In the world of injection molding, in most circumstances, the choice of materials is not a one-time decision. The selection of materials involves many considerations, including cost, properties, supply volume, and so on. This post provides a detailed analysis of 8 common plastic materials (ABS, PC, HDPE, PA, PBT, PET, PP, and POM) and their substitutes (PPSU, PPA, ASA, PCT, PPO, COC, PSU, SPS, and Tritan). The focus is on the characteristics, performance, applications, presumed cost, advantages and disadvantages of each material and our recommendation of substitution. We hope this article can inspire or assist you in choosing the right material for your project.

- Common Plastics

- Substitute Plastics

- 1. PESU (Polyethersulfone)

- 2. PPA (Polyphthalamide)

- 3. ASA (Acrylonitrile Styrene Acrylate)

- 4. PCT (Polycyclohexylenedimethylene Terephthalate)

- 5. PPO (Polyphenylene Oxide)

- 6. COC (Cyclic Olefin Copolymer)

- 7. PSU (Polysulfone)

- 8. SPS (Syndiotactic Polystyrene)

- 9. Tritan Plastic

- Summary Table of These 9 Substitute Materials

Common Plastics

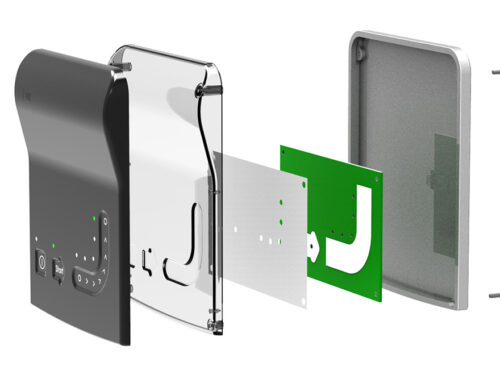

1. ABS (Acrylonitrile-Butadiene-Styrene Copolymer)

- Properties:

- High impact strength, good processability, and chemical resistance.

- Flexible, easy to color, and has a variety of hardness options.

- Can be reinforced with glass fiber and maintains its properties at low temperatures.

- Good tear and abrasion resistance, good sun and seawater resistance, and good oil and chemical resistance.

- Applications:

- Electronic enclosures, automotive parts, and toys.

- Used in 3D printing prototypes and injection molding.

2. PC (Polycarbonate)

- Properties:

- Transparent, heat-resistant, and impact-resistant.

- High transparency (up to 86-92% clarity), excellent print adhesion, and fully recyclable.

- Good resistance to chemical substances and weathering.

- Applications:

- Optical components, safety glasses, and electronic enclosures.

- Used in aircraft windows, protective helmets, and automotive components.

3. HDPE (High-Density Polyethylene)

- Properties:

- High density, chemical resistance, and lightweight.

- Low moisture absorption, good electrical insulation, and excellent chemical resistance.

- Poor low-temperature performance and prone to brittle fracture.

- Applications:

- Containers, pipes, and packaging materials.

- Used in water tanks, oil drums, and food packaging.

4. PA (Polyamide 6, 6.6)

- Properties:

- High wear resistance, heat resistance, and chemical resistance.

- Self-lubricating, good electrical insulation, and excellent mechanical strength.

- High moisture absorption, requiring drying before processing.

- Applications:

- Mechanical parts, textile fibers, and automotive components.

- Used in gears, bearings, and transmission systems.

5. PBT (Polybutylene Terephthalate)

- Properties:

- High rigidity, strength, and heat resistance.

- Good chemical resistance, but high moisture absorption.

- Poor low-temperature performance and prone to brittle fracture.

- Applications:

- Electrical connectors and automotive components.

- Used in automotive parts and industrial gears.

6. PET (Polyethylene Terephthalate)

- Properties:

- Transparent, good barrier properties, and heat resistance.

- Low moisture absorption, good chemical resistance, and excellent optical clarity.

- Applications:

- Beverage bottles and packaging materials.

- Used in food packaging, transparent containers, and film applications.

7. PP (Polypropylene)

- Properties:

- Heat-resistant, chemical-resistant, and lightweight.

- Low moisture absorption, good electrical insulation, and excellent chemical resistance.

- Poor low-temperature performance and prone to brittle fracture.

- Applications:

- Food packaging, automotive parts, and household appliances.

- Used in microwave ovens, washing machines, and medical devices.

8. POM (Polyoxymethylene)

- Properties:

- High hardness, low friction, and wear resistance.

- Excellent self-lubrication, good dimensional stability, and high mechanical strength.

- Poor heat resistance (deforms at 90-100°C).

