OEM High Precision Turning CNC Machining Aluminum Brass Stainless Steel Parts M80003

$0.09-0.94

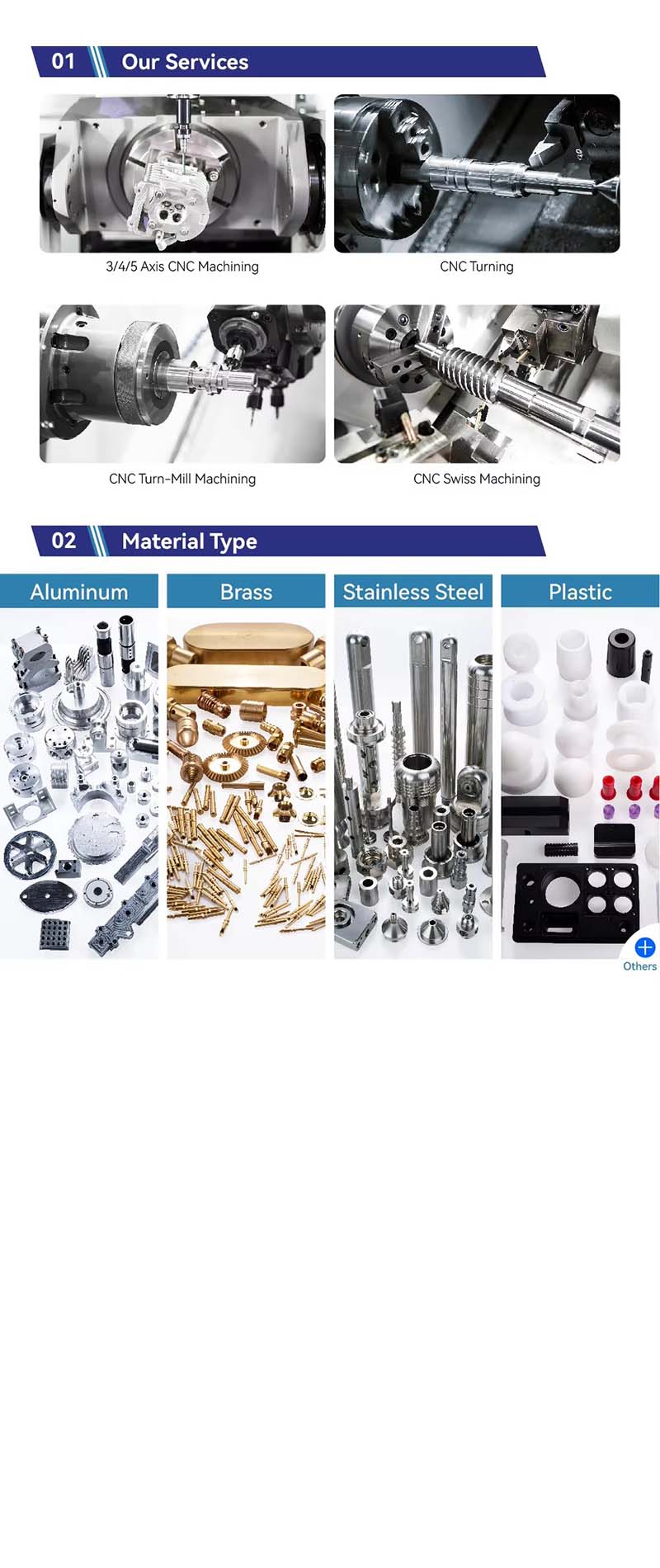

Manufacturing process: CNC turning

Parts material: Hardened Metals, Aluminum, Copper, Brass, Bronze, etc.

Application Industry: home appliance, furniture

Tolerance(Accuracy): ±0.01mm(±0.004″)

Click and read more:

Note: Due to the confidentiality agreement we have with the client, we only release the content that the client has permitted to be disclosed. All the cases that you can see on our website have been approved by the corresponding customers with sensitive information blurred.

