Wholesale Storage Bin Manufacturer

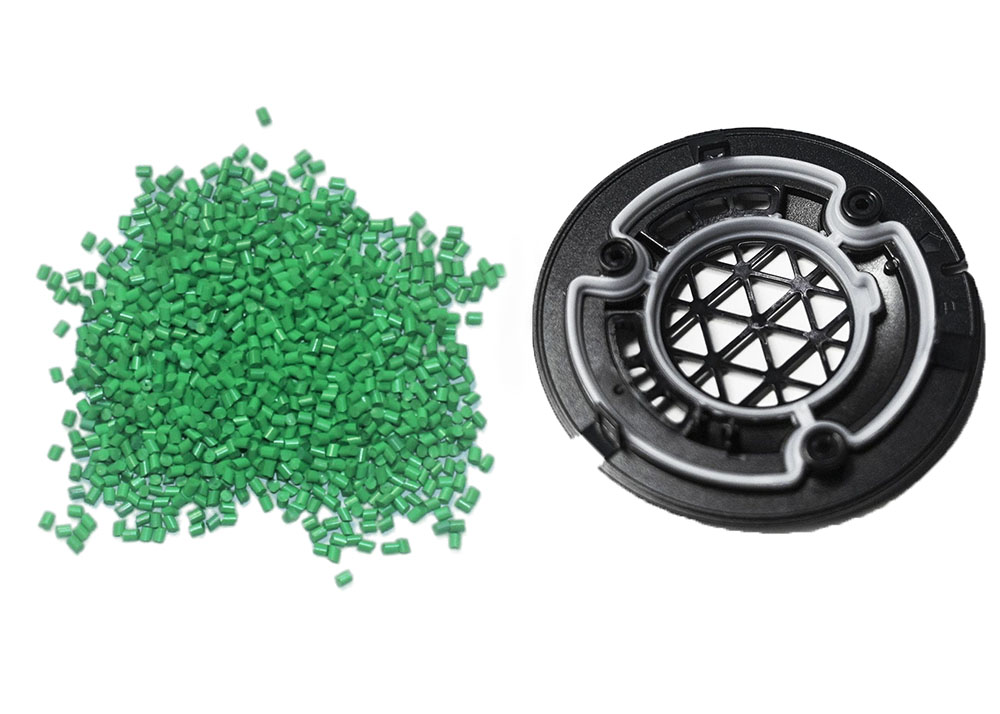

For over 10 years, KingStar Mold has been a leading wholesale plastic storage bins manufacturer in China, delivering premium quality and innovative design. Our bulk plastic storage containers meet rigorous global standards, certified by RoHS, Prop 65, and FDA, guaranteeing safety and durability for diverse applications. We specialize in customized solutions tailored to your needs, offering comprehensive OEM/ODM services.

- Custom logo, color, packaging

- Custom capacity, shape, structure

- Additional accessories

We’re equipped to bring your vision to life. With flexible MOQs and a commitment to precision, we ensure scalable solutions for businesses of all sizes. Welcome to purchase bulk custom storage boxes with KingStar Mold.

KingStar Wholesale Storage Boxes

Plastic Injection Molded Crates and Boxes Manufacturer

Injection Molded Crates for Storage and Agriculture

We produce durable, compact, and stackable plastic crates for fruits and vegetables, designed for easy handling and optimal air circulation to keep your produce fresh. Our diverse designs cater to various needs.

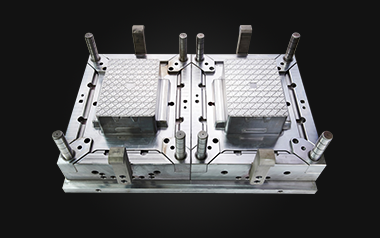

As a one-stop-shop plastic crate manufacturer, KingStar Mold offers full-service solutions. Our innovative design team develops crate designs and prototypes, which are refined into molds by our injection mold engineers. These molds are then used in our injection molding factory to produce high-quality plastic crates.

Custom Plastic Crate Mould Designed by Experts

Why Choose KingStar Mold’s Wholesale Storage Bins?

Only companies with extensive market experience and a deep understanding of customer needs can offer the best service.

Skilled

High-precision production equipment, skilled production staff, and guaranteed delivery times.

Experienced

Over ten years of industry experience, with a mature quotation system and technical support.

Thoughtful

Customized processing options that save time and effort, with active support throughout pre-sales and post-sales.

Equipped

Engineers review designs to identify and resolve potential issues, backed by advanced testing equipment.

Over 10+ Experience as an Injection Mould Manufacturer

of Storage Boxes

Bottle Crate

Beer Crate

General Purpose Crate

Folding Closet Organizers

Hunting Gear

Previous Plastic Crate Projects

KingStar Mold manufactures around 900-1000 molds annually, backed by our skilled mold designers and makers. We provide comprehensive, one-stop services, covering crate design, mold design, production, and delivery.

Our storage solutions include plastic crates and turnover boxes for warehouses and fruit & vegetable storage. Serving clients across America, Europe, and the Middle East, we also leverage our trusted network to deliver products globally.