- Applications:

- Precision gears, bearings, and sliding parts.

- Used in high-speed machinery and precision engineering.

Summary Table of These 8 Common Materials

| Material | Density (g/cm³) | Heat Resistance (°C) | Electrical Insulation | Moisture Absorption | Low-Temp Performance | Applications | Cost Level | Market Price (USD/kg) |

|---|---|---|---|---|---|---|---|---|

| ABS | 1.05 | 93–118 | Good | High | Good | Electronics, Automotive | Medium | 1.65–2.20 |

| PC | 1.20 | 125 | Good | Low | Poor | Safety Glasses, Optics | Medium-High | 2.80–3.50 |

| HDPE | 0.94 | 85–110 | Good | Low | Poor | Pipes, Packaging | Low | 1.15–1.35 |

| PA (Nylon) | 1.13–1.15 | 150–185 | Good | High | Poor | Gears, Automotive | Medium | 3.00–3.80 (PA6/PA66) |

| PBT | 1.30 | 150–200 | Good | High | Poor | Connectors, Automotive | Medium | 2.60–3.20 |

| PET | 1.42 | 70–115† | Good | Low | Good | Bottles, Packaging | Low | 1.25–1.45 |

| PP | 0.90 | 100–130 | Good | Low | Poor | Appliances, Packaging | Low | 1.10–1.25 |

| POM | 1.41 | 90–100 | Good | Low | Good | Bearings, Precision Parts | High | 2.20–6.50‡ |

(Cost For EU/US Market Reference, June 2025)

Notes:

Prices reflect spot market ranges (500+ kg orders) from: PlasticsExchange, ICIS (US), Platts Polymer Price Report (EU), S&P Global Commodity Insights (Global) excluding tariffs, logistics, or custom-compounded grades.

The above are the 8 common plastics that engineers are likely to recommend you to choose. However, there are always unexpected situations – you may need to adjust the cost, or you to improve a certain characteristic of your product, or simply – there may be no stock.

So in the following section, we will introduce 9 alternative materials that can replace the commonly used plastics previously mentioned. You can compare their characteristics to choose the one that suits your needs. Or we will recommend several (not all) most suitable alternative materials at the end of each section for your reference.

Substitute Plastics

1. PESU (Polyethersulfone)

Diphenyl sulfone and bisphenol A react to create PESU, a high-performance thermoplastic polymer. It belongs to the sulfone polymer family and is well known for having superior mechanical and thermal properties.

Repeating ether and sulfone linkages make up the polymer backbone, which balances chemical stability and mechanical strength to make PESU appropriate for demanding applications.

Properties:

- High-Temperature Stability: PESU can withstand continuous exposure to temperatures as high as 204°C, making it ideal for applications in high-heat environments.

- Hydrolytic Stability: It exhibits superior resistance to water and steam, which is essential for applications in the medical and food industries.

- Flame Retardant: PESU is naturally flame-retardant, eliminating the need for additional flame-retardant additives in many applications.

- Electrical Insulation: The material boasts excellent dielectric properties, which make it highly suitable for use in electrical components requiring insulation.

- Transparency: PESU offers good optical clarity, making it a versatile choice for applications that require transparency, such as medical or consumer products.

Applications:

- Medical Devices: Because PESU is biocompatible, thermally stable, and resistant to rigorous sterilization techniques, it is frequently used in sterilizable medical equipment such as water filters, dialyzers, and surgical tools.

- Automotive: Because of its strong heat resistance and electrical insulating qualities, the polymer finds extensive use in automobile applications, particularly for electrical components such as connections and housings.

- Food and Beverage Industry: Since PESU satisfies the stringent safety and hygienic standards of the sector, it is used in food-contact items, including components for coffee makers, faucets, and beverage dispensers.

PESU is especially suitable for applications requiring high heat resistance and thus can replace materials such as PA, PBT, and PPO.

