Cooperative Brands

Plastic Injection Molding Company for POS Display

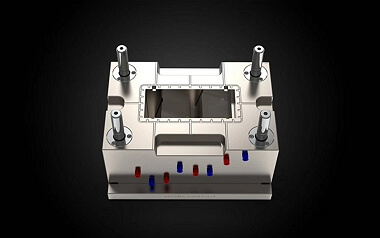

Custom POP Displays Mold by Experts

Creating custom POP display molds requires specialized expertise, and KingStar Mold works with professionals who manufacture molds to your exact specifications. Our services stand out by ensuring products meet both national and international standards.

Custom services offered include:

Why Choose Injection Molding For Plastic POS Display Manufacturing?

One key benefit of our injection molding technology is the rapid production of prototypes. By utilizing both 3D printers and CNC machines, we ensure your plastic pos display prototypes are created in the shortest time frame possible.

We take pride in being able to produce over 600 set molds in a year. This has garnered us a reputation for being able to fulfill any order, no matter how big it is. No matter how large the scale of the order, we are more than capable of fulfilling it.

KingStar Mold always adheres to a high standard of control. We follow the strictest quality control, and any plastic parts that we distribute, are tested by our specialized team of experts. Rest assured, any product you get from KingStar Mold is of the best quality possible.

By utilizing injection molding for your plastic pos displays, you are assured that you will be saving money. Just one injection mold could be used to create a myriad of parts. This means that you will save on both material and production costs.

Why Choose Us

We Believe You Will Choose Us Again

Only companies with extensive market experience and a deep understanding of customer needs can offer the best service.

Skilled

High-precision production equipment, skilled production staff, and guaranteed delivery times.

Experienced

Over ten years of industry experience, with a mature quotation system and technical support.

Thoughtful

Customized processing options that save time and effort, with active support throughout pre-sales and post-sales.

Equipped

Engineers review designs to identify and resolve potential issues, backed by advanced testing equipment.

