PC Injection Molding

PC injection molding is renowned for creating parts with exceptional clarity and strength, making it a leading option in the injection molding industry. Additionally, by modifying the material, it is possible to produce opaque parts as well.

With the need for precise processing, PC molding accommodates a variety of applications, ranging from transparent, high-clarity components to specialized, non-transparent parts tailored for specific requirements.

PC Injection Molding at KingStar Mold

Among transparent materials, PC injection molding is more commonly used than PMMA (Acrylic) and AS injection molding. KingStar Mold has accumulated extensive experience and a wide range of case studies in PC injection molding, second only to ABS. Our in-depth research on modified PC materials has expanded its potential applications, enabling us to produce a diverse array of high-quality, customizable parts.

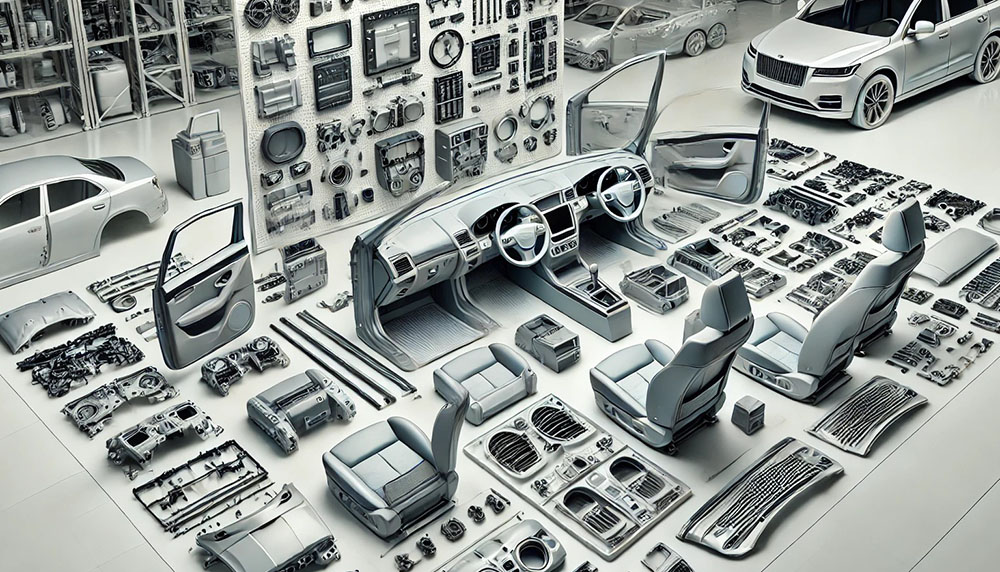

Automotive & EV

Consumer Electronics

Medical Devices

Industrial Equipment

PC injection molding is widely utilized across numerous industries, including Telecommunications, Art and Design, Energy, Construction, and beyond. Commonly used modified plastics such as Glass-Fiber Reinforced PC, PC/PBT, and PC/ABS blends provide enhanced performance and versatility. These materials deliver improved heat resistance, increased durability, and higher strength, making them ideal for demanding applications and environments.

Optimizing Clarity and Durability

KingStar Mold specializes in producing PC parts with exceptional clarity and toughness, ideal for high-performance applications. We ensure optimal material flow and cooling to achieve consistent transparency and strength.

Our advanced molding techniques allow us to produce intricate, high-precision PC components with tight tolerances. We focus on accuracy to ensure every part meets your specifications.

Enhanced Material Performance

KingStar Mold uses modified PC materials, such as PC/ABS blends and glass-fiber reinforced PC, to improve part strength and heat resistance. This allows us to deliver high-quality, durable products for demanding applications.