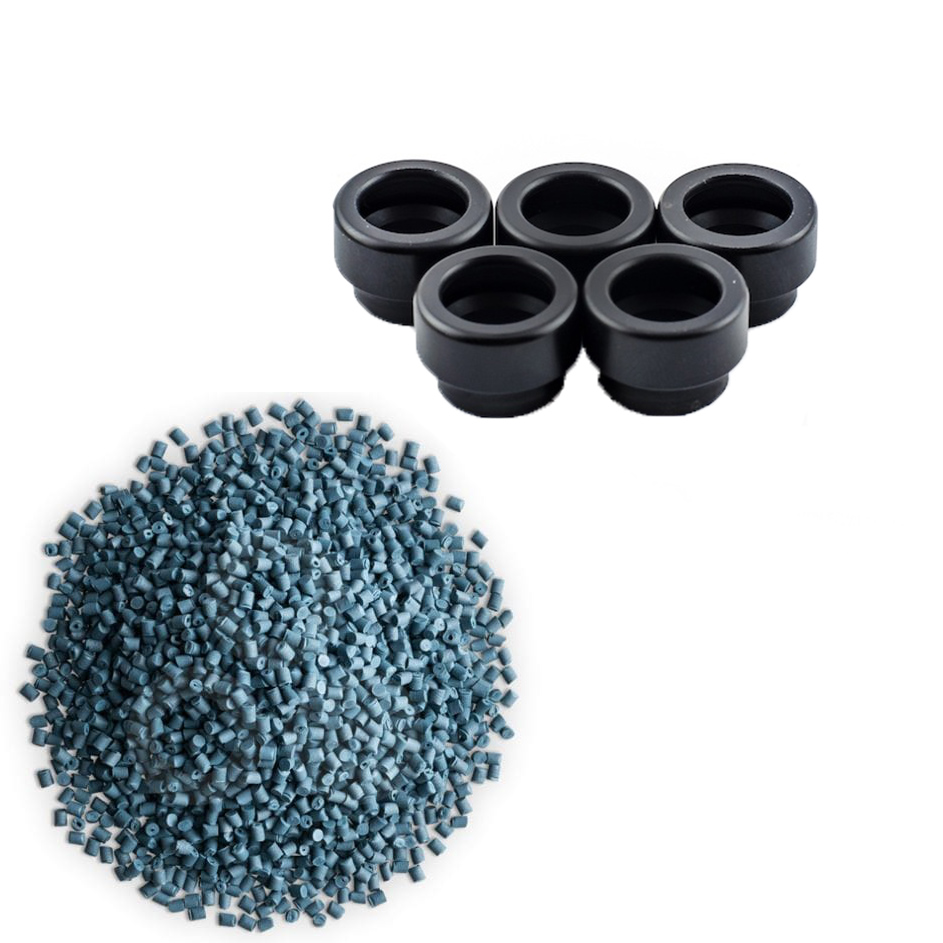

2. PPA (Polyphthalamide)

PPA is a high-performance engineering plastic belonging to the polyamide family. Unlike standard nylons (like PA6 or PA66), it’s synthesized using phthalic acid and diamines, giving it a semi-aromatic structure. This key difference translates to significantly better performance in demanding, high-heat environments.

Key Characteristics:

- Outstanding heat resistance: PPA‘s melting point and glass transition temperature are both relatively high. Compared to ordinary nylon, it can better maintain strength and rigidity in continuous high-temperature environments, making it highly suitable for use in automotive interior parts or high-temperature industrial settings.

- Strong Chemical Resistance: It holds up exceptionally well against a broad range of automotive fluids (fuels, oils, coolants), many industrial chemicals, and solvents. This durability ensures long-term reliability in harsh operating conditions.

- Superior Dimensional Stability: Even at elevated temperatures and under mechanical load, PPA parts maintain their shape and size very effectively. This is crucial for precision components like gears, bearings, and tight-tolerance electrical connectors where warping or creep is unacceptable.

Applications:

- Automotive: You’ll find it in fuel line components (connectors, rails), sensors, thermostat and water pump housings, engine covers, and transmission parts – places where heat, chemicals, and mechanical stress converge.

- Industrial Machinery: Its combination of strength, dimensional stability, heat resistance, and wear resistance makes PPA perfect for gears, bushings, bearings, pump impellers, and valve components in industrial equipment.

- Electronics & Electrical: PPA is widely used for surface-mount technology (SMT) connectors, sockets, bobbins, coil formers, and switch housings. Its ability to withstand soldering temperatures without deforming and maintain electrical properties under heat is critical here.

Similar to PESU, PPA is often chosen to replace materials like standard Nylons (PA), PBT, and PPO/PPE in applications where their heat resistance, chemical resistance, or dimensional stability falls short.