Peg Board Display Stand

Slant Sign Holder

Stand Organizer

Stand Riser

Storage Shelf

Display Case

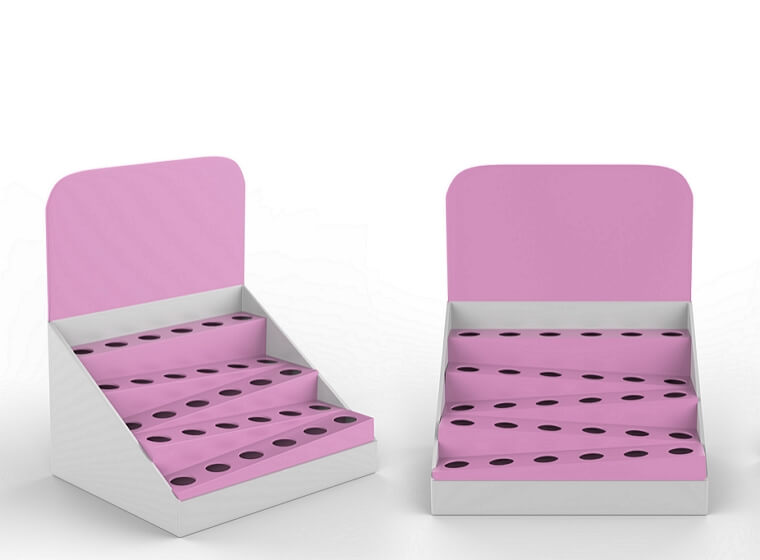

Showcase of Our Previous Injection Molded Plastic POS Displays

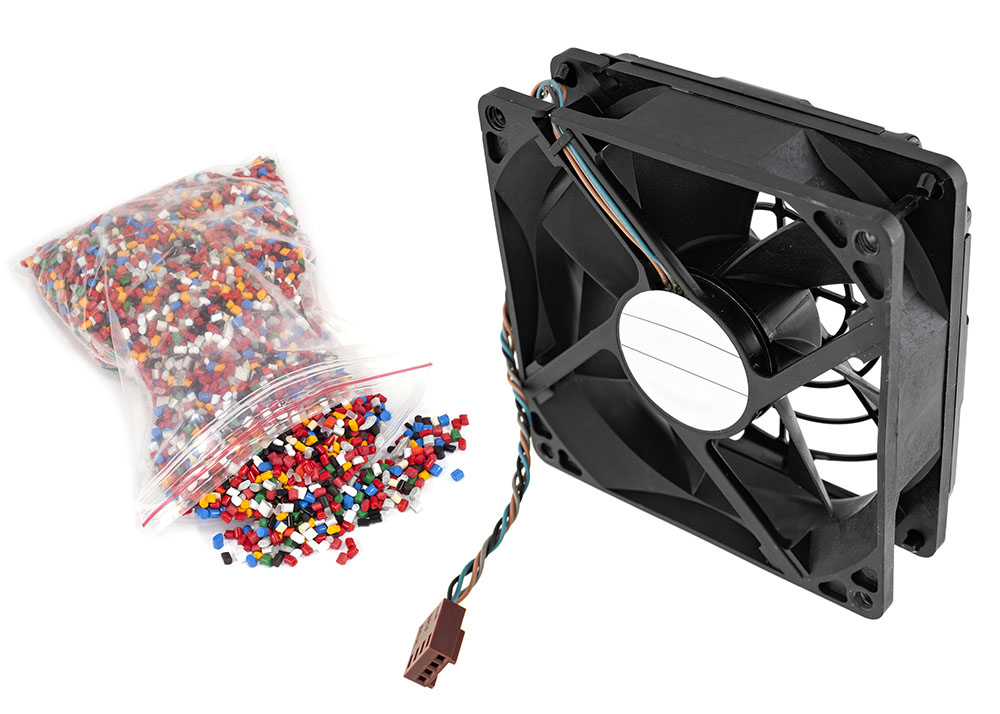

At KingStar Mold, we specialize in designing, manufacturing, and supplying high-quality molds to a rapidly expanding client base worldwide. Each year, we produce between 900 and 1,000 molds, catering to diverse industries with products like crate molds, baby product molds, plastic bucket molds, automotive molds, and home appliance molds.

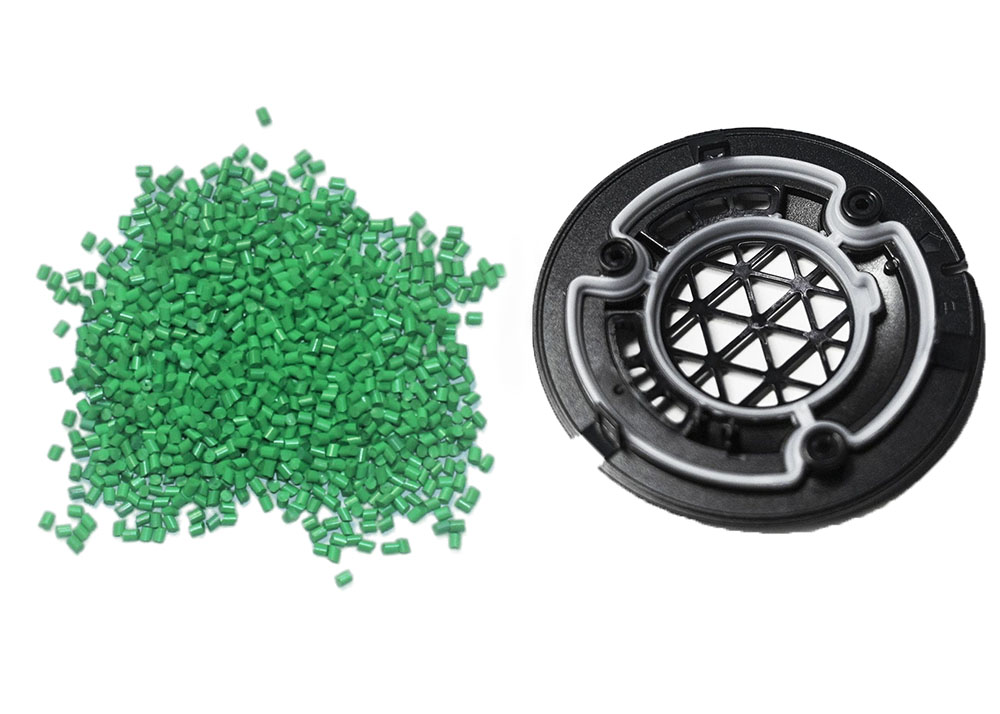

Although injection molding is our primary service, we also offer additional molding techniques such as insert molding and overmolding. These capabilities enable us to produce bulk plastic products that are both cost-effective and tailored to meet the specific needs of our clients.

Frequently Asked Questions

Plastic POS displays are widely used across industries that rely on visual merchandising and customer engagement at the point of sale. At KingStar Mold, we’ve provided custom display solutions for clients in retail, cosmetics, electronics, food and beverage, and sporting goods. Our cooperative partners include globally recognized brands such as Adidas, Sam’s Club, and other leading retail chains, all of whom trust us to deliver high-quality, visually striking, and durable POS displays that enhance product visibility and boost in-store marketing impact.

Yes, KingStar Mold can fully customize POS displays based on your brand’s design and visual identity. Whether you need unique shapes, custom dimensions, integrated lighting, printed logos, or color matching to your brand palette, our engineering and design teams work closely with you to bring your concept to life. We use a combination of CNC machining, precision mold making, and high-quality plastic materials to ensure your displays not only look great but are durable and functional in retail environments.