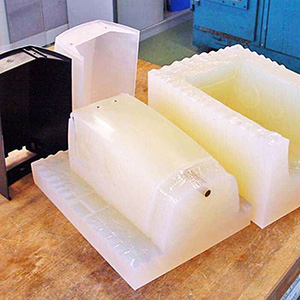

PC enclosure for thermal paper printers produced via precision injection molding

| Parts Material | PC |

| Application Industry | Consumer Electronic |

| Tolerance(Accuracy) | ±0.03mm |

| Manufacturing Process | Mold Making Service & Plastic Injection Molding Service |

| Mold Type | Production Tooling, Hot-runner Mold |

| Surface Treatment | Mold Texturing & Standard Smooth |

The component has been on the market for one year. All mold pictures, design drawings, and production images are strictly confidential to protect intellectual property and ensure client privacy.

Apologies, but the customer requirements for the Thermal Paper Printer Housing remain confidential.

Frequently Asked Questions

No worries—our case studies focus on the usual kinds of problems, but we deal with unique or tricky challenges all the time. Even if your specific issue isn’t featured, the problem-solving approach and technical skills you see in the case studies still apply. Send us a note with what you’re up against, and we’ll walk through how we’d tackle it for you.

We keep our case studies fresh—they show the methods we actually use right now. When we start using new tools, materials, or process fixes (like better mold simulation software or greener plastics), we update the case studies to include those too. That way, what you’re seeing matches how we work in today’s manufacturing landscape.

If a case study clicks with what you’re working on, just get in touch with our team. Share the details of your project, and we’ll talk through how the strategies highlighted—like material pairing, mold tweaks, or process adjustments—might fit your goals. If needed, we can also craft custom solutions that match what you need.

Feel free to reach out at sales@kingstarmold.com to start the conversation.

Yes, all our case studies are based on real client collaborations. To protect our clients’ rights, we only share details that have been approved for disclosure—including specific timelines, challenges, solutions, and measurable outcomes, all backed by data from client production records or third-party testing.

Each case study delves deeply into specific issues, such as how to extend the lifespan of components or how to accelerate production speed, and shows you how we solved these problems. Even if your project is not exactly the same as them, these cases can help you clearly understand how we handled the issues: breaking down the problem, adjusting the method, and achieving results. This enables you not only to see the outcomes we have achieved, but also to understand how we think about solutions – so you can roughly judge whether we can meet the requirements of your project.

We offer several ways for you to contact us. Firstly, you can click here to access our contact page, and all you need to do is fill out a form to provide us with your information, requirements, and you can also upload some documents. Alternatively, you can send us an email to the address: sales@kingstarmold.com. Or you can call us directly to discuss your needs by calling +86 512 5799 9297. No matter which method you choose, we will reply to you within 24 hours and provide you with a detailed quotation after clarifying the details through communication.

We keep costs down firstly through early DFM to simplify designs and avoid mold reworks, using processes like two-shot or insert molding to skip extra steps, and picking the right materials (no overspending on high-performance plastics when basic ones could work just as well).

Plus, our lower labor costs help trim expenses without cutting quality.

For a deeper look at factors impacting cost and ways to lower it, you can check our post Injection Molding Cost: All Factors and How to Reduce It

We handle a range of post-production steps to get your molded parts ready for use or shipping. That includes surface finishing like painting, silk-screening, sand blasting, black oxide and so on; assembly work (fitting components together, adding fasteners); quality checks (dimensional testing, defect inspections…); and custom packaging (from bulk crates to retail-ready boxes).

Note:

We maintain pre-market confidentiality agreements and sign NDA/NNN with all our customers. Every case you see has been shared with client approval. To protect sensitive information, some details have been blurred or modified. All photos were taken internally by KingStar Mold. Thank you for your support and cooperation.

One-Stop Manufacturing Service that Fits Your Product Life Cycle

Our Custom Manufacturing Services

Your one-stop solution for enhancing your product’s market potential.

Injection Molding

We offer comprehensive services of injection molding, producing a wide range of parts through two-shot molding, overmolding and custom molding techniques.

Mold Making

At KingstarMold, we develop and produce precision die-casting molds, injection molds, stack molds, and two-color molds using state-of-the-art equipment.

Sheet Metal Fabrication

We provide precise sheet metal fabrication solutions, offering custom-made parts with exceptional durability, tailored to meet the specific requirements of your project.

CNC Machining

Our CNC machining includes both 4-axis and 5-axis capabilities, with a focus on optimizing equipment arrangement to enhance efficiency.

Die Casting

Our die casting service ensures high-precision, high-volume production of metal parts with excellent surface finishes and tight tolerances.

Vacuum Casting

With vacuum casting, we produce high-quality, detailed prototypes and low-volume parts with exceptional accuracy.