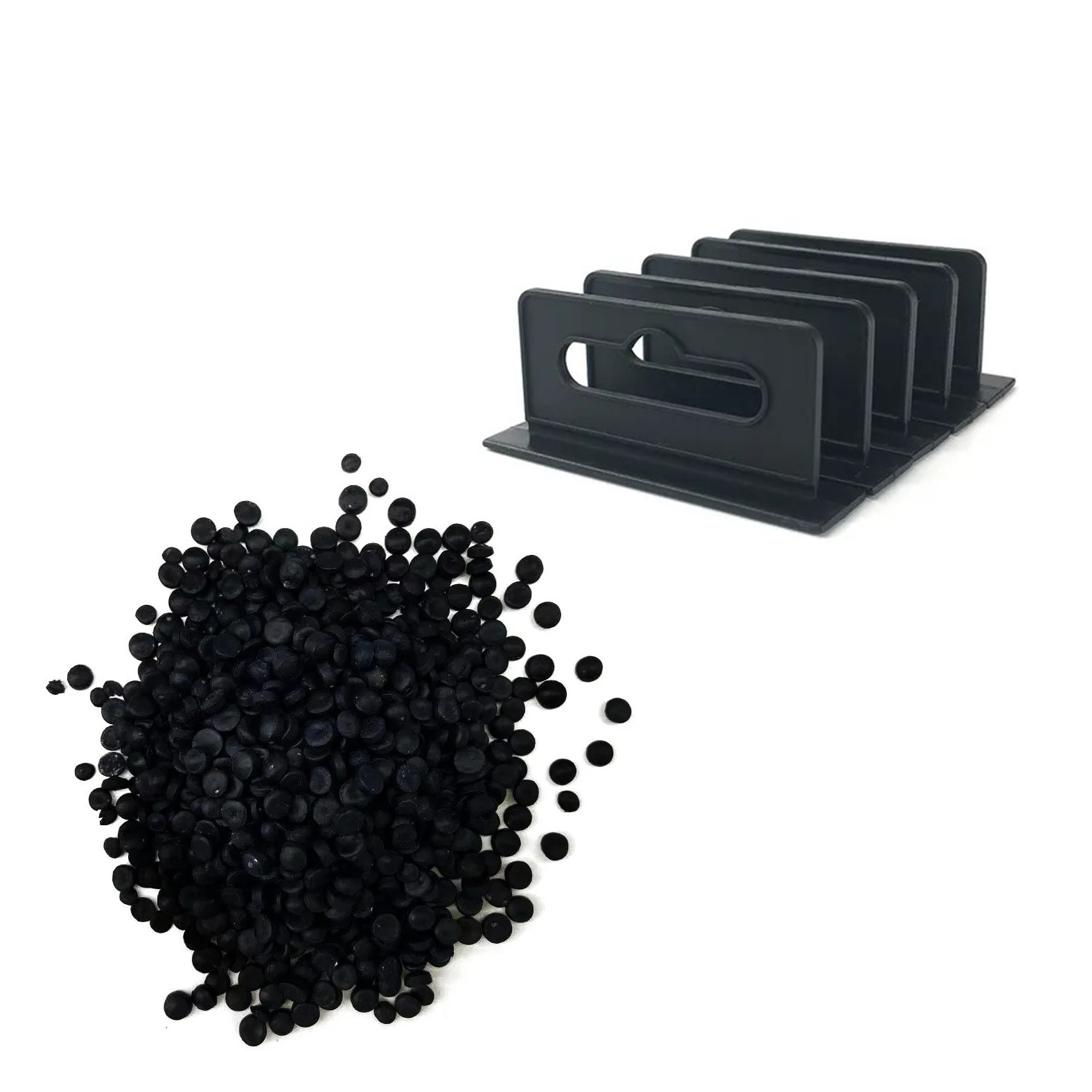

3. ASA (Acrylonitrile Styrene Acrylate)

ASA is a copolymer made from acrylonitrile, styrene, and acrylic ester. The chemical structure combines the impact strength of styrene with the weathering resistance of acrylic esters.

Chemical Structure:

- Acrylonitrile contributes to chemical resistance.

- Styrene provides high-impact strength and rigidity.

- Acrylic ester contributes to UV resistance and improves outdoor weathering properties.

Properties:

- UV Stability: Outstanding resistance to UV radiation, preventing degradation from prolonged exposure to sunlight.

- Weatherability: Excellent resistance to environmental factors such as rain, snow, and extreme temperatures.

- Impact Resistance: High impact strength, similar to ABS, which makes it suitable for parts subject to physical stress.

- Chemical Resistance: Resistant to a variety of acids, bases, and other chemicals.

Applications:

- Automotive: Used in exterior automotive parts such as mirror housings and grills.

- Consumer Products: Ideal for products exposed to outdoor conditions like garden furniture, electrical enclosures, and housing.

- Building and Construction: Commonly used in roofing materials and window profiles.

We recommend ASA as a substitute of ABS, PVC and PC particularly for applications requiring high weather resistance and UV resistance.

