PMMA Injection Molding Overview

POM (Polyoxymethylene), also known as acetal, is a high-performance engineering plastic recognized for its exceptional strength, low friction, and high dimensional stability. Its excellent wear resistance and minimal moisture absorption make POM an ideal choice for precision mechanical components like gears, bearings, and bushings. Additionally, POM can be modified to improve its performance in harsh environments, including chemical resistance and enhanced thermal stability.

Although POM tends to be more expensive than some other plastics, its superior mechanical properties and durability in demanding applications make it a top choice for industries such as automotive, aerospace, and consumer goods. At KingStar Mold, we leverage our extensive experience in POM injection molding to create high-precision, reliable parts that meet stringent quality standards for a wide range of industries.

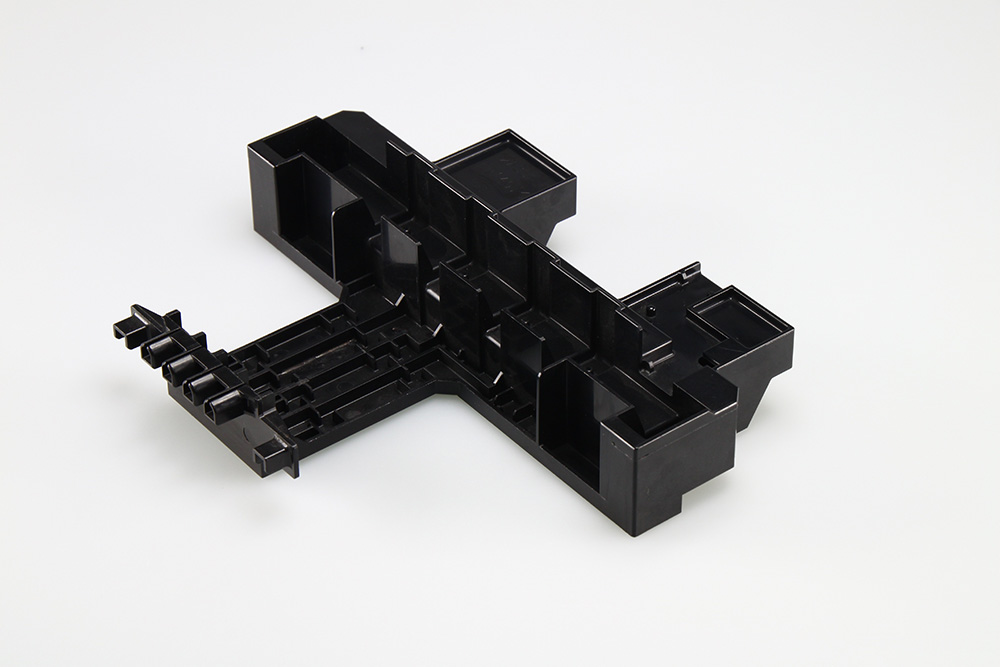

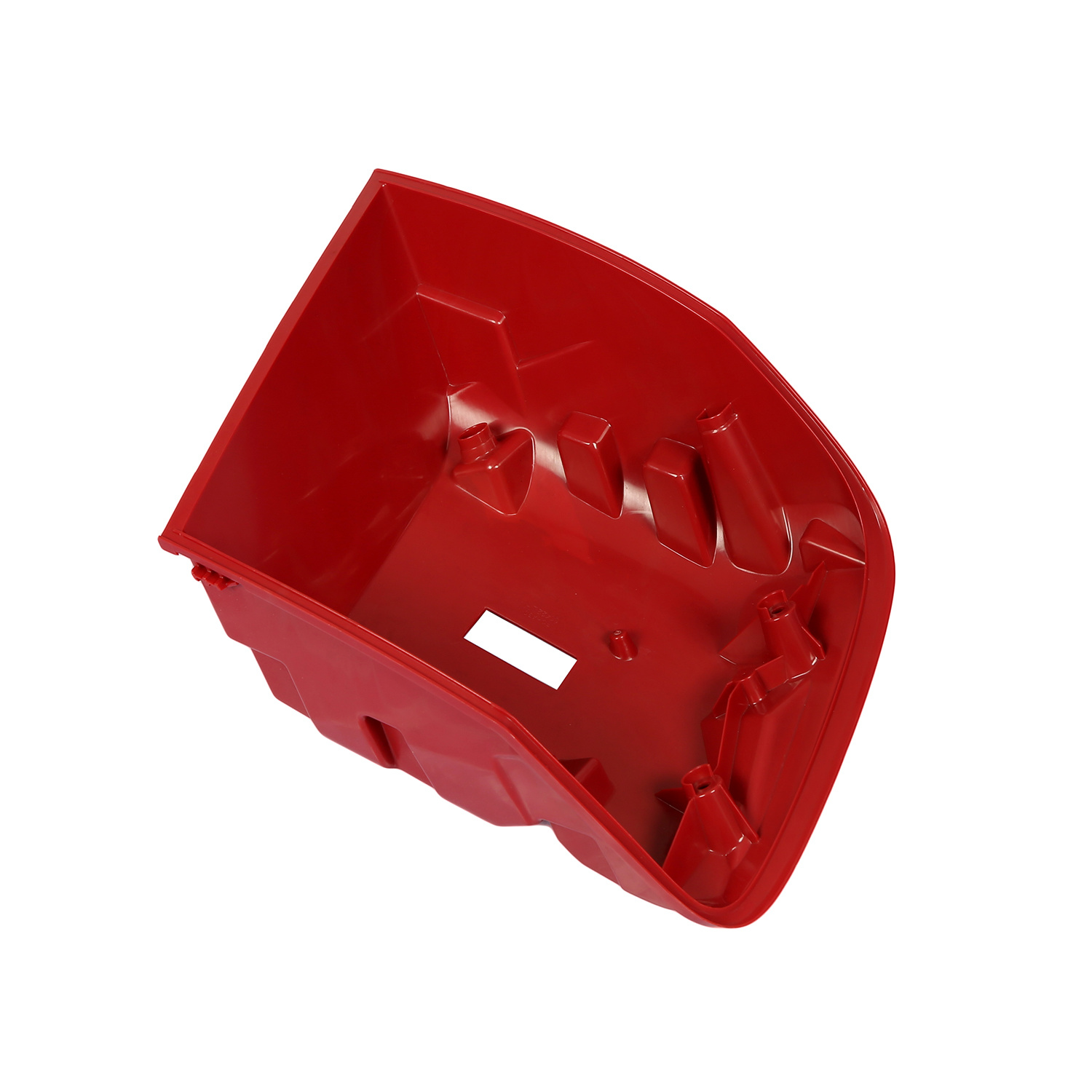

POM injection molding is widely used across industries that require high-strength, low-friction, and wear-resistant components. Known for its excellent dimensional stability and durability, POM is ideal for precision parts such as gears, bearings, and automotive components. Its resistance to chemicals, moisture, and high temperatures makes it a top choice in harsh environments, including aerospace and industrial applications.

Modified versions of POM, such as glass-filled or carbon-fiber-reinforced types, offer enhanced mechanical properties and thermal stability for even more demanding applications. Whether for high-performance automotive parts, electrical connectors, or industrial components, POM injection molding delivers reliable, long-lasting results with precise tolerances and low maintenance needs.

