PBT Injection Molding at KingStar Mold

Home Appliances

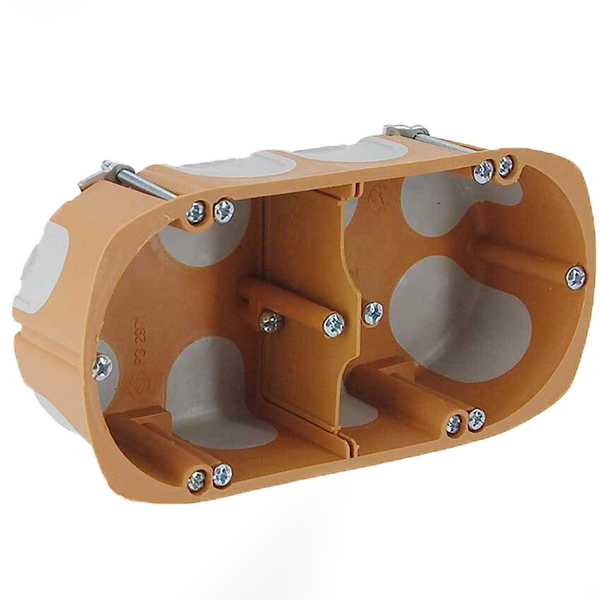

Consumer Electronics

Industrial Equipment

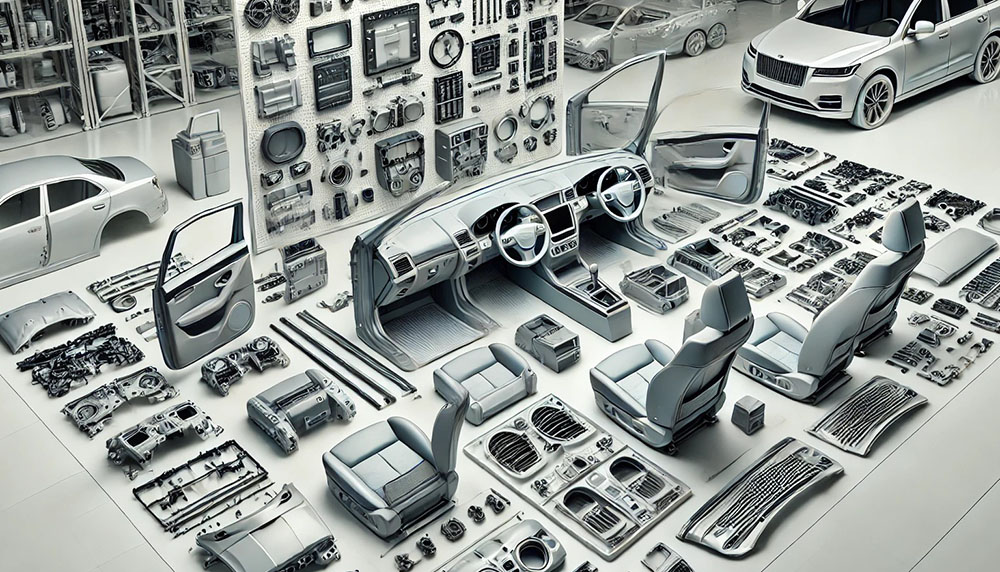

Automotive & EV

PBT Injection Molding

KingStar Mold’s Capabilities

KingStar Mold delivers high-quality injection molding solutions through expert mold design, precision manufacturing, and the use of premium materials. Our team utilizes advanced technologies like mold flow analysis and CNC machining to create efficient, durable molds. With a focus on reliability and performance, we ensure our parts meet the highest industry standards for diverse applications.

Expert Mold Design

KingStar Mold excels in mold design, employing cutting-edge engineering techniques to create highly efficient and precise molds. Our team utilizes advanced mold flow analysis and simulation tools to ensure optimal material flow and reduce potential defects. This ensures that every product is manufactured to the highest standards of quality and precision.

We use a wide variety of high-performance materials, including flame-retardant, glass-fiber reinforced, and modified PBT, tailored to specific industry needs. Our selection of premium materials ensures that the parts we produce offer superior strength, durability, and resistance to harsh conditions. This guarantees reliability and extended service life for components used in critical applications.

Precision Manufacturing

KingStar Mold is equipped with advanced CNC machines and state-of-the-art injection molding technologies, allowing us to achieve high-precision results for even the most complex parts. Our expert technicians monitor the production process closely, ensuring every part meets stringent dimensional tolerances and quality standards. This precision in manufacturing minimizes defects and enhances product performance.

PBT comes in various grades, including flame-retardant, glass-fiber reinforced, and modified PBT. These materials offer enhanced strength, heat resistance, and electrical insulating properties, suitable for diverse applications.

Yes, KingStar Mold specializes in custom PBT injection molding, offering tailored solutions to meet the unique requirements of your project. We work closely with clients to ensure product specifications are met.

PBT is widely used in automotive, electronics, electrical, and industrial sectors. Applications include connectors, sensors, motor housings, and parts requiring high strength and thermal resistance.

At KingStar Mold, we use state-of-the-art CNC machining and mold flow analysis to optimize mold design, ensuring high precision and minimal defects. We also implement rigorous quality control processes at every stage of production.

PBT offers high thermal stability, resistance to chemicals, and excellent mechanical properties. It is ideal for producing parts that require strength, durability, and precision, especially in automotive, electrical, and industrial applications.

PBT (Polybutylene Terephthalate) injection molding is a process used to create high-performance plastic parts from PBT material, known for its excellent chemical resistance, dimensional stability, and high strength.

PBT is durable and resistant to wear, which increases the longevity of products. Its recyclability also makes it an environmentally friendly choice for manufacturing, reducing waste and promoting sustainability.

KingStar Mold has established long-term relationships with reliable suppliers to ensure access to high-quality PBT materials. We also provide material certifications and can source specific materials upon client request.

Yes, PBT is commonly blended with materials such as PC (Polycarbonate) to create alloys with improved properties. These blends are used in applications like automotive bumpers and other parts requiring enhanced performance.

Common applications include automotive parts, electrical connectors, electronic housings, and components used in harsh environments requiring chemical and thermal resistance.

KingStar Mold utilizes advanced CNC machines and precise mold design techniques, ensuring that each PBT part meets the exact specifications and dimensional tolerances required by our clients.

The cycle time for PBT injection molding varies depending on part complexity, material grade, and mold design. Typically, cycle times range from 30 seconds to several minutes.