For manufacturers and engineers working with products made through PVC injection molding(especially wire and cable compounds, flexible films, and consumer goods) choosing the right plasticizer is critical to achieving optimal product performance, durability, and compliance with industry standards. With a wide range of plasticizer types available, each with unique strengths (e.g., cold resistance, flame retardancy, high-temperature stability) and limitations, navigating options can be complex.

As a leading injection molding company in China, we complied this technical guide which is built on industry standards, practical application data, and material science principles to address the challenge. It covers 7 major categories of PVC-compatible plasticizers, detailing their chemical characteristics, key performance metrics, representative products, and structure-property relationships. Additionally, it provides actionable selection criteria tailored to high-demand scenarios like wire insulation and heat-resistant applications, ensuring you can make informed decisions aligned with your product goals.

- 1. Phthalates (Phthalate Esters): The Core Plasticizer Category for PVC

- 2. Aliphatic Dibasic Acid Esters: Specialized Cold-Resistant Plasticizers

- 3. Triphenylolmethane: Heat-Resistant & Durable Plasticizers

- 4. Phosphates (Phosphate Esters): Flame-Retardant Multifunctional Plasticizers

- 5. Polyester Plasticizers: High-Durability Options for Demanding Applications

- 6. Epoxy Plasticizers: Plasticizers with Auxiliary Stabilizing Effects

- 7. Other Plasticizers

- 8. Summary of the Properties of Various Plasticizers (for Wire & Cable Compounds)

- 9. Selection of Plasticizers: Science-Based Criteria for PVC Applications

1. Phthalates (Phthalate Esters): The Core Plasticizer Category for PVC

1.1 Overview

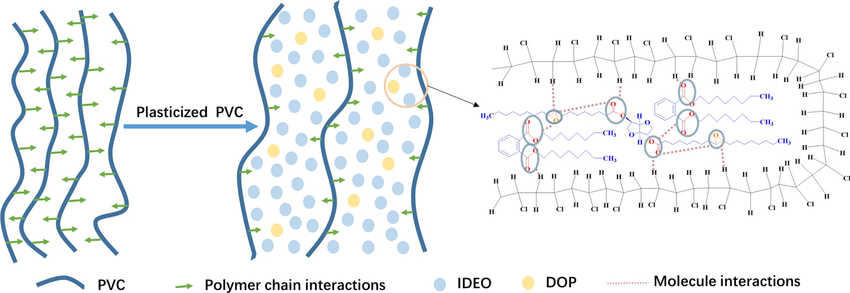

Most plasticizers can be classified into two categories in chemistry: one is high-boiling esters, and the other is substances with molecular structures, shapes, and sizes very similar to the plasticizer polymers. It is obvious that phthalates belong to the former category. Phthalate esters are the most important category among plasticizers. They have excellent compatibility with PVC, which is one of the major characteristics of phthalates. Phthalate esters generally have moderate polarity, and their solubility and dielectric constants are relatively close to those of PVC. A polymer can only be dissolved in a solvent when their solubility parameters are the same or similar.

1.2 Main Categories and Performance Characteristics

Phthalate esters include Ortho-Phthalates (o-Phthalates), Isophthalates (m-Phthalates) and Terephthalates (p-Phthalates). Ortho-phthalate further includes Low- and High-Carbon Alcohol Esters, Branched- and Linear-Chain Alcohol Esters, Single- and Mixed- Alcohol Esters, Alkyl Esters, Aryl Esters, and so on.

(1) Ortho-Phthalates (o-Phthalates)

