6L Mini Insulated Hard Cooler with Handle Pothook 6.3QT Ice Chest Poolside Camping HC04X505

$5.70-12.16

Product Features:

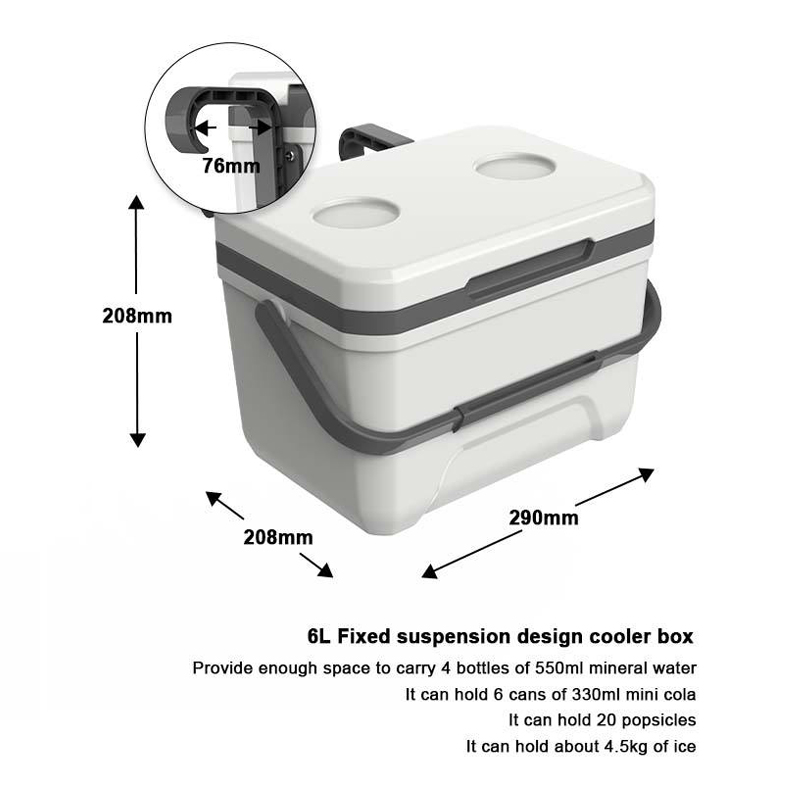

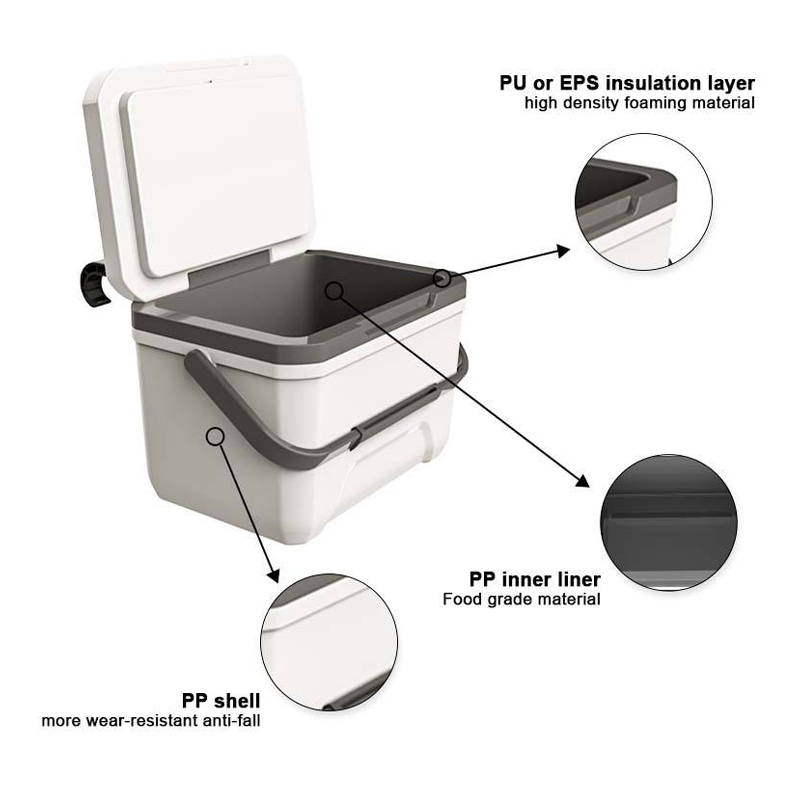

- Advanced Insulation Structure: With a built in food-grade material liner, high-density PU insulation layer, and a durable PP shell, the anti-fall cooler ensures you reliable cool storage.

