by statistical analysis of the large volume of collected data. The statistical results are then used to evaluate the dimensional quality of the batch.

By establishing a complete material performance inspection system, combined with advanced detection technology and strict process control, it is possible to achieve comprehensive quality assurance of plastic products and provide strong support for the optimization of the production process and the continuous improvement of product quality.

IV. Inspection Standards for Performance Requirements of Plastic Products

The performance requirements of plastic products include multiple aspects such as physical properties, mechanical properties, chemical properties, electrical properties and so on. The performance requirements for different types of plastic products also vary. The inspection standards for the performance requirements of plastic products include but are not limited to the following aspects:

| Category | Test Item | Common Standards (Examples) | Purpose / Key Information |

|---|---|---|---|

| Physical Properties | Density | ISO 1183, ASTM D792 | Measures mass per unit volume; related to part weight and material cost. |

| Water Absorption | ISO 62, ASTM D570 | Determines the amount of water absorbed under specified conditions; affects dimensional stability. | |

| Melt Flow Rate (MFR) | ISO 1133, ASTM D1238 | Measures the ease of flow of a melted polymer; critical for processing (e.g., injection molding). | |

| Heat Deflection Temperature (HDT) | ISO 75, ASTM D648 | Measures the temperature at which a material deforms under a specified load; indicates heat resistance. | |

| Mechanical Properties | Tensile Strength | ISO 527, ASTM D638 | Determines the material's resistance to breaking under tension. |

| Impact Strength (Izod/Charpy) | ISO 179/180, ASTM D256 | Evaluates resistance to impact or shock loading. | |

| Hardness (Shore/Rockwell) | ISO 868, ASTM D2240 | Measures resistance to surface indentation. Shore A for soft, Shore D for hard plastics. | |

| Flexural Strength | ISO 178, ASTM D790 | Measures the resistance to bending or flexure. | |

| Chemical Properties | Chemical Resistance | ISO 175, ASTM D543 | Assesses changes in properties (weight, dimensions, appearance) after exposure to chemicals. |

| Environmental Stress Cracking Resistance (ESCR) | ISO 22088, ASTM D1693 | Evaluates failure under stress in the presence of chemicals (e.g., detergents). | |

| Weatherability / UV Resistance | ISO 4892, ASTM G154 | Simulates long-term outdoor aging using UV light, and moisture. | |

| Electrical Properties | Insulation Resistance | IEC 60167, ASTM D257 | Measures a material's ability to resist the flow of electric current. |

| Dielectric Strength | IEC 60243, ASTM D149 | Measures the maximum voltage a material can withstand before electrical breakdown occurs. | |

| Surface/Volume Resistivity | IEC 60093, ASTM D257 | Measures electrical resistance across the surface or through the volume of a material. | |

| Comparative Tracking Index (CTI) | IEC 60112 | Measures the electrical breakdown (tracking) properties of an insulating material. |

V. Environmental Compliance Inspection Standards for Plastic Products

The environmental protection requirements for plastic products are one of the basic requirements for products in modern society. In order to protect the environment and human health, hte environmental compliance requirements for plastic products also need to be strictly inspected and controlled, including but not limited to the following aspects:

- Harmful substance testing: Test for heavy metals, organic solvents, flame retardants, and other harmful substances in plastic products to ensure that the products do not contain harmful substances that exceed the standard.

- Recycling and utilization of plastic waste: Encourage the use of recyclable plastic raw materials to produce products, enhance the recycling and utilization of waste plastic products, and reduce environmental pollution.

- Assessment of environmental protection of packaging materials: Evaluate the degradability, incinerability, etc. of packaging materials to reduce the environmental impact of plastic waste.

- Environmental compliance requirements for production processes: Encourage the adoption of low-energy consumption and low-pollution production processes to reduce the discharge of waste gas, waste water and solid waste.

The quality inspection standards for plastic products cover multiple aspects, such as the quality control of both raw materials and production processes, and requirements of both product performance and environmental compliance. By rationally formulating and implementing these standards, it can be ensured that plastic products possess excellent qualities in terms of safety, environmental compliance, and reliability, providing better products and services for society and consumers. The plastic industry should strengthen the formulation and update of standards to promote self-development and progress.

For a more detailed breakdown of specific part-level inspection procedures, refer to the Inspection Criteria for Plastic Parts.