Steel Ventilated Heat Sink High Precision Profile

| Manufacturing Process: | 5 Axis CNC Machining Service |

| Parts Material: | Steel |

| Solution: | Rapid Prototyping |

| Application Industry: | Automotive |

| Surface Treatment: | Smooth finish |

| Tolerance(Accuracy): | 0.01mm |

Our Expertise in Heat Sink CNC Machining Projects

- Precision Machining: Expertly crafting complex designs with high accuracy to ensure each heat sink fits perfectly and functions effectively.

- Material Expertise: Proficient in working with materials like aluminum and copper, known for their excellent thermal performance.

- Design Optimization: Partnering with clients to refine heat sink designs for manufacturability and maximum heat dissipation efficiency.

- Quality Control: Implementing rigorous quality assurance processes to ensure every heat sink meets exacting standards and performance requirements.

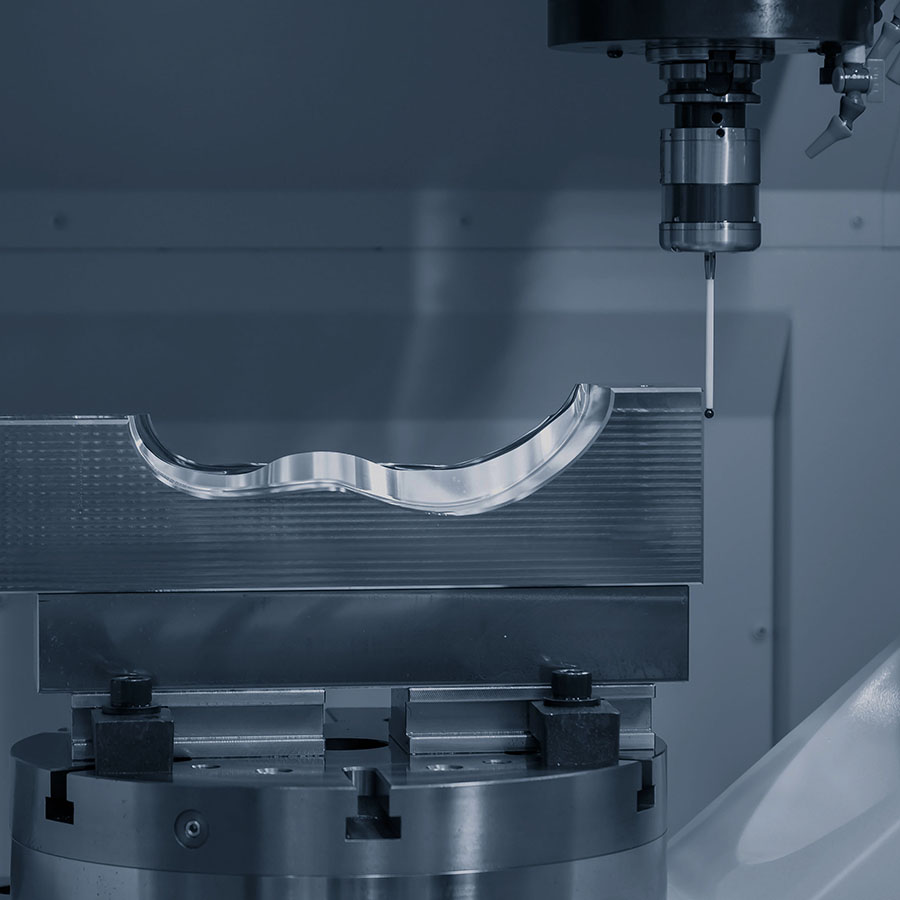

- Advanced CNC Machining: Employed 5-axis CNC machines for intricate cuts and precise slot creation.

- Tool Selection and Process Optimization: Used high-performance cutting tools and tailored machining parameters to handle the steel’s hardness and prevent tool wear.

- Quality Assurance: Conducted dimensional inspections with CMM (Coordinate Measuring Machine) and surface roughness tests to meet strict specifications.

