Movable Plastic Pet House Indoor Detachable Kennel Dog And Cat Cage PH018901

$16.15

Product Features:

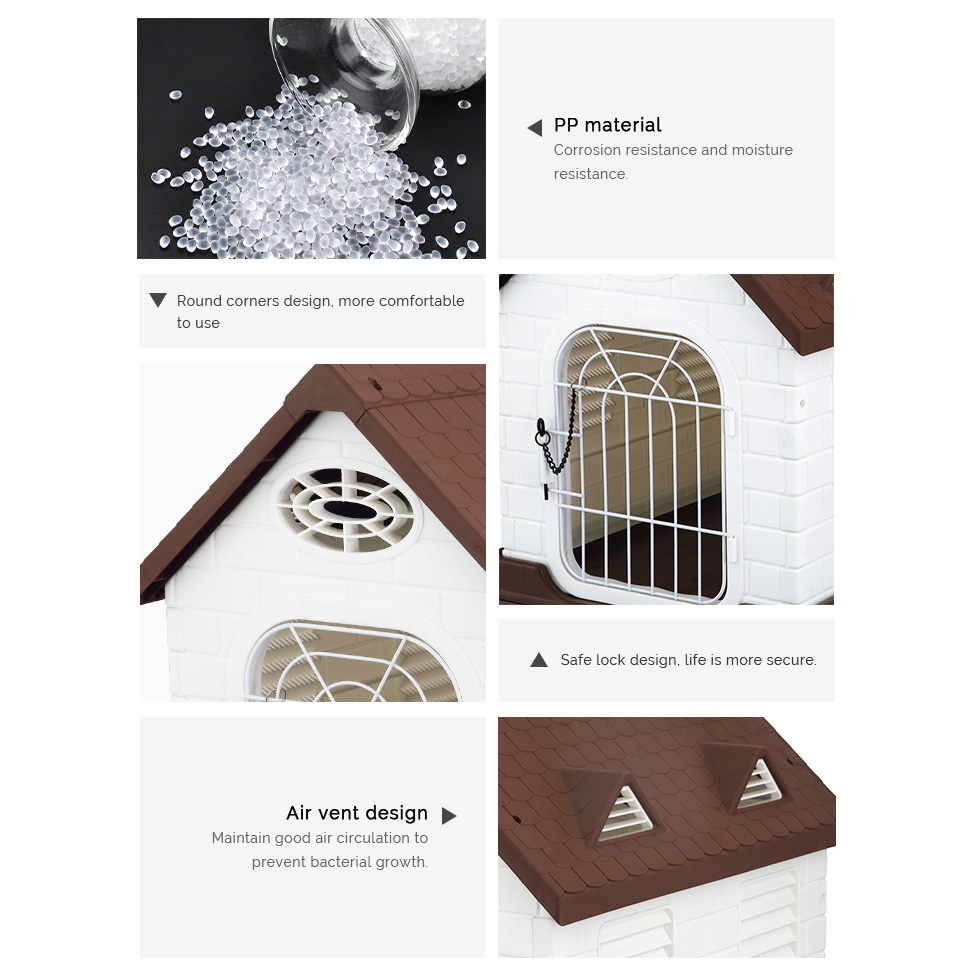

- Durable Build With Premium PP: Crafted from top-grade PP material, the pet house stands up well to everyday wear, moisture, and even changing weather—ideal for both indoor and covered outdoor use.

- Pet-Friendly Rounded Corners: All edges are gently rounded to help prevent scratches or bumps, giving dogs and cats a safer, more comfortable space to rest and play.

- Secure Metal Door with Lock: The front gate includes a durable metal door and locking chain. It keeps your dog or cat safely inside but makes it easy for you to open and close when needed.

- Airy Interior: Multiple side vents let fresh air circulate through the kennel. This helps reduce dampness and keeps unpleasant odors and bacteria from building up.

- Roof Vents for Better Flow: There are four roof vents—two on each side—to improve ventilation even more. It helps maintain a dry, breathable interior, especially in hot weather.

- Tool-Free Assembly: Putting this indoor pet house together is simple. The parts fit together easily, no tools required. It’s lightweight, so you can move or clean it without hassle.

- Weather-Smart Design: The raised base helps keep water out, and the sloped roof lets rain run off quickly. Whether placed indoors or in a sheltered outdoor space, it keeps your pet dry and cozy.

Customizing Options:

- Custom size & shape

- Custom structure

- Custom logo

- Custom color / graphic / pattern / texture

- Custom packaging

Specification

| Product Name: | Movable Plastic Pet House Indoor Detachable Kennel Dog And Cat Cage |

|---|---|

| Model Number / SKU: | PH018901 |

| MOQ: | 100 pcs |

| Material: | PP |

| Size: | 67*48.5*62.5cm or customized |

| Certificate: | BSCI |

| ODM / OEM: | Acceptable |

| Lead Free: | Yes |

| ECO Friendly: | Yes |

| BPA Free: | Yes |

Why Choose KingStar’s Detachable Kennel?