4. PCT (Polycyclohexylenedimethylene Terephthalate)

PCT stands out as a high-performance polyester engineered from cyclohexanedimethanol and terephthalic acid. This semi-crystalline material delivers significantly better heat and chemical resistance than standard PET, making it a top choice for demanding environments.

Key Strengths:

- Heat resistance: With a melting point around 285°C, PCT thrives where lesser plastics fail. It maintains performance reliably in high-temperature applications.

- Water resistance: Exceptional hydrolysis resistance means PCT laughs off moisture and water exposure. This is crucial for parts facing steam, weather, or wet conditions, especially under automotive hoods or in electronics.

- Tough on Chemicals: PCT shrugs off a wide range of solvents and aggressive chemicals, ensuring long-term stability and durability even in harsh industrial settings.

- Stays Precise: Its very low moisture absorption translates to outstanding dimensional stability. Parts keep their shape and size accurately, even in humid conditions or under load.

- Electrically Sound: Offering excellent dielectric strength, PCT provides reliable electrical insulation, making it a safe bet for critical electrical and electronic components.

Where It Excels:

- Automotive: PCT is a workhorse in automotive engine bays. You’ll find it in connectors, sensor housings, relays, switches, and other components that need to endure heat, chemicals, and moisture.

- Demanding Electronics: Its blend of electrical properties, heat tolerance, and moisture resistance makes PCT ideal for surface-mount (SMT) connectors, circuit board components, plug housings, bobbins, and protective enclosures exposed to harsh environments.

- Industrial Toughness: When standard PBT isn’t tough enough, PCT steps in. It’s a reliable upgrade for industrial parts like pump components, valve bodies, gears, and housings that face elevated temperatures, chemicals, or require precise dime ensions.

You can choose PCT to replace materials like PBT, PPO, or PESU when applications demand superior heat resistance, exceptional resistance to hydrolysis, or enhanced chemical stability – particularly in corrosive or high-heat settings.

5. PPO (Polyphenylene Oxide)

PPO stands as a high-performance engineering thermoplastic prized for its outstanding electrical properties and dimensional stability. While pure PPO is quite rigid, it’s almost always blended (most commonly with polystyrene, PS) to improve processability, impact strength, and cost-effectiveness, significantly widening its practical use.

Key Performance:

- Electrical Insulation: PPO’s exceptional dielectric properties make it a top choice for critical electrical and electronic components where reliable, long-term insulation is non-negotiable.

- Handles Heat & Steam: It maintains its integrity and key properties at elevated temperatures and offers excellent resistance to steam, hot water, and a broad range of chemicals, including many acids. This makes it tough in demanding environments.

- Dimensional Stability: Thanks to very low moisture absorption, PPO parts resist warping or swelling even when exposed to humidity or temperature swings, ensuring consistent fit and function.

- Strong & Stiff: The inherent structure provides good mechanical strength and stiffness, contributing to its durability.

While durable, PPO blends can be susceptible to stress cracking under sustained mechanical strain or when exposed to certain chemicals under stress. This needs consideration during design and material selection for high-stress parts.

Applications:

- Electronics & Electrical: You could find PPO blends in electrical connectors, switch housings, coil bobbins, relay bases, terminal blocks, and insulating components – anywhere stable insulation is key.

- Automotive: PPO is commonly used in automotive applications, including pump parts, fan impellers, and engine components, where high heat resistance and dimensional stability are essential.

- Hot & Tough Appliances: Commonly used in housings and internal components for dishwashers, coffee makers, water heaters, and other appliances needing resistance to heat, steam, and cleaning chemicals.

- Fluid Handling: Its chemical resistance makes it suitable for components in plumbing systems, water filters, and pumps handling hot water or certain chemicals.

PPO blends are often a strategic choice to replace materials like standard Nylons (PA), PBT, or even PESU in applications demanding superior electrical properties, excellent dimensional stability, and good heat/chemical resistance – especially where moisture exposure is a concern.

6. COC (Cyclic Olefin Copolymer)

COC is a polymer derived from cyclic olefins, such as norbornene, combined with various co-monomers to create a copolymer structure. While part of the polyolefin family, its unique molecular design results in distinct properties.

- Chemical Structure: COC is composed of cyclic olefin monomers and potentially other co-monomers, depending on the specific grade. It has a crystalline structure that contributes to its high transparency.

Properties:

- Transparency: Offers exceptional optical clarity, rivaling polycarbonate, making it ideal for applications requiring clear, unobstructed views.

- Low Moisture Absorption: Demonstrates extremely low moisture absorption, providing excellent stability and performance in humid environments.