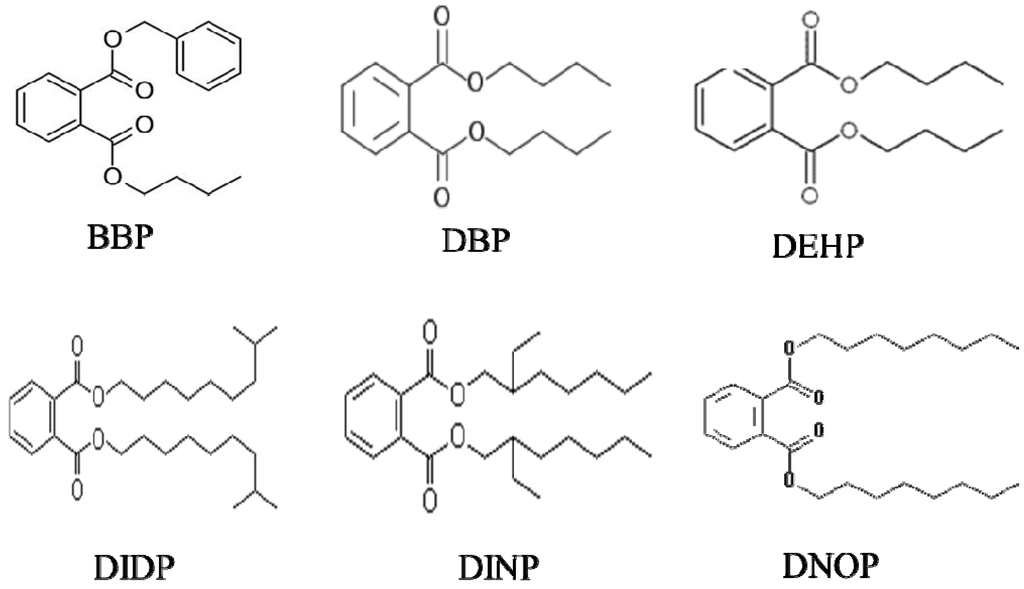

O-Phthalates, as a main type of plasticizers, have comprehensive properties and are either non-toxic or low-toxic. Among them, Dimethyl Phthalate (DMP) and Diethyl Phthalate (DEP) are not suitable for PVC due to their high volatility and irritancy. Despite that Dibutyl Phthalate (DBP) has high volatility and poor durability, it’s still occasionally used due to its good compatibility and high plasticizing efficiency. Among the phthalate plasticizers, the high-carbon alcohol esters with C6-13 carbon chains are the most widely used, including Dioctyl Phthalate (DOP), Diheptyl Phthalate (DHP), Diisooctyl Phthalate (DIOP), Diisononyl Phthalate (DINP), and Diisodecyl Phthalate (DIDP), etc.

(2) Isophthalates (m-Phthalates)

M-Phthalates is a crystalline solid and has poor compatibility with PVC, but C8-C9 alcohol esters with a certain degree of branching are liquids and have good compatibility with PVC. Resistant to migration, m-Phthalates possess superior volatility, low-temperature performance and electrical properties than corresponding o-phthalates. The representative variety is Di(2-ethylhexyl) Terephthalate (DOTP).

(3) Terephthalates (p-Phthalates)

Terephthalates have better solubility, volatility and extractability than Isophthalates. The representative variety is Dioctyl Isophthalate (DOIP).

1.3 Representative Products

(1) Dibutyl Phthalate (DBP) – a representative of Low-Carbon Alcohol Esters. It has good processing properties, low-temperature resistance, and aging resistance. However, due to its high volatility and poor water extraction resistance, it is not commonly used.

(2) Di(2-ethylhexyl) Phthalate (DEHP), commonly known as Dioctyl Phthalate, is a colorless or pale yellow oily transparent liquid (at room temperature). Its freezing point is -53°C and its boiling point is 386°C. DOP has good compatibility with resins, low volatility, good light and heat stability, good electrical properties, low-temperature resistance, and relatively low toxicity; it can meet the requirements of most general products and can be used alone without mixing in many formulations. It is a widely used standard plasticizer with comprehensive performance; but is not resistant to oil.

(3) Diisooctyl Phthalate (DIOP) has a relatively low melting point and plasticizing efficiency equivalent to DBP. It can be used interchangeably with DBP in flexible PVC. However, its volatility, low-temperature flexibility, and electrical properties are poorer compared to DBP.

(4) Di-Isononyl Phthalate (DINP) has similar general characteristics to DBP, but has lower volatility. This not only helps improve the processing environment but also enhances the durability and especially heat- and aging-resistance of final products.

(5) Diisononyl Phthalate (DINP) has good volatility, insulation properties, fogging resistance, and compared to DBP, it has better electrical properties and better resistance in migration, water, oil and heat. For application, it must be used together with low-temperature resistant plasticizers (such as DOA), or else the products may be too hard; it is often used in products requiring high- or low-temperature resistance.

2. Aliphatic Dibasic Acid Esters: Specialized Cold-Resistant Plasticizers

2.1 Overview

Aliphatic Dibasic Acid Esters are a typical type of cold-resistant plasticizers. The commonly used varieties include Adipates (Adipic Acid Esters), Azelates (Azelaic Acid Esters), and Sebacates (Sebacic Acid Esters). Main products include Di(2-ethylhexyl) Adipate (DOA), Di(2-ethylhexyl) Sebacate (DOS), and Di(2-ethylhexyl) Azelate (DOZ), etc.

2.2 Main Performance Characteristics

Compared with o-Phthalates, Aliphatic Dibasic Acid Esters mainly exhibit the following characteristics:

(1) Better low-temperature performance than DOP. And among which, the one with the best cold resistance is DOS.

(2) Better plasticizing efficiency than DOP.

(3) Low viscosity, and good stability when in the formulation of plastic paste.

(4) Poor compatibility. Usually used as secondary plasticizers.

(5) Poor durability. DOP already has poor durability, but Aliphatic Dibasic Acid Esters’ durability is even worse.

(6) The electrical insulation performance is poor. This is because these plasticizers have low polarity, allowing the dipoles on the polymer chain segments to have greater freedom, thus increasing the conductivity of PVC and reducing the electrical insulation.

(7) Poor optical rotation stability and weather resistance.

2.3 The Influence of Aliphatic Dibasic Acid Esters Structure on Cold Resistance

The molecular structure of Aliphatic Dibasic Acid Esters has a significant impact on their low-temperature performance as plasticizers. Generally, larger the ratio of the number of carbon atoms in the aliphatic chain to the number of ester groups (Ap/Po) in the molecule, better the cold resistance.

