Custom Plastic Injection Molding

We can sign NDA before you send us drawings, sketches or design ideas.

Best Injection Molding Factory In China

Precision Manufacturing for Diverse Industries

Fast Lead Times for Your Injection Molding Needs

At KingStar Mold, we understand the importance of quick turnaround times in today’s fast-paced market. Our efficient production processes and advanced equipment enable us to offer rapid lead times without compromising on quality. Whether you need prototype parts or large-scale production runs, we ensure that your orders are completed promptly and delivered on schedule, keeping your projects moving forward smoothly.

Fastest Lead Time: 7 Days

Expertise and Experience

With years of industry experience, we have the knowledge to handle complex injection molding projects with precision and efficiency.

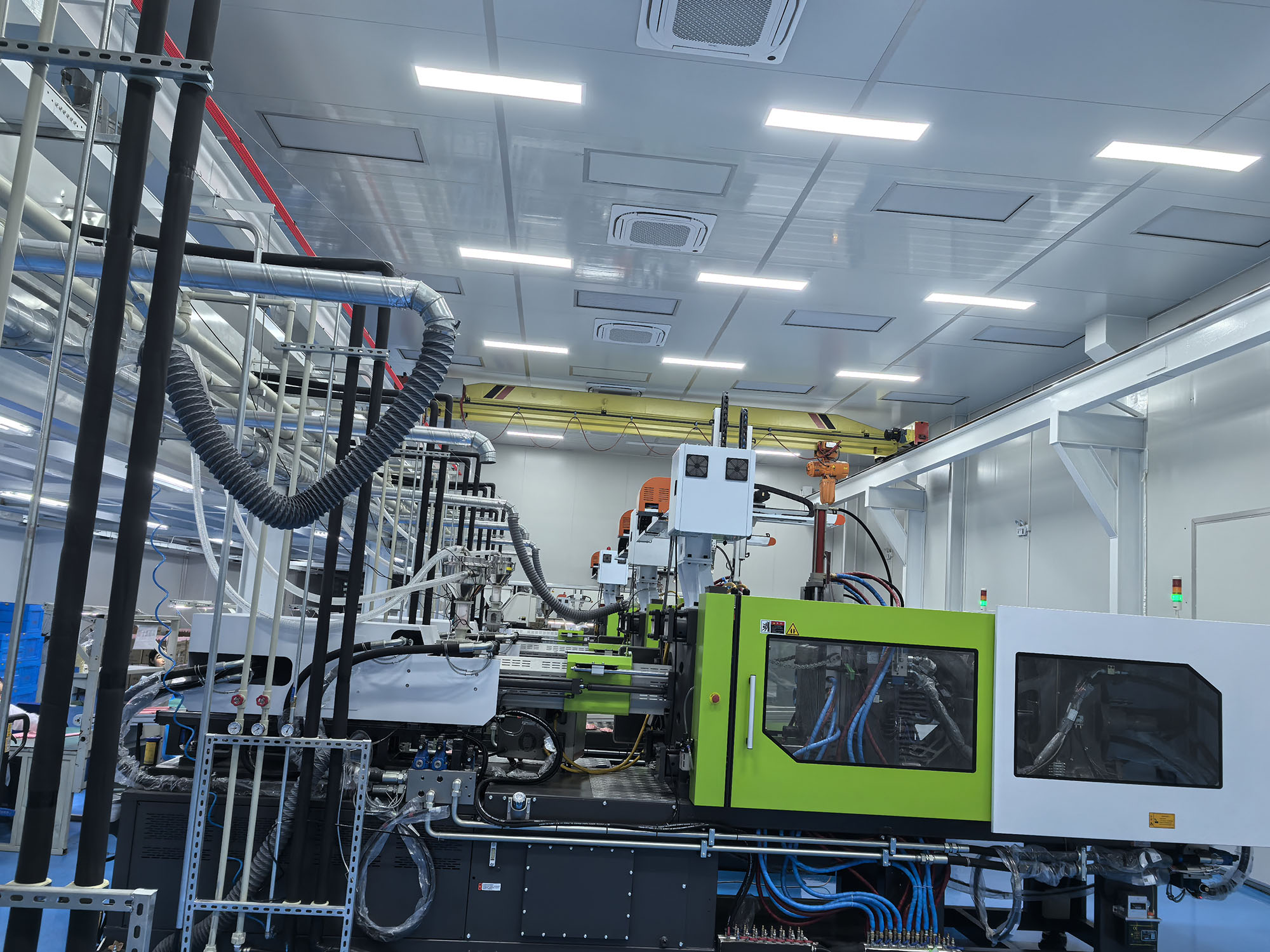

State-of-the-Art Technology

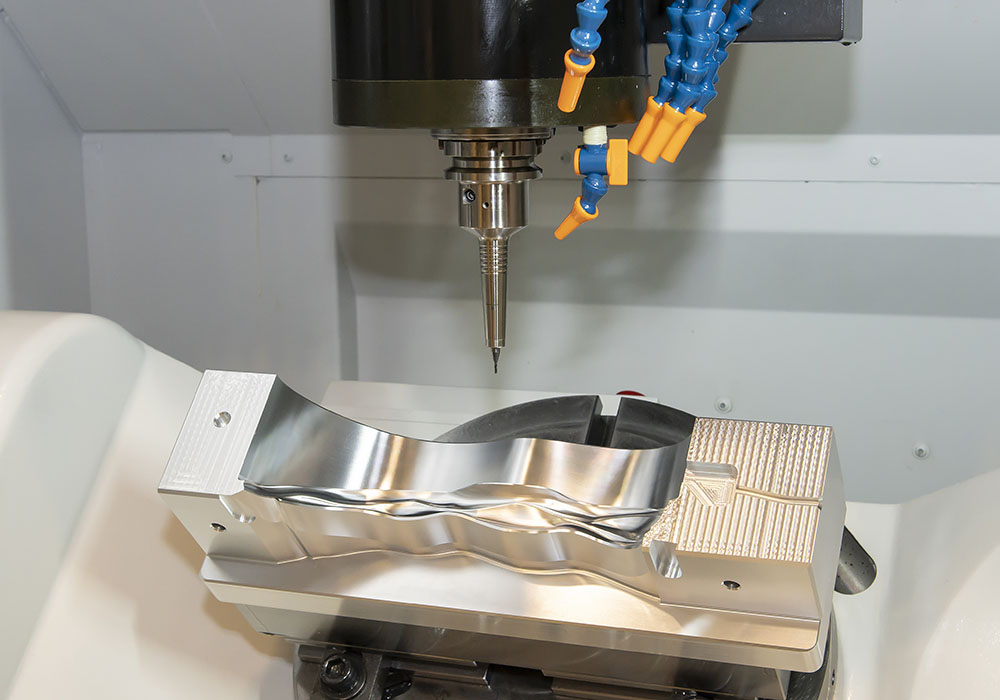

Our advanced machinery and equipment enable us to deliver high-quality, precise parts, regardless of your production scale.

Fast Turnaround Times

We prioritize quick lead times, ensuring your orders are completed on schedule to meet tight project deadlines.

Why Choose Us For Your Project

Wide Range of Materials

We offer a diverse selection of materials, from standard plastics to specialty compounds, to meet your specific product requirements.

Customization and Flexibility

Our team works closely with you to create customized solutions that align with your unique needs and specifications.

Commitment to Quality

We follow rigorous quality assurance procedures to make sure that every component we manufacture delivers exceptional durability and top-tier performance.

30 +

Monthly Molds Fabrication

2,000,000 +

Monthly Parts Production

90-1000 T

Injection Molding Tolerance

0.005 mm

Mold Tolerance

Injection Molding Machines

Additional Equipment

| Production Capability | Details | Production Capability | Details |

|---|---|---|---|

| Injection Molding Machines | 30+ advanced machines for high-volume production | Production Speed | High-volume runs, up to 2,000,000 + parts per month |

| Part Weight | Up to 2,000 grams per part | Tolerance | ±0.005 mm precision |

| Max Mold Size | 600mm x 600mm (L x W) | Quality Control | Rigorous inspections for every batch |

| Material Options | Thermoplastics, elastomers, specialty plastics | Lead Time | As fast as 7–14 days depending on complexity |

Orders Workflow

Initial Consultation & Design Review

We begin by discussing your project’s goals and reviewing the design to ensure it’s optimized for the specific manufacturing process. At this stage, we suggest improvements or adjustments to enhance efficiency, functionality, and manufacturability.