Specification

| Product Name | OEM High Precision Turning CNC Machining Aluminum Brass Stainless Steel Parts |

|---|---|

| Model Number / SKU | M80003 |

| MOQ | 1 pcs |

| Material | Brass, Aluminum, Stainless Steel, Metal, etc. |

| CNC Machining or Not | Yes, CNC Machining |

| Micro Machining or Not | No, Not Micro Machining |

| Type | DRILLING, Etching / Chemical Machining, Broaching… |

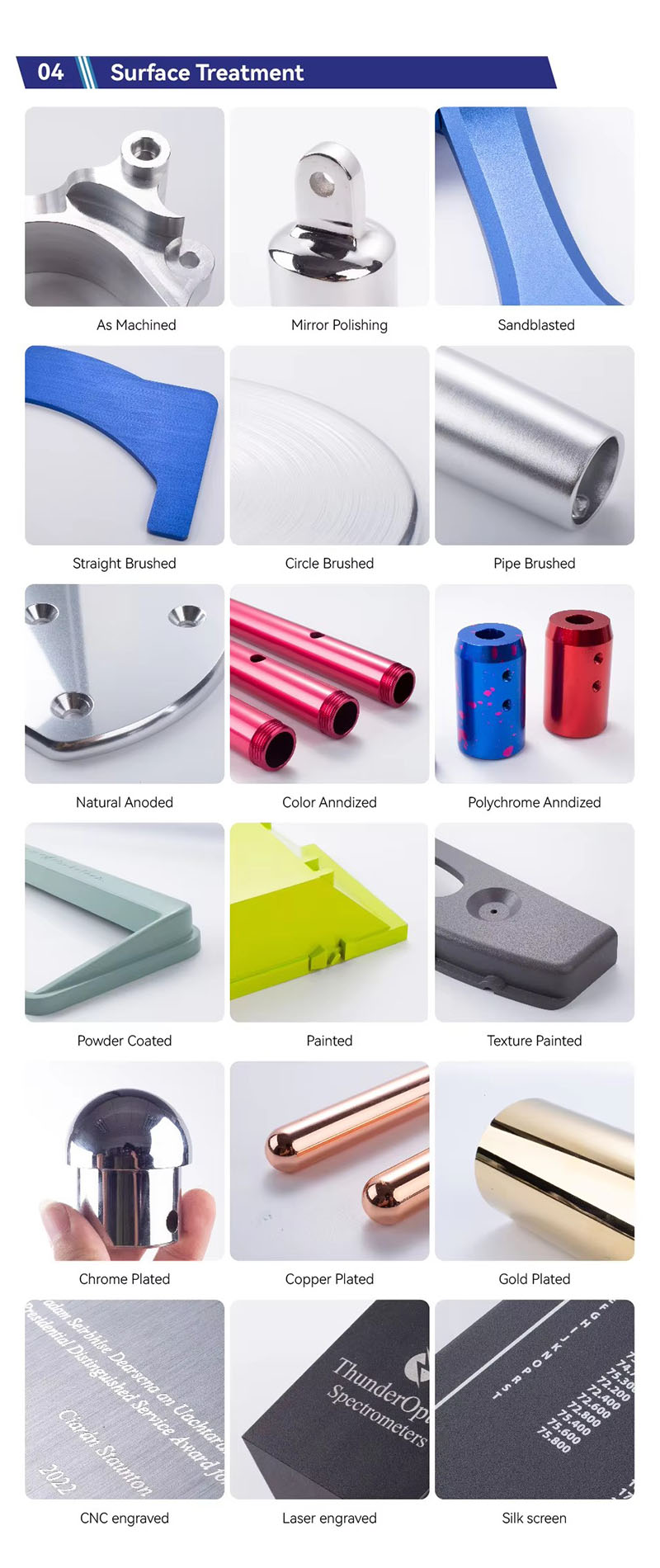