2.4 Representative Varieties

(1) Di(2-ethylhexyl) Adipate (DOA) is a non-toxic plasticizer with good cold-resistance and good compatibility with PVC, having a certain degree of heat resistance, light resistance and water resistance. It shows good lubrication during extrusion, resulting in good hand feel. With poor oil resistance, it is usually used together with DOP and DIDP in cold-resistant formulations.

(2) Di(2-ethylhexyl) Azelate (DOZ) is a nearly white transparent liquid, an excellent cold-resistant plasticizer for Vinyl Resins. It has low viscosity, high boiling point, high plasticizing efficiency, low volatility and migration, and excellent light and heat resistance, with better cold resistance than DOA.

(3) Di(2-ethylhexyl) Sebacate (DOS) is a pale yellow or colorless transparent oily liquid. It can be processed safely at high temperatures, has better water resistance than DOA, but has poor oxidation resistance, weather resistance, and extrusion resistance. When used, it should be combined with the main plasticizer, with the dosage not exceeding one-third of the main plasticizer.

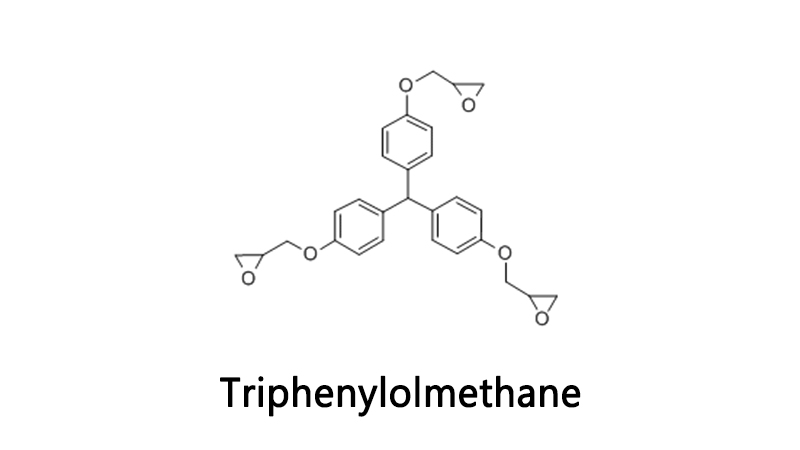

3. Triphenylolmethane: Heat-Resistant & Durable Plasticizers

3.1 Overview

Triphenylolmethane belongs to the category of Polybenzoates. This type of ester is characterized by low volatility, resistance to extraction, and resistance to migration. It has advantages similar to those of polyester plasticizers, while also having compatibility, processing properties, and low-temperature performance similar to Monomeric Phthalates. Therefore, it combines the advantages of both monomer plasticizers and polymer plasticizers. It is typically used as a heat-resistant and durable plasticizer.

3.2 Main Varieties and Properties

The commonly used Triphenylolmethane include Triphenylolmethane tri(2-ethylhexyl) (TOTM), Triphenylolmethane tri(isooctyl) (TIOTM), and Triphenylolmethane tri(isdecyl) (TIDTM), etc.

(1) Triphenylolmethane tri(2-ethylhexyl) (TOTM) is a representative product of triphenylolmethane. Triphenylolmethane tri(2-ethylhexyl) (TOTM) is a heat-resistant and durable plasticizer. Its plasticizing efficiency is similar to that of phthalates, and its compatibility can rival that of polyesters, but its oil resistance is inferior to that of polyester plasticizers.

(2) Triphenylolmethane tri(isooctyl) (TIOTM) is mainly used as a heat-resistant plasticizer, and its properties and applications are similar to Triphenylolmethane tri(2-ethylhexyl) (TOTM).

(3) Triphenylolmethane tri(isdecyl) (TIDTM) has similar properties to triphenylolmethane tri(2-ethylhexyl) (TOTM) with lower volatility, excellent durability, and better processing performance.

The structure of Triphenylolmethane is similar to that of Phthalates, and it also has good compatibility with PVC. It can also be used as a main plasticizer. Triphenylolmethane is relatively expensive and is often combined with High-Carbon Alcohol Esters of Phthalic Acid. Even in applications such as electrical wire insulation materials for construction where heat resistance is highly demanded, the practice of using Triphenylolmethane tri(2-ethylhexyl) (TOTM) or Triphenylolmethane tri(isooctyl) (TIOTM) in combination with Diisodecyl Phthalate (DIDP) is still widely adopted.

Compared to polyester plasticizers, the disadvantage of Triphenylolmethane is its poor oil resistance and lower extractability. Its migration is also relatively poor. Therefore, when building electrical wires that require oil resistance and heat resistance, polyester plasticizers must be selected over Triphenylolmethane. Triphenylolmethane is mainly used in situations requiring low volatility, low water extractability, low migration, heat resistance, and good electrical insulation performance, and can be used as a main plasticizer in such situations.