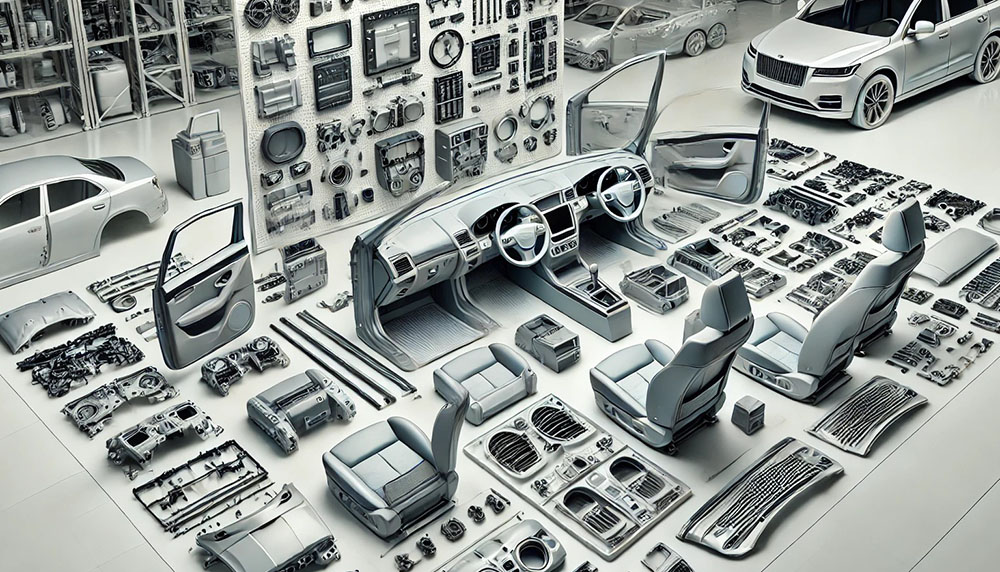

Automotive Components

Medical Devices

Precision Instrumentation

Consumer Electronics

POM Injection Molding

KingStar Mold’s Capabilities

Expert Material Selection and Customization

At KingStar Mold, we specialize in POM injection molding by selecting the right material for each application, including high-performance grades like glass-filled and impact-resistant POM. We ensure the material’s properties match customer requirements, optimizing durability, strength, and performance.

Our skilled engineers use advanced mold flow analysis and precision CNC machining to design and manufacture POM molds that meet the highest standards. KingStar Mold’s expert mold design ensures tight tolerances, minimizing defects and enhancing the production efficiency of each part.

Efficient Production and Quality Control

With a focus on streamlined production processes, KingStar Mold guarantees fast, high-quality POM injection molding services. Our comprehensive quality control system monitors every stage, from raw material selection to final inspection, ensuring reliable, defect-free parts for all applications.

Why Choose Us

Advantages of KingStar Mold

Competitive Pricing

Tailored Solutions for Complex Designs

Advanced Technology Integration

Dedicated Customer Support

Automotive, electronics, medical devices, and industrial sectors benefit greatly from POM’s mechanical properties, making it suitable for parts like gears, connectors, and valves.

Yes, POM can be modified with additives like glass fibers or lubricants to enhance its strength, heat resistance, and wear properties.

POM offers excellent wear resistance, low friction, high dimensional stability, and resistance to harsh chemicals, making it ideal for demanding industrial and mechanical applications.

POM offers superior mechanical strength and chemical resistance, especially in applications where low friction, high wear resistance, and dimensional stability are critical.

POM is commonly used in automotive, electronics, and industrial applications for gears, bearings, fasteners, and precision components that require durability and dimensional stability.

POM is a highly durable engineering plastic known for its excellent mechanical properties, high stiffness, and low friction, making it ideal for precision parts in various industries.

With over 10 years of experience, KingStar Mold offers expert mold design, precision manufacturing, and efficient solutions tailored to meet the unique demands of POM injection molding across industries.

Common challenges include managing high mold temperatures, controlling shrinkage, and achieving uniform material distribution during molding.

Yes, POM is commonly used in medical devices due to its strength, durability, and biocompatibility, making it suitable for surgical instruments, connectors, and housings.

POM has a high melting point, which makes it resistant to high-temperature environments. However, proper temperature control during molding is crucial to ensure optimal part quality and consistency.

Lead times for POM parts vary based on the complexity of the design and quantity, but we strive for efficient turnaround times, ensuring timely delivery for our customers.

At KingStar Mold, we use advanced technologies such as mold flow analysis, CNC machining, and thorough quality control processes to ensure precision and performance in every part.