Two Core Types of Powder Coating: Thermoplastic & Thermoset

Pros & Cons of Powder Coating

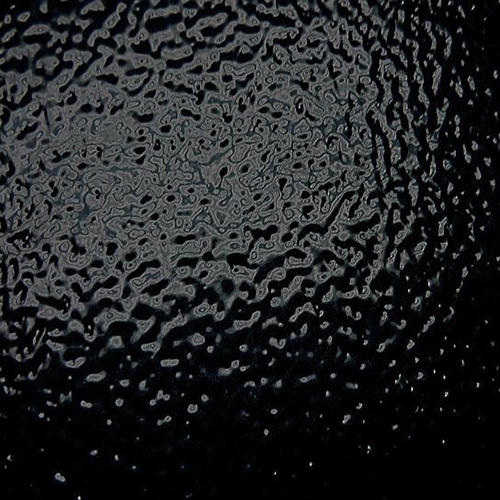

Commonly Used Powder Coating Textures

Top Applicable Materials

Types of Finish Gloss – Comparison Table

| Gloss Category | Matte | Satin | Medium Gloss | Full Gloss |

|---|---|---|---|---|

|  |  |  |

|

| Reflectivity (%) | 0–20 | 20–40 | 40–60 | 80+ |

| Typical Textures | Sand, Wrinkle, Hammer | Wrinkle, Hammer | Hammer, Smooth | Smooth |

| Surface Roughness | Coarse | Medium | Fine | Smooth |

| Thickness Impact | Applied as thin layers; coarse texture makes them seem less thick | Thicker coatings balance durability and a smooth look | Moderate thickness for a robust, polished appearance | Thicker layers needed for durability and shine; imperfections show more |

| Common Applications | Hides scratches on furniture; non - reflective for outdoor gear; low - maintenance for industrial machines | Classic look for furniture; easy - clean for appliances; elegant for decor | Sleek look for consumer electronics and automotive trims; polished touch for decor accessories | Sophisticated for consumer electronics; luxurious touch for decor items |

| Key Advantages | Conceals flaws; cuts down on glare; great for tough settings | Mix of durability and good looks; hides minor flaws | Simple to clean; boosts polished design appeal | Max visual impact; highlights high - quality materials |

| Things to Note | Gets grimy easily; hard to clean | Easier to fix than full gloss | Less upkeep than high - gloss | Scratches easily; needs polishing to stay shiny |

Design Guidelines for Powder Coating

Powder coating adds 0.003 inches (0.08 mm) to the size of cutouts after application. This thickness must be accounted for in pre-coating design to avoid post-coating fit issues.

Example: If a 1-inch diameter hole is needed in the powder-coated surface to install a component, the pre-coating hole diameter should be 1.006 inches (1 inch + 0.003 inches × 2), ensuring 0.003 inches of coating on each inner side of the hole.

The spray gun needs access to all surfaces for an even coat. Tight bend radii, small holes, and enclosed areas can cause difficulties. In addition, internal cavities may trap excess powder, leading to an uneven finish. Solution: Add vent holes to facilitate powder escape and ensure a uniform coating.