PEEK Injection Molding

Resources for The Complete Guide to PEEK Injection Molding

What is PEEK?

PEEK (Polyether ether ketone) is a high-strength, semi-crystalline thermoplastic polymer valued for its outstanding thermal stability, chemical inertness, and mechanical durability.

First synthesized in 1977 and commercially produced by 1981, it stands out for its ability to operate continuously at temperatures up to 250°C while maintaining excellent mechanical and electrical properties. Additionally, it performs reliably in high-pressure water or steam environments up to 300°C.

Unlike fluoropolymers like PTFE or PFA, PEEK does not include fluorine. Its unique molecular structure, comprising ether and ketone bonds, ensures outstanding thermal stability and durability under extreme conditions, making it a go-to material for challenging industrial uses.

Can PEEK materials be injection molded?

Yes, you can injection mold PEEK (Polyether Ether Ketone). PEEK has a high melting point (around 343°C/649°F), so you need specialized equipment and processing conditions. PEEK also features high viscosity combined with relatively low flowability, which makes filling intricate geometries and mold cavities a challenge. However, successful injection molding of PEEK is achievable by using proper equipment, specialized expertise, and optimized processing parameters.

Here are some key considerations:

- Material Preparation:

Before molding, PEEK must be thoroughly dried to eliminate any residual moisture. This typically involves drying the material for 2 to 4 hours at temperatures between 150°C and 160°C. - PEEK Material Selection:

Choosing the right PEEK grade is crucial, as some grades are better suited for injection molding. Look for grades with improved flowability and lower viscosity to ensure smoother processing. - Processing Conditions:

Carefully control the processing conditions, including temperature, pressure, and injection speed, to ensure proper filling and cooling of the mold. Typical conditions for PEEK molding include a barrel temperature of 370-390°C, injection pressure of 120MPa, and a mold temperature of around 170°C. - Post-processing:

Due to large injection gates or the inability to create certain structural molds, post-processing is often necessary. PEEK parts may need additional steps such as cutting, grinding, or surface treatment to achieve the desired surface finish and dimensions. - Cooling:

PEEK parts require slow and controlled cooling to avoid warping or distortion. This may involve utilizing cooling systems or delaying the ejection of the part from the mold to ensure uniform cooling.

What are the characteristics of PEEK injection molding material?

PEEK (Polyetheretherketone) is a versatile material known for its exceptional properties. Some key features of PEEK include:

- High Temperature Resistance: PEEK can endure temperatures up to 250°C (482°F) without compromising its strength or dimensional stability, making it ideal for high-temperature applications.

- Chemical Resistance: PEEK offers outstanding resistance to a wide range of chemicals, including acids, alkalis, and organic solvents, making it well-suited for use in harsh chemical environments.

- Mechanical Properties: PEEK possesses excellent mechanical strength, rigidity, and wear resistance, making it ideal for demanding applications requiring durability and long-term performance.

- Biocompatibility: PEEK is biocompatible, making it an excellent choice for medical devices and implantable applications.

- Electrical Insulation: PEEK also provides excellent electrical insulation, making it suitable for electronic and electrical applications.

What are the properties of PEEK injection molding?

PEEK (Polyetheretherketone) is a high-performance thermoplastic polymer with exceptional mechanical strength, excellent electrical insulating properties, and resistance to radiation. Known for its high temperature resistance, it also offers impressive flame retardancy, impact resistance, and wear and fatigue durability. Additionally, PEEK resists acids, alkalis, and hydrolysis, making it a versatile material for demanding environments.

| Property | Description |

|---|---|

| High Temperature Resistance | Can withstand temperatures up to 250°C (482°F) without losing strength. |

| Mechanical Strength | Offers high tensile and compressive strength, ensuring durability. |

| Chemical Resistance | Resists acids, alkalis, and organic solvents, making it ideal for harsh environments. |

| Wear Resistance | Exceptional wear and abrasion resistance, ensuring long service life. |

| Fatigue Resistance | Withstands repeated stress and strain without failure. |

| Impact Resistance | Exhibits high impact strength, resistant to cracking or breaking. |

| Flame Retardancy | Self-extinguishing and resistant to flame propagation. |

| Radiation Resistance | Resistant to degradation from exposure to radiation. |

| Electrical Insulation | Excellent dielectric properties, making it a good insulator. |

| Dimensional Stability | Maintains its shape and size even under extreme temperatures and stresses. |

| Low Moisture Absorption | Minimal water absorption, making it suitable for sensitive environments. |

| Biocompatibility | Safe for medical and healthcare applications, including implants. |

| Processing Temperature Range | Suitable for injection molding at temperatures of 370°C to 390°C. |

| High Toughness | Retains toughness even at high temperatures, reducing brittleness. |

| Surface Quality | Provides excellent surface finishes with minimal post-processing. |

Why is PEEK injection molding’s price so high?