1) Certified for Safety and Quality – Our plastic pet houses are CE, FDA, Prop 65, and RoHS certified, ensuring that your pets enjoy a safe and comfortable environment built to the highest global standards.

2) Durable and Weather-Resistant Design – KingStar’s Plastic Pet Houses are made with tough, weather-resistant materials that withstand the elements. Whether for indoor or outdoor use, these pet houses are designed to keep your furry friends cozy and secure, no matter the season. Ideal for both domestic use and pet care businesses, they provide lasting protection and comfort.

3) Branding Support for Pet Care Businesses – KingStar is here to assist with your branding needs. We collaborate with pet businesses, offering custom-branded pet houses that align with your brand identity. Need them delivered to your Amazon FBA warehouse or a different location? We’ve got you covered with seamless delivery options.

4) Perfect for Promotional Gifting – KingStar’s plastic pet houses make excellent corporate gifts and promotional items for pet-related events or businesses. We can customize them with your logo to create a lasting impact. Simply share your design requirements, and we’ll handle the rest, ensuring prompt delivery to your office, warehouse, or event location.

5) Eco-Friendly, Stylish, and Practical – Live sustainably without sacrificing style. Our plastic pet houses are built using eco-conscious materials that are both durable and aesthetically pleasing. We ensure that all our products meet the highest standards for environmental responsibility, so you can feel good about what you’re supporting.

6) Efficient Manufacturing with Cutting-Edge Technology – Since our establishment in 2009, KingStar has invested in advanced automation technology to maximize production efficiency. This allows us to offer high-quality plastic pet houses at competitive prices and fast delivery times, all while maintaining exceptional quality.

7) Customizable and Confidential Manufacturing Services – Specializing in OEM & ODM manufacturing, KingStar offers full customization to meet your needs. With a creative team spanning the U.S., Europe, and Asia, we release over 200 patented designs annually. Concerned about confidentiality? We’ll sign an NDA/NNN to protect your intellectual property, ensuring that your private label pet houses are exactly what you envision. Click and read more: What is FDM 3D Printing?

KingStar Mold is a leading wholesale plastic pet house manufacturer with over 20 years of experience delivering high-quality, durable products globally. Our four cutting-edge manufacturing facilities in China and Mexico are strategically positioned to ensure fast, reliable production and timely deliveries. We provide top-tier plastic pet houses to customers in 220+ countries, supporting a range of industries from pet care brands to e-commerce giants, helping businesses grow and succeed.

Our designs go beyond industry standards—they set new benchmarks for innovation and functionality. With prestigious awards such as the Red Dot, IAI, IDA, and MUSE under our belt, we continue to push the envelope in pet house design. Ready to take your business to the next level? Partner with us for custom plastic pet houses tailored to your precise specifications, and let’s achieve your growth ambitions together.

Frequently Asked Questions

Yes, sample orders are available upon request. For existing models, we can usually ship samples quickly from our current inventory. For customized pet houses, we can build prototype samples based on your design specifications—lead time and costs will vary depending on the complexity. Our team will guide you through the sample process to ensure everything aligns with your expectations before full production.

KingStar uses high-quality, weather-resistant materials such as HDPE, PP, and other engineered plastics to ensure durability, safety, and outdoor performance. These materials are selected for their resistance to UV rays, moisture, impact, and temperature changes, making them ideal for both indoor and outdoor use. For advanced designs, we also offer insulated or double-wall construction to improve thermal comfort. Additionally, we accept customer-supplied resins upon request, provided they meet our processing and safety standards. This flexibility allows us to meet specific performance or sustainability goals set by our clients.

Yes, KingStar offers full OEM & ODM support for custom pet houses. Our in-house design team can work with your concept, sketch, or functional goals to create a tailored solution. From unique shapes and ventilation systems to color schemes and branding, we develop both the aesthetics and structure based on your market needs—under full NDA protection if required.

For our existing pet house models, the minimum order quantity (MOQ) is typically listed on the individual product page and may vary depending on the size, material, and stock availability.

For customized pet house orders, the MOQ depends on the complexity of the design. Factors such as unique shapes, materials, branding elements, or additional features will influence the required minimum. We evaluate each custom request individually and will advise you on the most cost-efficient quantity based on your specific needs.

Absolutely. KingStar’s pet houses are specifically engineered to endure outdoor conditions. We use UV-resistant and waterproof materials that hold up against prolonged sun exposure, rain, and temperature fluctuations. Depending on the design, we apply advanced molding techniques—such as injection molding or rotomolding—to enhance structural integrity and ensure seamless construction that resists cracking and leaks. Combined with our strict multi-stage quality control process, this guarantees each pet house delivers long-term durability and reliable shelter for your pet in any outdoor environment.

Yes, KingStar Mold offers full customization options. You can adjust the size, shape, ventilation, insulation, and even color to meet your specific pet housing needs.

Inquiry Now

Please submit your inquiry via the form below or email sales@kingstarmold.com; Our team guarantees a response within 24 hours.