179.6QT Large Size Trolley 170L Wheeled Cooler Box for Camping Fishing Marine HC04X508

$78.56-79.42

Product Features:

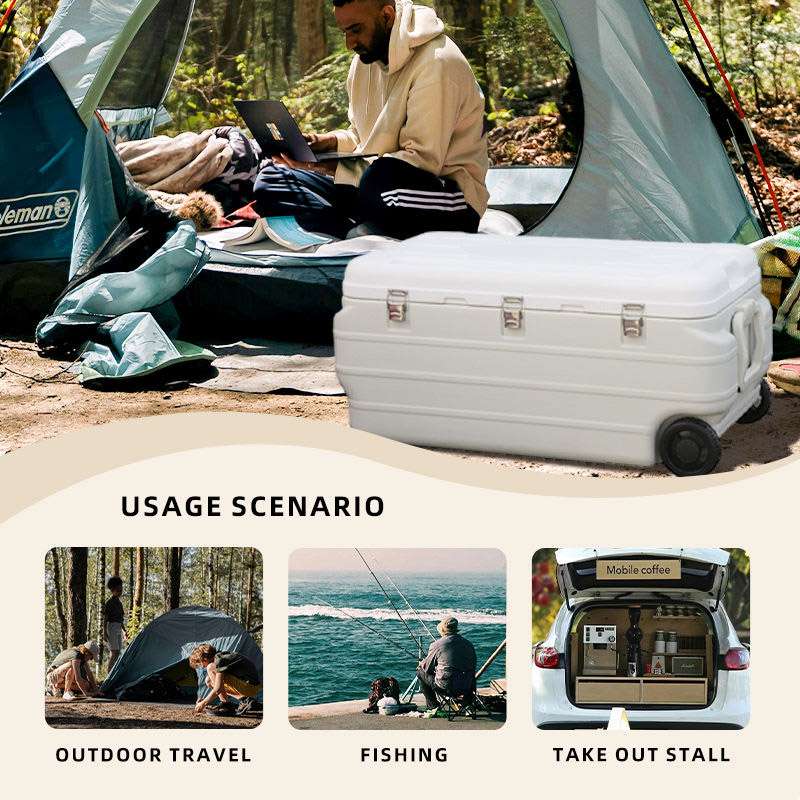

- Smooth-Rolling Wheels: Two built-in wheels make it easy to pull the cooler, even when fully loaded — perfect for camping, fishing, or beach trips.

- Strong Stainless-Steel Buckles: Comes with three heavy-duty metal buckles that keep the lid tightly sealed and help the cooler hold its shape over time.

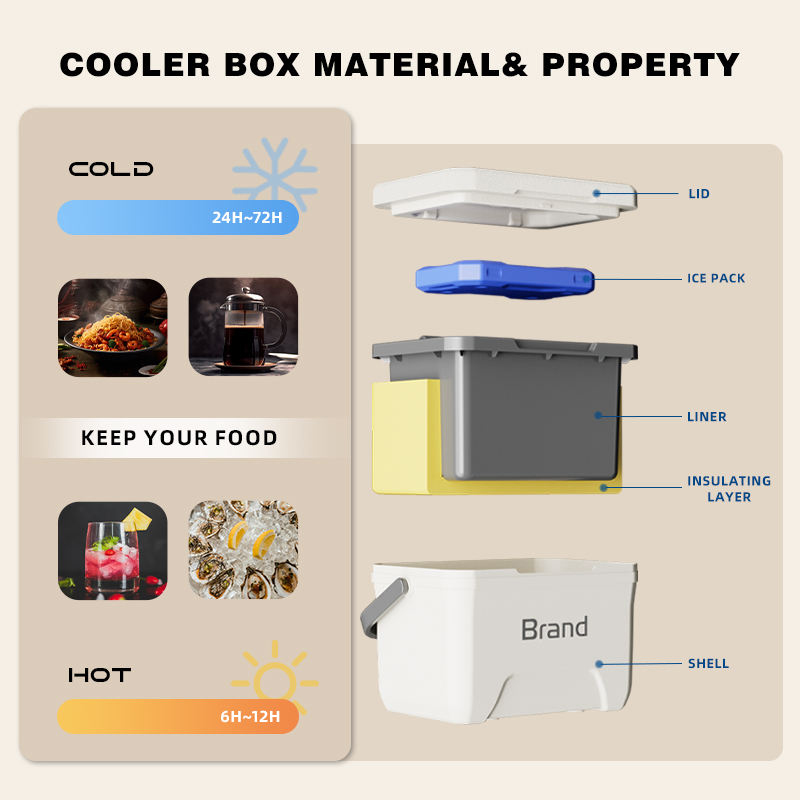

- Thick Insulated Build: Made with a food-safe PS liner, PU foam insulation, and HDPE outer shell, it keeps items cold longer and stands up to rough use.