- Chemical Resistance: Exhibits resistance to a wide range of solvents and chemicals, which makes it well-suited for use in chemically aggressive settings.

- Biocompatibility: Non-toxic and biocompatible, making it a safe choice for medical and pharmaceutical applications.

- Dimensional Stability: Maintains its shape and integrity even in high-humidity conditions, ensuring long-lasting performance.

Applications:

- Medical Devices: Ideal for use in diagnostic disposables, drug packaging, and medical device housings, thanks to its transparency and biocompatibility.

- Optical Components: Widely used for lenses, optical fibers, and light guides due to its high clarity and precise dimensional stability.

- Packaging: Commonly used in food and pharmaceutical packaging because of its superior barrier properties, ensuring product protection and safety.

COC can replace materials such as PC, PMMA, PVC, and PE, and is applicable in the fields of optics, medicine, and packaging.

7. PSU (Polysulfone)

Polysulfone (PSU) is a high-performance thermoplastic synthesized through a nucleophilic aromatic substitution reaction of bisphenol A and diphenylsulfone. As a member of the sulfone polymer family, polysulfone is renowned for its outstanding thermal stability, mechanical strength, and chemical resistance.

- Chemical Structure: PSU has a repeating structure of ether and sulfone groups in its polymer chain, providing it with outstanding resistance to high temperatures and a variety of chemicals.

Properties:

- Thermal Stability: PSU can withstand high temperatures, typically up to 180°C (356°F), and is suitable for continuous service in high-heat environments.

- Hydrolytic Stability: The material offers exceptional resistance to water, steam, and hydrolytic attack, making it ideal for use in applications that involve exposure to high-temperature water or steam.

- Chemical Resistance: PSU resists a wide range of acids, bases, and solvents but is sensitive to certain polar solvents, such as benzene and toluene.

- Mechanical Strength: PSU provides high tensile and impact strength, comparable to polycarbonate, while maintaining excellent dimensional stability.

- Electrical Insulation: The material has good electrical insulating properties, making it suitable for various electrical and electronic applications.

Applications:

- Medical Devices: Polysulfone is widely used in sterilizable medical equipment, including components for dialysis machines, water treatment filters, and coffee machines.

- Automotive: PSU is used in automotive under-the-hood components such as electrical connectors, sensors, and manifolds due to its thermal and chemical resistance.

- Food and Beverage Industry: Polysulfone is also found in food-processing equipment, including sterilizable containers and water treatment systems, where hygiene and durability are critical.

PSU can replace materials such as PBT, PPO, and PESU, and is suitable for applications requiring high heat resistance.

