Precision Mold Building Service at KingStar Mold

Delivering High-Quality, Accurate Molds for Every Project

At KingStar Mold, we specialize in precision mold building services, ensuring that each mold we create meets the highest standards of accuracy, durability, and functionality. Our skilled engineers utilize advanced technologies, such as CNC machining and high-quality materials, to craft molds that offer precise dimensions and superior performance. Whether you’re producing small-scale prototypes or large production runs, we provide tailored solutions to meet your specific requirements.

We focus on every detail, from material selection to design optimization, to ensure your molds are built to last and function efficiently. Our precision mold building service is ideal for industries ranging from automotive to medical, where the smallest tolerances and intricate designs matter most. At KingStar Mold, we are committed to delivering molds that improve your production quality and ensure the success of your projects.

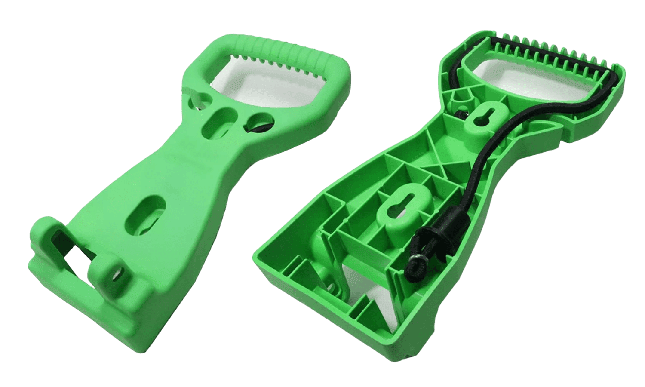

Precision Mold Gallery

KingStar Mold’s Precision Mold Building Capabilities

At KingStar Mold, our precision mold building capabilities are backed by years of expertise and advanced technology to ensure the highest level of accuracy and performance. We are dedicated to crafting molds that meet the strictest industry standards, whether for prototypes or large-scale production runs. From material selection to intricate design and meticulous machining, we guarantee that every mold is made to precise specifications to optimize your production process.

Tight Tolerances

Advanced CNC Machining

High-Quality Materials

Complex Design Support

Multi-Axis Capabilities

Prototyping Excellence

Rapid Turnaround

Durability & Longevity

Surface Finishing Expertise

Cost-Efficiency

At KingStar Mold, we understand the concern that excellence in precision molds might imply lower quality for other molds. However, we assure you that our high standards apply to all molds we produce. Whether for precision or larger-scale molds, we use the same advanced technology and stringent quality control processes to deliver outstanding results.

Our expertise in precision mold making enhances our overall capabilities. The same skills and materials used in precision molds ensure that all types of molds—whether standard or complex—are crafted with the same attention to detail, performance, and durability.

KingStar Mold specializes in achieving extremely tight tolerances, often within microns, ensuring that our molds meet the most demanding specifications for precision and quality.

Precision molds are essential in industries such as automotive, aerospace, medical devices, electronics, and consumer goods, where high accuracy and performance are crucial.

Common materials include tool steels (P20, H13), aluminum alloys, beryllium copper, stainless steel, and polymers like POM and Nylon, selected based on strength, durability, and heat resistance.

If your project requires exact tolerances, intricate designs, or high-performance standards, precision mold building is ideal. KingStar Mold can help evaluate your needs and recommend the best approach.

Precision mold building involves creating molds with extremely tight tolerances, ensuring accurate dimensions and high-quality finishes. These molds are used in industries where precision is critical, such as aerospace, medical, and automotive.

Simply contact KingStar Mold with your project details, and our team will guide you through the process, from design and material selection to production and delivery.

Yes, KingStar Mold provides additional services such as mold design optimization, prototyping, surface finishing, and post-production support to ensure the best results for your project.

Yes, precision molds are versatile and can be used for both small batches and large-scale production. Their high durability and accuracy make them ideal for both low and high-volume runs.

The cost of precision mold building depends on factors such as material selection, design complexity, and production volume. KingStar Mold provides cost-effective solutions tailored to your project needs.

Precision molds improve product quality, reduce defects, enhance part consistency, and extend the lifespan of molds, making them ideal for high-volume and high-accuracy production runs.

Lead times vary depending on the complexity of the mold, but KingStar Mold offers rapid turnaround times while maintaining the highest standards of precision and quality.