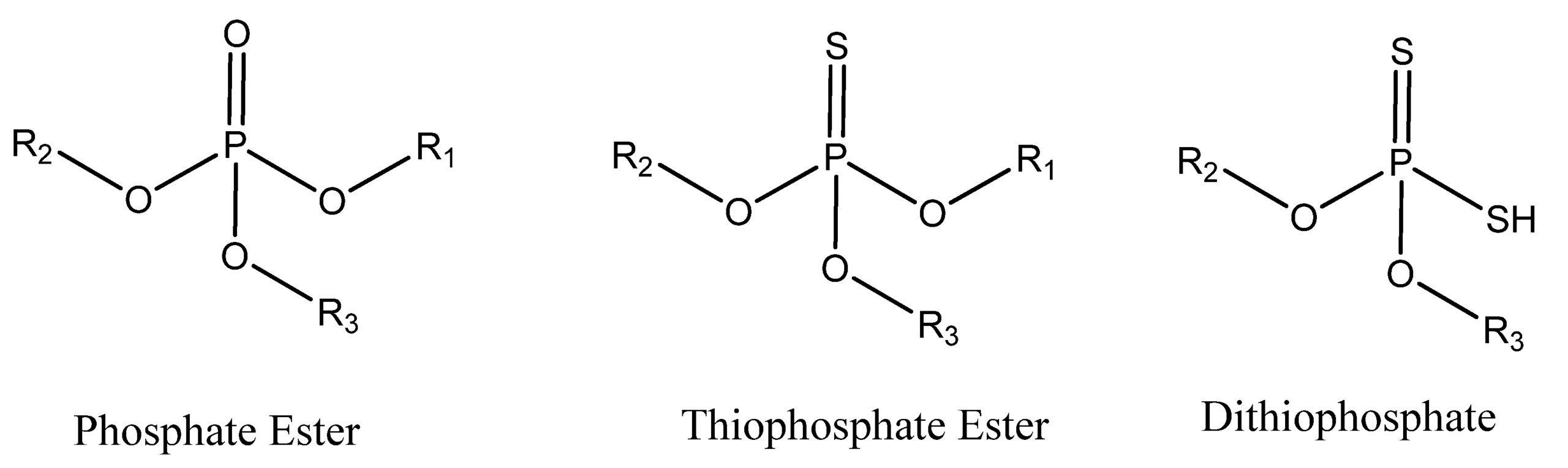

4. Phosphates (Phosphate Esters): Flame-Retardant Multifunctional Plasticizers

4.1 Overview

Phosphate esters are widely used flame-retardant plasticizers. They can be used as main plasticizers and are considered as multifunctional new products. There are typically four types: Trialkyl Phosphates, Triaryl Phosphates, Alkyl Aryl Phosphates, and Chlorinated Phosphates. The commonly used ones include Tri(2-ethylhexyl) Phosphate (TOP), Diphenyl Octyl Phosphate (ODP) , Cresyl Diphenyl Phosphate (CDP), and Tricresyl Phosphate (TCP).

4.2 Performance Characteristics

(1) Good compatibility. Trialkyl Phosphates have better compatibility than Triaryl Phosphates.

(2) Excellent flame retardancy. All Phosphate Esters exhibit good flame retardancy which is more obvious when used alone. The flame retardancy increases with the increase of phosphorus content and gradually changes from self-extinguishing to difficult-to-extinguish. The fewer alkyl groups in the molecule, the better its fire resistance. The addition of halogen atoms in the Phosphate Esters can further improve the flame retardancy.

(3) Good durability. Better volatility and extractability than DOP.

(4) Most Phosphate Esters have antibacterial and weather resistance.

(5) Cold resistance is generally poor: triaryl phosphates show poor cold resistance but low volatility, while trialkyl phosphates have slightly better cold resistance yet higher volatility.

(6) Toxicity. Most Phosphate Esters are toxic, with only Diphenyl Octyl Phosphate (ODP) being low in toxicity.

(7) High price. Often used in combination with Chlorinated Hydrocarbons.

Phosphate esters have antagonistic effects with common flame retardants (such as Sb2O3), thus cannot be used in combination.

4.3 Representative Products

(1) Tricresyl Phosphate (TCP) has a slightly pungent, light-colored liquid. It has good hydrolytic stability, excellent oil resistance, electrical insulation, and antibacterial properties. It has poor cold resistance but can be improved by combining with DOA.

(2) Cresyl Diphenyl Phosphate (CDP) is a colorless, odorless clear liquid. It has good compatibility with resins. Compared with TCP, it has similar durability, flame retardancy, and electrical properties, but has higher plasticizing efficiency, better low-temperature properties, and better wear resistance of the final products. It has poor light stability and more volatility.

(3) Diphenyl Octyl Phosphate (ODP) is non-toxic. ODP has low volatility and good cold resistance and weather resistance. When combined with DOP or DIDP, it can improve the toughness and weather resistance of the final products.