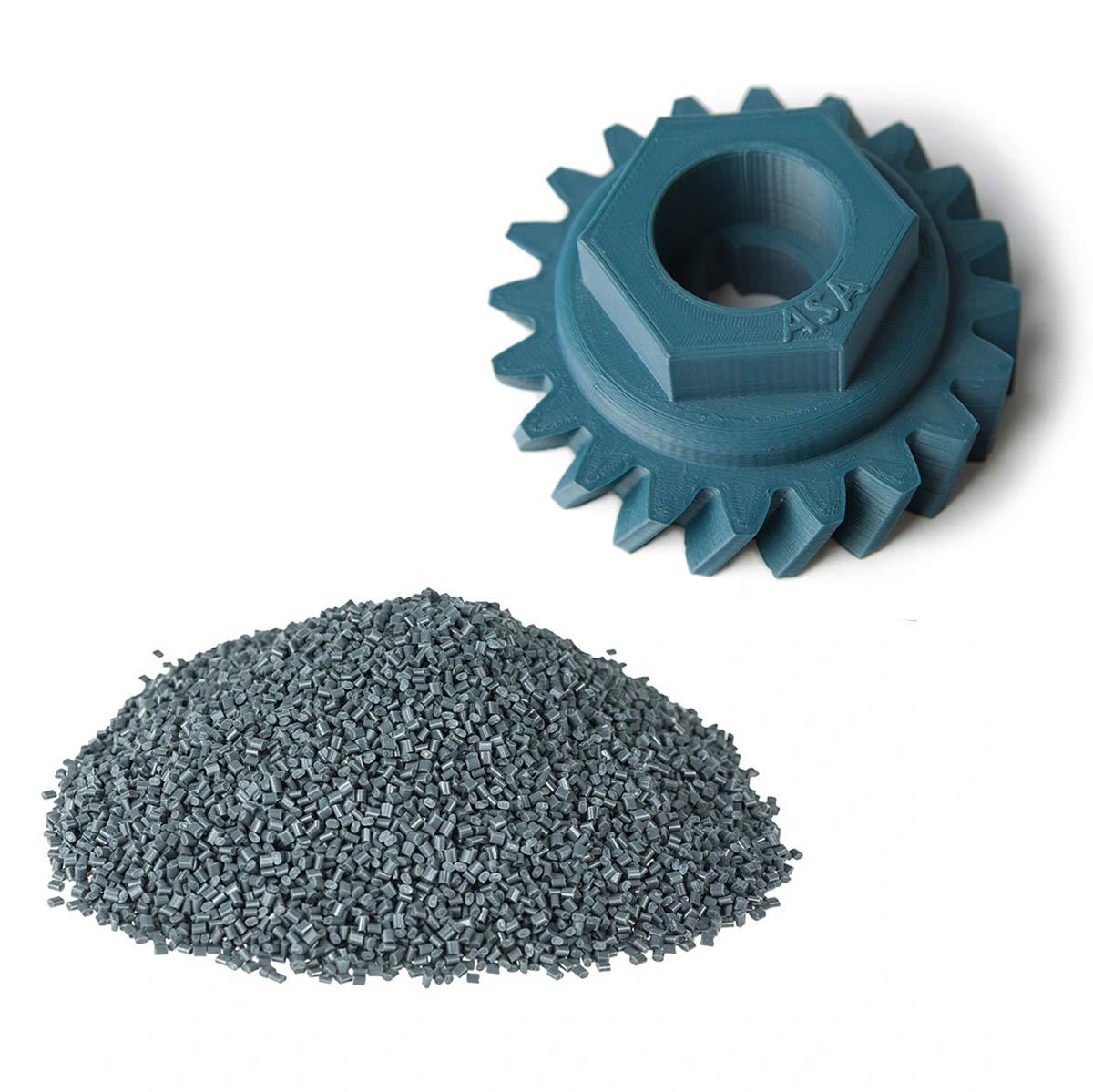

8. SPS (Syndiotactic Polystyrene)

Syndiotactic Polystyrene (SPS) is a semi-crystalline engineering thermoplastic synthesized through metallocene catalysis. This process creates a highly ordered syndiotactic configuration of benzene rings, resulting in significantly enhanced properties compared to conventional atactic polystyrene.

Key Characteristics:

- Elevated Thermal Performance: SPS exhibits a heat deflection temperature (HDT) of up to 250°C (482°F), enabling reliable operation in high-temperature environments unsuitable for standard styrenics.

- Exceptional Chemical Resistance: The material demonstrates strong resistance to mineral/organic acids, alkalis, automotive fluids (oils, brake fluids, antifreeze), and various industrial chemicals.

- Low Density: With a specific gravity significantly lower than many engineering thermoplastics, many engineers tend to give priority to SPS when designing lightweight components.

- Superior Dielectric Properties: SPS possesses a low dielectric constant and dissipation factor, making it highly effective for high-frequency electrical applications requiring signal integrity.

- Minimal Moisture Absorption: Low water uptake contributes to excellent dimensional stability under humid conditions.

- High Processability: SPS offers excellent melt flow characteristics suitable for producing complex, thin-walled parts via injection molding.

Primary Applications:

- Automotive: Utilized in under-hood connectors (including wave-solderable types), sensors, ignition components, and fluid handling systems where thermal and chemical resistance are critical.

- Electronics & Telecommunications: Employed in high-frequency components such as RF connectors, antenna elements, chip carriers, and sockets due to its stable dielectric properties.

- Appliances: Specified for internal components in dishwashers, microwave ovens (e.g., waveguide covers, turntable supports), and other heat-exposed appliance parts.

Material Alternative: SPS serves as a viable alternative to PBT, PPO, and PESU in applications demanding high heat resistance, chemical resistance (particularly to hydrocarbons), and excellent high-frequency electrical performance combined with low density.

9. Tritan Plastic

Tritan is a copolymer composed of bisphenol A and other materials that do not release bisphenol A (BPA). It provides a safe alternative to polycarbonate. It belongs to the polyester family and specifically is a modified polyester.

- Chemical Structure: Tritan’s structure combines polyester based on bisphenol A with additional monomers to improve strength, safety, and clarity.

Qualities:

- BPA-Free: Tritan is a safer alternative for food and drink containers since it is devoid of Bisphenol A (BPA), which is frequently present in polycarbonate plastics.

- Impact Resistance: Tritan is comparable to polycarbonate in terms of impact resistance, but it lacks the disadvantages of BPA.