- Reinforced Flip-Top Lid: The lid is attached with a flexible strip that prevents it from opening too far, helping to protect the hinge and extend its lifespan.

- Easy Drainage Plug: A built-in drain valve at the bottom lets melted ice flow out easily — no need to lift or tilt the cooler.

Customizing Options:

- Custom logo

- Custom color / graphic / pattern / texture

- Custom shape

- Custom structure / capacity

- Custom packaging / accessories

Specification

| Product Name: | 170L Large Size Trolley 179.6QT Wheeled Cooler Box for Camping Fishing Marine |

|---|---|

| Model Number / SKU: | HC04X508 |

| MOQ: | 50 pcs |

| Inner Material: | Food Grade PS |

| Insulation Layer Material: | PU |

| Shell Material: | HDPE |

| Capacity: | 170L or customized |

| Cold Sustainable Time: | More than 72 hours |

| ODM / OEM: | Acceptable |

| Lead Free: | Yes |

| ECO Friendly: | Yes |

| BPA Free: | Yes |

Why Choose KingStar’s Wheeled Hard Cooler?

1) Certified for Quality & Safety

KingStar’s hard coolers meet the highest safety and environmental standards, including CE, FDA, Prop 65, and RoHS certifications, ensuring top-tier quality and compliance.

2) Heavy-Duty & Stackable Design

Designed with impact-resistant materials, our hard coolers feature a rugged, stackable structure that provides durability and reliable performance for outdoor, industrial, and commercial use.

3) Branding & eCommerce Support

KingStar fully supports your branding and business growth. Whether you sell on Amazon FBA, TikTok, Temu, or other eCommerce platforms, we offer seamless private labeling and direct shipping to your preferred warehouse or destination.

4) Customizable for Corporate & Promotional Gifting

Our wholesale hard coolers are perfect for corporate gifts and promotional branding. With extensive experience in customization, we handle logo printing, packaging, and logistics—delivering personalized coolers directly to your office, warehouse, or retail location.

5) Eco-Friendly & Built to Last

Sustainability meets performance in our premium hard coolers. Crafted for long-term use, they uphold the highest verified social and environmental standards, ensuring a responsible and transparent manufacturing process.

6) Advanced Automation for Efficiency

Since 2009, KingStar has led the industry with automation-driven manufacturing. Our investment in cutting-edge robotics and technology results in faster production, reduced costs, and high-quality custom hard coolers delivered at competitive speeds.

7) OEM & ODM Expertise

We specialize in OEM & ODM hard cooler manufacturing, offering full customization to meet your needs. Our global design team—50+ experts across the U.S., Europe, and Asia—introduces over 200 new, patented designs annually. Need confidentiality? We’re ready to sign an NDA/NNN to protect your intellectual property and business ideas. Click and read more: Roto Molded vs Injection Molded Coolers: What Are Their Differences?

KingStar Mold is a leading wholesale hard cooler manufacturer with two decades of expertise in designing, producing, and exporting high-performance cooling solutions worldwide. With four state-of-the-art manufacturing facilities in China and Mexico, we guarantee fast, efficient production and seamless global delivery. Our rugged, innovative hard coolers serve customers across 220+ countries, supporting major outdoor brands and e-commerce businesses—helping startups scale rapidly and boost profitability.

We don’t just meet industry standards—we redefine them. Our award-winning designs have earned global recognition, including Red Dot, IAI, IDA, and MUSE honors. Looking to take your business to the next level? Partner with us for fully customizable hard coolers tailored to your needs, and let’s drive your growth together.

Frequently Asked Questions

Our coolers aren’t fully airtight or watertight—and this is intentional. A completely airtight design would trap pressure inside, caused by temperature differences between the cooler’s interior and the outside. This pressure could make the lid nearly impossible to open, especially after being closed for a while.

Instead, our coolers are designed to be water-resistant. They won’t leak under everyday use, like when you’re storing ice, drinks, or food. But they aren’t meant to float or be fully submerged in water—so avoid using them as flotation devices or submerging them completely.

For optimal results, we recommend a 2:1 ice-to-contents ratio, meaning 2/3 of the cooler should be filled with ice and 1/3 with food or drinks. Here’s why this ratio is crucial:

Block + Cube = Balance: Use block ice for long-term ice retention as it melts more slowly. Combine it with cubed ice to fill in the gaps. Minimizing air space within the cooler slows down the ice-melting process.

Our MOQ varies depending on the cooler model and customization requirements. For standard models, the MOQ is relatively reasonable to accommodate businesses of different scales and is usually marked on each product page, typically from 0 to 350 (if MOQ is not indicated in the product page, then it is generally 0).

Inquiry Now

Please submit your inquiry via the form below or email sales@kingstarmold.com; Our team guarantees a response within 24 hours.