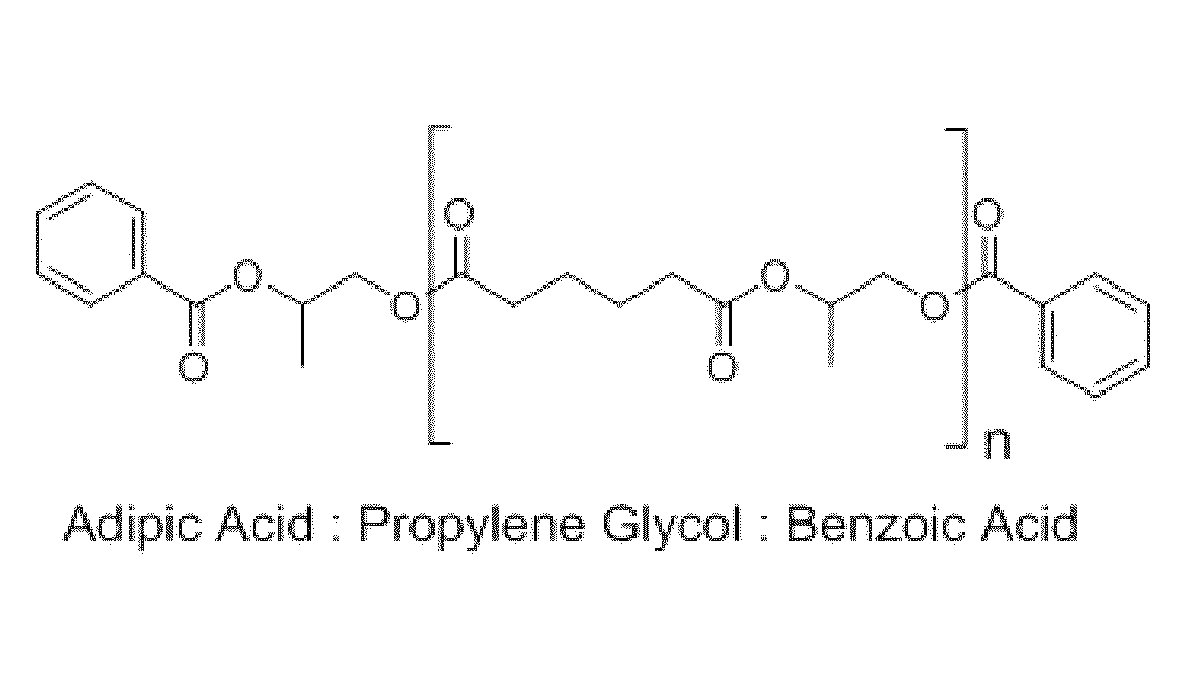

5. Polyester Plasticizers: High-Durability Options for Demanding Applications

5.1 Overview

Polyester plasticizers are mainly used in products with particularly high durability requirements and can be used as main plasticizers or in combination with other plasticizers.

5.2 Types and Properties of Polyester Plasticizers

The commonly used Dibasic Acids for preparing polyester plasticizers include Adipic Acid, Sebacic Acid, Azelaic Acid and Phthalic Anhydride. The commonly used diols include 1,2-Propanediol, 1,3-Butanediol, and Diethylene Glycol. The one-component alcohols used for sealing include 2-Ethylhexanol, Butanol. The End-Capping Monoalcohols include Lauric Acid and Caprylic Acid. Considering the difference in combinations and molecular weights of the above raw materials, there are many types of polyester plasticizers, and their properties vary greatly.

Compared with traditional plasticizers, polyester plasticizers mainly have the following characteristics:

(1) Poor compatibility. Generally, Adipic Acid polyester plasticizers have poor compatibility, while Sebacic Acid and Phthalic Acid polyester plasticizers have slightly better compatibility.

(2) Lower plasticizing effect than DOP.

(3) Low volatility and low volatile loss.

(4) Polyester plasticizers have a slower diffusion rate in PVC, so their migration is less than that of DOP.

(5) Resistant to various solvent extractions.

(6) Electrical properties slightly lower than phthalic esters.

(7) Low toxicity of polyester plasticizers.

5.3 The Impact of Chemical Structure on Performance

(1) The Influence of Chemical Structure on Compatibility: Polyesters made from low-carbon Dibasic Acids have poor compatibility and are prone to leakage; while those made from high-carbon Dibasic Acids do not exhibit this characteristic. When the Dibasic Acids are fixed, Diols (Dihydric Alcohols) with side chains can achieve better compatibility.

(2) The Influence of Chemical Structure on Mechanical Properties: When the diol is fixed, the tensile strength of PVC products increases as the number of carbon atoms in the Dibasic Acids increases; when the Dibasic Acids are fixed, the tensile strength decreases as the number of carbon atoms in the diol increases.

(3) The Influence of Chemical Structure on Extractability: The number of carbon atoms in the diol increases, and the extraction of polyester plasticizers from PVC by gasoline increases. Using diols with side chains results in less gasoline extraction. The extraction by soap water is the opposite.

(4) The Influence of Molecular Weight: The increase in the molecular weight of polyester plasticizers leads to an increase in viscosity, a decrease in plastic efficiency, poorer compatibility, and lower extractability and volatility.