| Finish | Polishing/Anodized/Powder Coating/Sandblasting/Electroplating… |

| Drawing Format | .pdf / .dwg / .igs / .stp / x_t. |

| Tolerance | ±0.01mm |

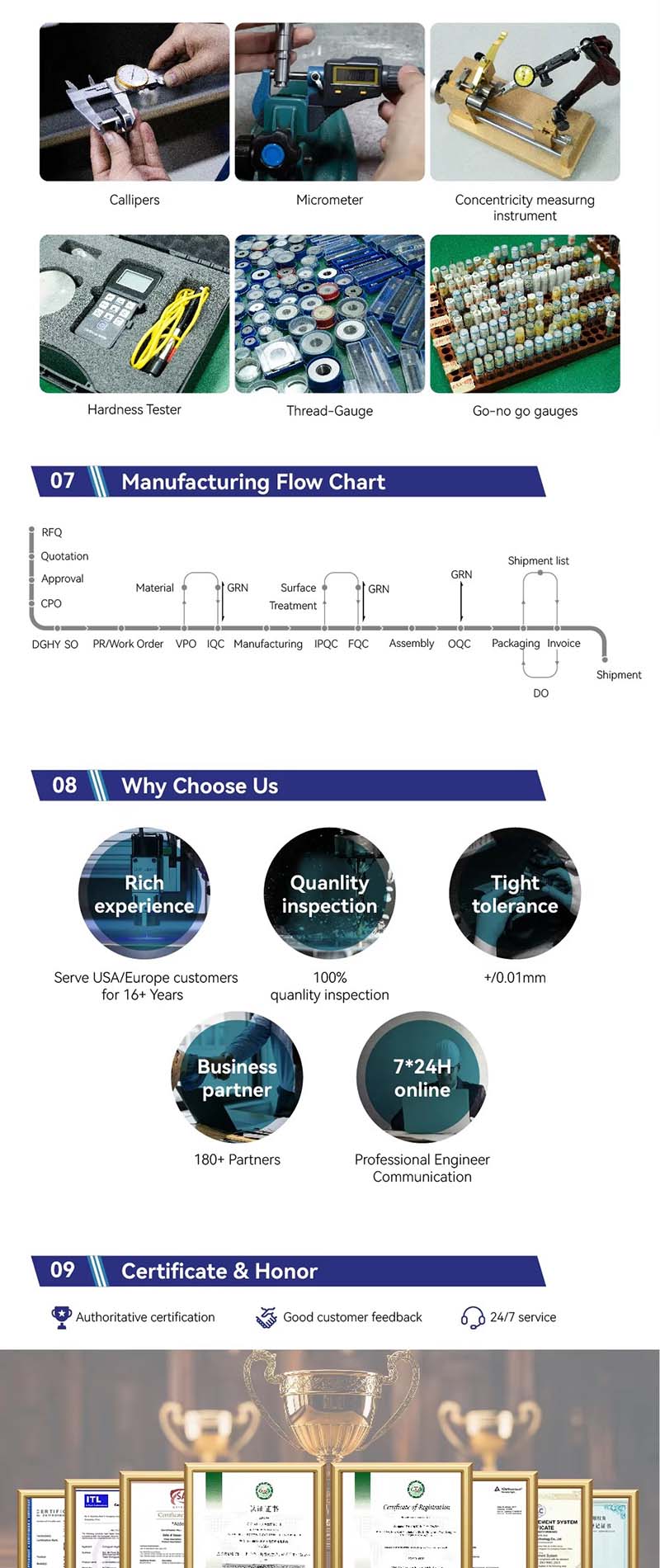

| QC Control | 100% inspection before shipping |

| ECO-Friendly | Yes |

| Lead Free | Yes |

| ODM / OEM | Acceptable |

| Delivery Time | Sample: 3-5 day; Production: 10-20 days. |

Why Choose KingStar’s CNC Turning Service?