- Spacious 6L Capacity: Can hold up 4 bottles of 550ml water, 6 cans of 330ml soda, 20 popsicles, or about 4.5kg of ice—perfect for outdoor camping, relaxation by the pool, and many more!

- Eco-Friendly Cooling Design: Equipped with an inner ice pack, the cooler runs energy-free, friendly to families and the environment.

- Dual Cup Holders on Lid: The cooler’s lid includes two cup holders, keeping drinks secure and within arms reach—in hope to bring you leisure pleasure even lying down.

- Seamless One-Piece Lid Design: One-piece constructed lid enhances the cooler’s wear-resistance , its seamless design can keep its cool for more than 72 hours!

- Reinforced Portable Handle: The strong handle design allows a steady firm grip, even when the cooler is at its fullest.

Customizing Options:

- Custom logo

- Custom color / graphic / pattern / texture

- Custom shape

- Custom structure / capacity

- Custom packaging / accessories

Specification

| Product Name: | 6L Mini Insulated Hard Cooler with Handle Pothook 6.3QT Ice Chest Poolside Camping HC04X505 |

|---|---|

| Model Number / SKU: | HC04X505 |

| MOQ: | 50 pcs |

| Inner Material: | Food Grade PP |

| Insulation Layer Material: | PU or EPS |

| Shell Material: | PP |

| Capacity: | 6L or customized |

| Cold Sustainable Time: | More than 72 hours |

| ODM / OEM: | Acceptable |

| Lead Free: | Yes |

| ECO Friendly: | Yes |

| BPA Free: | Yes |

Why Choose KingStar’s Wholesale Portable Camping Hard Cooler?

1) Certified for Quality & Safety

KingStar’s hard coolers meet the highest safety and environmental standards, including CE, FDA, Prop 65, and RoHS certifications, ensuring top-tier quality and compliance.

2) Heavy-Duty & Stackable Design

Designed with impact-resistant materials, our hard coolers feature a rugged, stackable structure that provides durability and reliable performance for outdoor, industrial, and commercial use.

3) Branding & eCommerce Support

KingStar fully supports your branding and business growth. Whether you sell on Amazon FBA, TikTok, Temu, or other eCommerce platforms, we offer seamless private labeling and direct shipping to your preferred warehouse or destination.

4) Customizable for Corporate & Promotional Gifting

Our wholesale hard coolers are perfect for corporate gifts and promotional branding. With extensive experience in customization, we handle logo printing, packaging, and logistics—delivering personalized coolers directly to your office, warehouse, or retail location.

5) Eco-Friendly & Built to Last

Sustainability meets performance in our premium hard coolers. Crafted for long-term use, they uphold the highest verified social and environmental standards, ensuring a responsible and transparent manufacturing process.

6) Advanced Automation for Efficiency

Since 2009, KingStar has led the industry with automation-driven manufacturing. Our investment in cutting-edge robotics and technology results in faster production, reduced costs, and high-quality custom hard coolers delivered at competitive speeds.

7) OEM & ODM Expertise

We specialize in OEM & ODM hard cooler manufacturing, offering full customization to meet your needs. Our global design team—50+ experts across the U.S., Europe, and Asia—introduces over 200 new, patented designs annually. Need confidentiality? We’re ready to sign an NDA/NNN to protect your intellectual property and business ideas. Click and read more: How Much Does It Cost To Make A Plastic Injection Mold.

KingStar Mold is a leading wholesale hard cooler manufacturer with two decades of expertise in designing, producing, and exporting high-performance cooling solutions worldwide. With four state-of-the-art manufacturing facilities in China and Mexico, we guarantee fast, efficient production and seamless global delivery. Our rugged, innovative hard coolers serve customers across 220+ countries, supporting major outdoor brands and e-commerce businesses—helping startups scale rapidly and boost profitability.

We don’t just meet industry standards—we redefine them. Our award-winning designs have earned global recognition, including Red Dot, IAI, IDA, and MUSE honors. Looking to take your business to the next level? Partner with us for fully customizable hard coolers tailored to your needs, and let’s drive your growth together.

Frequently Asked Questions

Inquiry Now

Please submit your inquiry via the form below or email sales@kingstarmold.com; Our team guarantees a response within 24 hours.