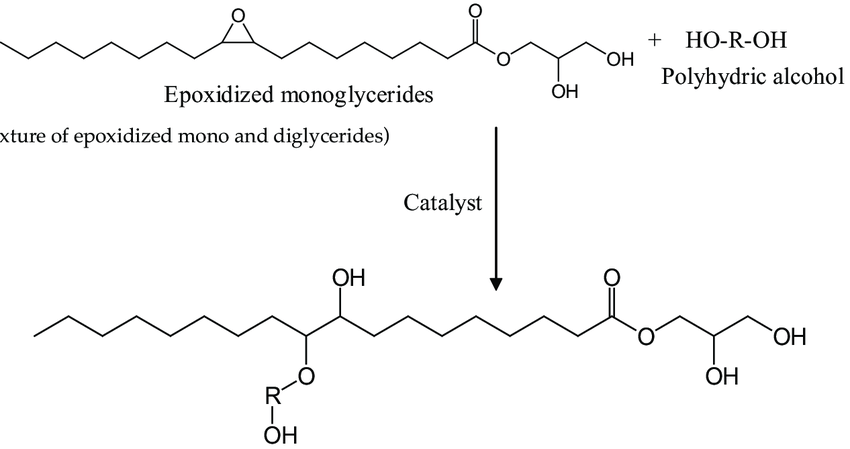

6. Epoxy Plasticizers: Plasticizers with Auxiliary Stabilizing Effects

6.1 Overview

Epoxy plasticizers are plasticizers containing a Three-Membered Epoxy Ring. Most epoxy plasticizers can be used as auxiliary stabilizers for PVC. A small amount of addition can improve the light and heat stability of the products.

6.2 Main Properties

(1) When the amount of epoxy plasticizers is too high, compatibility problems will occur.

(2) Excellent light and heat stability performance.

(3) Good durability. Among the commonly used epoxy plasticizers, epoxy soybean oil has the lowest volatility. The extractability resistance of epoxy plasticizers is superior to that of DOP. The migration resistance of epoxy soybean oil is extremely good.

(4) Low toxicity.

6.3 Representative Products

The currently used epoxy plasticizers mainly consist of three types: Epoxidized Oils, Epoxidized Fatty Acid Monoesters, and Epoxytetrahydrophthalates.

(1) Epoxy Oils. They have a chemical structure of Epoxidized Glycerol Trihydroxy Acid Esters. This is the most widely used type of epoxy plasticizer, and the main varieties include Epoxidized Soybean Oil (ESO) and Epoxidized Linseed Oil. The main component of ESO is C18 Unsaturated Fatty Acids, and the composition varies greatly depending on the source. Epoxy soybean oil has low volatility and small migration, and has excellent thermal stability and light stability, good water-oil resistance and oil resistance, and results in good mechanical strength, weather resistance and electrical properties in the final products. When used in combination with polyester plasticizers, it can reduce the migration of polyester and shows a good synergistic effect when used with heat stabilizers.

(2) Epoxidized Fatty Acid Monoesters. These are also made from natural oils. Their performance is relatively comprehensive, with good plasticizing efficiency, excellent compatibility and extractability resistance.

(3) Epoxytetrahydrophthalates. They are a type of synthetic epoxy plasticizers. Due to the characteristics of their structure, these plasticizers have the properties of both Phthalates and Epoxy Esters, making them a relatively ideal multi-functional plasticizer.

7. Other Plasticizers

(1) Polyol Esters: Polyol esters mainly include ethylene glycol esters, propylene glycol esters, mono-ethylene glycol diesters, glycerol and benzoic acid esters, etc.

(2) Citrate Esters: Citrate Esters Citric acid, whose chemical name is 2-hydroxy-1,2,3-propanetricarboxylic acid, undergoes esterification with alcohols of appropriate carbon chain length. The resulting citrate esters are truly non-toxic plasticizers.

(3) Chlorinated Hydrocarbons: Compared to non-chlorinated hydrocarbons, chlorinated hydrocarbons have slightly poorer thermal stability and light stability, but they have better compatibility and lower volatility. Common Chlorinated Paraffins are classified based on their chlorine content as Chlorinated Paraffin-42, Chlorinated Paraffin-50, Chlorinated Paraffin-52, and Chlorinated Paraffin-70. Chlorinated paraffin-42 can be used in PVC up to a limit of 25-40 PHR, while chlorinated paraffin-52 can be used up to 35-60 PHR. Chlorinated paraffins can be used in 105°C wire formulations. The products’ thermal and light stability, as well as the flame retardancy of chlorinated paraffins depend on their chlorine content, independent of the length of the molecular chain.

Compared with traditional plasticizers, polyol esters show certain advantages in the following aspects.

- Excellent low-temperature performance (similar to that of DOA); however, they have poor compatibility with PVC and thus are only used as secondary plasticizers.

- Excellent heat resistance, aging resistance and extractability. Their electrical properties are also good, and they can be used as plasticizers for heat-resistant and high-temperature insulation materials.

- Good resistance to pollution and non-toxicity.