Material Selection

Our experts assist in selecting the right materials for your product based on performance requirements and compatibility with the manufacturing process. The correct material choice ensures durability, cost-effectiveness, and the desired product functionality.

Design & Engineering

Using advanced CAD and simulation tools, we develop a custom design for your project. This step ensures precise details and identifies potential challenges early in the process, optimizing the design for efficient manufacturing.

Prototyping & Sample Testing

A prototype or sample is created to verify design accuracy, functionality, and performance. Rigorous testing is conducted to ensure the product meets your specifications before moving into full-scale production.

Production Setup & Initial Production

We set up the required machines, molds, or tools for the manufacturing process. The initial production run is performed to confirm the setup, assess quality, and fine-tune settings for optimal results.

Final Production & Quality Control

After final approval, we proceed with full-scale production, ensuring continuous quality checks. Comprehensive inspections at each stage ensure that every part meets the highest standards before delivery.

See Our Injection Molding Production

Materials For Injection Molding

ABS

A strong, impact-resistant plastic commonly used in automotive and consumer goods applications.

PEEK

A thermoplastic with excellent chemical and thermal resistance, used in aerospace and medical applications.

PEI

A tough, high-heat resistant plastic used in automotive, aerospace, and electrical applications.

PA

Also known as nylon, it’s a durable, wear-resistant plastic ideal for automotive and industrial parts.

PBT

A strong, heat-resistant plastic used in automotive, electrical, and electronic components.

PC

A tough, high-impact plastic with excellent clarity, used in eyewear lenses and automotive parts.

PE

A versatile, lightweight plastic known for its chemical resistance and low friction properties.

PMMA

A transparent plastic often used as a glass substitute in lighting, signage, and optical lenses.

POM

A high-performance, low-friction plastic used in precision engineering applications like gears and bearings.

PP

A flexible, durable plastic with high resistance to chemicals and fatigue, often used for containers and packaging.

PPS

A high-temperature, chemically resistant plastic used in automotive and electrical applications.

PS

A rigid, inexpensive plastic often used in disposable products like packaging and cutlery.

TPU

A flexible, durable plastic with excellent abrasion and impact resistance, used in footwear and automotive applications.

PTFE

Known as Teflon, it’s a non-stick, high-temperature resistant material used in seals, gaskets, and cookware.

PPSU

A durable, high-temperature plastic used in plumbing, medical, and aerospace industries.

PVC

A rigid or flexible plastic used in construction, plumbing, and electrical applications.

PLA

A biodegradable, plant-based plastic, ideal for eco-friendly applications and easy to mold.

Our Satisfied Clients

We can handle high-volume runs, producing up to 2,000,000+ parts per month, depending on the project requirements.

We can handle molds up to 600mm x 600mm in size, accommodating a variety of part dimensions.

You can request a quote by submitting your project details through our website or contacting us directly for a consultation.

Our typical lead time is between 7 to 14 days, depending on the complexity and size of the order.

We work with a wide range of materials, including thermoplastics, elastomers, and specialty plastics, tailored to your project needs.

We provide injection molding services for various industries, including automotive, furniture, consumer goods, and more.

Our highly trained team and advanced machinery ensure that every part produced maintains the same high standards for quality and consistency.

We use a variety of state-of-the-art injection molding machines, capable of producing both small and large-volume parts with high precision.

KingStar Mold offers advanced technology, expert design support, fast lead times, and a commitment to high-quality production, ensuring the best results for your projects.

Absolutely! Our team works with you to create custom molds that meet your specific design and functionality needs.

At KingStar Mold, we use rigorous inspection protocols, including dimensional checks and material testing, to ensure every part meets your specifications.

Yes, we provide prototype services to test and refine designs before full-scale production.