PEEK injection molding is considered expensive due to several factors related to the material’s unique properties, processing requirements, and manufacturing challenges. Here are 9 key reasons:

- High Material Cost: PEEK is a premium material with complex production processes, making it significantly more expensive than standard thermoplastics like ABS or polycarbonate.

- High Processing Temperatures: PEEK requires high injection molding temperatures (typically 370-390°C), demanding specialized, high-temperature-resistant equipment, which drives up costs.

- Specialized Equipment: The molding process for PEEK requires advanced machines capable of handling high temperatures and pressures. These machines often come with a higher initial investment and maintenance costs.

- Longer Cycle Times: Due to the high melting point and viscosity of PEEK, the injection molding process for PEEK parts is slower, leading to longer cycle times and lower throughput compared to standard thermoplastics.

- Mold Wear and Tear: PEEK’s hardness and high processing temperatures can lead to greater wear on molds, requiring them to be made from high-quality, heat-resistant steel, which is more costly.

- Material Preparation: PEEK must be thoroughly dried before injection molding to avoid moisture-related defects. This additional step adds to both material and labor costs.

- Specialized Labor: Manufacturing with PEEK requires highly skilled technicians who are familiar with the material’s specific handling and molding requirements, leading to higher labor costs.

- Limited Availability: PEEK is produced in limited quantities, and only a few suppliers offer the raw material, which increases its cost due to supply-demand factors.

- Post-Processing Needs: After molding, PEEK parts often require additional finishing processes, such as trimming, grinding, or surface treatments, which can further increase overall production costs.

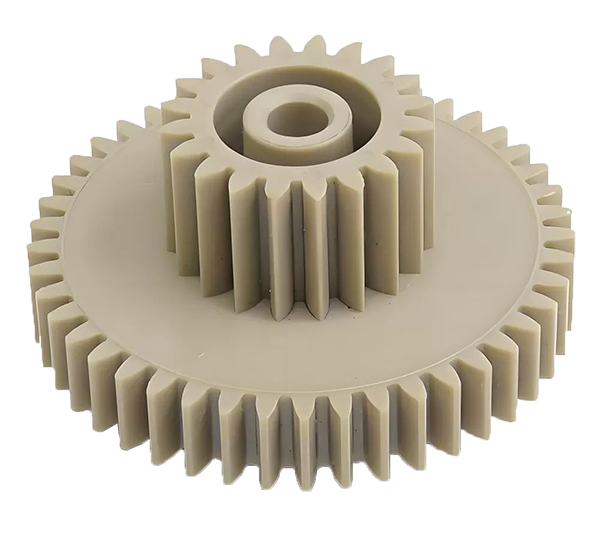

PEEK injection molding: Applications

PEEK is a material with excellent comprehensive properties. It can replace traditional materials such as metals and ceramics in many special fields. The combination of its excellent high-temperature stability, self-lubricating property, superior wear durability, and strong fatigue endurance makes PEEK among the most sought-after high-performance engineering plastics in use today. It is mainly used in aerospace, automotive, electronics and electrical, medical equipment, and other fields.

| Industry | Application Examples | Benefits of Using PEEK |

|---|---|---|

| Aerospace | Aircraft brackets, bushings, and insulators | High-temperature resistance, lightweight, and durable |

| Automotive | Gears, seals, and fuel system components | Chemical resistance and wear resistance |

| Medical | Implantable devices, surgical tools, and dental instruments | Biocompatibility and sterilization compatibility |

| Electronics | Connectors, insulators, and microchip sockets | Excellent electrical insulation and heat resistance |

| Oil and Gas | Valve seats, seals, and downhole tools | High pressure and chemical resistance |

| Industrial | Pumps, compressor components, and wear plates | Durability and wear resistance in harsh environments |

| Food Processing | Bearings, gears, and non-stick coatings | FDA compliance and chemical resistance |

| Semiconductors | Wafer carriers, chip testing sockets, and cleanroom parts | Low outgassing and dimensional stability |

| Energy | Battery components and insulators for renewable systems | Thermal stability and chemical resistance |

| Consumer Goods | High-performance sports equipment and electronic casings | Strength, durability, and lightweight properties |