8. Summary of the Properties of Various Plasticizers (for Wire & Cable Compounds)

The plasticizers we use are mainly applied in PVC wire and cable compounds, and their performance requirements must all comply with those of wire and cable compounds.

The table below lists the plasticizers we use and their main properties:

| Plasticizer | Abbr. | Temperature Resistance and/or Other Characteristics | Properties |

|---|---|---|---|

| Dioctyl phthalate | DOP | 600C | Good compatibility with resins, low volatility, good light and heat stability, excellent electrical properties, low temperature resistance, and low toxicity; Able to meet the requirements of most general products and can be used alone in many formulations; A standard plasticizer with comprehensive performance and the widest application range; Disadvantage: poor oil resistance |

| Polyester Plasticizer | PN-1030 W-2050 | 1050C; Migration Resistance | Non-migratory, oil resistance, solvent resistance, heat resistance and volatility; Disadvantage: high viscosity (difficult to mix), poor plasticizing efficiency and cold resistance |

| Trioctyl trimellitate | TOTM | 1050C | Excellent heat resistance, electrical insulation properties and oil resistance; Good volatility and cold resistance; A high-temperature resistant plasticizer |

| Diisodecyl phthalate | DIDP | 900C | Excellent volatility, insulation, and anti-fog properties; Good mobility, water resistance, oil resistance, heat resistance and electrical characteristics compared to DOP; Must be used together with low-temperature resistant plasticizers (such as DOA), otherwise, the product will be overly hard; Commonly used in products that require high temperature resistance or low-temperature resistance |

| Diisononyl phthalate | DINP | 900C | Lower volatility, slightly inferior cold resistance and plasticization efficiency than DOP, with other properties comparable to those of DOP |

| Dioctyl adipate | DOA | Cold Resistance | Excellent cold resistance plasticizer; Poor compatibility and high volatility when mixed with PVC, thus can only be used as an auxiliary plasticizer |

| Tri isodecyl trimellitate | TIDTM | Low-Temperature Resistance; Migration Resistance | Excellent resistance to low- and high-temperature and migration |

| Chlorinated paraffin | CERECLOR S52 | Flame Resistance | Excellent electrical performance and flame retardancy, reasonable price, but poor compatibility; Seeps out when used in large quantities; Poor light-heat stability and cold resistance; Can only be used as an auxiliary plasticizer |

| Epoxidized soya bean oil | ESBO B-22 O-130 | Heat Resistance; Stabilizer | Also used as a stabilizer; Low volatility, heat-resistance and light-resistance; Hard to be extracted; Good electrical properties, with poor cold resistance and compatibility; Cannot be used alone |

9. Selection of Plasticizers: Science-Based Criteria for PVC Applications

Selecting the optimal plasticizer is a balancing act, requiring careful consideration of the final product’s performance requirements, processing conditions, regulatory constraints, and cost. The following science-based criteria provide a structured approach to this critical decision-making process.

Step 1: Define the Primary Performance Requirement

Start by identifying the single most critical property for your PVC application. This primary requirement will narrow down the field of potential candidates significantly.

- For General Purpose & Cost-Effectiveness:General Phthalates (DINP, DIDP) are the default choice. They offer a balanced profile of compatibility, processability, and mechanical properties. DINP is widely used in consumer goods, while DIDP offers slightly better volatility resistance.

- For Superior Cold Flexibility:Aliphatic Dibasic Acid Esters (DOA, DOZ, DOS) are essential. Use them as secondary plasticizers in blends (typically 10-30% of the plasticizer system). DOS provides the best low-temperature performance.

- For High-Temperature Resistance (e.g., 105°C Wire):Trimellitates (TOTM, TIDTM) are the industry standard. They offer excellent long-term heat aging resistance and low volatility. For the highest heat endurance, Polyester Plasticizers (e.g., PN-1030) are preferred, though they sacrifice some processability and low-temperature performance.

- For Flame Retardancy (FR):Phosphate Esters (TCP, CDP) are highly effective. They act as both plasticizers and flame retardants. Remember they are antagonistic with Sb₂O₃. For cost-effective FR, Chlorinated Paraffins can be used as secondary plasticizers but be mindful of their lower compatibility and stability.

- For Low Migration & High Durability (e.g., automotive interiors, gaskets):Polyester Plasticizers are unmatched in resistance to extraction and migration. They are the choice for applications where plasticizer loss would lead to stiffening, shrinkage, or contamination of adjacent materials.

- For Non-Toxicity & Sensitive Applications (e.g., food contact, medical, toys):Citrates, Benzoates, and Epoxy Plasticizers (ESBO) are the leading choices. ESBO also provides valuable auxiliary heat stabilization.

Step 2: Evaluate Secondary Performance & Processing Needs

Once a primary candidate is identified, assess it against other important requirements. Often, a blend of plasticizers is necessary to achieve the full spectrum of desired properties.