- Heat Dissipation Testing: Each unit underwent thermal testing to ensure uniform performance across the batch.

Material Specifications:

- Material Type: Steel

- Material Properties: High thermal conductivity, corrosion resistance, and structural integrity

Design Specifications:

- Tolerance: ±0.005 inches (±0.127 mm) for critical dimensions

- Ventilation Design: Includes detailed specifications for slot width, length, and spacing in the ventilation pattern

Surface Finish and Treatment:

- Surface Finish: Smooth with a maximum roughness of Ra 1.6 µm

- Heat Treatment: Necessary to improve thermal conductivity and mechanical properties

Quantity and Lead Time:

- Prototype Quantity: 5 units for initial testing and evaluation

- Lead Time: Target completion is within 1 week from order confirmation

What advantages does 5-axis CNC machining offer for producing steel ventilated heat sinks?

5-axis CNC machining enables the creation of complex geometries and intricate designs with exceptional precision. This makes it ideal for producing ventilated heat sinks, as it optimizes airflow paths for superior thermal management while reducing manufacturing time and material waste.

What finishing options are available for steel ventilated heat sinks?

Steel ventilated heat sinks can be enhanced with various finishing options, such as anodizing, powder coating, and plating. These finishes improve corrosion resistance, enhance thermal performance, and meet aesthetic requirements.

What kind of post-production testing is conducted on steel ventilated heat sinks?

Post-production testing includes structural integrity checks, surface finish inspections, and thermal performance evaluations under simulated operational conditions to verify the heat sink’s efficiency and reliability.

What kind of support does your team offer throughout the production process?

Our team provides end-to-end support, including design consultation, material selection advice, prototyping assistance, and consistent updates throughout the production process, ensuring the final product aligns with your specifications.

How is the cost determined for CNC machining a steel ventilated heat sink?

The cost is influenced by the design’s complexity, the type of material, precision requirements, finishing processes, and production quantity. We deliver detailed quotes after a thorough design review and assessment of project requirements.

Note:

We maintain pre-market confidentiality agreements and sign NDA/NNN with all our customers. Every case you see has been shared with client approval. To protect sensitive information, some details have been blurred or modified. All photos were taken internally by KingStar Mold. Thank you for your support and cooperation.

One-Stop Manufacturing Service that Fits Your Product Life Cycle

Our Custom Manufacturing Services

Your one-stop solution for enhancing your product’s market potential.

Injection Molding

We offer comprehensive services of injection molding, producing a wide range of parts through two-shot molding, overmolding and custom molding techniques.

Mold Making

At KingstarMold, we develop and produce precision die-casting molds, injection molds, stack molds, and two-color molds using state-of-the-art equipment.

Sheet Metal Fabrication

We provide precise sheet metal fabrication solutions, offering custom-made parts with exceptional durability, tailored to meet the specific requirements of your project.

CNC Machining

Our CNC machining includes both 4-axis and 5-axis capabilities, with a focus on optimizing equipment arrangement to enhance efficiency.

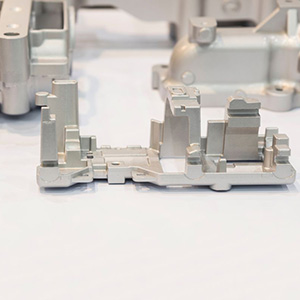

Die Casting

Our die casting service ensures high-precision, high-volume production of metal parts with excellent surface finishes and tight tolerances.

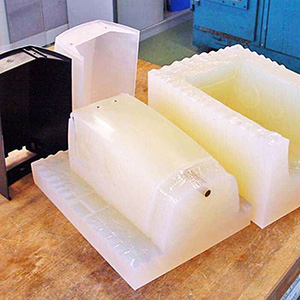

Vacuum Casting

With vacuum casting, we produce high-quality, detailed prototypes and low-volume parts with exceptional accuracy.