- Thermal Resistance: It is resistant to deformation at temperatures as high as 100°C (212°F).

- Clarity: It offers exceptional optical clarity, which makes it ideal for uses that need for transparency, like complex lenses, bottles, and beverage containers.

- Chemical Resistance: Its resistance to a variety of chemicals and detergents makes it ideal for food and medical industries.

- Dishwasher Safe: It is dishwasher safe, retaining its clarity and strength even after multiple washing cycles.

Applications:

- Consumer Goods: Frequently used in food and beverage containers, including reusable water bottles, baby bottles, and food storage containers.

- Medical Devices: Tritan is used in medical components that require clarity, strength, and resistance to sterilization processes.

- Household Products: Common in kitchen appliances, baby products, and various household goods requiring high impact resistance and clarity.

Tritan can replace materials such as PC, PVC, and PE, and is suitable for applications requiring transparency and heat resistance.

Summary Table of These 9 Substitute Materials

| Material | Density (g/cm³) | Heat Resistance (°C) | Electrical Insulation | Moisture Absorption (%) | Low-Temp Performance | Applications | Cost Level | Market Price (USD/kg) |

|---|---|---|---|---|---|---|---|---|

| PESU | 1.37-1.43 | 220 (HDT @1.8MPa) | Excellent | 0.6-0.8 | Good (-100°C) | Medical sterilizable trays, aerospace | Very High | 35.00-50.00 |

| PPA | 1.17-1.25 | 310 (Tm) / 150-170 (HDT) | Good | 0.8-1.2‡ | Poor (<-10°C) | Fuel system components, ECU housings | High | 8.20-12.00 |

| ASA | 1.05-1.07 | 85-95 (HDT @1.8MPa) | Good | 0.3-0.6 | Poor (<-20°C) | Automotive trims, outdoor housings | Medium | 2.80-3.50 |

| PCT | 1.23-1.30 | 285 (Tm) / 120-135 (HDT) | Excellent | 0.15-0.20 | Moderate (-30°C) | SMT connectors, automotive sensors | High | 7.50-9.80 |

| PPO | 1.06-1.10 | 95-170 (HDT)§ | Excellent | 0.07-0.10 | Moderate (-40°C) | EV battery modules, pump housings | Medium-High | 4.50-6.20 |

| COC | 1.01-1.02 | 140-170 (Tg) | Excellent | <0.01 | Good (-40°C) | Medical syringes, optical lenses | High | 15.00-25.00† |

| PSU | 1.24-1.29 | 180 (HDT @1.8MPa) | Excellent | 0.3-0.4 | Excellent (-100°C) | Coffee machine boilers, aircraft interiors | Very High | 30.00-45.00 |

| SPS | 1.05-1.08 | 250 (HDT @1.8MPa) | Excellent | 0.01-0.03 | Good (-30°C) | Automotive sensors, RF antennas | High | 9.50-14.00 |

| Tritan™ | 1.18-1.23 | 109 (HDT @0.45MPa) | Good | 0.15-0.20 | Moderate (-10°C) | BPA-free bottles, small appliances | Medium-High | 6.80-8.50 |

(Cost For EU/US Sourcing, Q2 2025)

Note:

Price Data compiled from: ICIS Engineering Plastics Monthly (June 2025), S&P Global Polymer Forecast, manufacturer datasheets (BASF, Covestro, Eastman). Prices valid for 1-5 ton orders, EXW terms. Medical/food grades add 15-30% premium.

Selecting the optimal engineering plastic transcends basic specifications. It directly impacts product longevity, safety compliance, and your ability to meet rigorous industry standards – from automotive thermal demands to FDA food contact requirements. Throughout this analysis, we’ve examined how specialized polymers deliver critical advantages like Precision Performance, Regulatory Compliance, Sustainability Impact and Cost Efficiency and how they can be as substitutes of those common plastics.

The 17 plastics profiled (8 industry staples + 9 advanced alternatives) represent proven solutions and best practices of our company.

With over 10 years in precision injection molding, KingStar Mold provides more than manufacturing. We offer material selection guidance grounded in real-world application data. Our engineers help you:

- Navigate Complex Requirements: Balance thermal, mechanical, chemical, and regulatory needs

- Avoid Costly Validation Delays: Leverage our database of certified material data sheets

- Optimize for Manufacturability: Ensure your chosen resin performs reliably in production

Review full technical specifications and compliance certifications for all polymers we process:

Plastics Materials For On Demand Manufacturing(some datasheets may not contained in the page, but you can always send email to sales@kingstarmold.com to get access).

Contact KingStar Team for a performance analysis tailored to your application.