Plasticizing Efficiency & Softness

Efficiency refers to the amount of plasticizer required to achieve a specific level of softness (e.g., a target Shore A hardness or low-temperature flex modulus). This has a direct impact on raw material cost. DOP is often the benchmark. To achieve the same softness, you might need ~5-10% more DINP, ~15-25% more TOTM, and potentially 30-50% more of a high-molecular-weight polyester. This “efficiency factor” must be calculated into your final compound cost. For cost-sensitive general applications, highly efficient general phthalates (DINP, DOP) are preferable. When a low-efficiency plasticizer like TOTM is mandated for heat resistance, consider blending it with a small portion of a highly efficient co-plasticizer like Epoxidized Soybean Oil (ESBO) to improve softness and lower overall cost.

Compatibility & Exudation

Ortho-phthalates and trimellitates exhibit excellent compatibility and can be used as primary plasticizers at high loadings. Aliphatic esters (DOA, DOS) have moderate to poor compatibility and should typically be limited to ≤25% of the total plasticizer system. Chlorinated paraffins have poor compatibility and will exude at loadings often above 15-20 phr. A simple but effective test is to place a pressed film of the compound in an oven at 70-90°C for 24-48 hours and inspect for surface oiliness or haze. More rigorously, migration tests against specific materials (e.g., PS, ABS) should be conducted.

Viscosity and Plastisol Processing

For spread coating, slush molding, or rotational casting, the viscosity of the plastisol is critical. Aliphatic Esters (DOA) and some linear phthalates help maintain low viscosity and good viscosity aging stability. High molecular weight Polyesters can cause a significant viscosity increase.

Electrical Insulation

The polarity, purity and ionic content of plasticizers directly affect the volume resistivity and dielectric strength of the final polyvinyl chloride (PVC) compound. Tri-octyl trimellitate (TOTM) and di-isononyl phthalate (DIDP) have the best electrical insulation performance, and thus are the preferred choices for the main insulation layer. Aliphatic esters and most phosphate esters plasticize PVC, thereby increasing ionic mobility and reducing volume resistivity. Therefore, they are mainly used in sheaths or applications with lower requirements.

Step 3: Formulate with Synergy in Mind

Rarely is a single plasticizer the perfect solution. Strategic blending is the key to optimizing performance and cost.

- Heat Resistance + Processability:Blend TOTM with DIDP. TOTM provides the heat resistance, while DIDP improves low-temperature flexibility and processing characteristics.

- Durability + Low-Temperature Performance:Blend a Polyester plasticizer with DOA or ESBO. The polyester provides permanence, while the secondary plasticizer counteracts its poor cold resistance.

- Flame Retardancy + Flexibility:Blend Phosphate Esters with general-purpose Phthalates. This maintains flame retardancy while improving the flexibility and cost-profile compared to using phosphates alone.

- Stabilization + Plasticization:Incorporate Epoxy Soybean Oil (ESBO, 5-10 phr) into any formulation to enhance the heat and light stability of the PVC compound, reducing the load on primary heat stabilizers.

Step 4: Verify Compliance and Cost

Beyond the technical performance matrix, the final selection must pass through the critical filters of regulatory compliance and total cost of ownership. The regulatory landscape is a primary driver behind the ongoing industry shift, moving away from traditional phthalates like DOP toward options such as DINP for certain applications, and increasingly to non-phthalate alternatives like DOTP, DINCH, and citrates, especially in sensitive markets like toys, food contact materials, and medical devices. It’s imperative to verify that your chosen plasticizer system not only meets but is demonstrably compliant with all relevant regional regulations (e.g., REACH, RoHS) and industry-specific standards (e.g., FDA, CPSC, UL).

Following the compliance check, a nuanced cost analysis is essential. This goes far beyond comparing price-per-kilo; it involves calculating the total cost of the plasticizer system in your formulation. A more expensive but highly efficient plasticizer may be used at a significantly lower loading to achieve the same softness, while a premium, high-performance option like TOTM or a polyester, by preventing premature field failures and ensuring product longevity, often delivers superior long-term value and reduces the total cost of ownership, making it the more economically sound choice in demanding applications.

Summary Workflow:

By systematically applying these criteria: Primary Requirement → Secondary Needs → Synergistic Blending → Compliance/Cost Check, manufacturers can move from a trial-and-error approach to a science-based strategy for selecting the right plasticizer, ensuring product performance, durability, and market suitability.

At this point, the article aims to provide a convenient reference for the development, quality control, and procurement teams of polyvinyl chloride (PVC) products. By matching the properties of the plasticizers with your specific application requirements, it can help you optimize product performance while reducing the cost of repeated experiments.

For complex scenarios (e.g., custom formulations or compliance with strict regional standards like EU REACH or U.S. FDA), we recommend cross-referencing this guide with material safety data sheets (MSDS) and consulting with plasticizer manufacturers to validate selections. Stay updated on industry advancements, as new low-toxicity and high-performance variants continue to expand the plasticizer landscape for PVC applications. Contact us at sales@kingstarmold.com for more real-time updated resources or get a customized and detailed quote for your project.

Learn more about plasticizers in our related posts about plasticizers:

Plasticizer: What Is It & How Does It Work?

Plasticizer Performance and Evaluation: PVC Application Focus