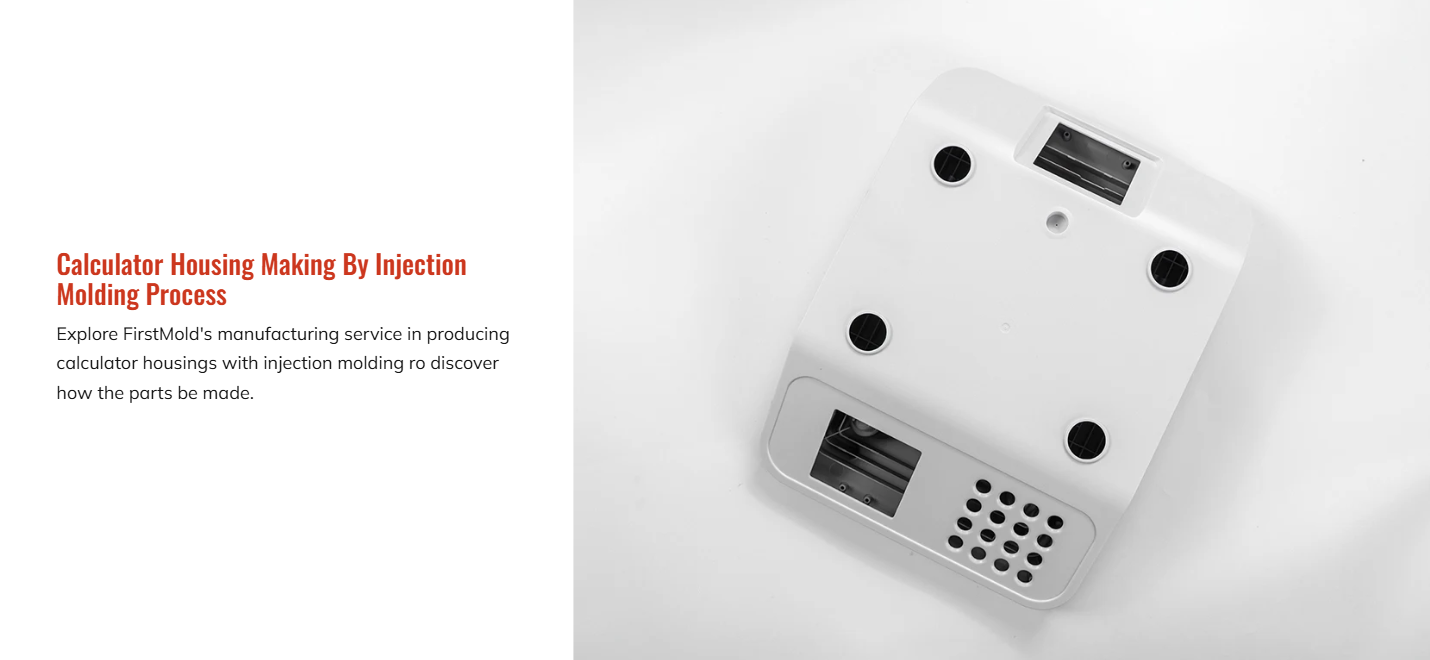

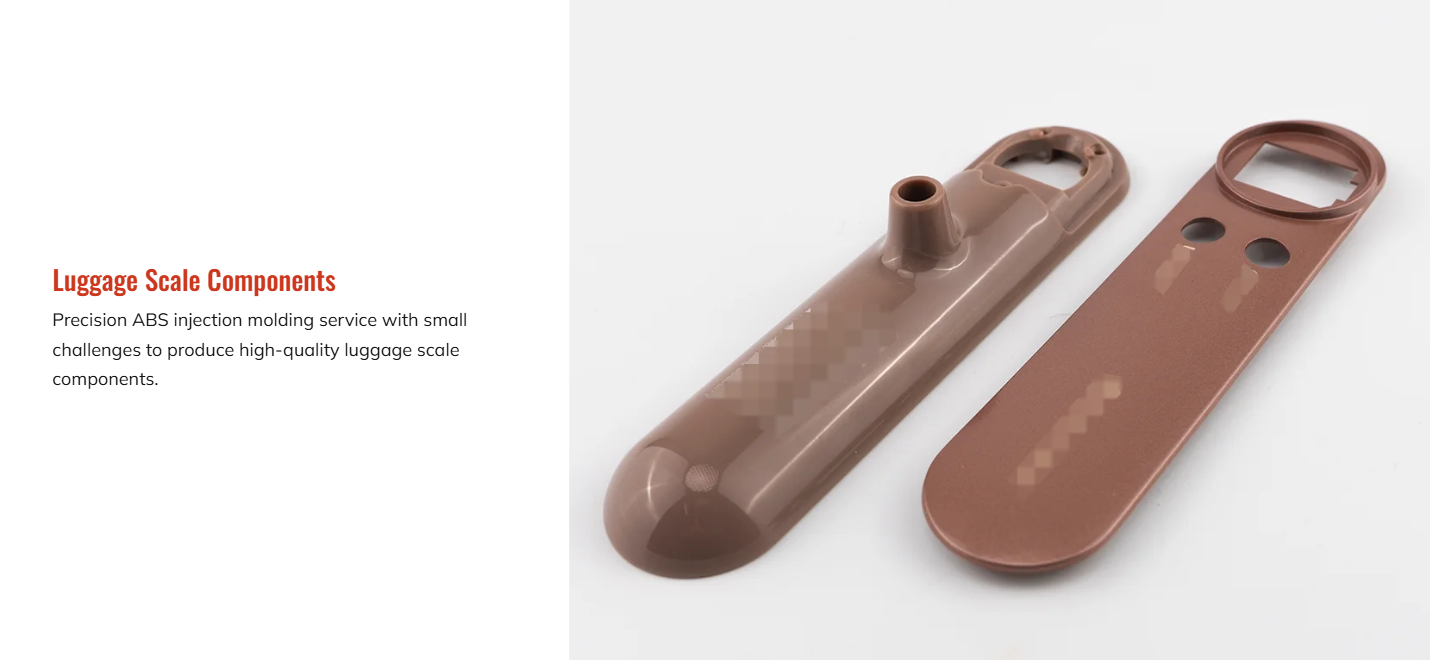

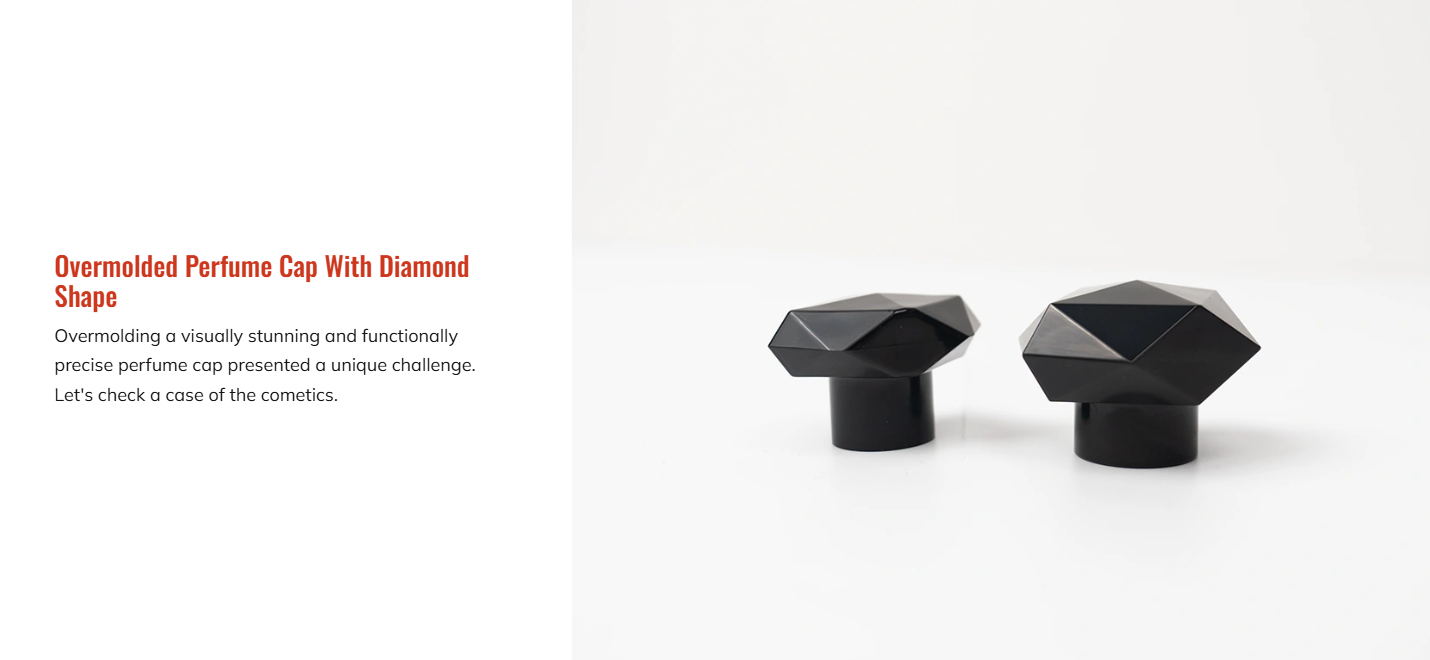

PC Injection Molding Cases

PC offers superior impact resistance and clarity compared to materials like PMMA (Acrylic) and AS, while also having better heat resistance than many other plastics.

Yes, with the right modifications, PC can be molded into both transparent and opaque parts, offering versatility in design.

PC injection molding is widely used in automotive, consumer electronics, medical devices, telecommunications, and industrial applications.

Common types include standard polycarbonate, PC/ABS blends, glass-fiber reinforced PC, and PC/PBT.

PC offers high strength, optical clarity, excellent impact resistance, and resistance to high temperatures, making it ideal for demanding applications.

PC injection molding is a process that uses polycarbonate (PC) plastic to create parts with exceptional clarity, impact resistance, and heat tolerance.

KingStar Mold uses advanced molding techniques, rigorous quality control, and in-depth experience with modified PC materials to ensure high-quality, defect-free parts for every project.

Common defects include warping, sink marks, voids, jetting, and poor surface finish, which can often be mitigated with the right processing techniques.

Proper cooling is critical to avoid warping or internal stresses in the molded parts. Cooling systems are carefully controlled to ensure even temperature distribution.

Steel molds are commonly used for PC injection molding, offering durability and the ability to withstand high injection pressures.

By using glass-fiber reinforced PC or PC/ABS blends, injection molding can produce parts with enhanced strength and dimensional stability.

Challenges include managing material viscosity, controlling cooling rates, and addressing issues like warping, sink marks, or voids.