1) One-stop multi-process manufacturing solution – We are proficient in various processing technologies, covering the entire lifecycle of custom parts, from prototype design to large-scale production. We provide comprehensive services including CNC machining (metal/plastic), 3D printing, injection molding (plastic/rubber), sheet metal processing, die casting and more. Whether you need a single prototype for design verification or a large-scale production part of over 100,000 pieces, we can eliminate the hassle of coordinating with multiple suppliers.

2) Professional engineering and design support – We know that prototype design is crucial for early detection of design flaws. We have a team of engineers with over 10 years of experience or more to provide end-to-end technical support: optimizing part design to improve manufacturability (i.e., DFM, such as reducing CNC machining time, improving injection mold flowability, etc.), adjusting processes to meet material performance requirements (such as hardening metal components, enhancing rubber flexibility, or applying protective coatings to components, etc.), and continuously improving samples until they meet your exact specification requirements.

3) All materials strictly follow quality standards and compliance requirements – each component (metal, plastic, rubber) undergoes strict testing to meet global standards: RoHS standards for harmful substances, ISO 9001 standards for manufacturing quality, food-grade certification for plastic/rubber components (FDA/CE), and aerospace-grade accuracy checks for precision CNC components (±0.005 mm). We ensure the safety, durability, and consistency of each batch of products.

4) Flexible OEM/ODM services with protection of your intellectual property – We support comprehensive customization services: selecting materials (metal, plastic, rubber), custom structures (CNC milling slots, 3D printing hollow cavities, injection molded snap-fit connections…), and choosing surface treatment methods (anodizing, electroplating, screen printing…). To protect your unique design, we will always sign NNN/NDA agreements to ensure that the custom components exclusive to your brand are only used by your brand.

5) Economical mass production – For large-scale orders, we use precision molds (mold manufacturing) to enhance production capacity, and compared with small-batch CNC machining, the unit cost can be reduced by 30%-50%. Our automated production lines (injection molding, CNC turning centers) ensure stable quality and rapid delivery, even for the production of over 100,000 parts.

6) E-commerce and supply chain optimization – No matter where you sell your product, whether through Amazon FBA, TikTok stores or B2B wholesale channels, we will support your sales channels. Our services include custom packaging (providing anti-static packaging for precision parts and sterile packaging for medical components), direct delivery to your distribution center, and batch label printing for inventory tracking – thus saving you the effort in logistics management. Read more: Hardware Integration into Sheet Metal: Design Tips and Operation

KingStar is a reliable partner with over 20 years of experience in manufacturing high-quality custom metal CNC turning components for global customers. We have more than one modern manufacturing plant, located in China (mainly) and Mexico (all equipped with CNC workshops, 3D printing laboratories, injection molding lines and mold workshops), which ensures timely delivery, strict quality control and seamless scalability – serving customers all around the world.

Not only do we comply with industry standards – we also optimize according to your needs: whether you’re a startup looking to test prototypes, an e-commerce brand expanding production scale, or an enterprise improving core products, we will adjust our processes based on the balance of cost, speed and performance. Are you ready to turn your design into actual components? Partner with us to create custom components that can drive the success of your products.

Frequently Asked Questions

Simply upload your CAD files and project details through our website (click here to go to contact page or click the “request a quote” button at the top right corner of the page, and fill in the form that appears) or contact our team() directly. We’ll respond quickly with a detailed quote, lead time, and suggestions to optimize your design for cost and manufacturability.

We accept common 3D and 2D file formats including STEP, IGES, STL, and DWG. To ensure the best results, it’s helpful to include both 3D models and detailed 2D drawings with tolerances and surface finish requirements. There are 2 ways to send them to us: click here to the contact page to directly upload the files or send them via email: sales@kingstarmold.com

Inquiry Now

Please submit your inquiry via the form below or email sales@kingstarmold.com; Our team guarantees a response within 24 hours.